Thin steel sheet, plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing thin steel sheet, and method for producing plated steel sheet

A manufacturing method and technology for hot-rolled steel sheets, applied in chemical instruments and methods, manufacturing tools, heat treatment furnaces, etc., can solve problems such as reduced workability, and achieve the effects of excellent platability, improved collision safety, and improved fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] Hereinafter, the present invention will be specifically described based on examples. The technical scope of the present invention is not limited to the following examples.

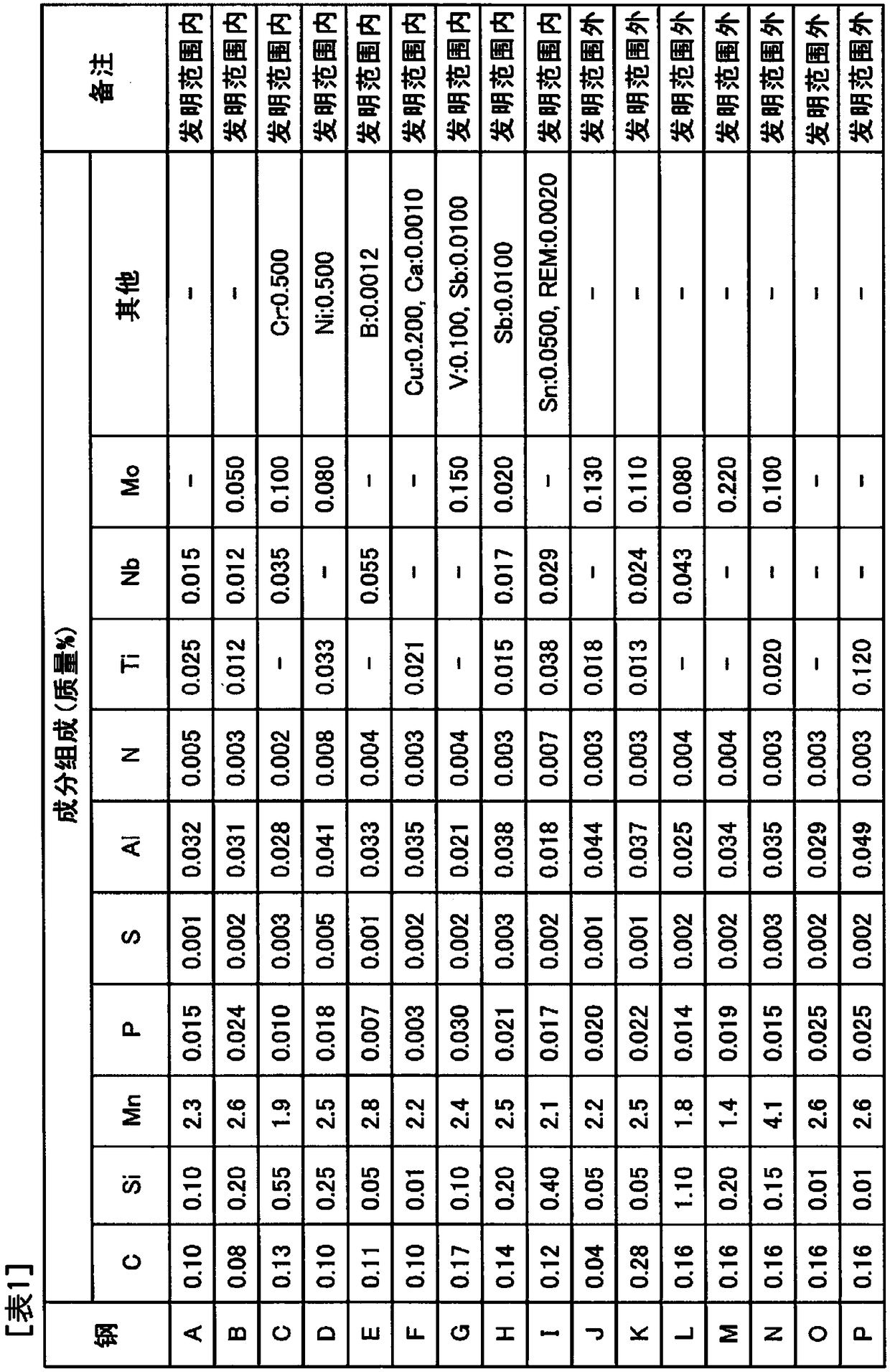

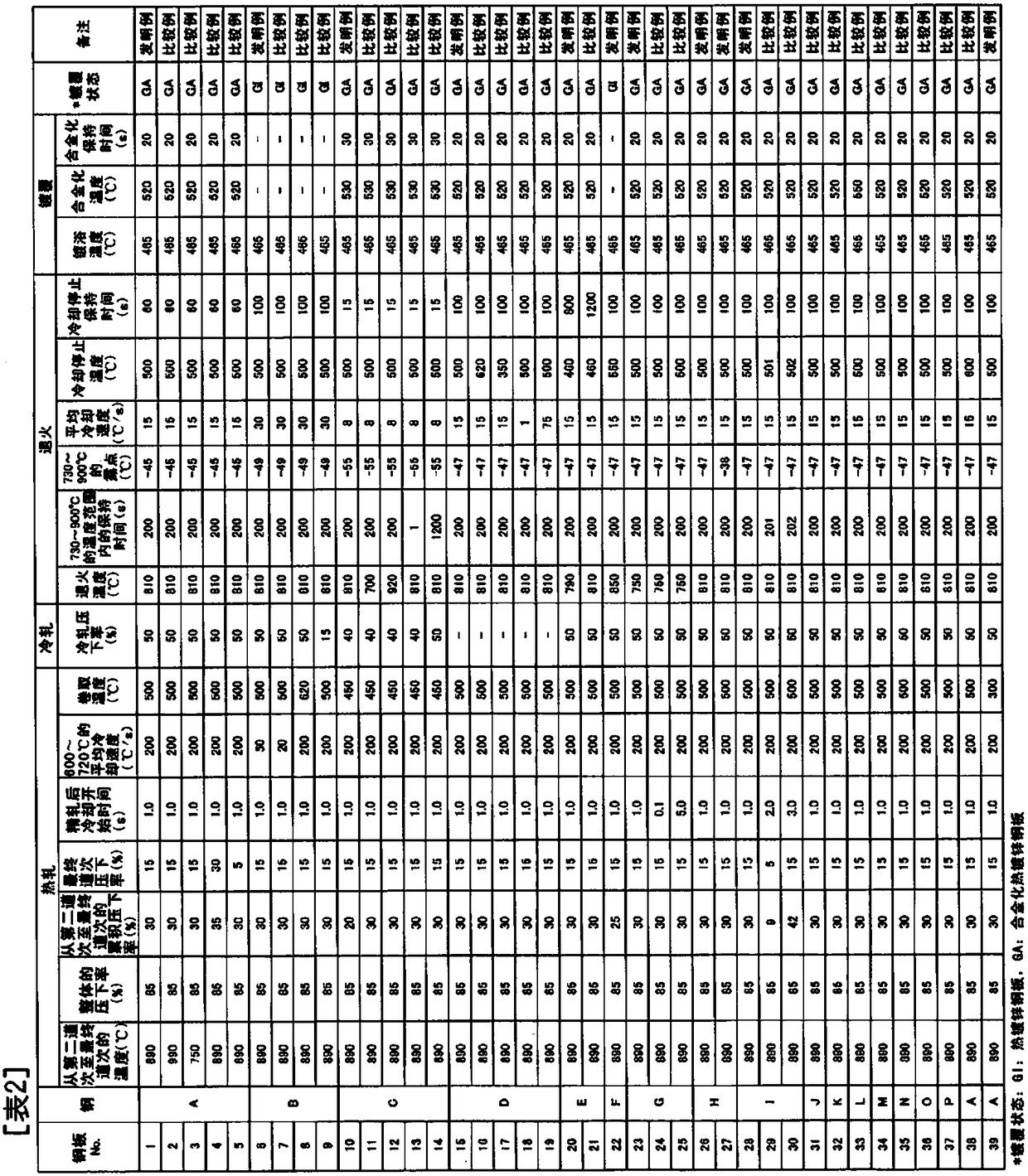

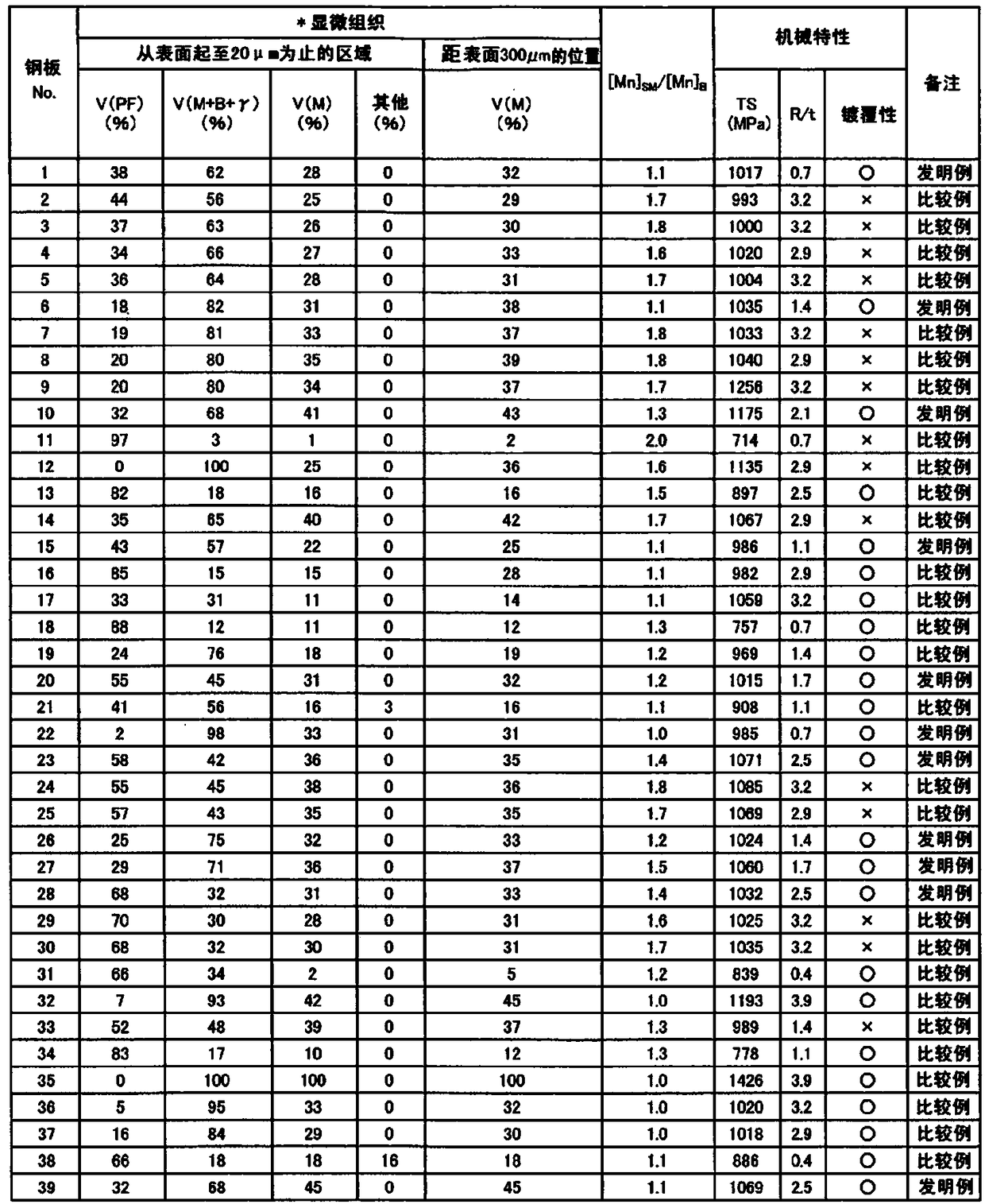

[0150]Steel with the composition shown in Table 1 (the balance being Fe and unavoidable impurities) was melted in a vacuum melting furnace in a laboratory, and rolled to form a billet. These billets were heated to 1200° C., rough-rolled, and then hot-rolled under the conditions shown in Table 2 to obtain hot-rolled steel sheets (HR). Next, a part was cold-rolled to 1.4 mm to make a cold-rolled full-hard steel sheet (CR). The obtained hot-rolled steel sheets and cold-rolled full-hard steel sheets were subjected to annealing. Next, a galvanizing treatment and, if necessary, a galvanizing treatment are performed to produce a galvanized steel sheet (GI) and a galvanized steel sheet (GA). Annealing was carried out in the laboratory under the conditions shown in Table 2 using a heat treatment and plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com