Patents

Literature

39results about How to "Improve thermal insulation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

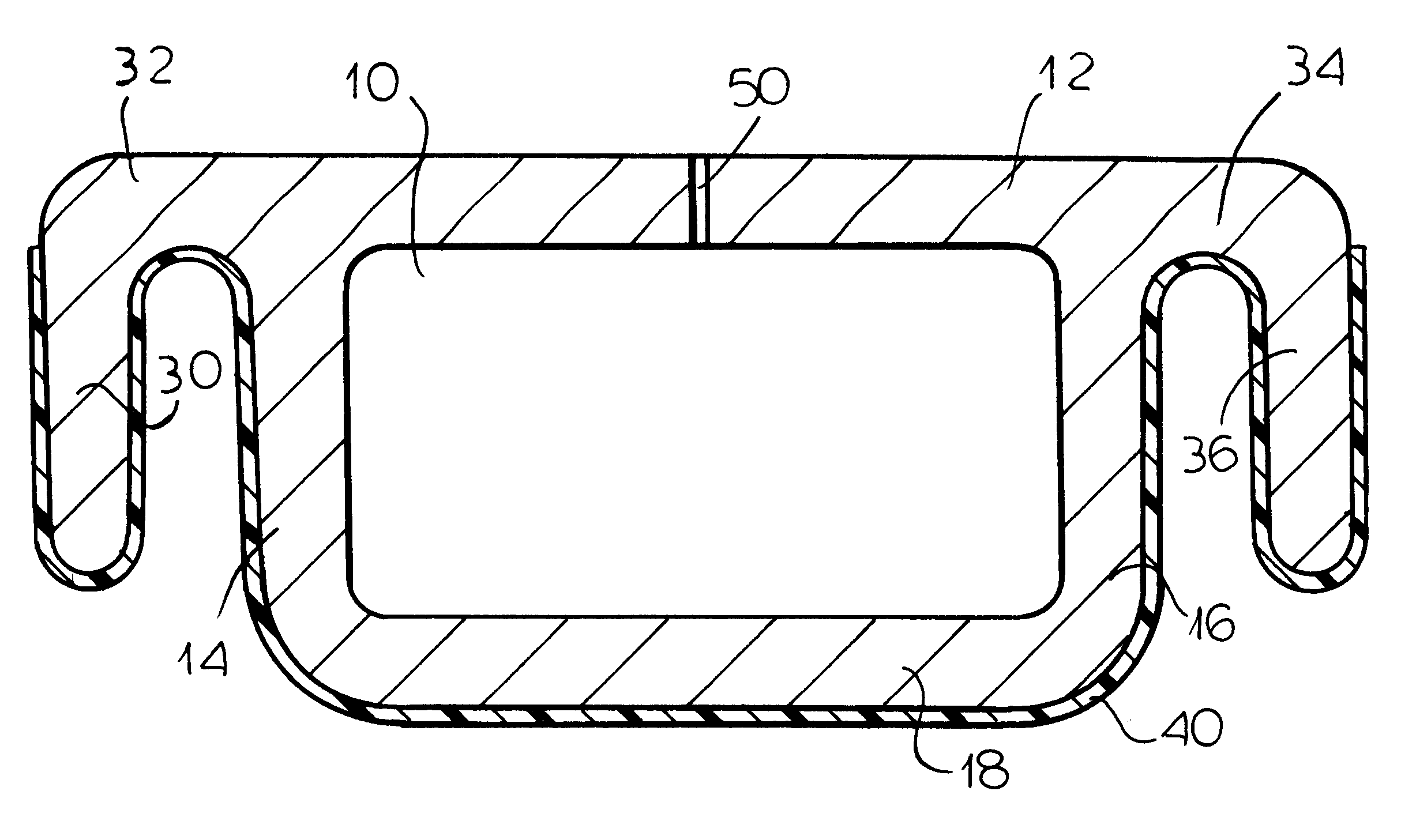

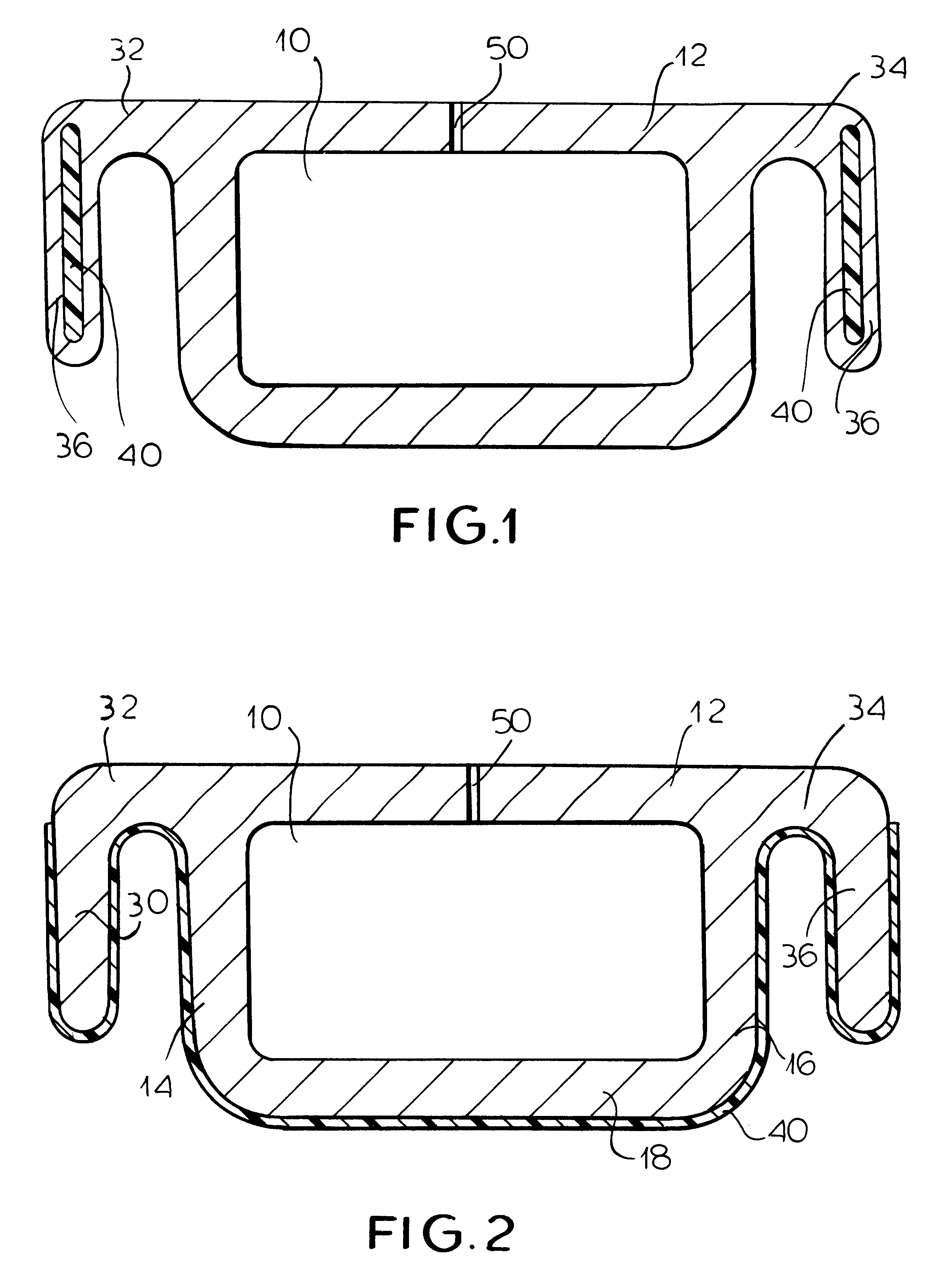

Profiled spacers for insulation glazing assembly

InactiveUS6339909B1High heat insulate characteristicAvoid deformationUnits with parallel planesInsulated glazingElectrical and Electronics engineering

A spacer profile for a spacer frame to be mounted in an insulating window unit by forming a space between the panes, with a chamber for receiving hygroscopic materials and with at least one contact web to lie against the inner side of a pane, which is connected via a bridge section with the chamber, is characterized i that the profile corpus of the spacer profile consists of an elastically-plastically deformable material with poor heat conductivity, and that at least the contact webs are permanently materially connected with a plastically deformable reinforcement layer.

Owner:TECHNOFORM CAPRANO & BRUNNHOFER

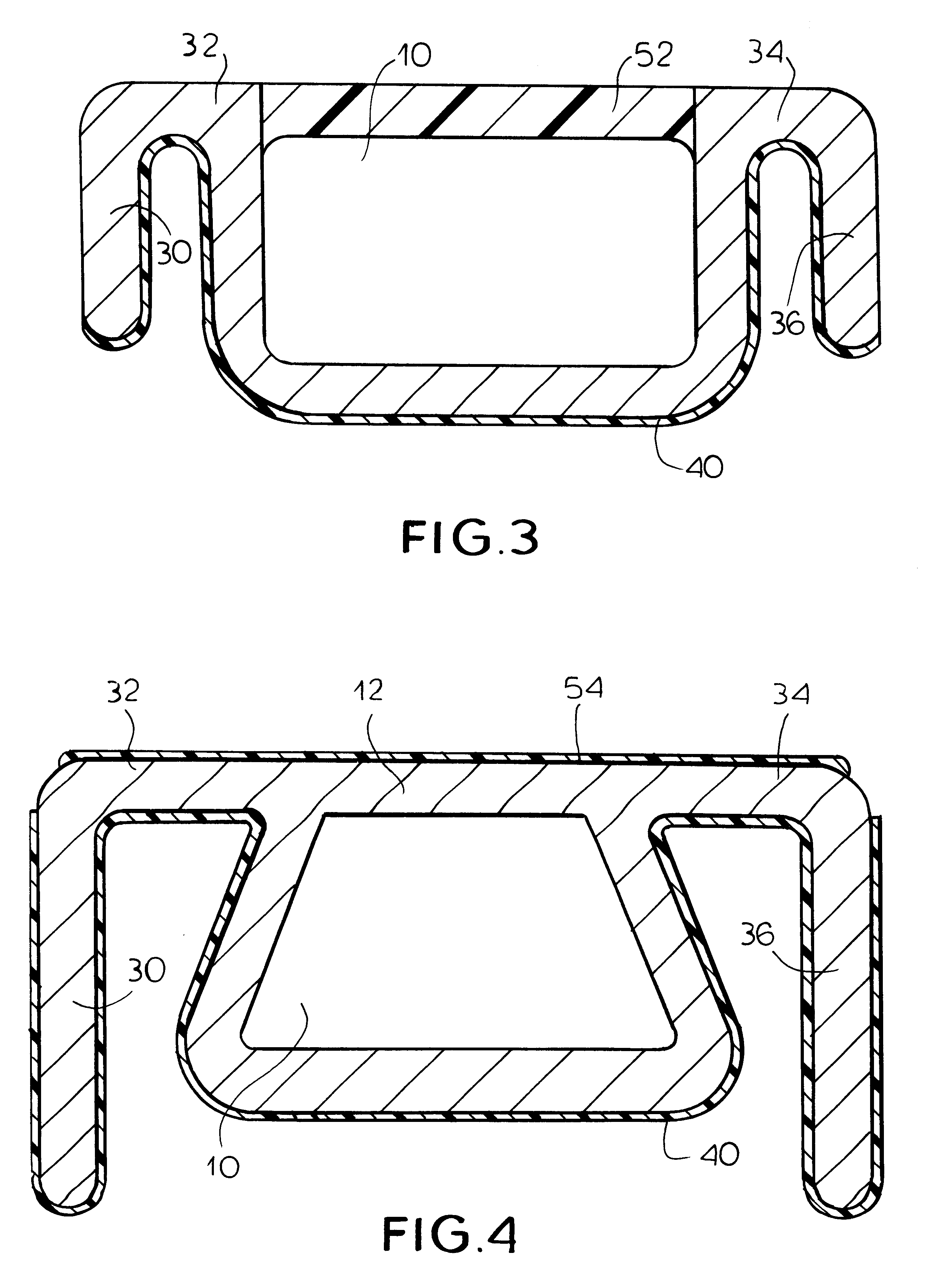

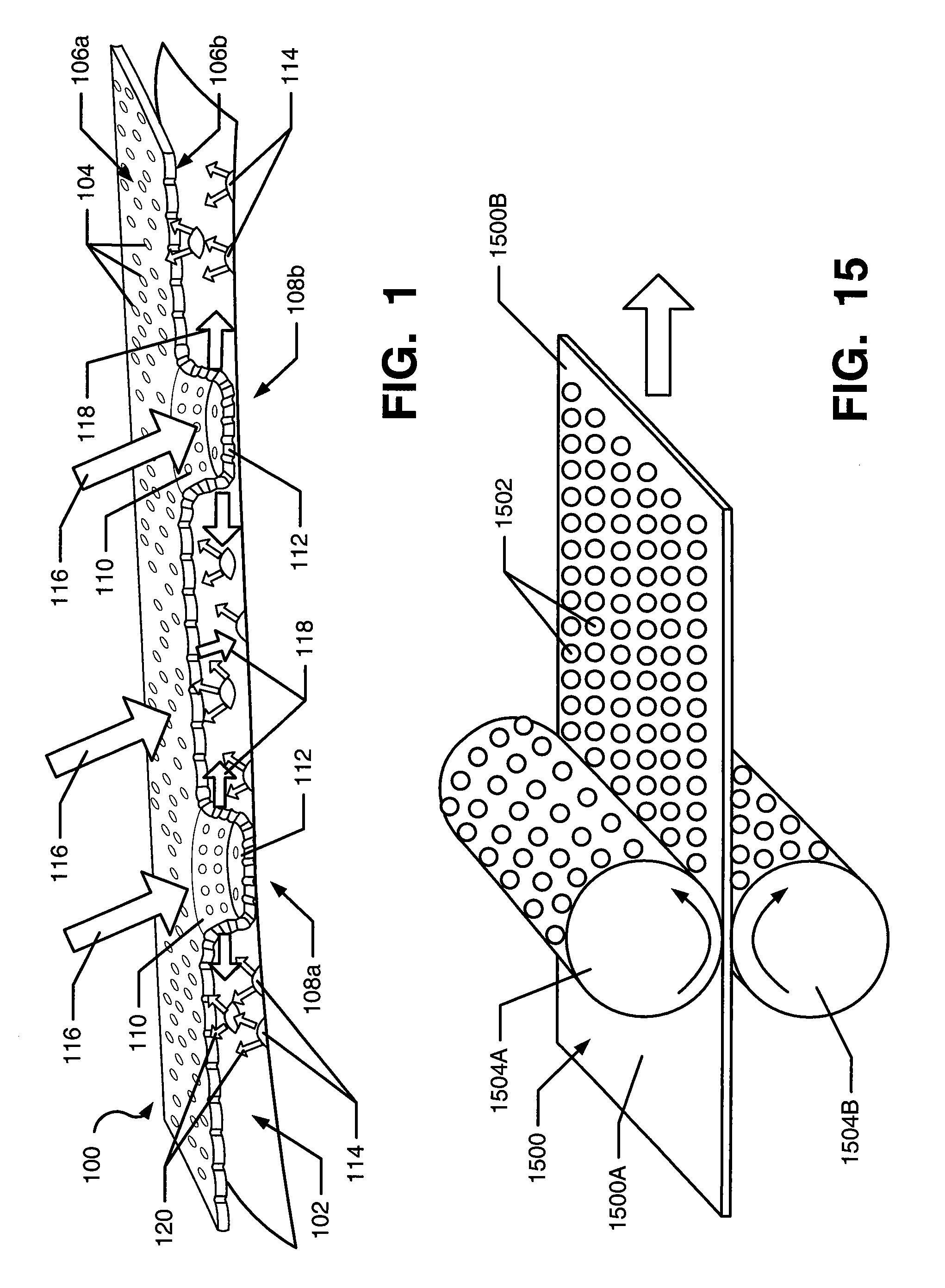

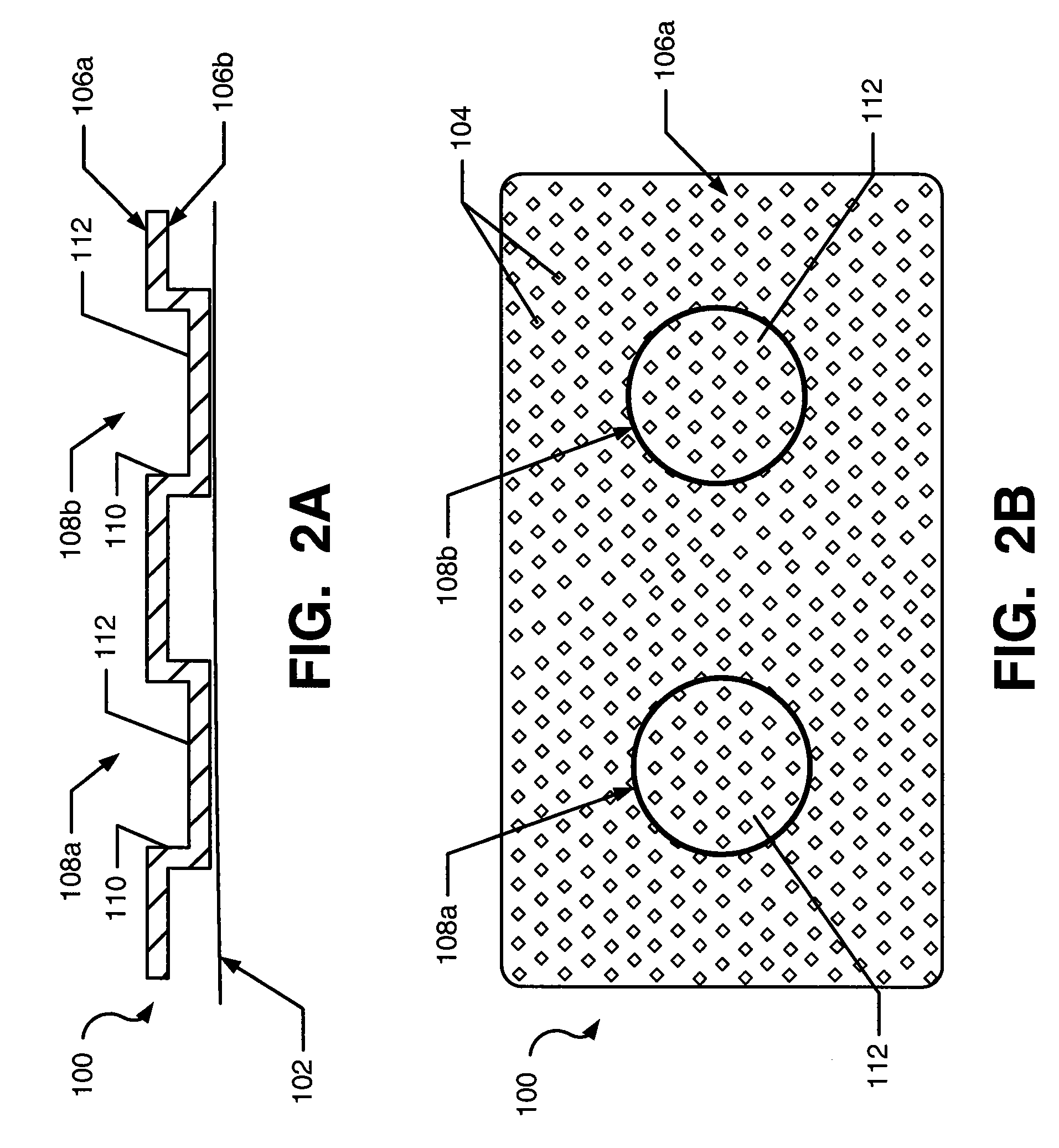

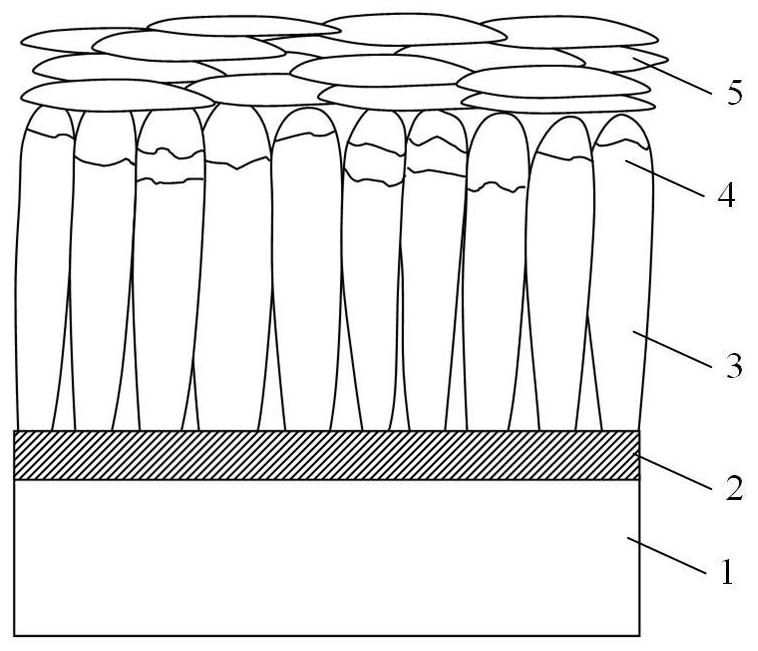

Fabrics and articles of apparel including dimensionalized mesh and other fabrics

ActiveUS20070293106A1Promote evaporative coolingImprove thermal insulation propertiesGarment special featuresMechanical working/deformationEngineeringSurface modified

