Photoelectric pulse composite processing method of novel composite microstructure of Ti-6Al-4V alloy

A ti-6al-4v, 1.ti-6al-4v technology, applied in the field of obtaining a new composite microstructure of Ti-6Al-4V alloy, can solve the problem that the hardness and plasticity cannot meet the requirements of industrial applications, the difference in alloy properties, etc. problems, to achieve the effect of improving mechanical properties, reducing oxygen content, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: The photoelectric pulse current treatment method of Ti-6Al-4V alloy novel composite microstructure is carried out according to the following steps,

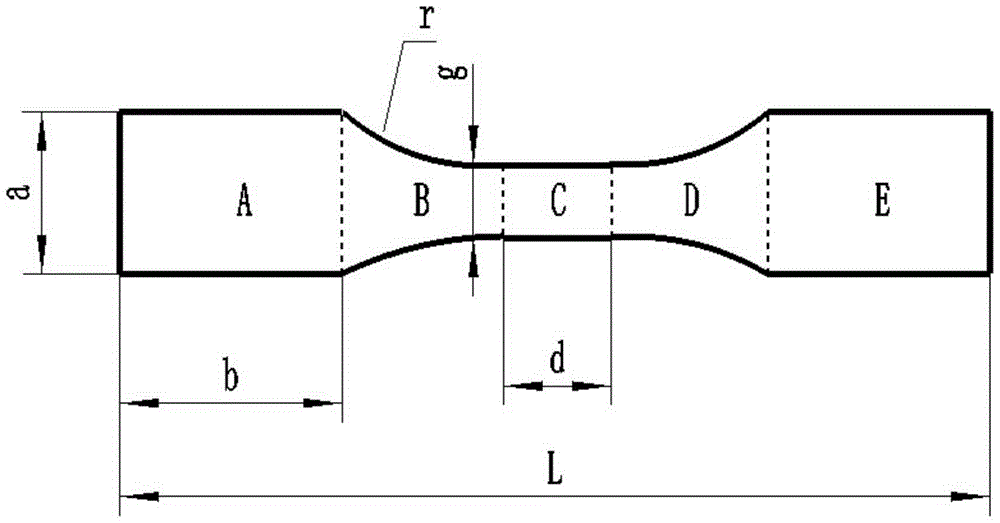

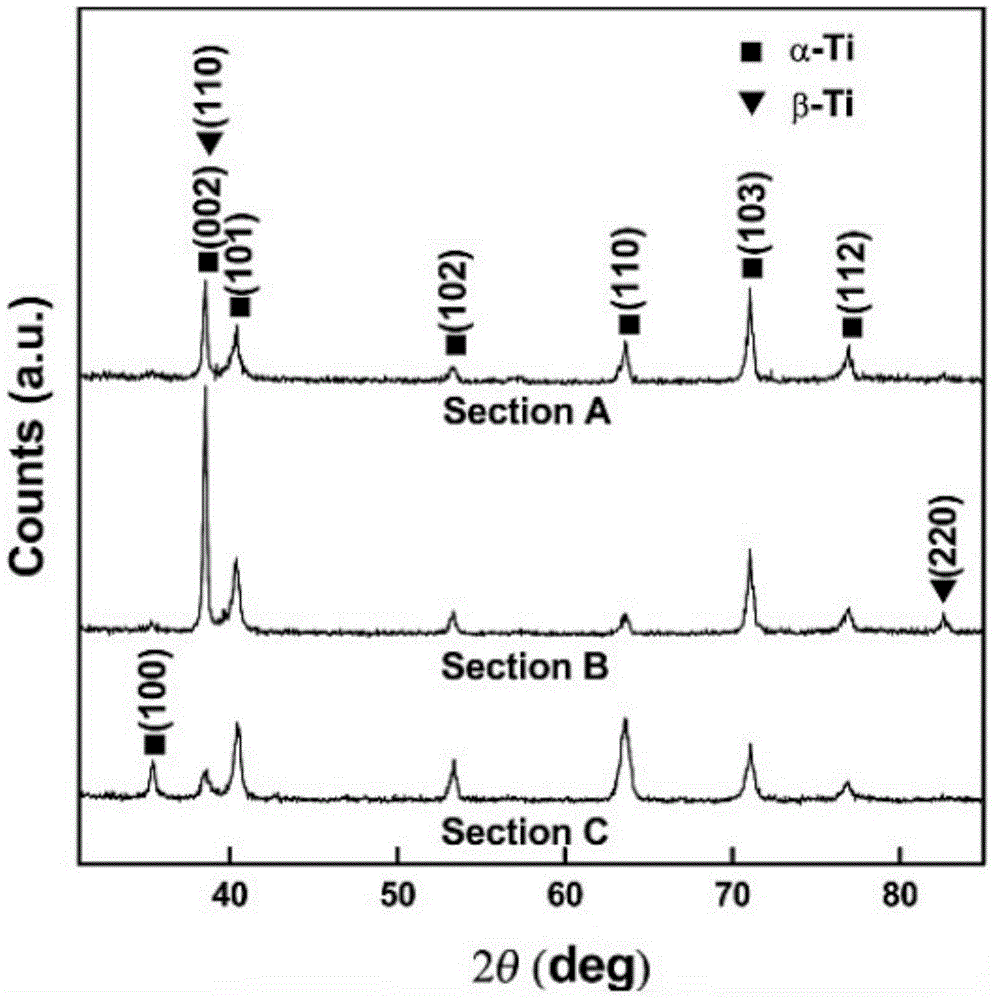

[0045] Step 1: Take the Ti-6Al-4V alloy part with a thickness of 1.2mm and cut the tensile sample along the pressing direction with a wire cutting machine. The mass fraction of its chemical composition is Al, 6.08%, V, 5.03%, Fe, 0.35% , C, 0.09%, N, 0.60%, H, 0.018%, O, 0.16%, Ti is composed of β-Ti and α-Ti10%. The dimensions of the tensile sample parts are a=10mm, b=8mm, d=6mm, r=10mm, L=35mm, and are subjected to mechanical polishing and plasma beam thinning treatment.

