Method for preparing ultrafine cemented carbide by taking nano WC-6Co composite powder added with Co powder as raw materials

A technology of composite powder and cemented carbide, which is applied in the field of preparation of ultra-fine cemented carbide rods, can solve the problems of low strength of cemented carbide, and achieve the effects of good compression molding performance, uniform particle size and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

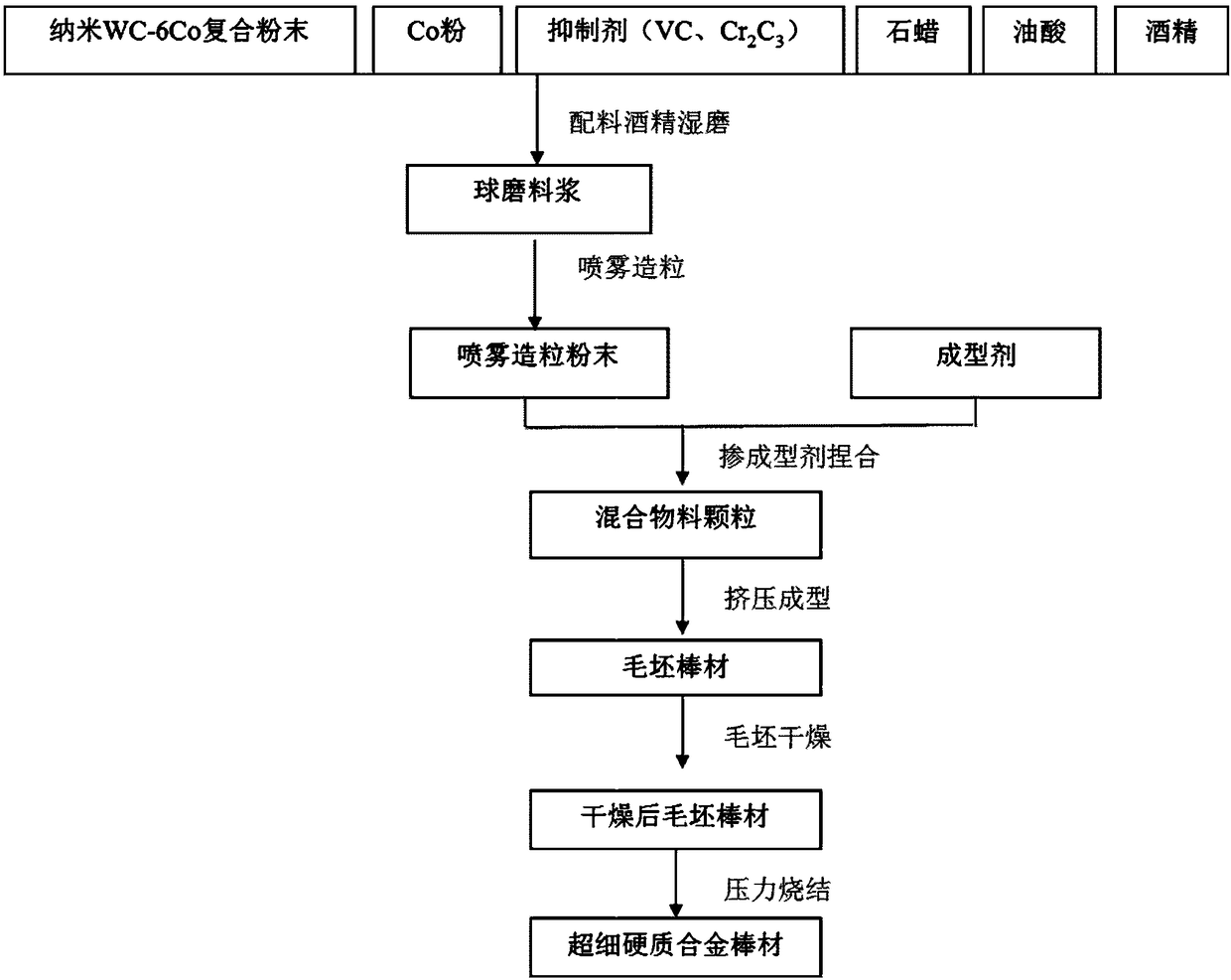

Method used

Image

Examples

Embodiment 1

[0055] 1) Alcohol wet grinding of ingredients

[0056] Take Co-coated WC nano-WC-6Co composite powder with a grain size of ≤200nm and a Co mass content of 6%, and mix it with a cemented carbide mixture with a Co content of 8.5% (WC-8.5Co);

[0057] Add 234.9kg of nano WC-6Co composite powder to a 300L tiltable rolling ball mill, add 5.1Kg of Co powder with a particle size of FSSS of 0.95μm, and add 0.72Kg of grain growth inhibitor VC, Cr 3 C 2 1.92Kg, add 2.4Kg of binder paraffin, add 15L of oleic acid, 60Kg of alcohol, and finally add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1200kg, ball mill for 48h, and obtain Ball mill slurry.