Fabrics and garments may include “dimensionalized” structures. The fabric may be “dimensionalized” by integrally forming a plurality of self-standing fabric surface modifying elements in the fabric material to thereby provide a fabric contact level different from (and / or reduced in surface area as compared to) the fabric base level. Garments may include this “dimensionalized” material, e.g., positioned at various locations to promote better evaporative cooling of the body or heat retention, such as along the wearer's spine, sides, and / or other locations that release substantial heat. The “dimensionalizing” structure may be formed in the material, for example, by molding, rolling, embossing, calendering, stretching, crimping, pressing, heating, and / or the like.

Owner:NIKE INC

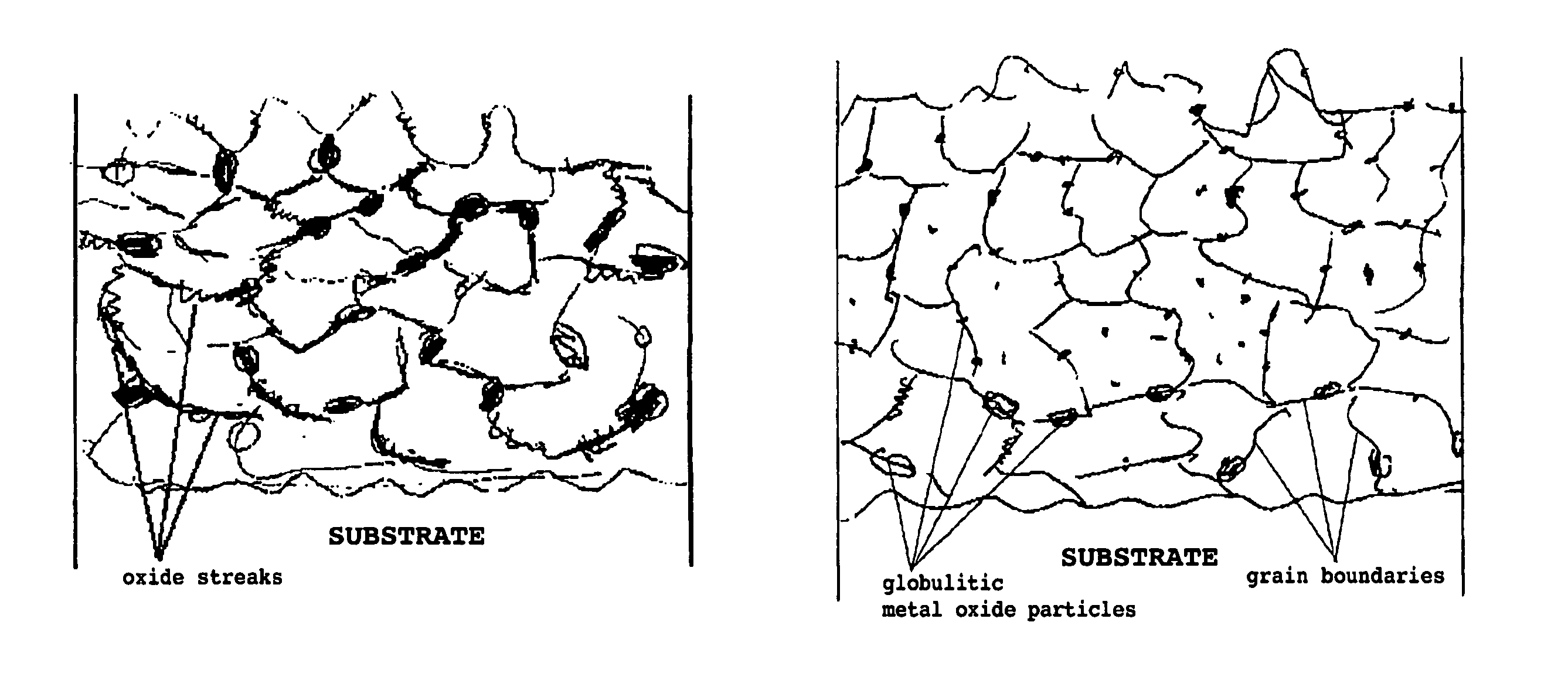

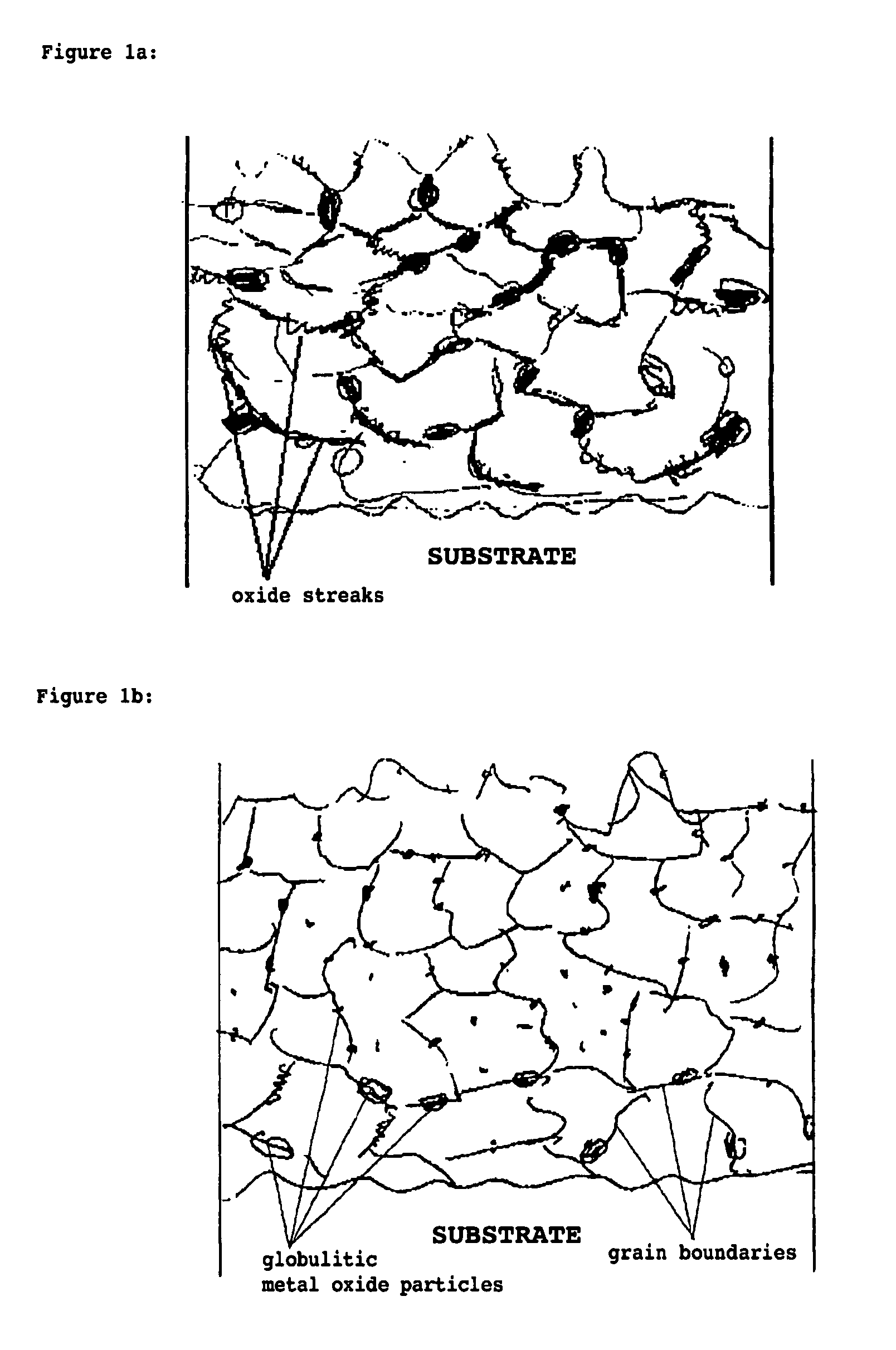

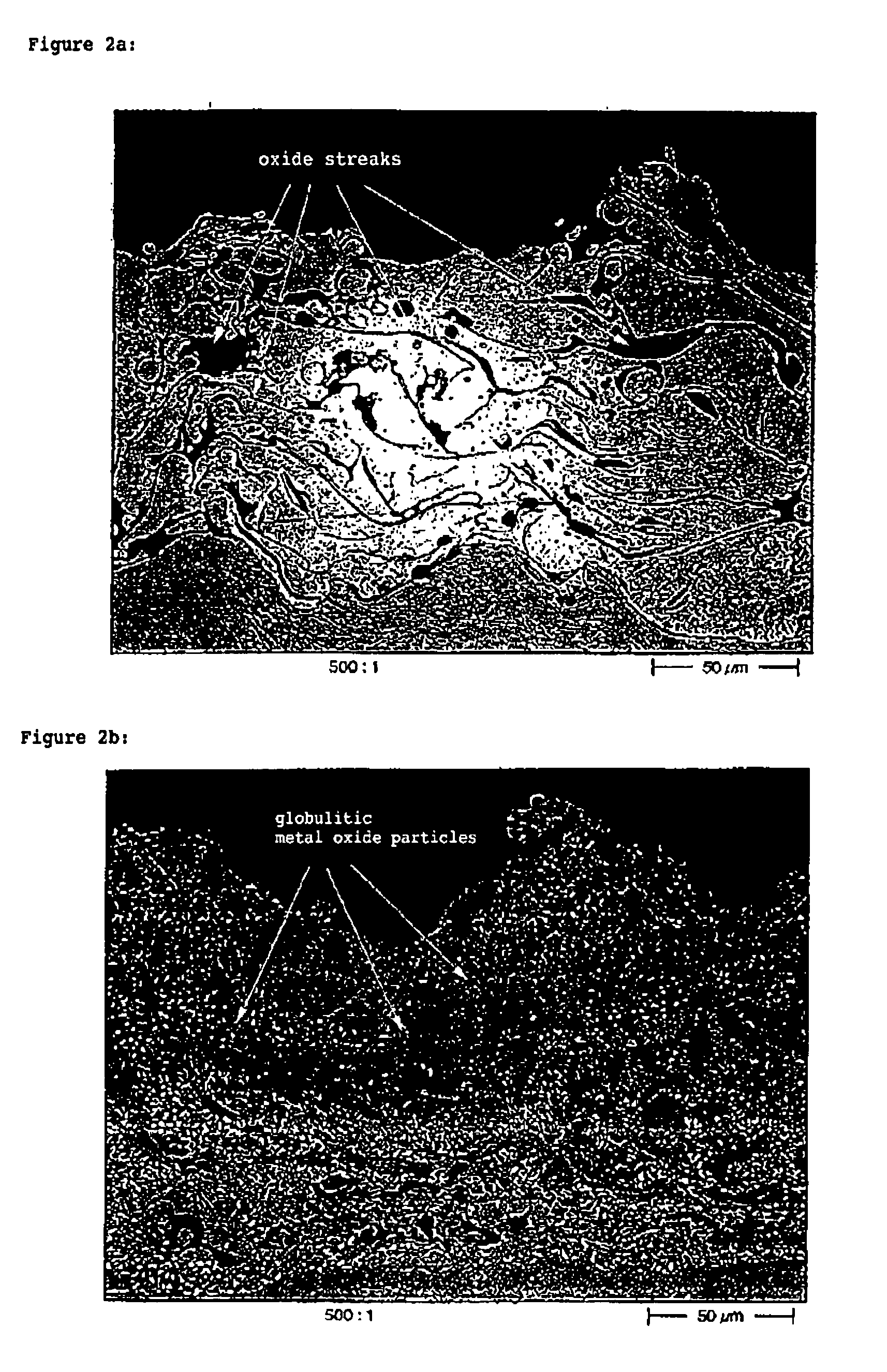

Protective coating for application to a substrate and method for manufacturing a protective coating

InactiveUS20060292390A1High heat and corrosion resistanceCost-effective manufacturingMolten spray coatingPretreated surfacesMetallic materialsSpray coating

A refractory, oxidation-resistant, and corrosion-resistant protective coating for application to a substrate, in particular for application to parts of turbines or aircraft propulsion engines, is described, including a spray coating made of a thermally sprayed, primarily metallic material, the coating being at least partially subjected to a thermochemical aluminum (Cr, Si) deposition process having a specifically high aluminum deposition activity after the application of the protective coating to the substrate, in such a way that the protective coating has alloy gradients of Al (Cr, Si) which increase from the substrate surface to the coating surface and isolated globulitic metal oxide particles. Furthermore, a method for manufacturing this protective coating and its use are described.