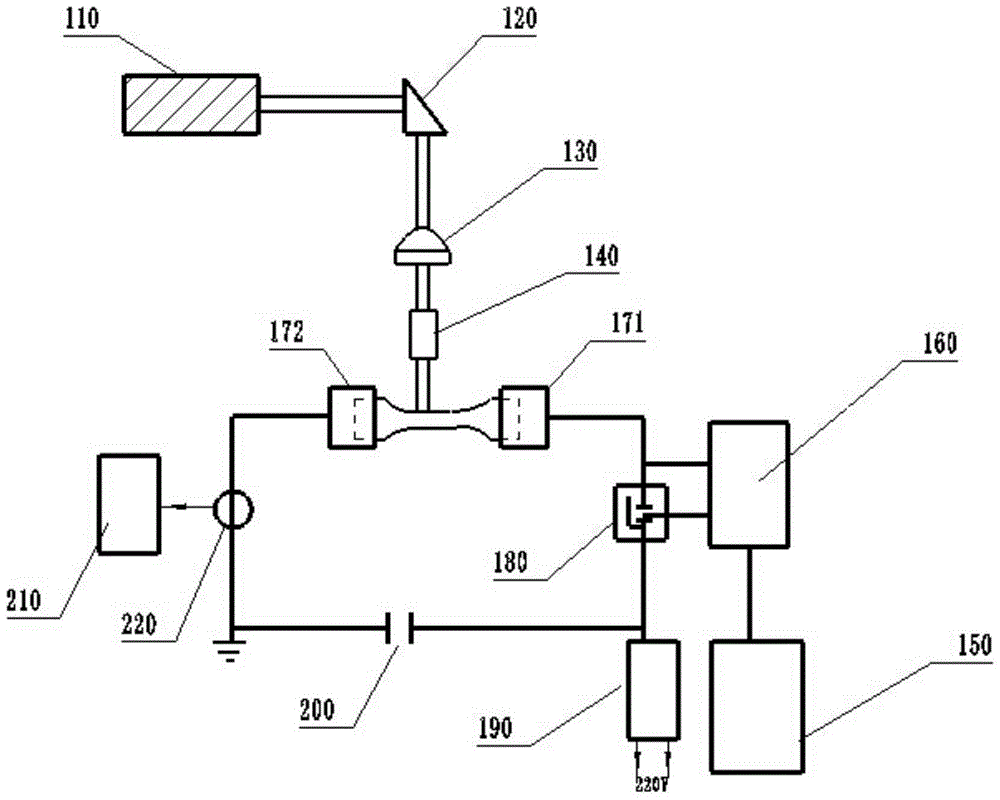

[0046] Step 2: The pulsed laser 110 is reflected by the total reflection prism 120 to change the direction of light propagation, and then the Gaussian light is converted into flat-top light by the Gaussian flat-top lens 130, and then the beam is expanded by the beam expander 140, and the output is expanded. After beaming, the light impac...

Embodiment 2

[0050] Embodiment 2, step 1: the Ti-6Al-4V alloy part that is 1.2mm in thickness adopts wire cutting machine to cut off tensile sample along the pressing direction, and the mass fraction of its chemical composition is Al, 6.08%, V, 5.03%, Fe, 0.35%, C, 0.09%, N, 0.60%, H, 0.018%, O, 0.16%, Ti is composed of β-Ti and α-Ti10%. The dimensions of the tensile sample parts are a=10mm, b=8mm, d=6mm, r=10mm, L=35mm, and are subjected to mechanical polishing and plasma beam thinning treatment.

[0051] Step 2: The pulsed laser 110 is reflected by the total reflection prism 120 to change the direction of light propagation, and then the Gaussian light is converted into flat-top light by the Gaussian flat-top lens 130, and then the beam is expanded by the beam expander 140, and the output is expanded. After beaming, the light impacts the Ti-6Al-4V alloy sample with energy, so that the three parts B, C, and D of the Ti-6Al-4V alloy sample receive the light evenly. The process parameters ar...

Embodiment 3

[0055] Embodiment 3, step 1: the Ti-6Al-4V alloy part that is 1.2mm in thickness adopts wire cutting machine to cut off tensile sample along the pressing direction, and the mass fraction of its chemical composition is Al, 6.08%, V, 5.03%, Fe, 0.35%, C, 0.09%, N, 0.60%, H, 0.018%, O, 0.16%, Ti is composed of β-Ti and α-Ti10%. The dimensions of the tensile sample parts are a=10mm, b=8mm, d=6mm, r=10mm, L=35mm, and are subjected to mechanical polishing and plasma beam thinning treatment.

[0056] Step 2: The pulsed laser 110 is reflected by the total reflection prism 120 to change the direction of light propagation, and then the Gaussian light is converted into flat-top light by the Gaussian flat-top lens 130, and then the beam is expanded by the beam expander 140, and the output is expanded. After beaming, the light impacts the Ti-6Al-4V alloy sample with energy, so that the three parts B, C, and D of the Ti-6Al-4V alloy sample receive the light evenly. The process parameters ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com