Detection method of damage of one-way silicon carbide fiber toughening silicon carbide ceramic matrix composite in oxidation environment

A silicon carbide fiber and composite material technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. Overcome costly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

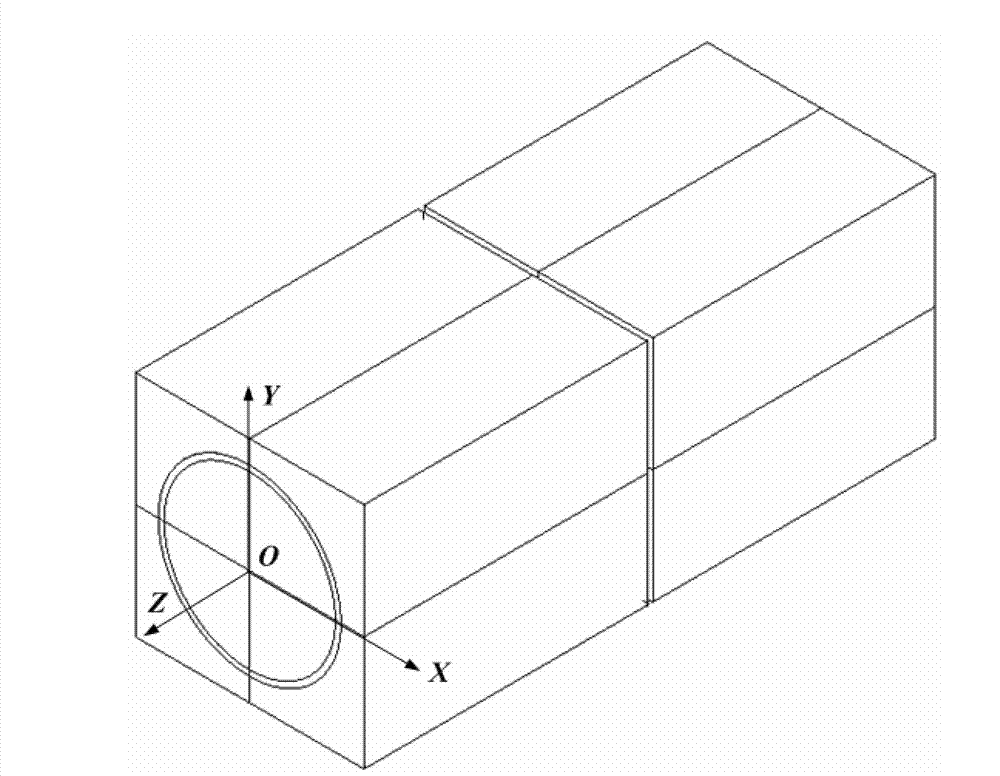

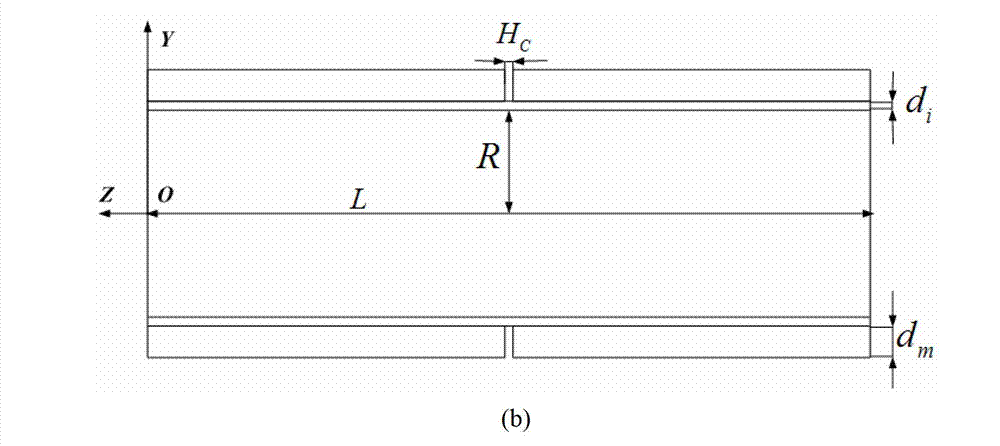

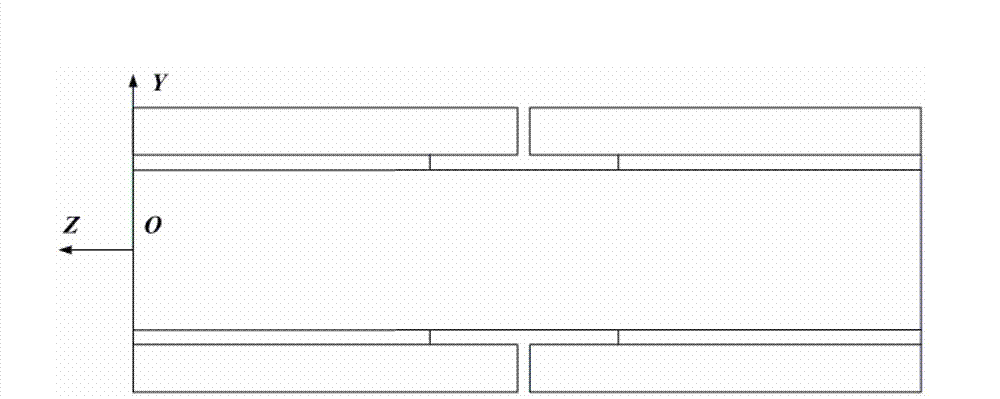

[0026] The specific steps of the detection method for the damage of the unidirectional silicon carbide fiber toughened silicon carbide ceramic matrix composite material in the oxidizing environment of the present invention are as follows:

[0027] In the following, for a unidirectional SiC / SiC composite material subjected to an axial tensile stress of 800MPa in an air environment of 600°C and 100KPa, the material damage at different oxidation times is calculated. The radius R of the silicon carbide fiber bundle in the unidirectional SiC / SiC composite is 2 mm, and the thickness d of the carbon interface and the silicon carbide matrix is i 、d m 200μm and 800μm respectively, the width H of the matrix microcrack C The distance between adjacent microcracks, that is, the z-direction length L of the periodic microstructure is 16 mm. The performance parameters of each component material are shown in Table 1.

[0028] Table 1 Performance parameters of component materials

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com