Owner:MTU AERO ENGINES GMBH

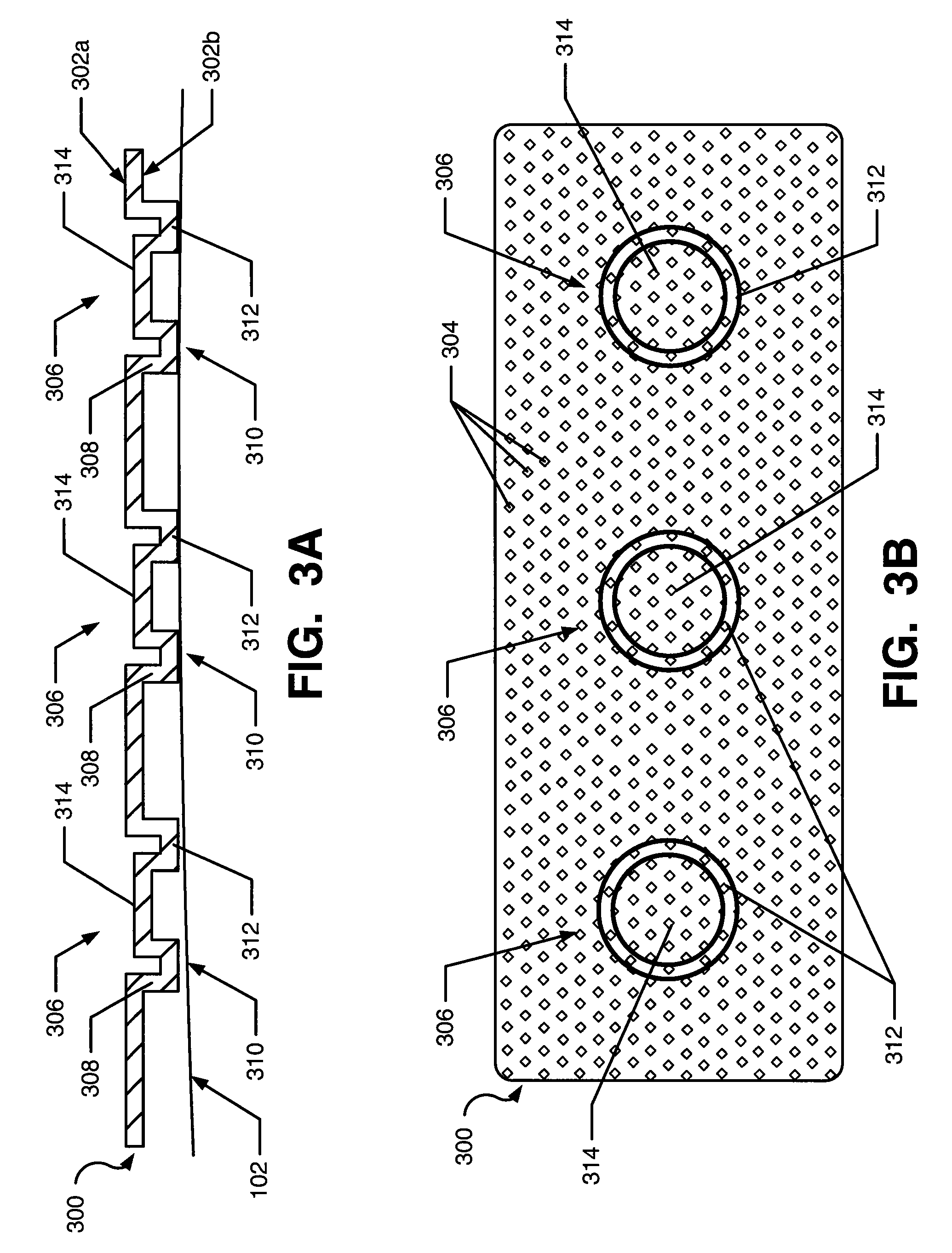

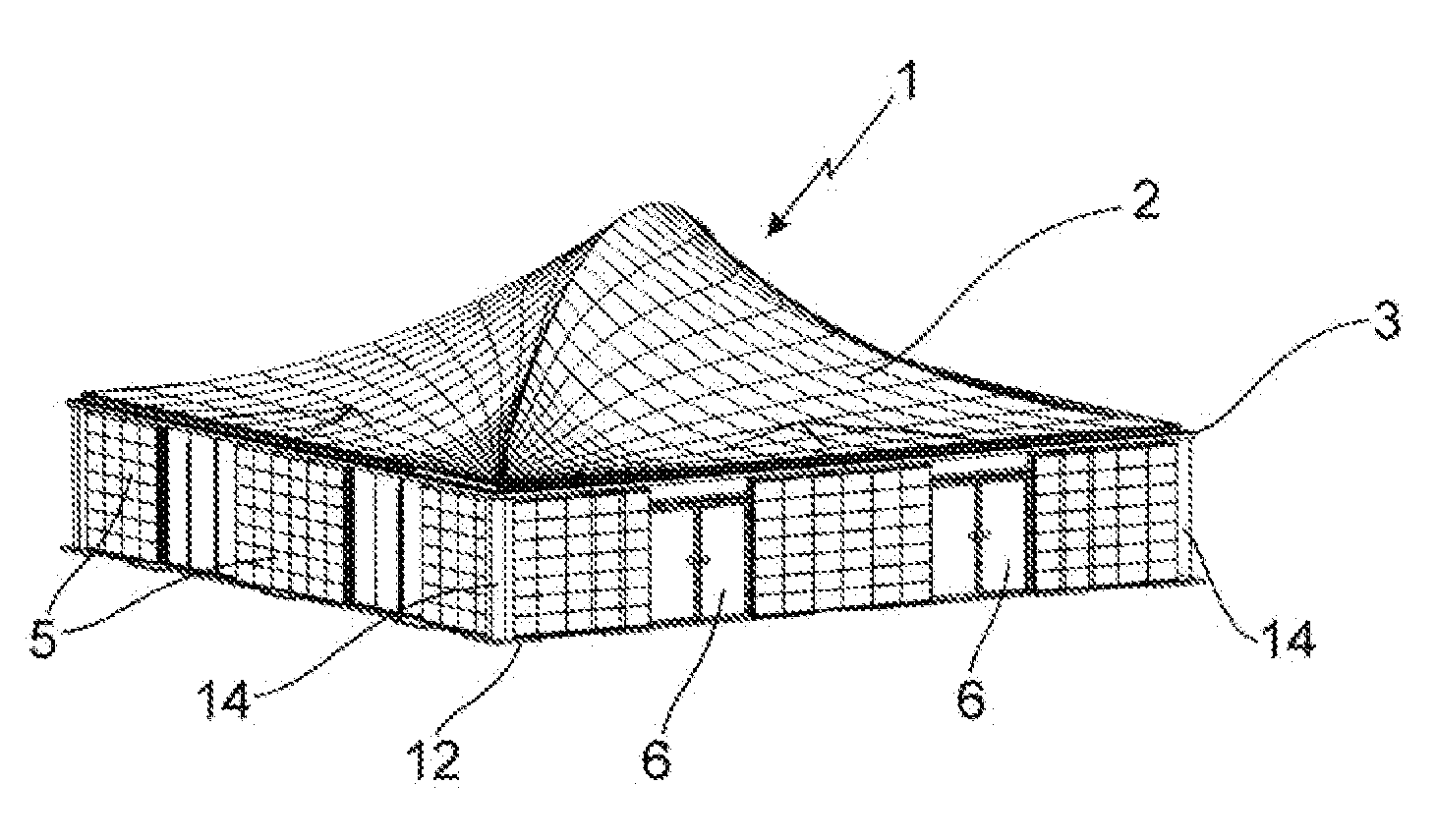

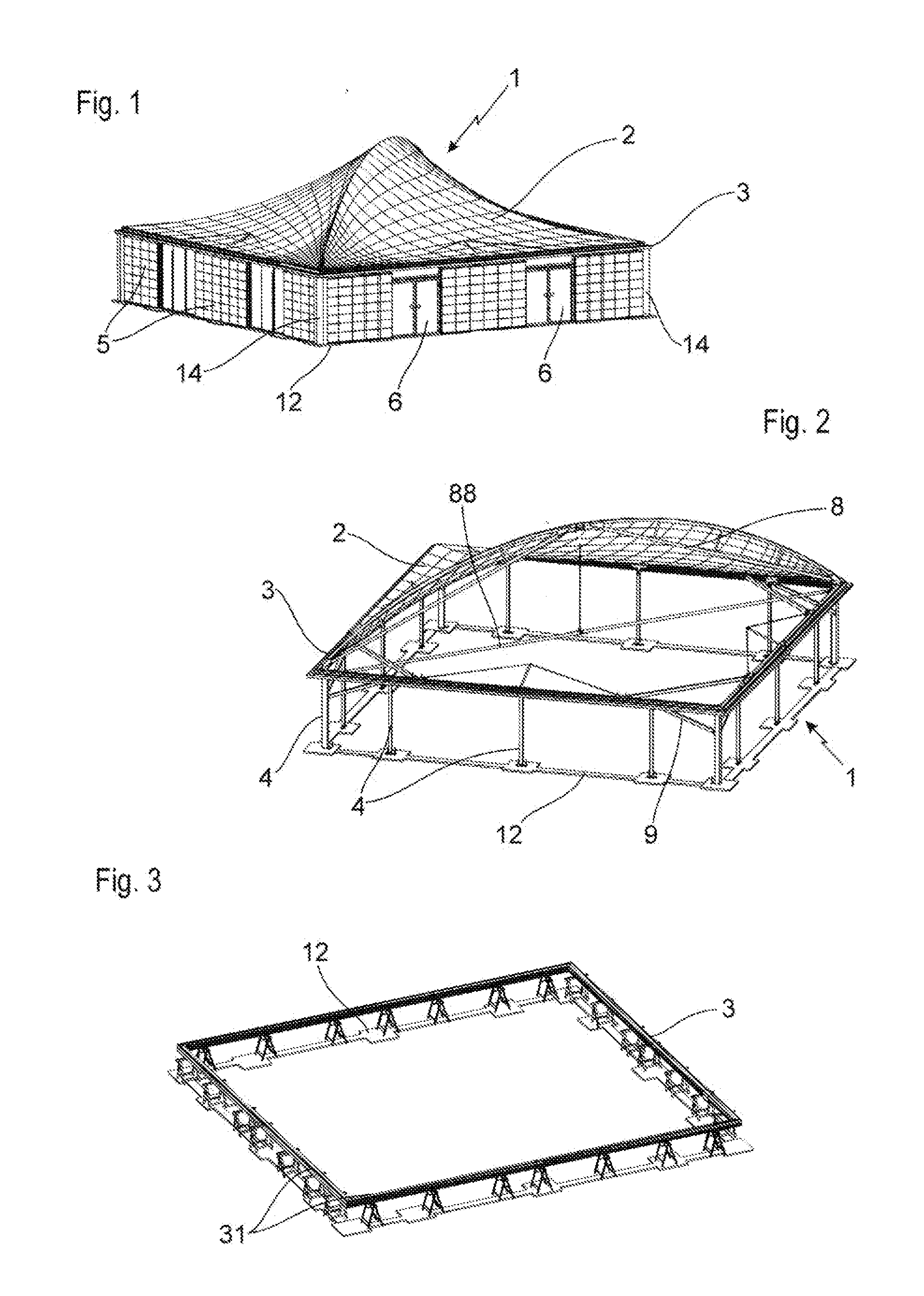

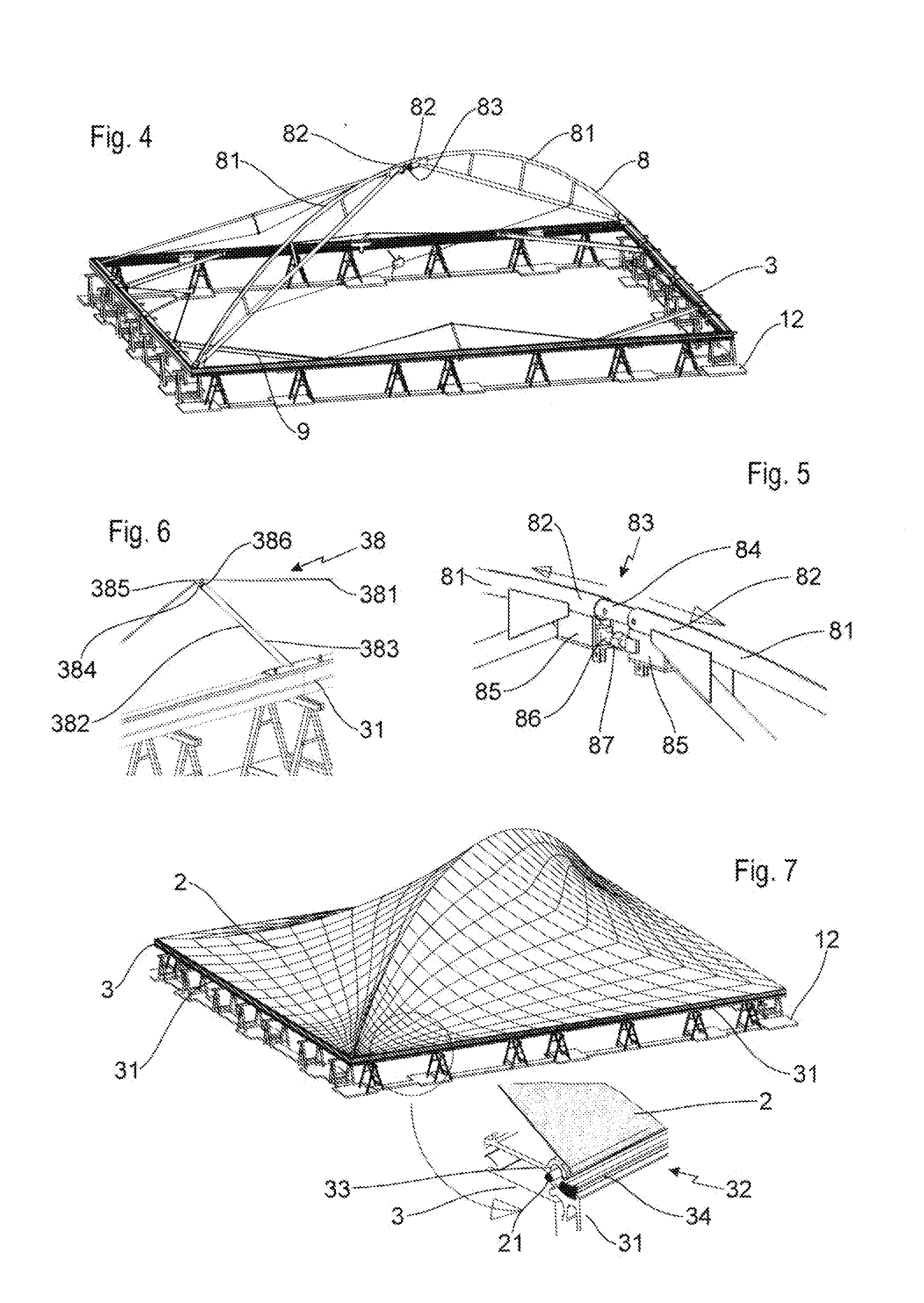

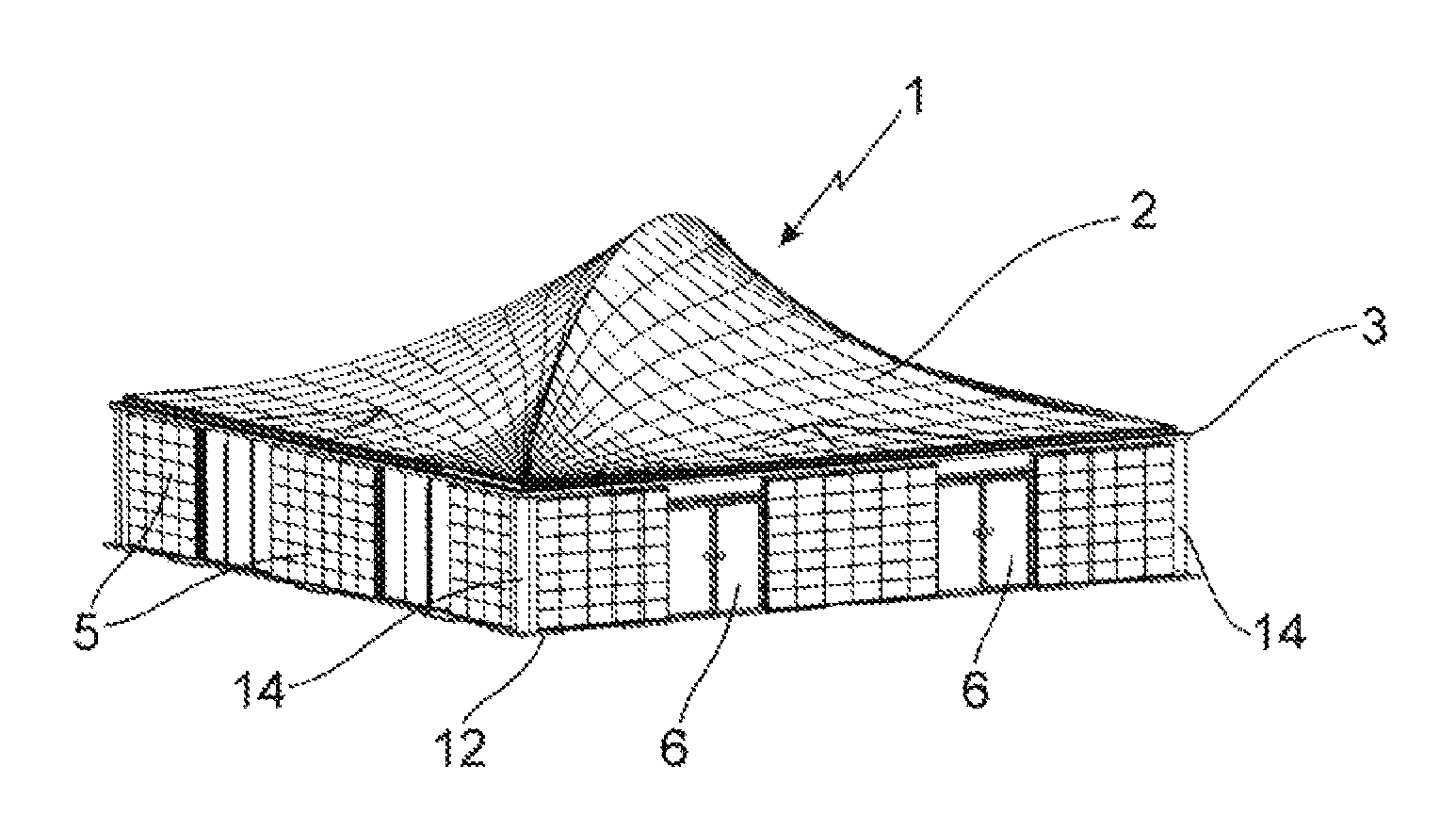

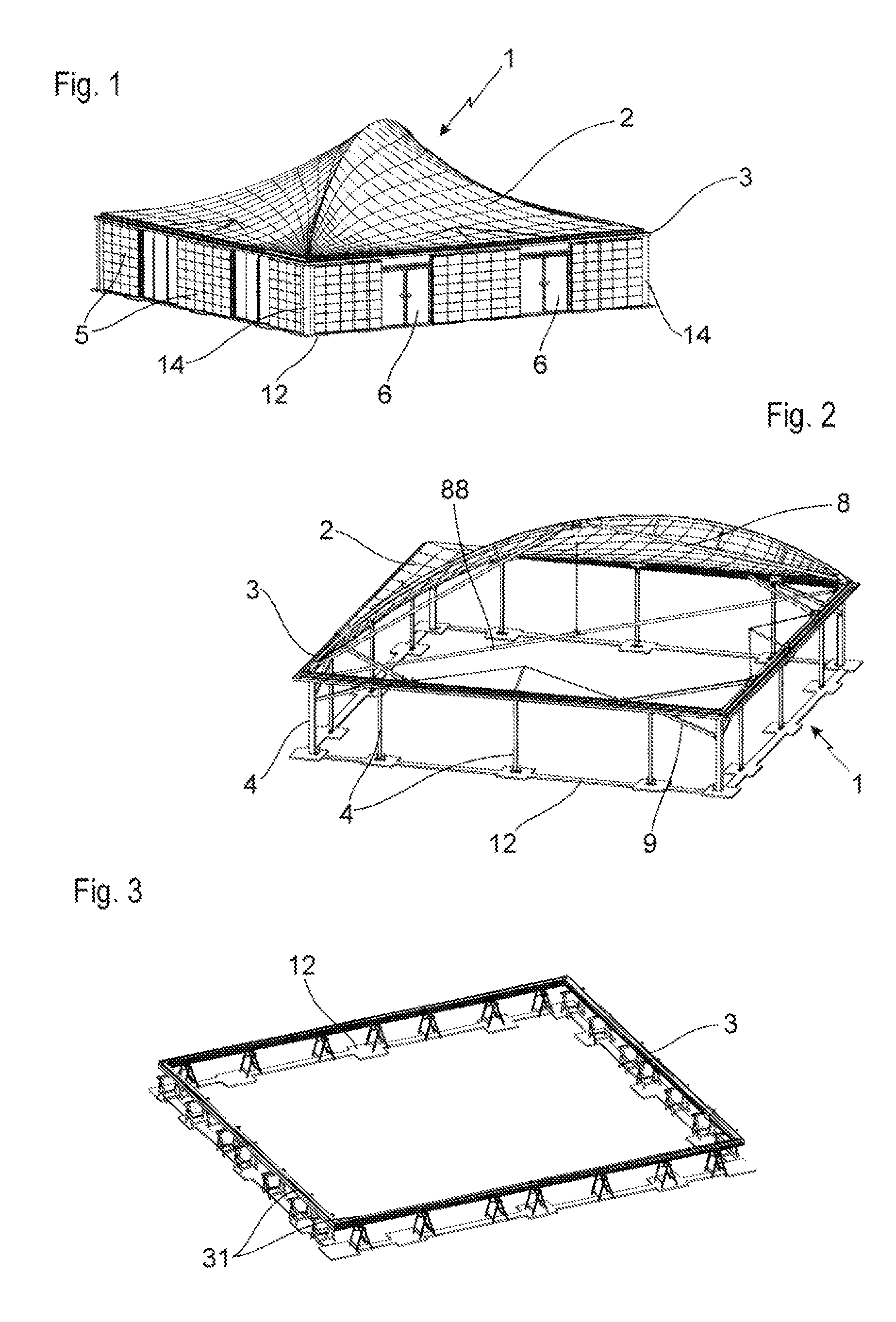

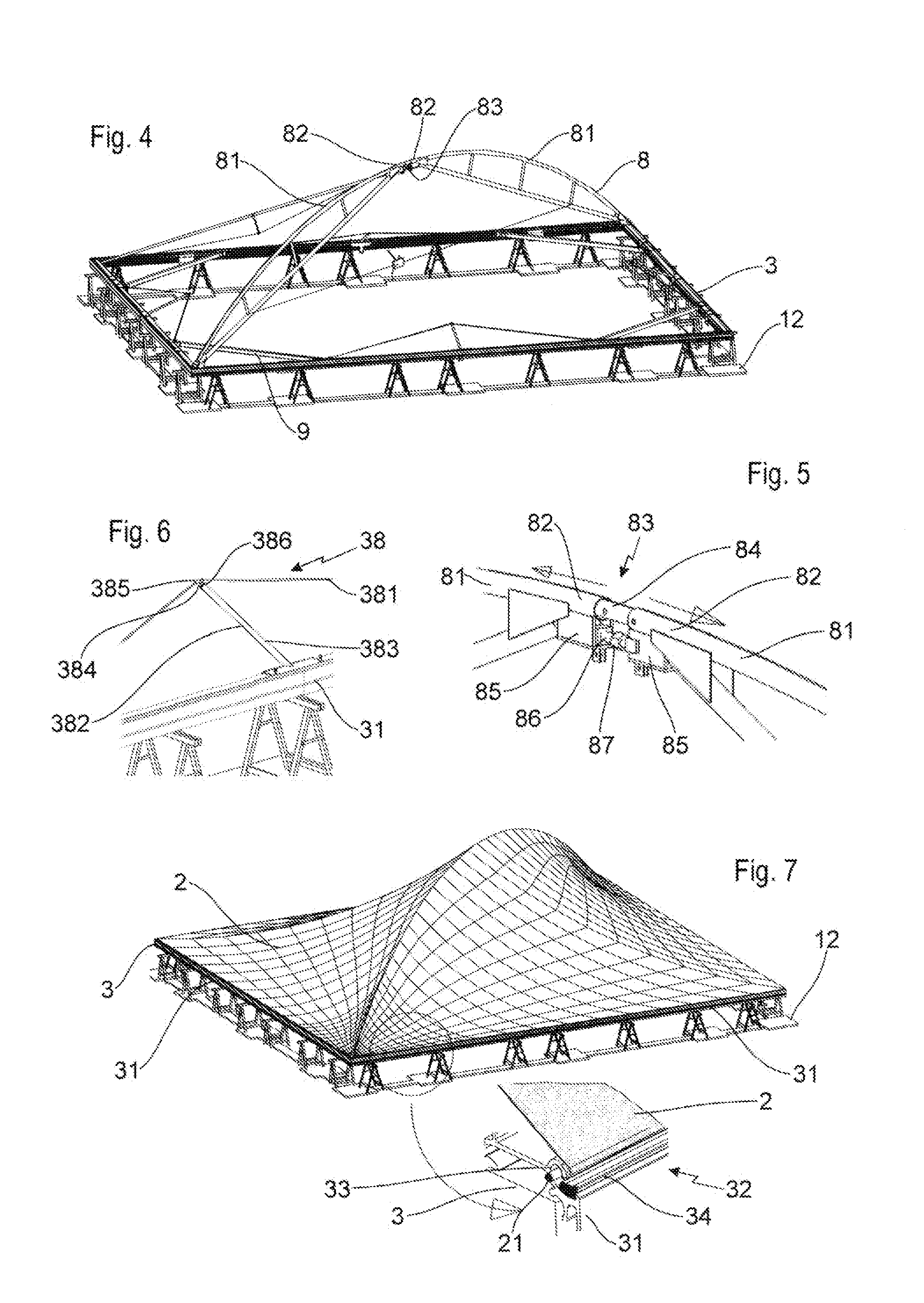

Lightweight housing module and modular building

InactiveUS20110258941A1Improve thermal insulation propertiesEasy to implementBuilding roofsRoof coveringMarine engineeringModularity

This invention relates to a lightweight housing module comprising at least one stretched fabric intended to form the roof of said module and fixed along its lower edge on a rigid frame maintained at a distance from the ground by a plurality of lateral posts, remarkable in that it comprises vertical panels and / or opening frames in order to close in a substantially sealed manner its vertical facades and a false ceiling arranged in order to be arranged under said fabric inside said lightweight housing module and fixed to the frame. This invention also relates to a modular building remarkable in that it comprises a plurality of lightweight housing modules, according to the invention, arranged next to one another, and a system for sealing between the adjacent lightweight housing modules. This invention also relates to their method of assembly.

Owner:DALO CATHERINE

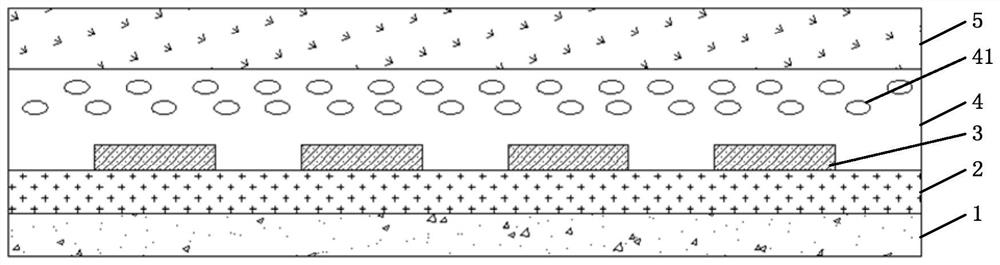

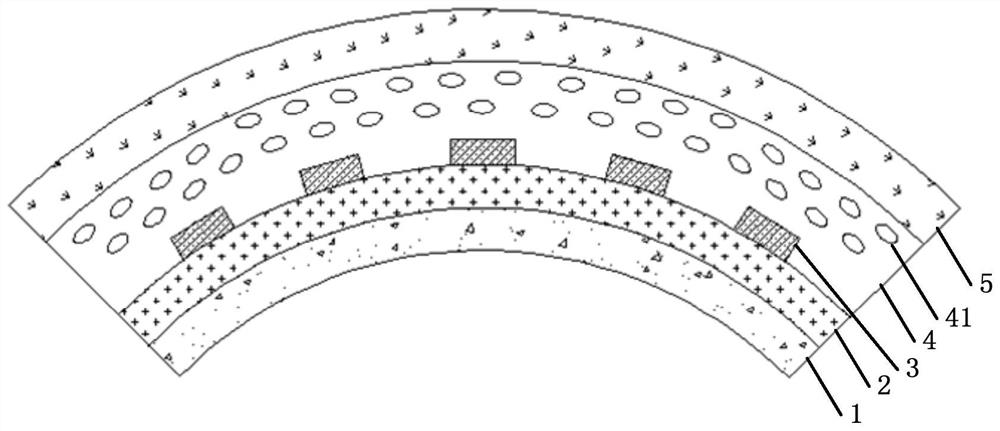

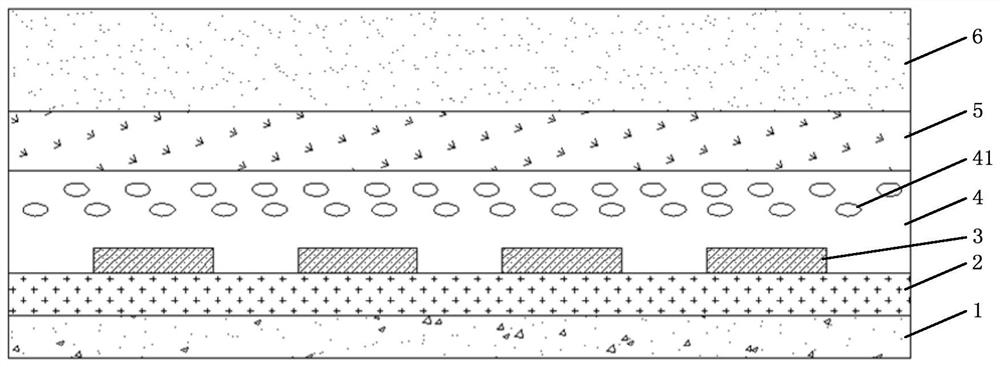

Nano-porous aerogel/fiber composite super thermal insulation material and preparation method thereof

The invention discloses a nano-porous aerogel / fiber composite super thermal insulation material and a preparation method thereof. The aerogel / fiber composite super thermal insulation material comprises silicon dioxide aerogel, alumina micro powder, zirconium oxide fibers and opacifying agent of titanium dioxide. The preparation method comprises that organic solvent, cross-linking agents and organic monomers make up pre-mixed solution according to a certain proportion, the silicon dioxide aerogel, the alumina micro powder, the zirconium oxide fibers, pore-forming agents, suspending agents and the titanium dioxide make up slurry through a ball milling process according to a certain proportion, then a certain amount of initiating agents and a certain amount of catalytic agents are dropwise added into the slurry through vacuum bubble removal, composite material in-situ solidification is achieved through a gel injection moulding process, and then demoulding, vacuum drying and degreasing glue discharging are conducted. The nano-porous