Nano-porous aerogel/fiber composite super thermal insulation material and preparation method thereof

A fiber composite and thermal insulation material technology is applied in the preparation of the composite thermal insulation material and in the field of composite super thermal insulation materials, which can solve the problems such as the inability to form nano-scale or micro-scale pore structures, the limitation of the application scope of thermal insulation materials, and the difficulty in achieving super thermal insulation effects. , to achieve the effect of excellent thermal insulation properties, excellent thermal shock resistance, and improved operating temperature and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

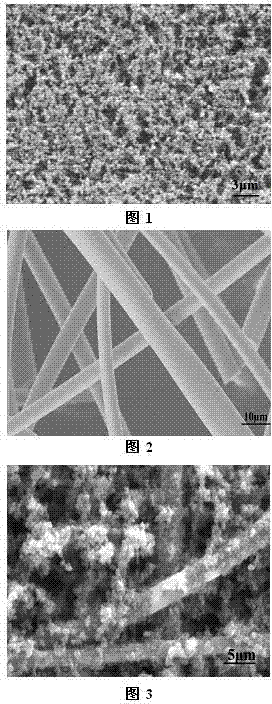

Image

Examples

Embodiment approach 1

[0042] (1) The organic solvent tert-butanol, organic monomer acrylamide, and cross-linking agent N,N'-methylenebisacrylamide were thoroughly stirred and mixed for 25 hours to prepare a premixed liquid, in which tert-butanol, acrylamide and N, N'-methylenebisacrylamide, the weight ratio of the three is 180:37:3.5; (2) Add silica airgel, alumina micropowder, zirconia fiber, Sunscreen agent titanium dioxide, pore-forming agent polyethylene glycol-2000, and suspending agent sodium tripolyphosphate were mixed for 5 hours in a planetary ball mill to prepare a slurry with a solid phase content (volume fraction) of 19%, in which silicon oxide gas-condensed Glue, alumina micropowder, zirconia fiber, opacifying agent titanium dioxide, the weight ratio of the four is 0.7:2.3:1.4:0.08, and the addition amount of pore-forming agent polyethylene glycol-2000 is silica airgel, alumina 2.7% of the total weight of micropowder, zirconia fiber and opacifying agent titanium dioxide, and the additi...

Embodiment approach 2

[0044] (1) The organic solvent tert-butanol, organic monomer acrylamide, and cross-linking agent N,N'-methylenebisacrylamide were thoroughly stirred and mixed for 25 hours to prepare a premixed liquid, in which tert-butanol, acrylamide and N, N'-methylenebisacrylamide, the weight ratio of the three is 175:32:2; (2) Add silica airgel, alumina micropowder, zirconia fiber, Sunscreen agent titanium dioxide, pore-forming agent polyethylene glycol-2000, and suspending agent sodium tripolyphosphate were mixed for 4 hours in a planetary ball mill to prepare a slurry with a solid phase content (volume fraction) of 21%, in which silicon oxide gas-condensed Glue, alumina micropowder, zirconia fiber, opacifying agent titanium dioxide, the weight ratio of the four is 1.1~1.3:2.8:3~3.3:0.14, and the amount of pore-forming agent polyethylene glycol-2000 added is silica gas condensation 1.5~4.5% of the total weight of glue, alumina micropowder, zirconia fiber and opacifying agent titanium dio...

Embodiment approach 3

[0046] (1) Fully stir and mix the organic solvent tert-butanol, organic monomer acrylamide, and cross-linking agent N,N'-methylenebisacrylamide for 24 to 48 hours to form a premixed liquid, in which tert-butanol, acrylamide and N,N'-methylenebisacrylamide, the weight ratio of the three is 174:39~40:6~9; (2) Add silica airgel and alumina to the premix in step (1) Micropowder, zirconia fiber, opacifying agent titanium dioxide, pore-forming agent polyethylene glycol-2000 and suspending agent sodium tripolyphosphate were mixed for 4.5 hours in a planetary ball mill to prepare a slurry with a solid content (volume fraction) of 35%. , wherein the weight ratio of silica airgel, alumina micropowder, zirconia fiber, and opacifying agent titanium dioxide is 0.7~1.0:2.5~4.0:1.8~3.1:0.12~0.23, and the pore-forming agent polyethylene glycol The addition amount of -2000 is 4.6% of the total weight of silica airgel, alumina micropowder, zirconia fiber and opacifying agent titanium dioxide, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com