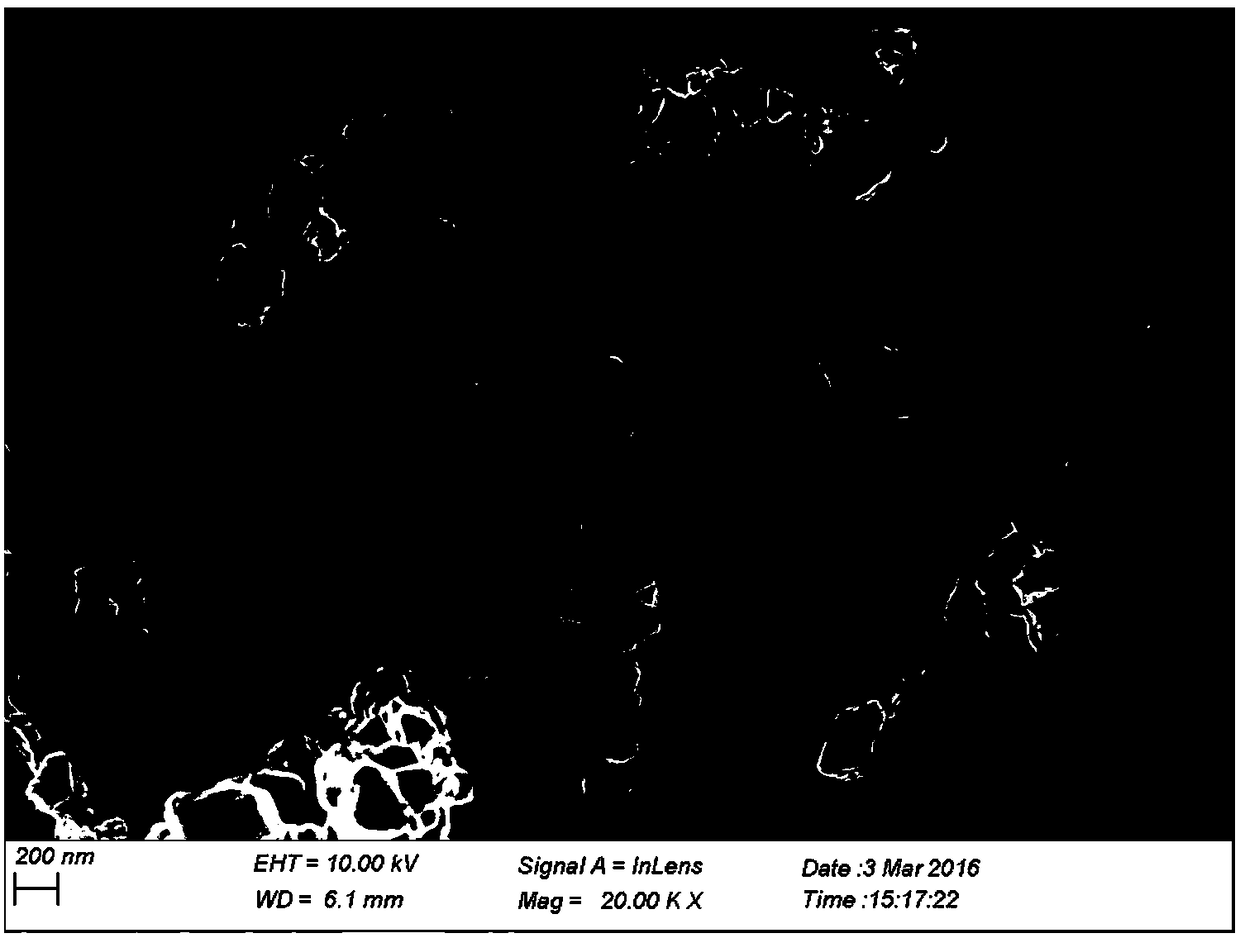

[0058] The SEM image of the raw material nano WC-6Co composite powder used in this example is as follows figure 2 As shown, it can be seen that the grain size of the raw material is small and uniform.