aerogel / fiber composite super thermal insulation material has a nano-porous / reinforced fiber composite microstructure, the heat conductivity is 0.040-0.046W*m<-1>*K<-1> (298K), and the flexure strength is as high as 12-14MPa. Preparation processes are simple, industrialized application is easily achieved on a large scale, and the nano-porous aerogel / fiber composite super thermal insulation material is suitable for thermal protection of aerospace, military affairs and severe rugged environments.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

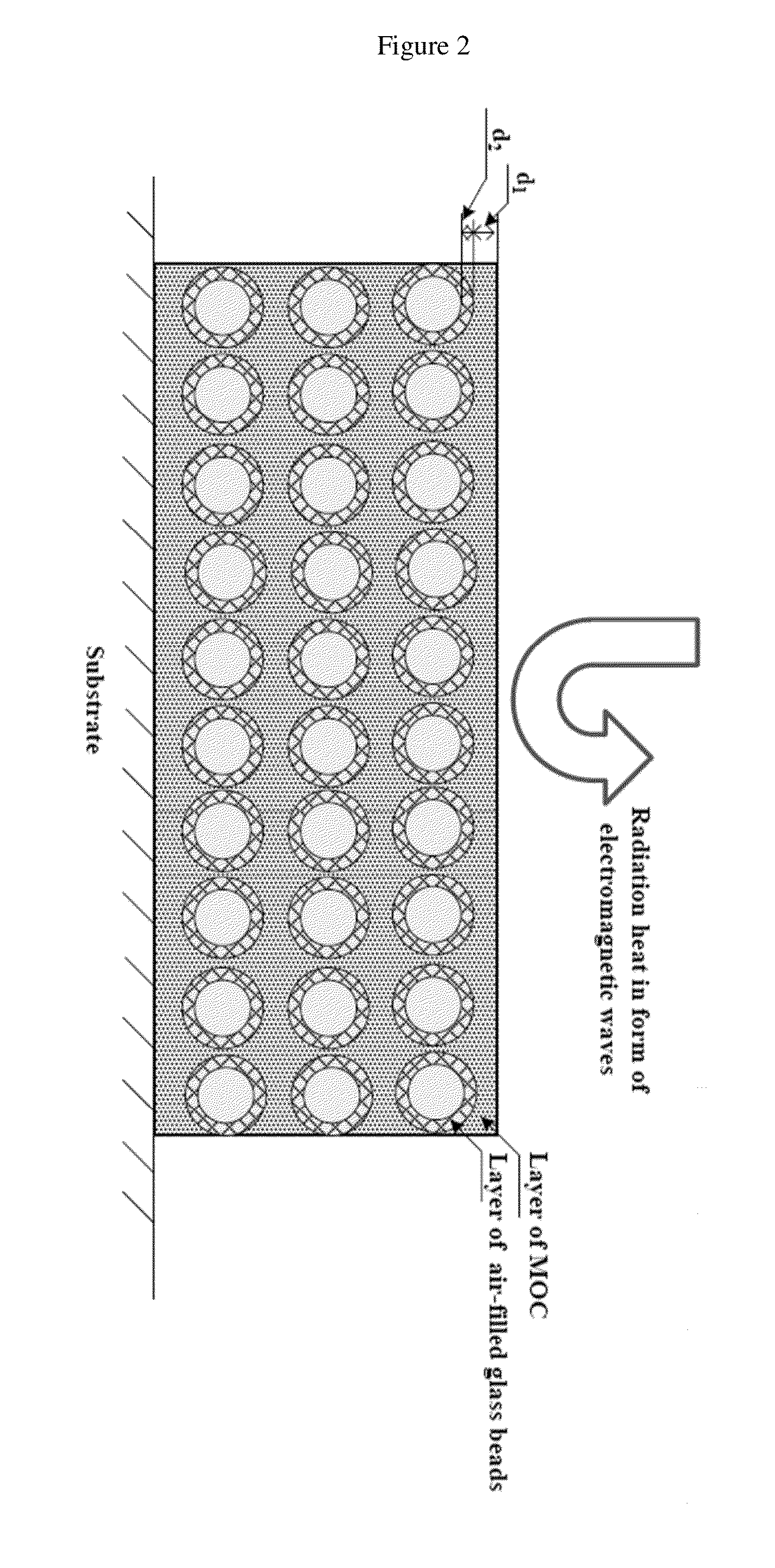

Advanced inorganic material for reflection of electromagnetic waves

ActiveUS20130256578A1Shorten working lifeLower life cycle costsHeat proofingThermal insulationPhosphate

This invention provides a composition for thermal insulation, comprising magnesium oxychloride cement (MOC) and air-filled glass or ceramic beads, and a method of preparing said composition. The composition may further comprise one or more additives selected from the group consisting of titanium dioxide, fly ash, pigment, potassium dihydrogen phosphate (KH2PO4) and sodium dihydrogen phosphate (NaH2PO4).

Owner:NANO & ADVANCED MATERIALS INST

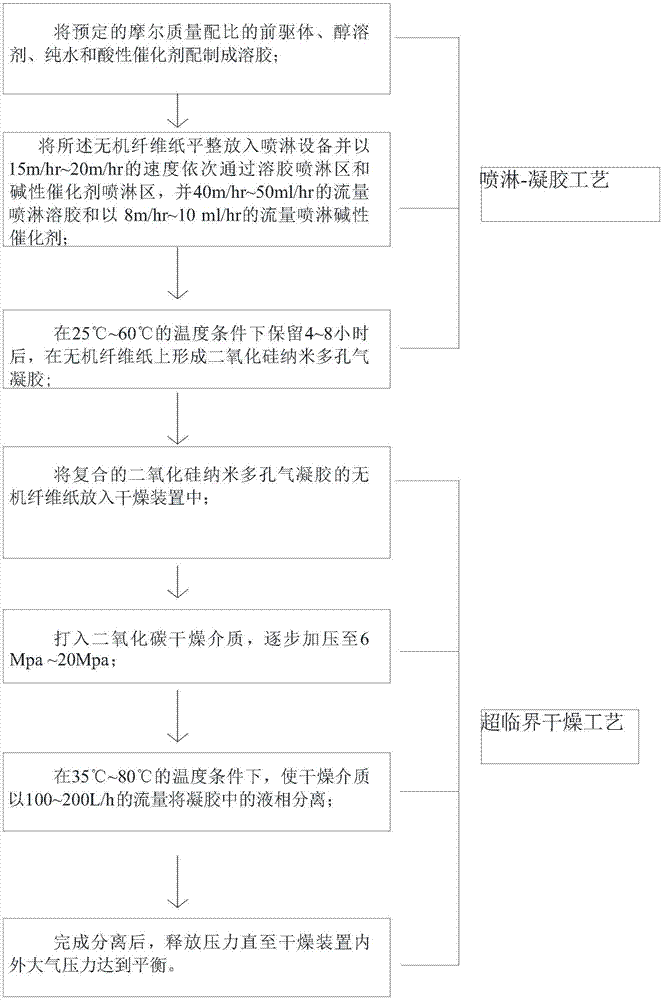

Hydrophobic heat-preserving and heat-insulating paper and preparation method thereof

InactiveCN107313289ALow thermal conductivityImprove thermal insulation propertiesSilicaWater-repelling agents additionThermal insulationThermal conductivity

The invention discloses a hydrophobic thermal insulation paper, comprising: a base material layer; silicon dioxide nanoporous airgel is attached to the base material layer, the base material layer adopts inorganic fiber paper, and the The silicon nanoporous airgel has a specific surface of 400g / m2-800g / m2, a density of 0.015g / cm3-0.20g / cm3, a porosity of 80%-95%, and a pore size of 30nm-100nm. In the present invention, silica airgel with a nano-network pore structure is compounded on inorganic fiber paper to form thermal insulation paper, which not only retains the original characteristics of high temperature resistance and non-combustibility, but also greatly reduces the overall thermal conductivity, significantly Improved thermal insulation properties. In addition, silica airgel has good hydrophobic properties, thus further expanding the advantages of the material, and greatly improving its application value and application range. The product of the invention has the advantages of high temperature resistance, no burning in case of fire, good hydrophobicity, low thermal conductivity, etc., and excellent thermal insulation effect.

Owner:浙江贝来新材料有限公司

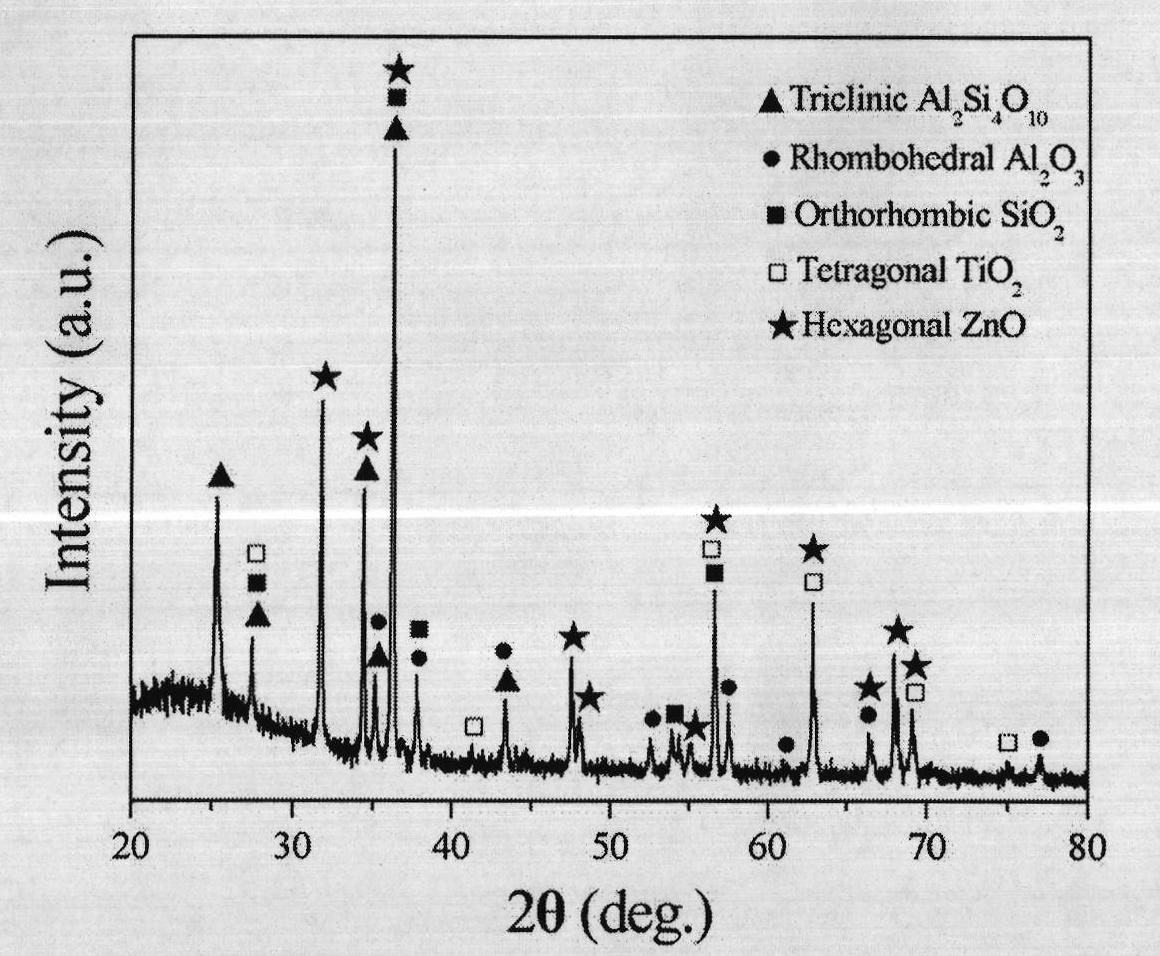

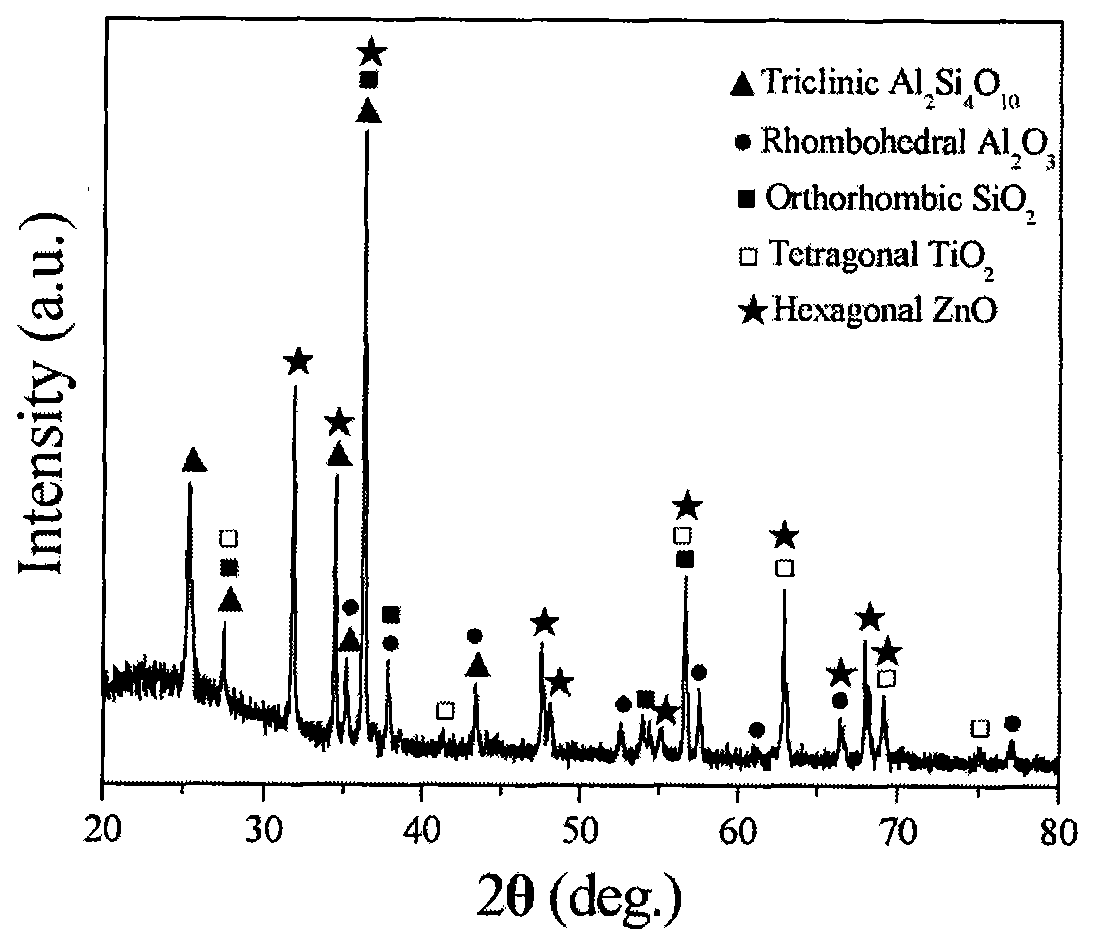

Aluminium silicate nano composite insulation coating and preparation method thereof

The invention discloses an aluminium silicate nano composite insulation coating and a preparation method thereof. The composite insulation coating comprises the following components of 10 to 40% of nano aluminium silicate, 15 to 30% of vinegar acrylic emulsion or acrylic emulsion, 30 to 50% of water, 2 to 6% of nano silicon dioxide, 2 to 6% of nano aluminum oxide, 2 to 5% of nano zinc oxide, 2 to 5% of nano titanium oxide or titanium white, 0.1 to 2% of film forming assistant, 0.1 to 2% of defoaming agent, 0.1 to 2% of wet dispersing agent, 0.5 to 2% of antifreeze and 0.1 to 2% of flatting agent. The preparation method comprises the following steps of stirring the water, the nano aluminium silicate, the wet dispersing agent and a half of the defoaming agent at high speed in a low speed stirring mode to be fully dispersed; adding other inorganic nano powder in the course of stirring; stirring on a multi-function disperser at high speed; slowly adding the emulsion at low stirring speed; adding the rest defoaming agent, the film forming assistant, the antifreeze and the flatting agent to be stirred at low speed; and finally canning to prepare the finished coating product. The invention can ensure that the surface of building materials is coated with a layer of coating of the thickness lower than 1mm; the heat conductivity coefficient of the building materials coated with the coating is reduced by 0.07 W / m.K when the temperature is 100 DEG C relative to the building materials without the coating.

Owner:CHINA MCC17 GRP

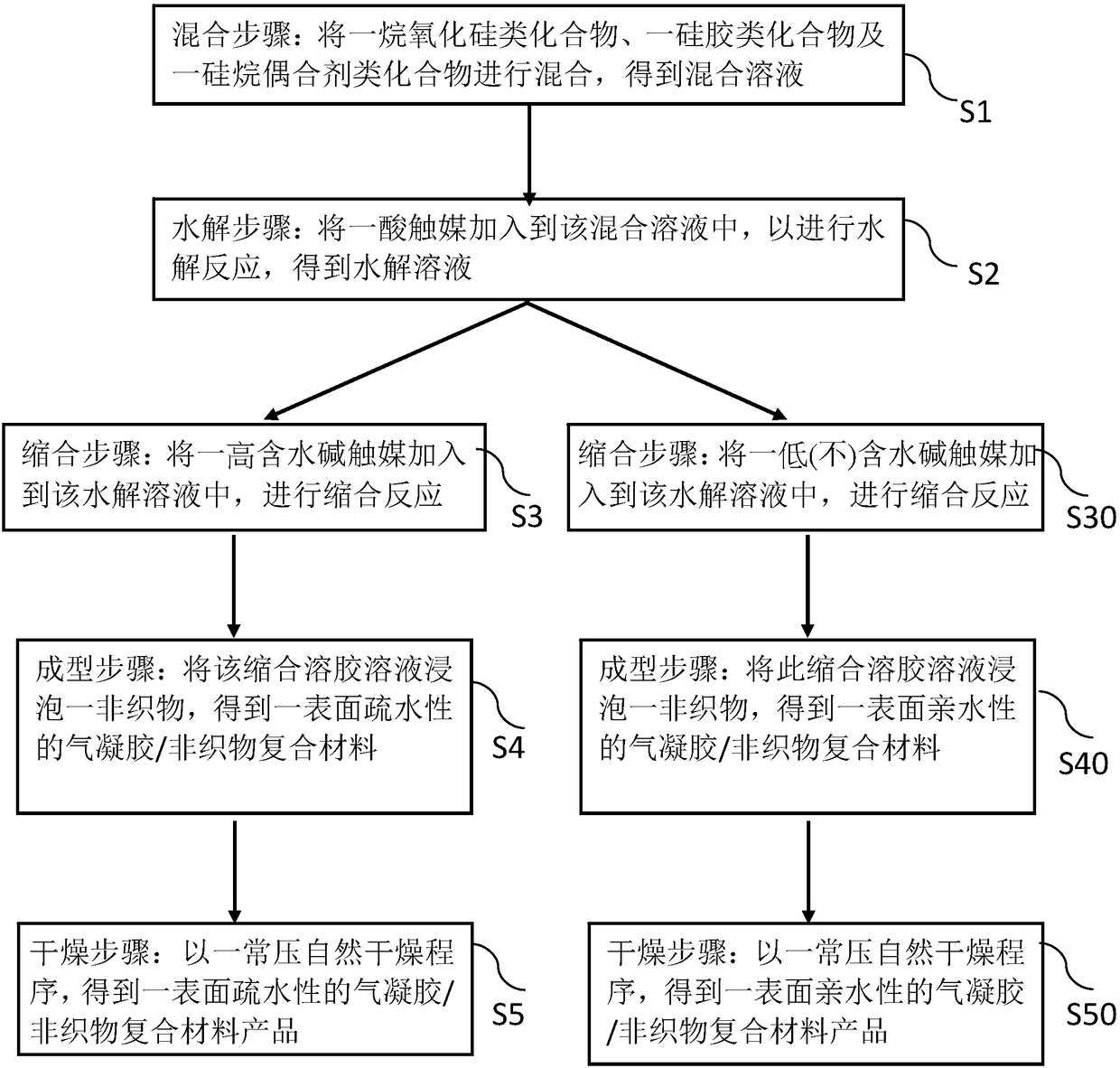

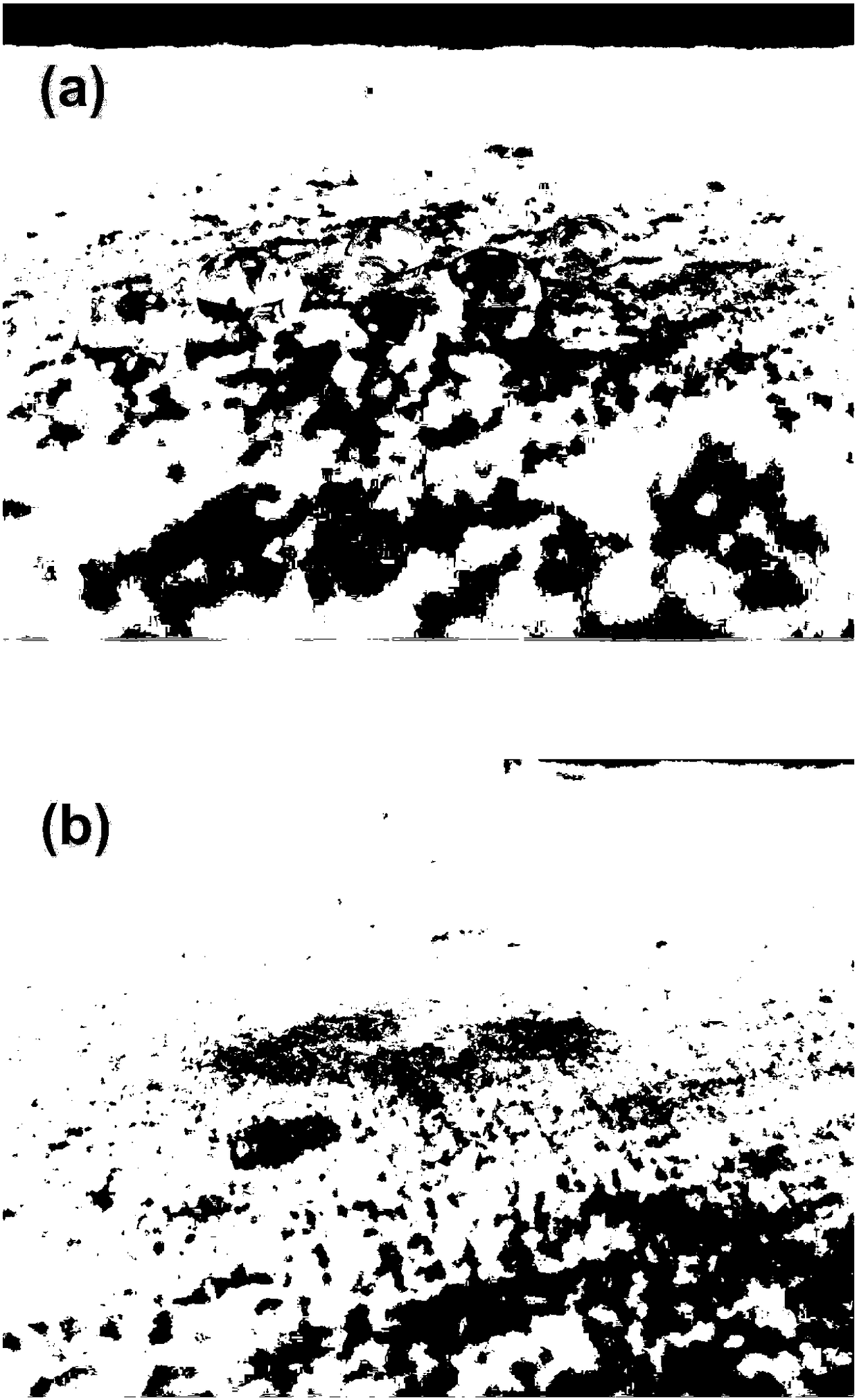

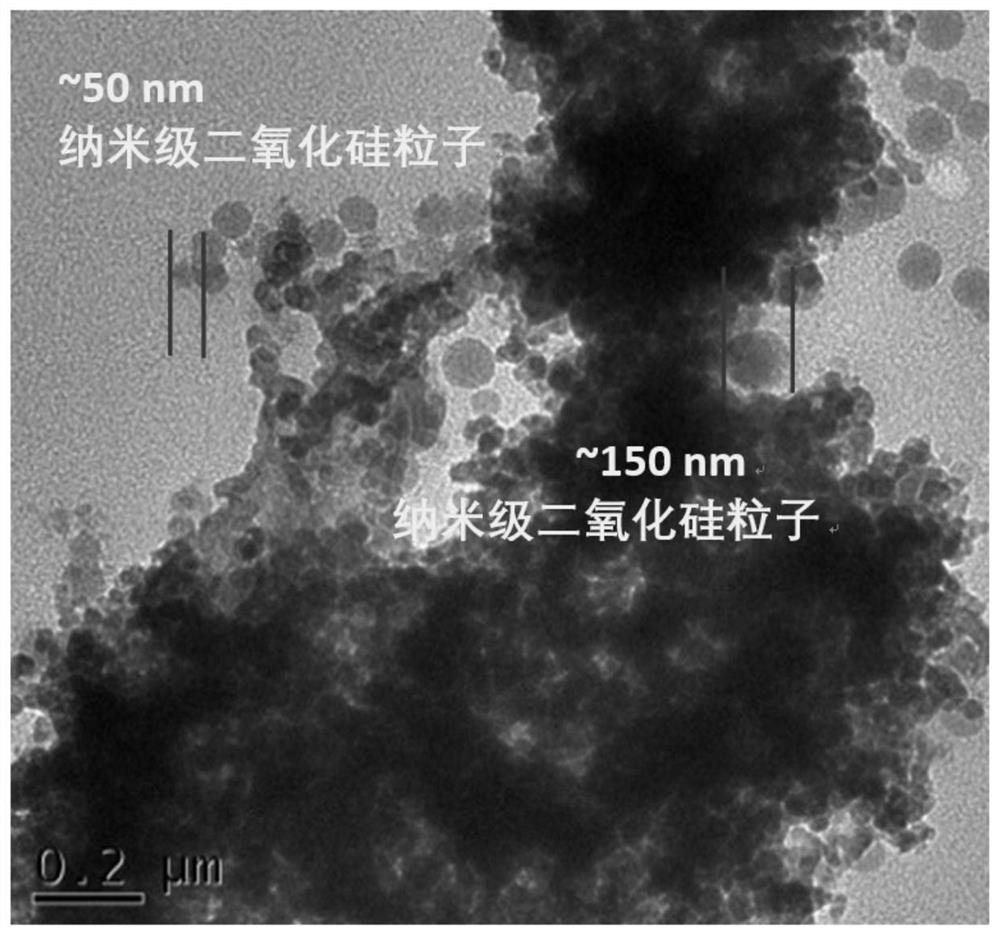

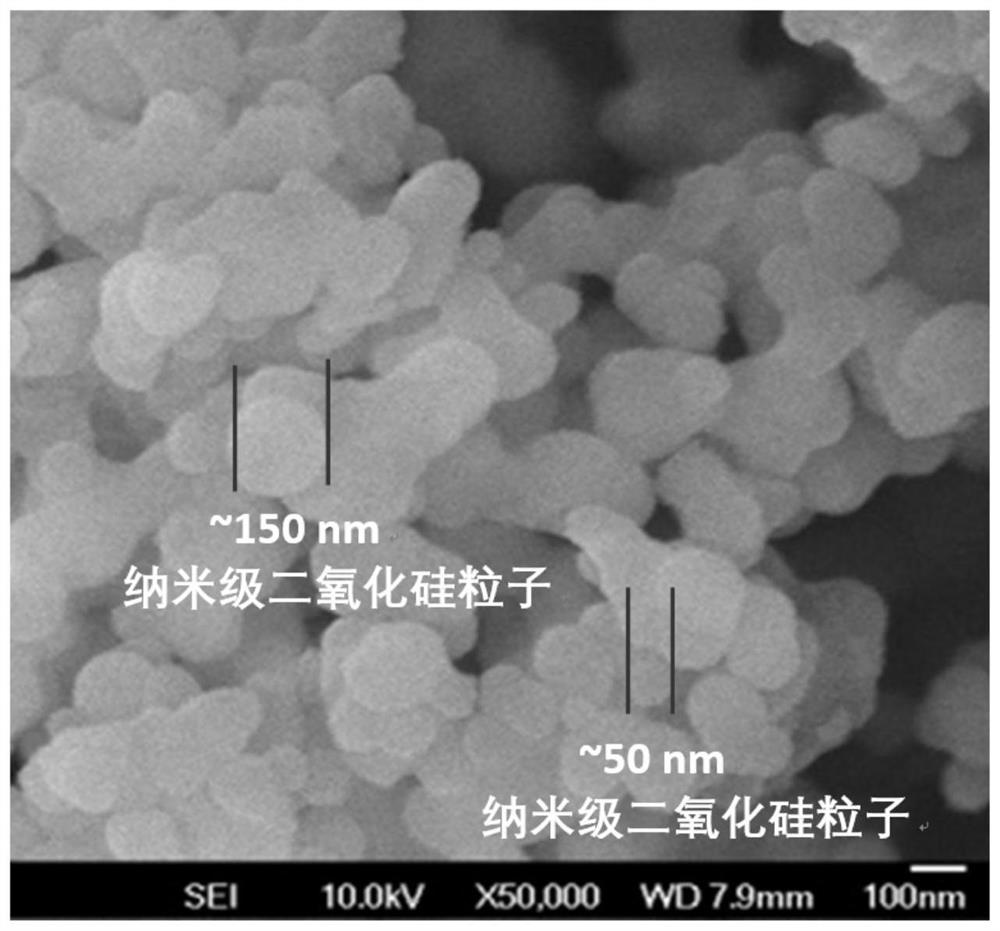

Method of preparing aerogels/nonwoven composites fireproof and heat-insulating materials

ActiveCN109403022AImprove fire performanceImprove thermal insulation propertiesLiquid surface applicatorsOrnamental textile articlesSilanesHydrolysis

A method of preparing aerogels / nonwoven composites fireproof and heat-insulating materials with a hydrophobic or hydrophilic surfaces and includes steps as follows. A mixture solution in which alkoxysilane, silicones and silane coupling agents are mixed and stirred is instilled by acidic catalysts for a hydrolysis reaction during which a silane coupling agent solution is added for continuous stirring; a hydrous alkali catalytic (anhydrous alkali catalytic) organic solution is added in the mixture solution for a condensation reaction and development of a 'silicones-silica aerogels-silane coupling agents' aerogel mixture solution; a non-woven felt is impregnated with the mixture solution for development of soft hydrophobic (hydrophilic) aerogels / nonwoven composites fireproof and heat-insulating materials after curing and natural drying. The aerogels / nonwoven composites materials with softness and surface hydrophobicity / hydrophilicity available in mass production are applicable to thermal-insulating materials for high-temp industrial facilities or indoor heat-insulating and fireproof panels of a building structure.