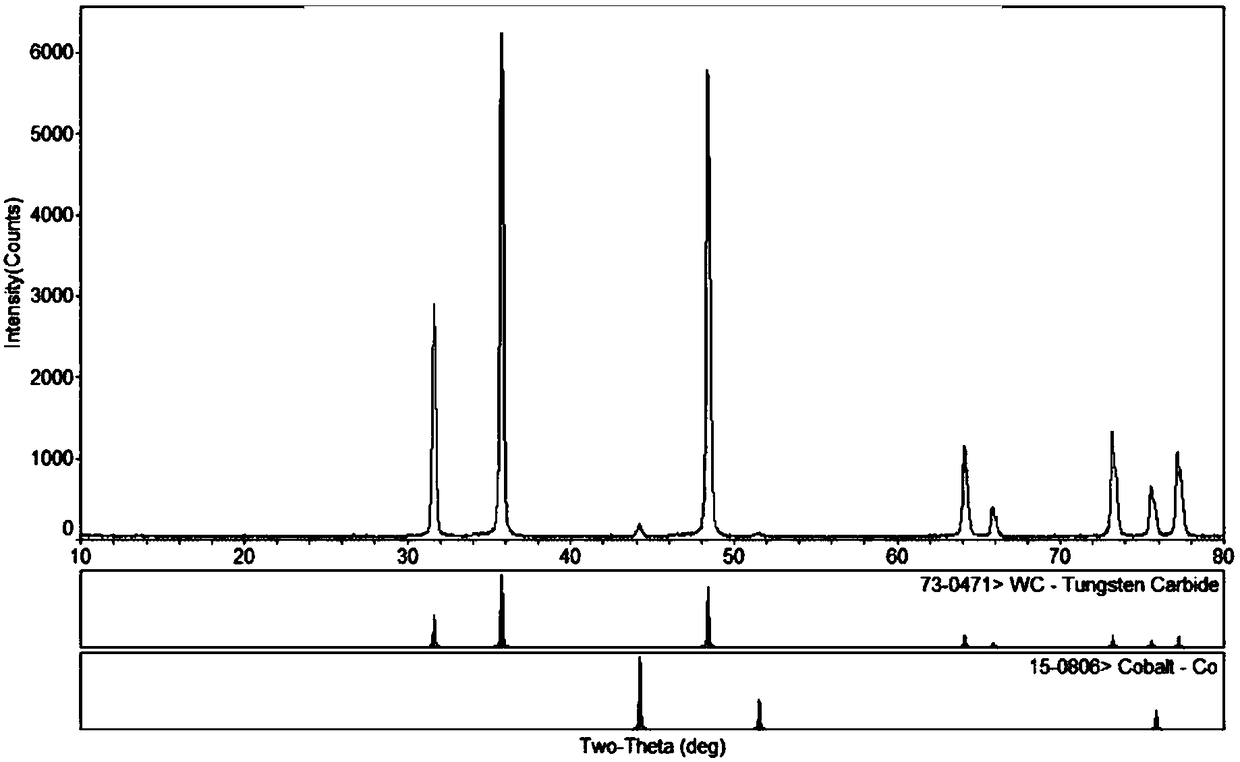

[0059] The XRD pattern of the raw material nano WC-6Co composite powder used in this example is as follows ...

Embodiment 2

[0090] 1) Alcohol wet grinding of ingredients

[0091] Take Co-coated WC nano-WC-6Co composite powder with a grain size of ≤200nm and a Co mass content of 6%, and mix it according to the cemented carbide mixture with a Co content of 9% (WC-9Co):

[0092] Add 232.34kg of nano-WC-6Co composite powder to a 300L tiltable rolling ball mill, add 7.66Kg of Co powder with a particle size of FSSS of 0.95μm, and add 0.72Kg of grain growth inhibitor VC, Cr 3 C 2 1.92Kg, add 2.4Kg of binder paraffin, add 15L of oleic acid, 60Kg of alcohol, and finally add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1200kg, ball mill for 52h, and obtain Ball mill slurry.

[0093] 2) Spray granulation

[0094] Add 12Kg alcohol to wet grinding for 10min in the obtained ball mill slurry in step 1), discharge the material through a 325 mesh sieve, and heat while stirring to prevent the paraffin from separating out;

[0095] The stirred slurry is passed through the closed spra...

Embodiment 3

[0116] 1) Alcohol wet grinding of ingredients

[0117] Take Co-coated WC nano-WC-6Co composite powder with a grain size of ≤200nm and a Co mass content of 6%, and mix it according to the cemented carbide mixture with a Co content of 10% (WC-10Co):

[0118] Add 229.78kg of nano-WC-6Co composite powder to a 300L tiltable rolling ball mill, add 10.22Kg of Co powder with a particle size of FSSS of 0.95μm, and add 0.48Kg of grain growth inhibitor VC, Cr 3 C 2 2.16Kg, add 2.4Kg of paraffin wax as a binder, add 15L of oleic acid, 60Kg of alcohol, and finally add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1200kg, ball mill for 60h, and obtain Ball mill slurry.

[0119] 2) Spray granulation

[0120] Add 12Kg alcohol to wet grinding for 10min in the obtained ball mill slurry in step 1), discharge the material through a 325 mesh sieve, and heat while stirring to prevent the paraffin from separating out;

[0121] The stirred slurry is passed through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com