Owner:KUN SHAN UNIVERSITY

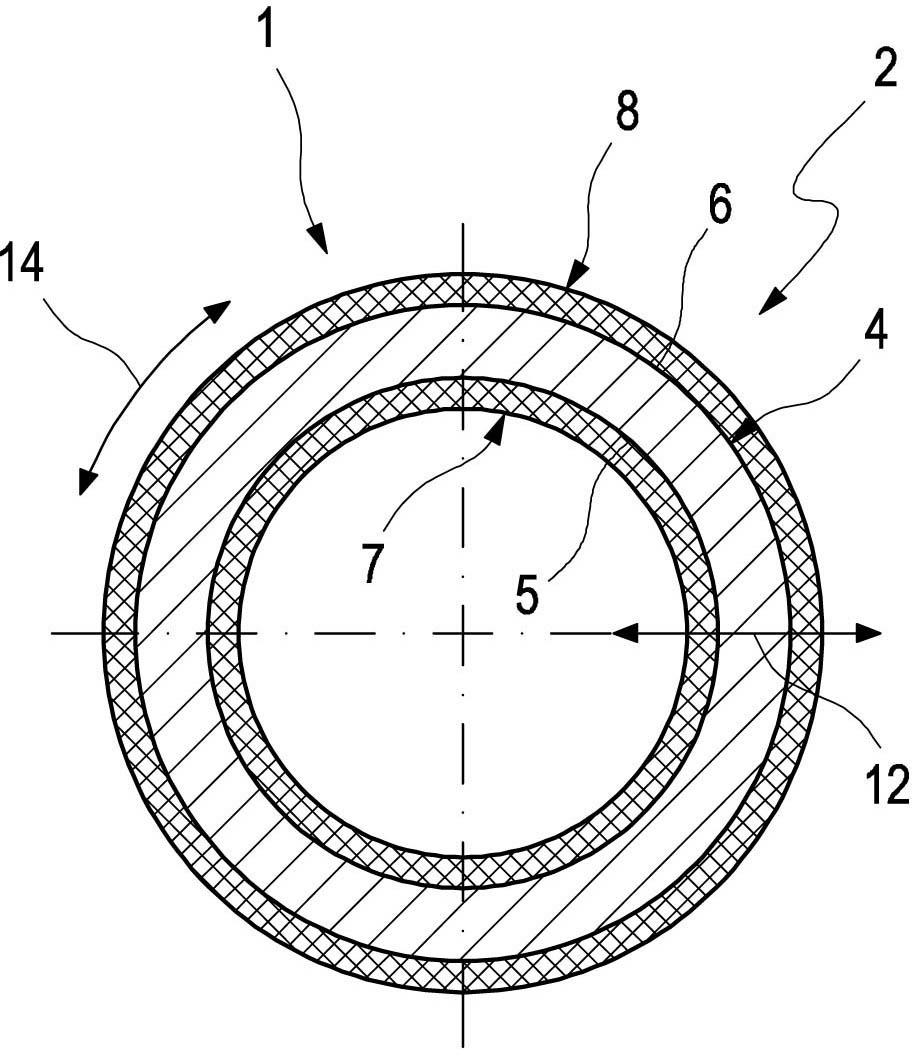

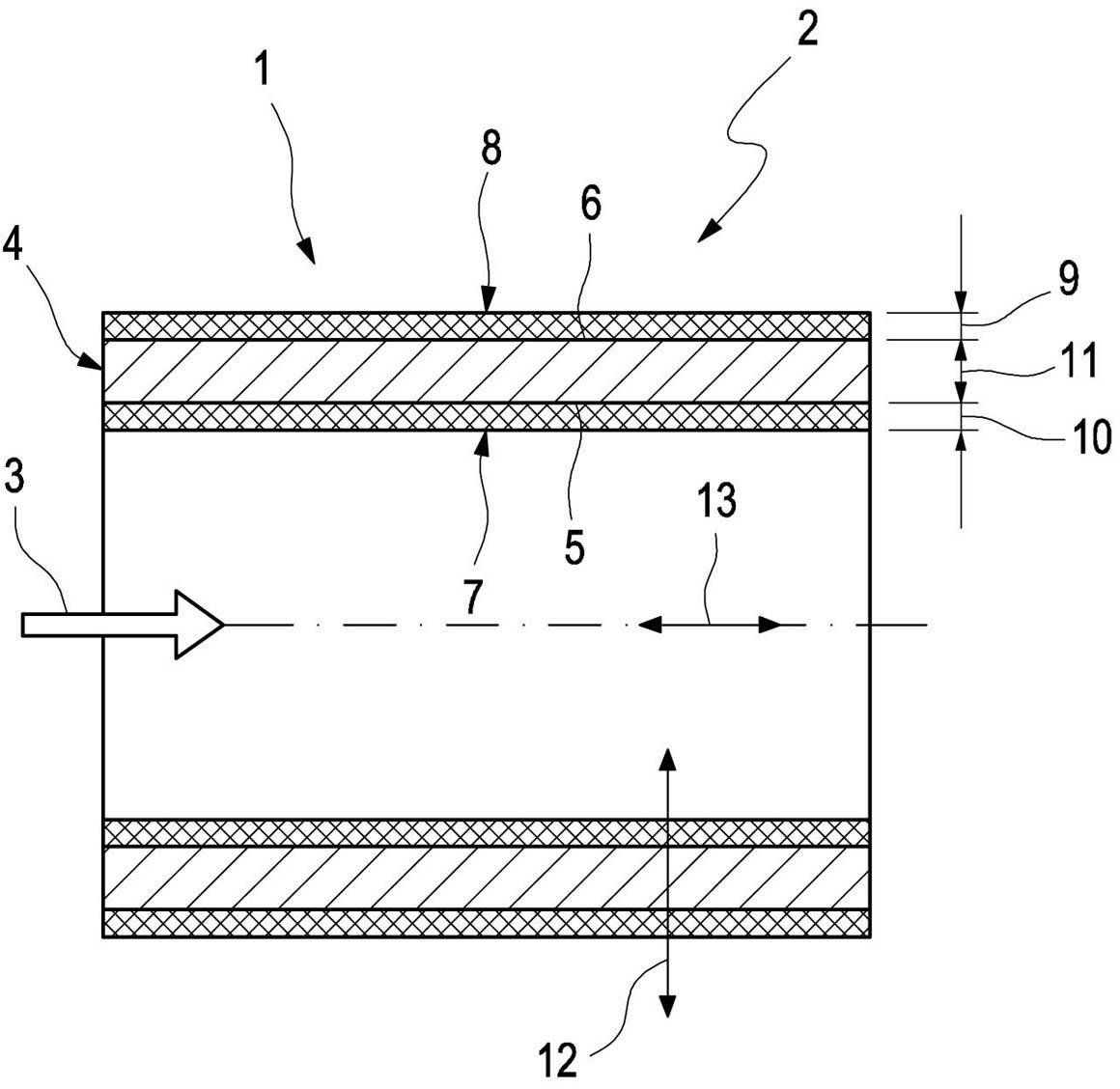

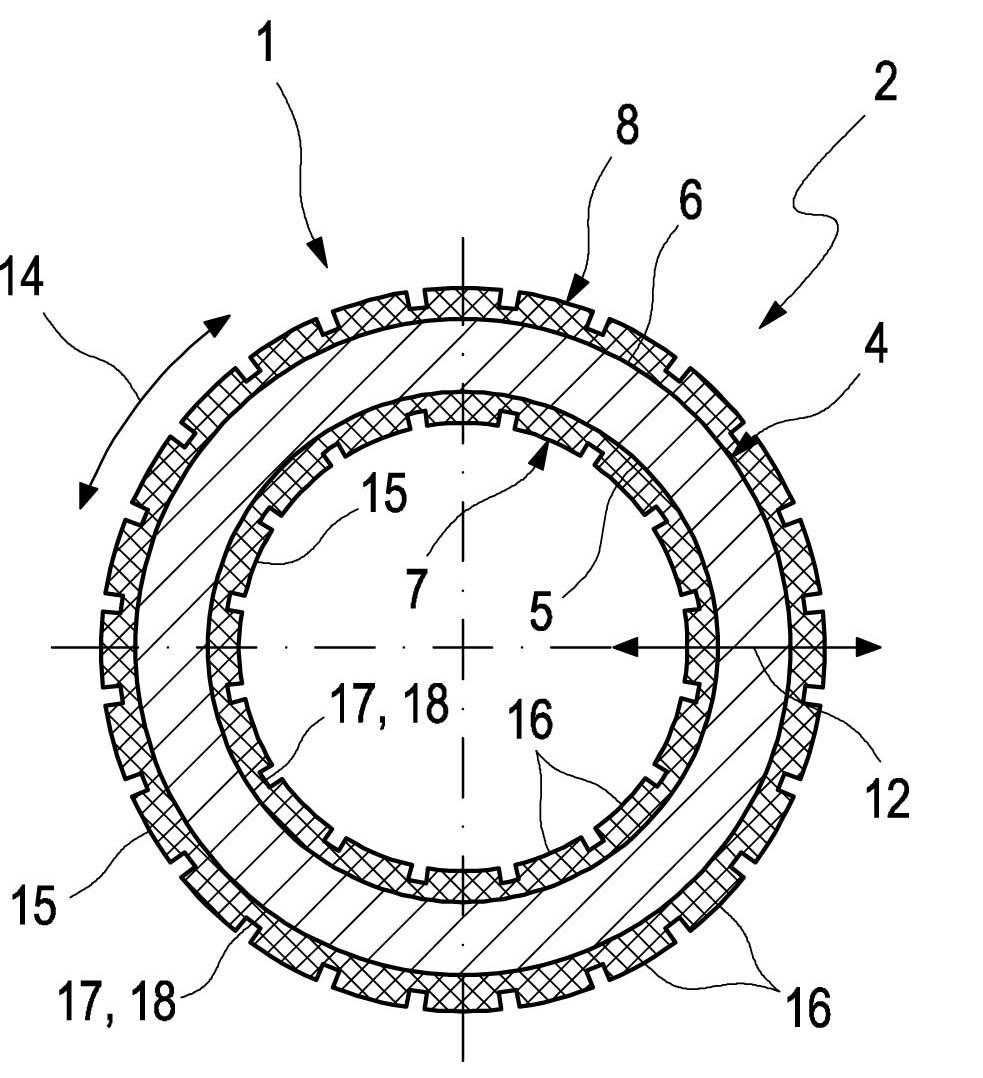

Tubular member and exhaust system

ActiveCN102128073AWeight increasePersistent connectionThermal insulationSilencing apparatusComposite ceramicNanoparticle

An exhaust gas-carrying tubular body (1) is provided for an exhaust system (2) of an internal combustion engine, especially of a motor vehicle. The tubular body (1) is provided on its inside (5) facing the exhaust gas and / or on its outside (6) facing away from the exhaust gas with a coating (7, 8), which is formed of a composite ceramic based on nanoparticles.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO

Nano thermal insulation coating

The invention discloses nano thermal insulation coating which comprises the following components in part by weight: 25 to 40 parts of nano-aluminum phosphate, 10 to 15 parts of acrylate emulsion, 5 to 10 parts of nano manganese oxide, 2 to 8 parts of nano-zirconia, 3 to 7 parts of nano titanium carbonitride, 1 to 5 parts of sodium dioctyl sulfosuccinate, 9 to 14 parts of lauryl sodium sulfate, 21 to 28 parts of polyvinyl alcohol, 11 to 14 parts of nano perlite, 4 to 9 parts of nano calcium silicate powder, 5 to 7 parts of polypropylene fibre, 7 to 16 parts of nano beta-hemihydrate gypsum powder, and 30 to 35 parts of water. The nano thermal insulation coating improves comprehensive performances of the coating, such as heat insulation property, washability, antibacterial self-cleaning property and the like.

Owner:XINHUASHENG ENERGY SAVING TECH CO LTD

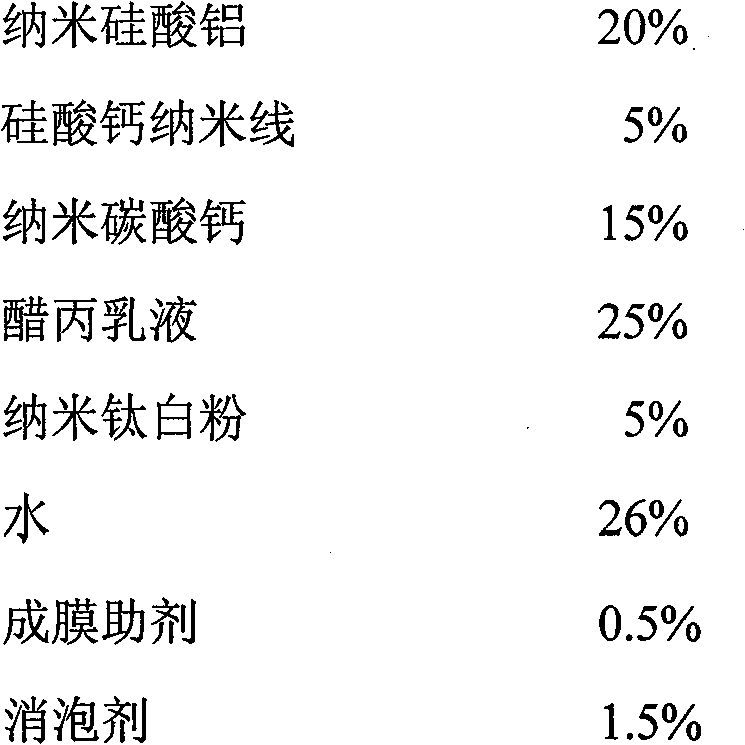

Nano multifunctional outer wall heat preservation coating

InactiveCN101914329BFully dispersedImprove thermal insulation propertiesCoatingsCalcium silicateThermal insulation

The invention provides a nano multifunctional outer wall heat preservation coating. The coating consists of the following components in percentage by mass: 10 to 20 percent of nano aluminum silicate, 5 to 15 percent of calcium silicate nanowires, 10 to 20 percent of nano calcium carbonate, 15 to 30 percent of vinyl acetate / acrylic emulsion or styrene-acrylate emulsion, 20 to 40 percent of water, 4 to 10 percent of nano titanium dioxide, 0.1 to 1 percent of film coalescing aid, 0.1 to 2 percent of antifoaming agent, 0.1 to 0.5 percent of wetting dispersant, 0.5 to 1 percent of anti-freezing agent and 0.1 to 2 percent of flatting agent. A preparation method for the coating comprises the following steps of: adding the water, the nano aluminum silicate, the calcium silicate nanowires, the nano calcium carbonate, the wetting dispersant and half of the antifoaming agent with low-speed stirring, and stirring for 1 to 3 hours at a high speed; adding other inorganic nano-powder with stirring; stirring the mixture on a multifunctional dispersion machine at the high speed for 1 to 3 hours; dropwise adding an emulsion slowly at a low stirring speed; adding residual antifoaming agent, the filmcoalescing aid, the anti-freezing agent and the flatting agent and stirring for 3 to 5 hours at the low speed; and finally canning to obtain a finished product of the coating. The outer wall heat preservation coating of the invention has the characteristics of high heat preservation and thermal insulation properties, strong adhesive force, high washability and anti-bacterial self-cleaning property, non-toxicity and odorless.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

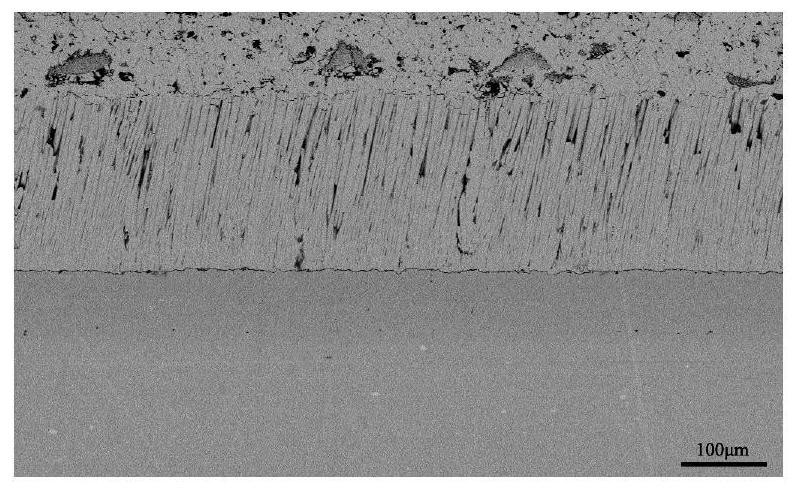

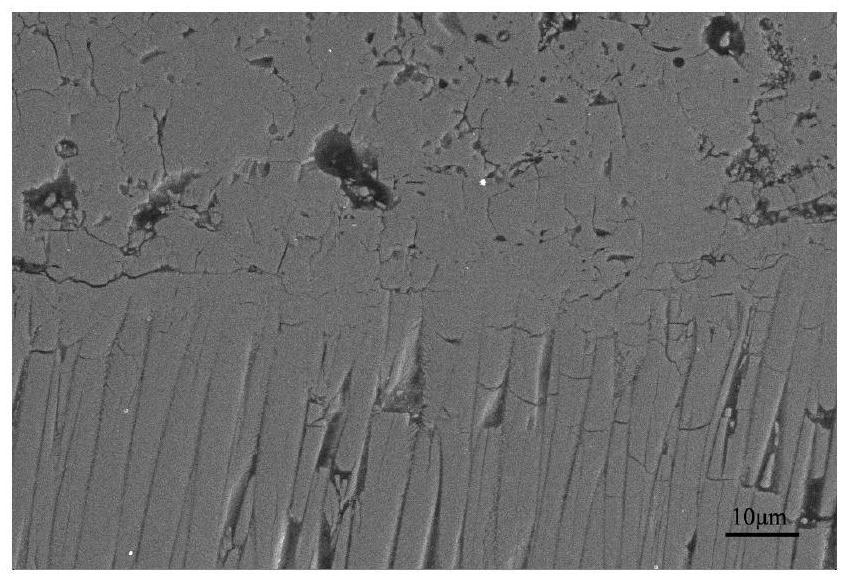

EB-PVD/APS composite structure double-ceramic-layer thermal barrier coating and preparation method thereof

PendingCN111962028AHigh bonding strengthIncreased strain toleranceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionThermal insulation

The invention discloses an EB-PVD / APS composite structure double-ceramic-layer thermal barrier coating. The thermal barrier coating comprises a MCrAlY metal bonding layer, a columnar crystal structureceramic layer, a layer-like-structured columnar crystal transition layer and a layered structure ceramic layer, wherein the layer-like-structured columnar crystal transition layer is obtained by performing surface treatment on the columnar crystal structure ceramic layer, and a thickness of the layer-like-structured columnar crystal transition layer is 20-50 micrometers. A preparation method of the thermal barrier coating combines the thermal barrier coating characteristics of a columnar crystal structure prepared by electron beam physical vapor deposition and an atmospheric plasma spraying layered structure, the layer-like-structured columnar crystal transition layer improves bonding capacity between the layered structure and the columnar crystal structure ceramic layer, bending resistance and thermal shock resistance of the thermal barrier coating are remarkably improved, the long service life and the high thermal insulation performance of the composite structure double-ceramic-layer thermal barrier coating are achieved, and the long service life and high thermal insulation coordination design of the novel structural thermal barrier coating are realized at a low cost.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE

Optical fiber surface coating adhesive

InactiveCN104910856AHigh tensile strengthHigh dielectric strengthNon-macromolecular adhesive additivesGlass fiberAdhesive

The present invention discloses an optical fiber surface coating adhesive, which consists of the following raw materials in parts by weight: 25 to 30 parts of organosilicone rubber; 5 to 10 parts of high molecular weight polyisobutylene; 5 to 10 parts of medium molecular weight polyisobutylene; 10 to 15 parts of low molecular weight polyisobutylene; 10 to 15 parts of inorganic filler; 0.5 to 1 part of an antioxidant; 5 to 10 parts of glass fiber; and 5 to 10 parts of silicate.

Owner:成都亨通光通信有限公司

Optical cable with high-hardness protective layer

InactiveCN104914526AExcellent ozone resistanceImprove featuresFibre mechanical structuresEpoxyAdhesive

The invention discloses an optical cable with a high-hardness protective layer. The optical cable comprises a loose bushing, a protective layer arranged outside the loose bushing, an internal protective layer arranged outside the protective layer and an external sheath arranged outside the internal protective layer. The loose bushing is internally provided with at least one optical fiber. The high-hardness protective layer is arranged between the internal protective layer and the external sheath. The high-hardness protective layer is composed of raw materials with the following parts by weight: 25-30 parts of organic silicone rubber, 5-10 parts of high molecular weight polyisobutylene; 5-10 parts of medium molecular weight polyisobutylene; 10-15 parts of low molecular weight polyisobutylene; 10-15 parts of inorganic filling material; 0.5-1 part of anti-oxidant; 70-80 parts of ultrafine steel fiber; 70-80 parts of glass fiber; 5-10 parts of silicate; 10-20 parts of fine sand of which the diameter is 0.1mm-0.25mm; 10-20 parts of epoxy resin; 10-20 parts of aluminum hydroxide; and 10-20 parts of hot-melt adhesive.

Owner:成都亨通光通信有限公司

Lightweight housing module and modular building

InactiveUS8863443B2Improve thermal insulation propertiesEasy to implementBuilding roofsRoof coveringMarine engineeringModularity

This invention relates to a lightweight housing module comprising at least one stretched fabric intended to form the roof of said module and fixed along its lower edge on a rigid frame maintained at a distance from the ground by a plurality of lateral posts, remarkable in that it comprises vertical panels and / or opening frames in order to close in a substantially sealed manner its vertical facades and a false ceiling arranged in order to be arranged under said fabric inside said lightweight housing module and fixed to the frame. This invention also relates to a modular building remarkable in that it comprises a plurality of lightweight housing modules, according to the invention, arranged next to one another, and a system for sealing between the adjacent lightweight housing modules. This invention also relates to their method of assembly.

Owner:DALO CATHERINE

Power transmission optical cable

InactiveCN104900332AExcellent ozone resistanceImprove featuresPower cablesFibre mechanical structuresFiberAdhesive

The invention discloses a power transmission optical cable. The power transmission optical cable comprises a filling layer provided with an optical fiber assembly and electrical lines which are arranged in the filling layer; the filling layer is coated with an isolation layer; the isolation layer is covered with a PE outer sheath; the optical fiber assembly includes a loose bushing; a fiber paste layer is arranged in the loose bushing; and optical fibers of which the surfaces are coated with an optical fiber surface coating adhesive are arranged in the fiber paste layer. The optical fiber surface coating adhesive is composed of the following raw materials in parts by weight: 25 to 30 parts of organic silicone rubber; 5 to 10 parts of high-molecular weight polyisobutylene; 5 to 10 parts of medium-molecular weight polyisobutylene, 10 to 15 parts of low-molecular weight polyisobutylene; 10 to 15 parts of inorganic filler; 0.5 to 1 part of antioxidant; 5 to 10 parts of glass fibers; and 5 to 10 parts of silicate.

Owner:成都亨通光通信有限公司

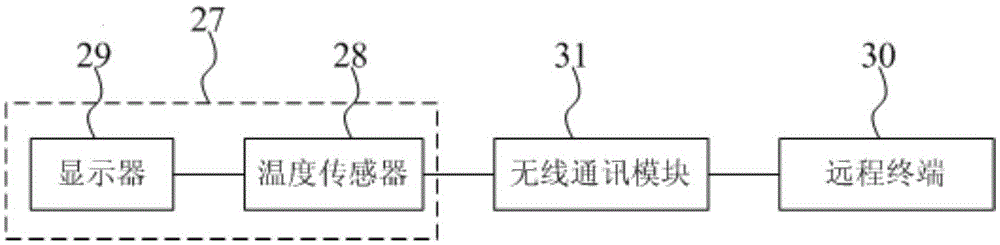

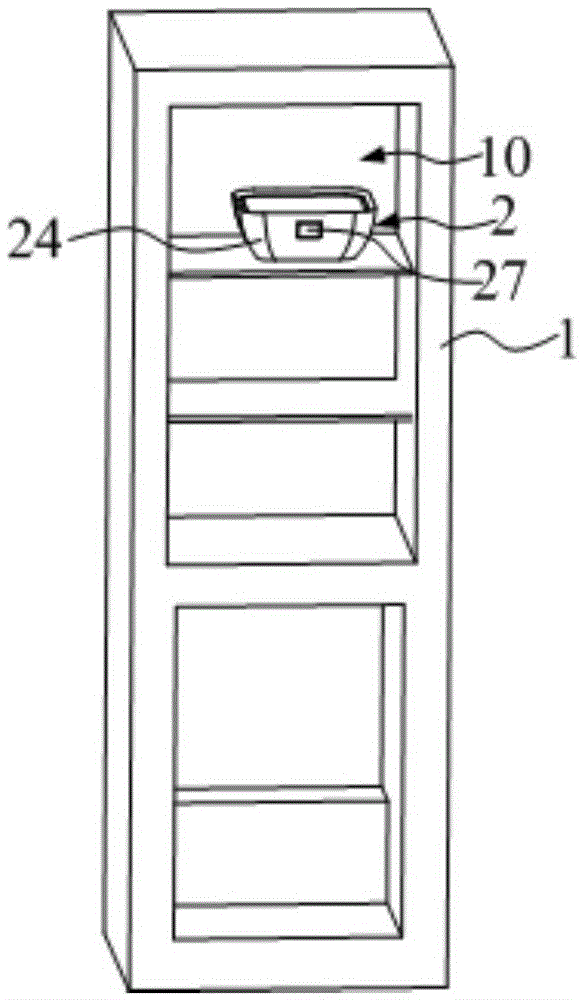

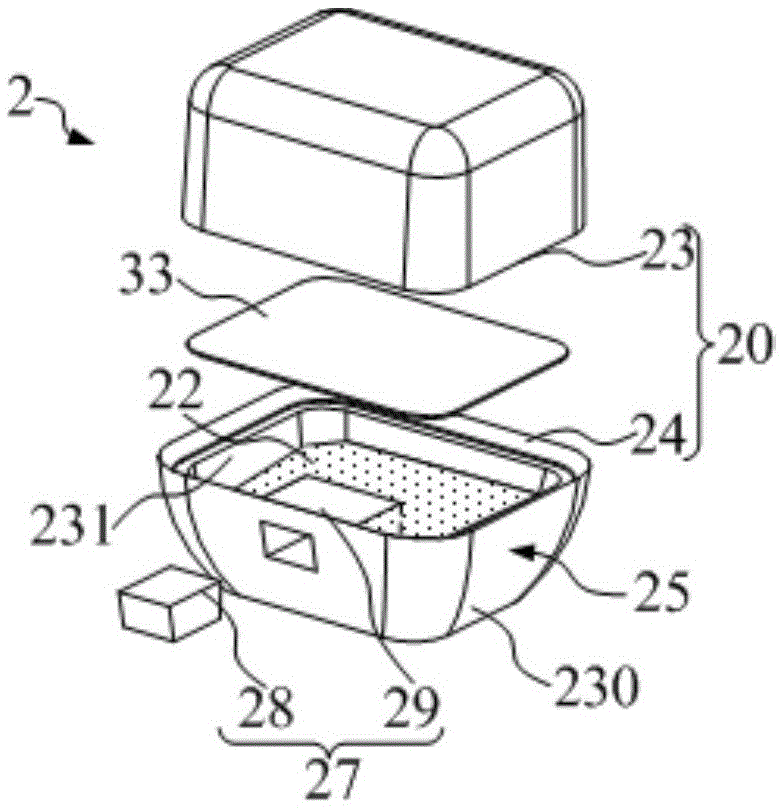

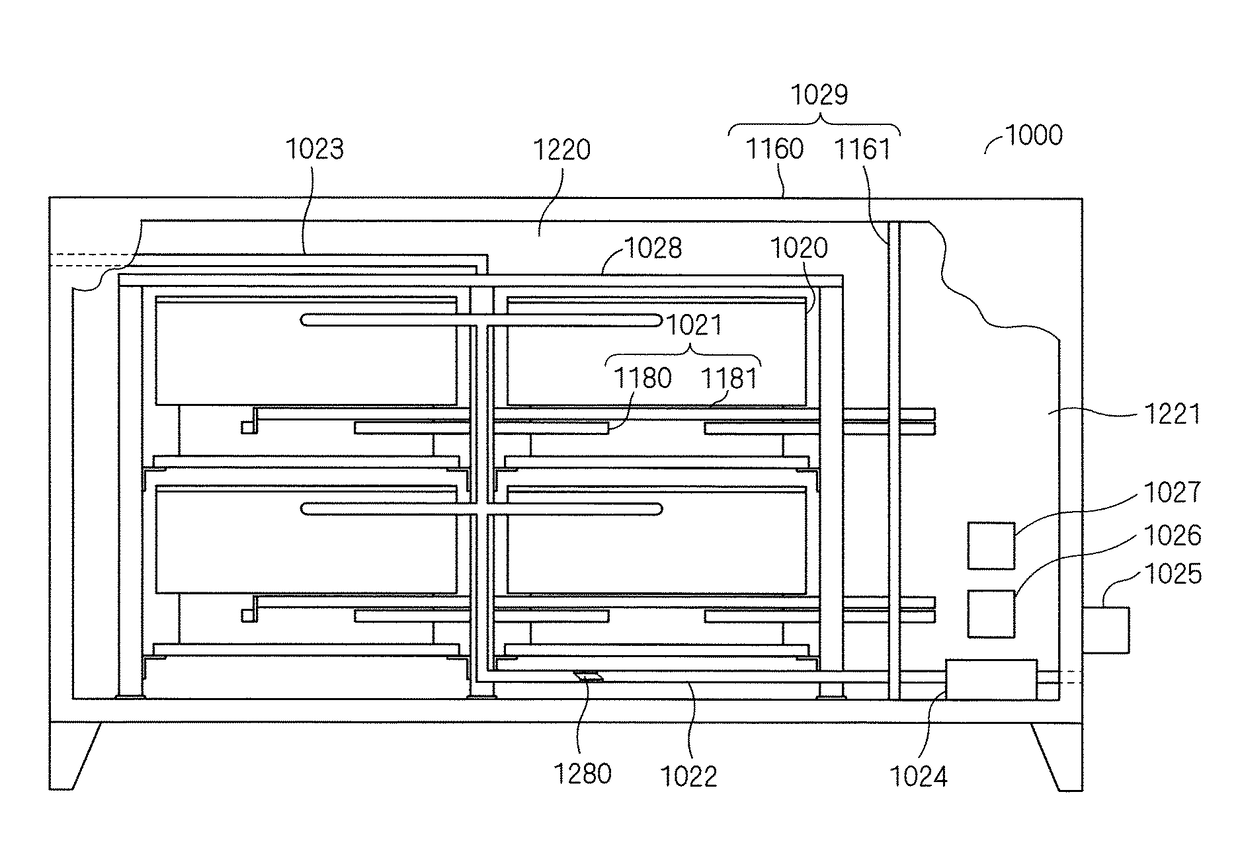

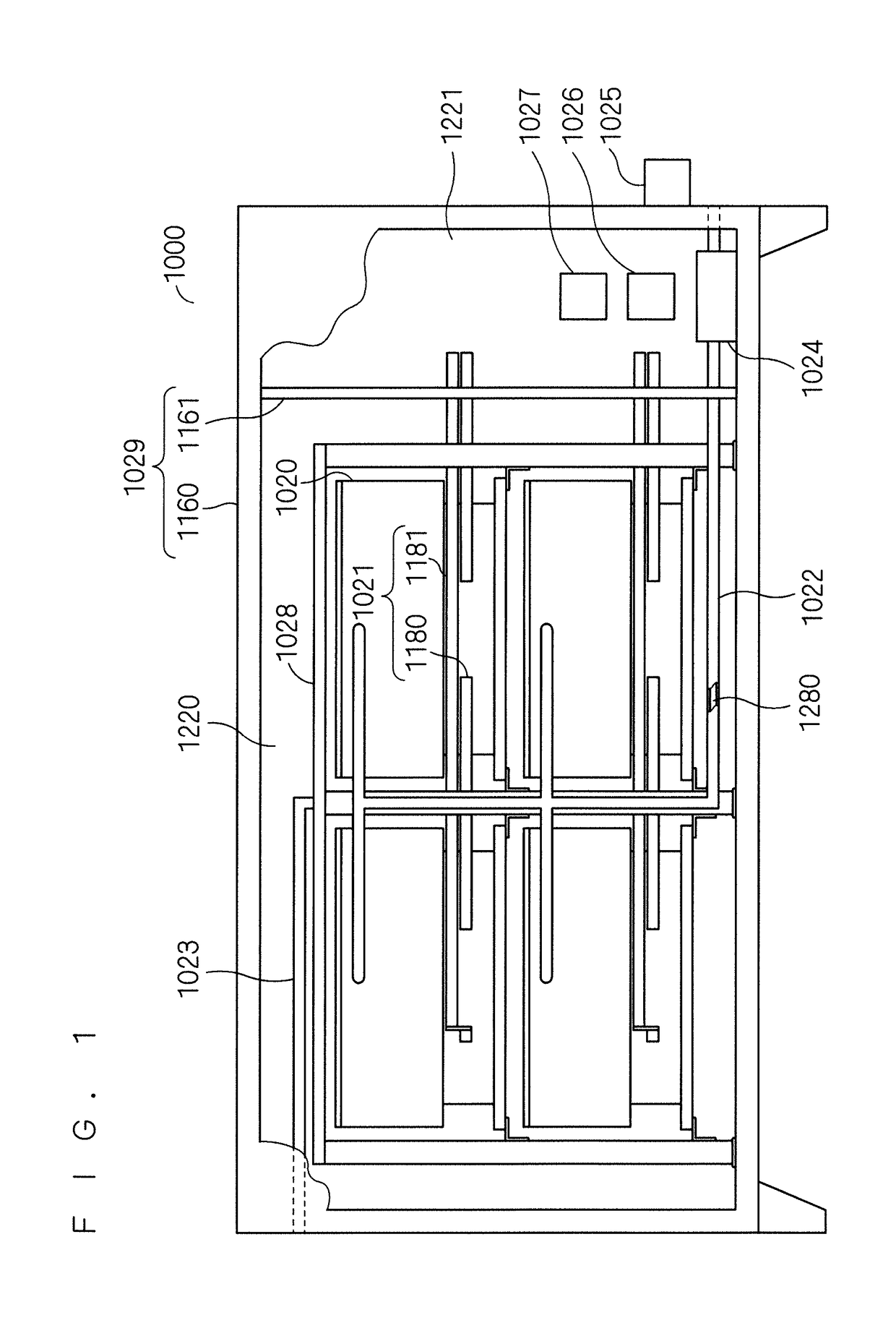

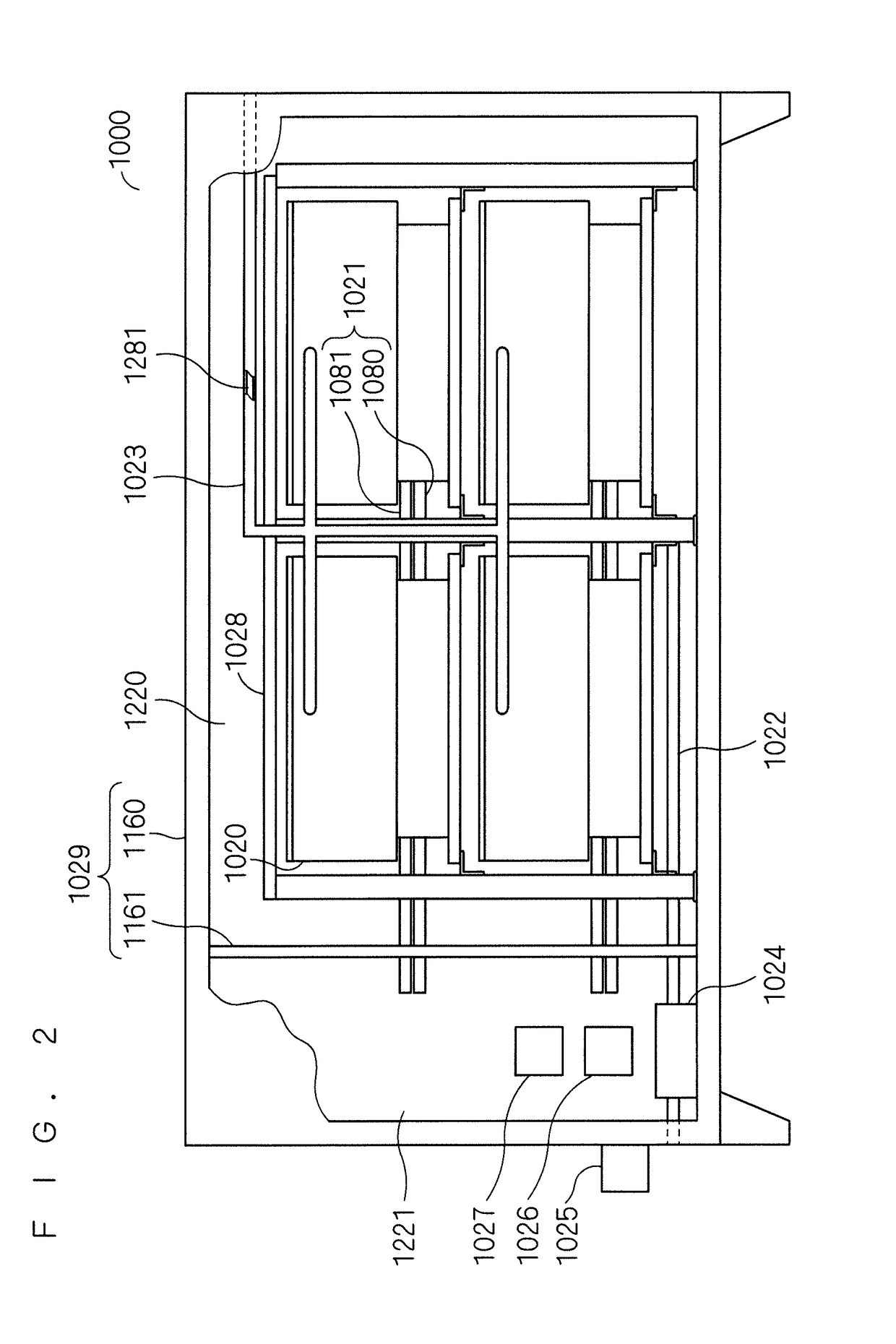

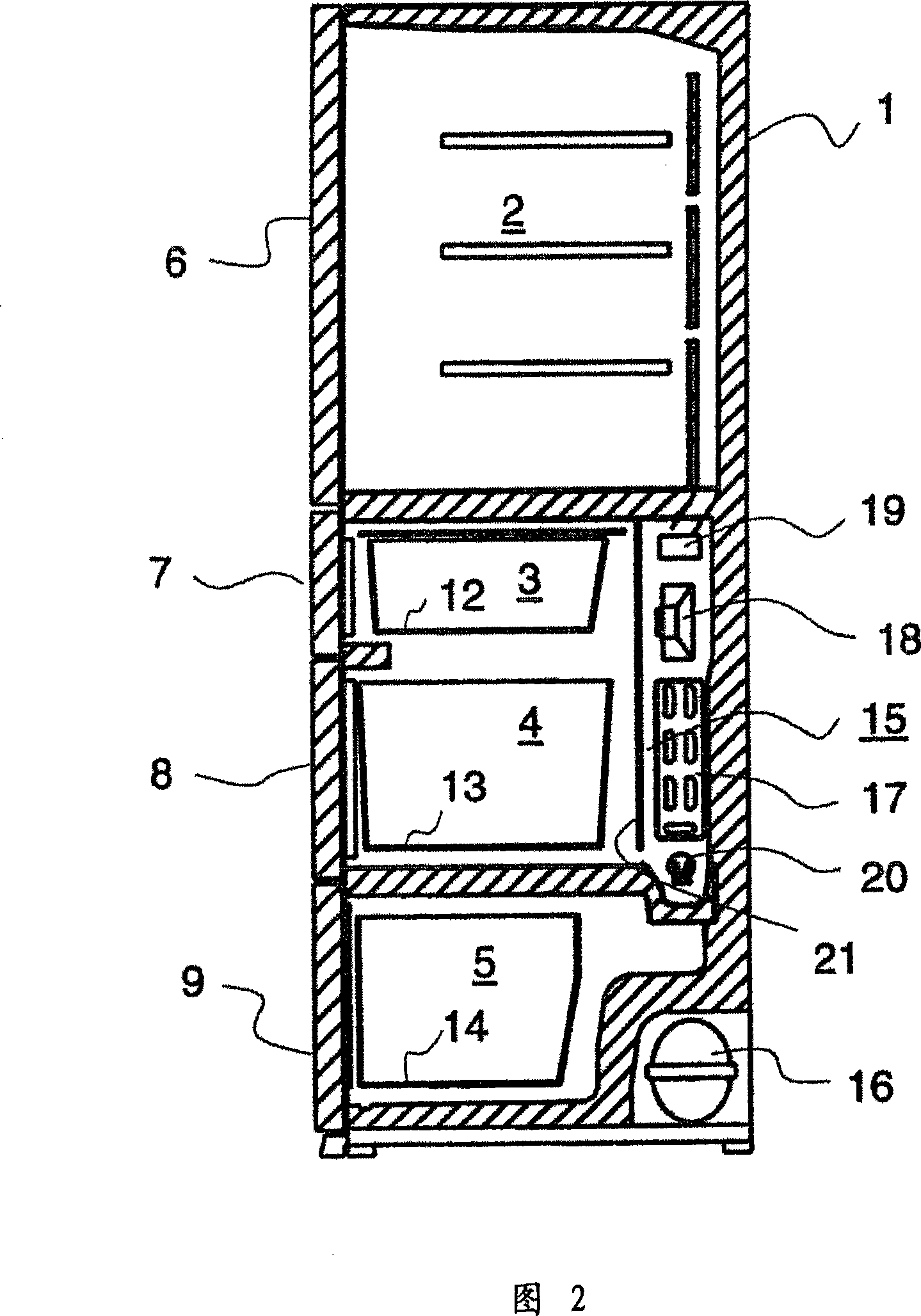

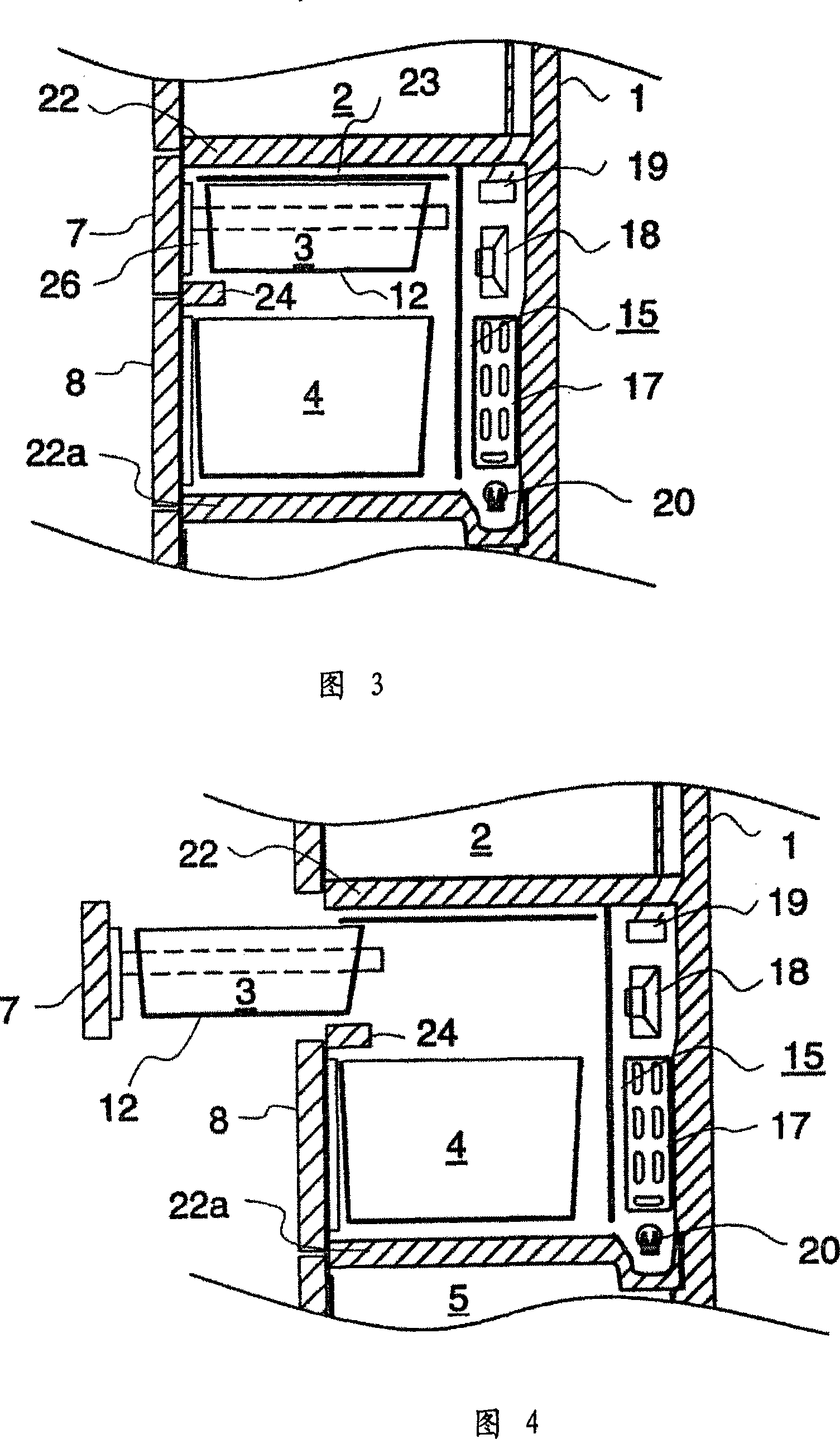

Refrigeration device and storage container thereof

InactiveCN106809516AGuaranteed freshnessEasy to storeMachines using electric/magnetic effectsShock-sensitive articlesEngineeringProcess engineering

The invention discloses a refrigeration device (1) and a storage container (2) of the device. The storage container (2) comprises a heat insulation shell (20) which is provided with a storage space (21), and the storage container (2) is provided with cooling units (22 and 22') used for cooling the storage space (21). When the storage container (2) is arranged outside the refrigeration device (1), the cooling units (22 and 22') perform cooling heat preservation on the storage space (21), the shell (20) isolates heat exchange between the exterior environment and the storage space (21), low-temperature environment of the storage space (21) is maintained, and long-time freshness of food is maintained. Compared with the manner that food is stored in the refrigeration device (1), the container has the beneficial effects that the storage container (2) is used, a user can quite conveniently store and use food outside the refrigeration device (1), particularly for the instant food such as cold dish, salad, sashimi and the like, the low-temperature state of the food can be maintained only on the dining table, and the user can eat quite conveniently.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

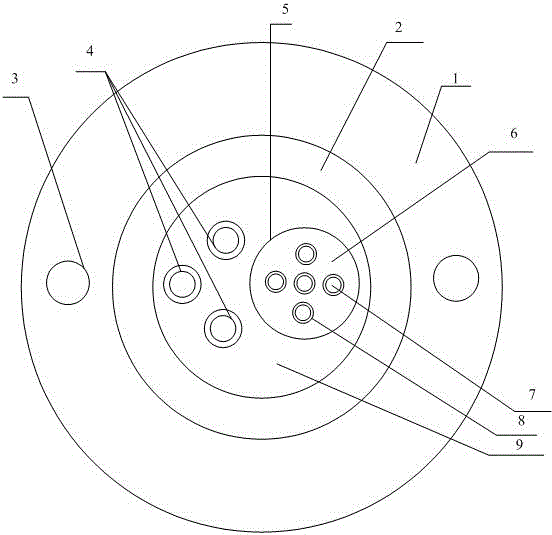

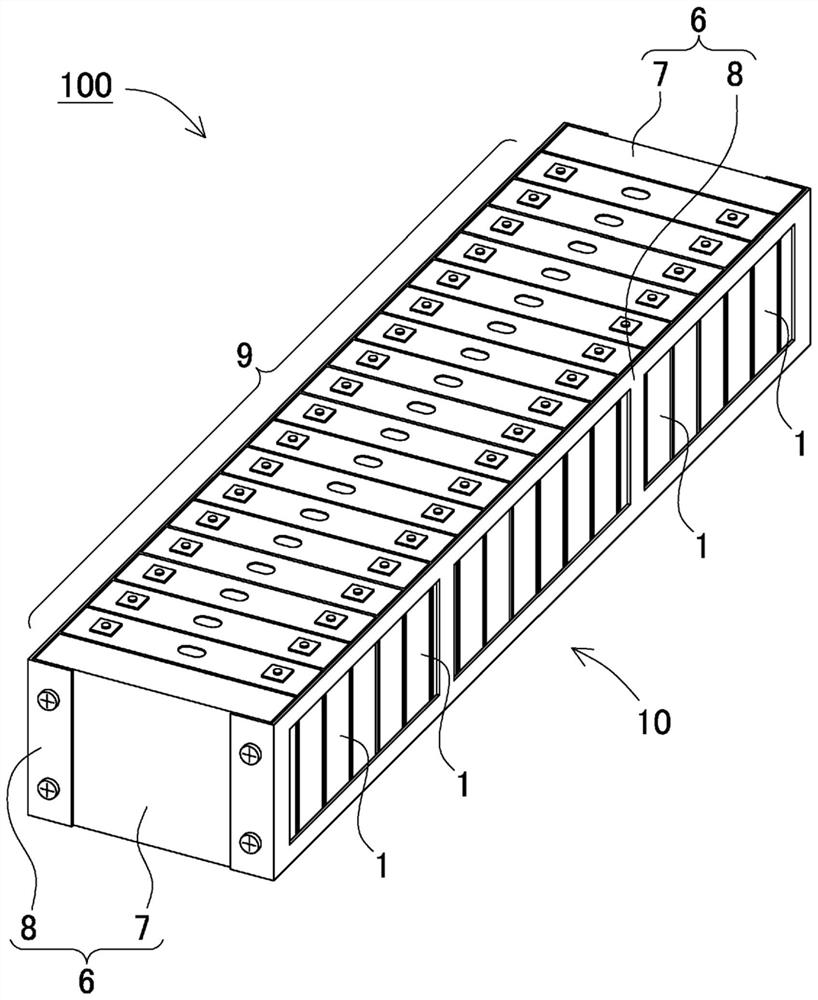

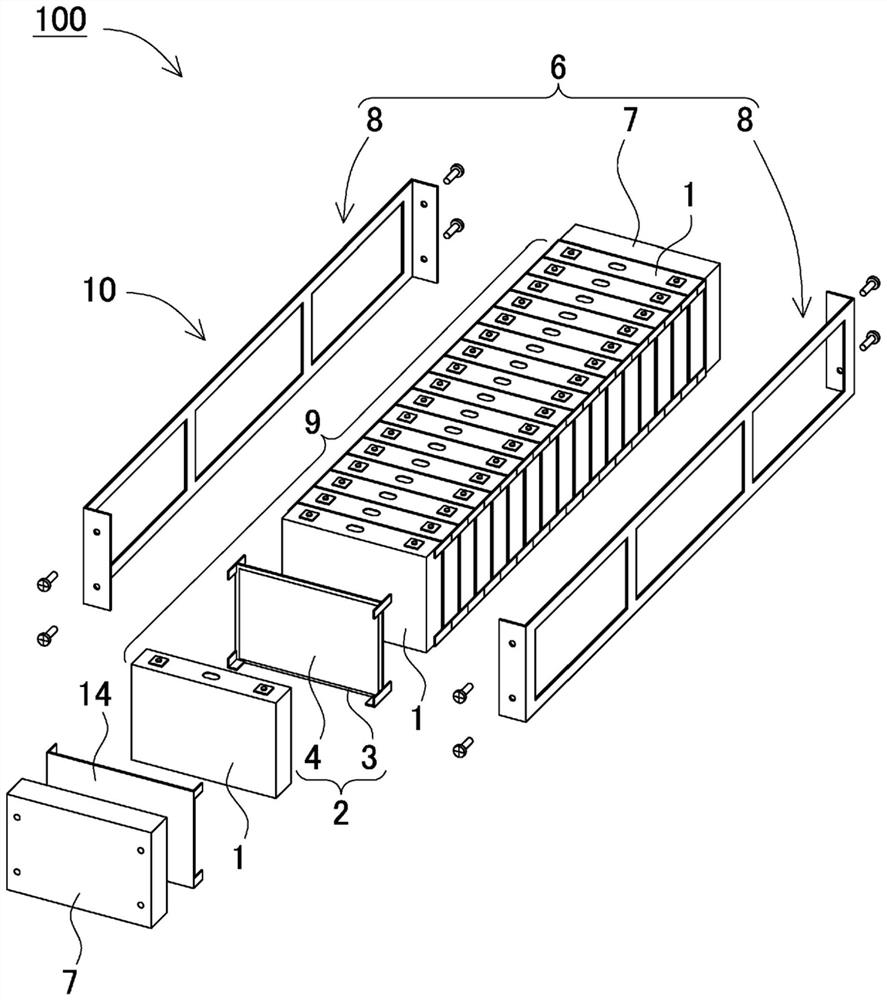

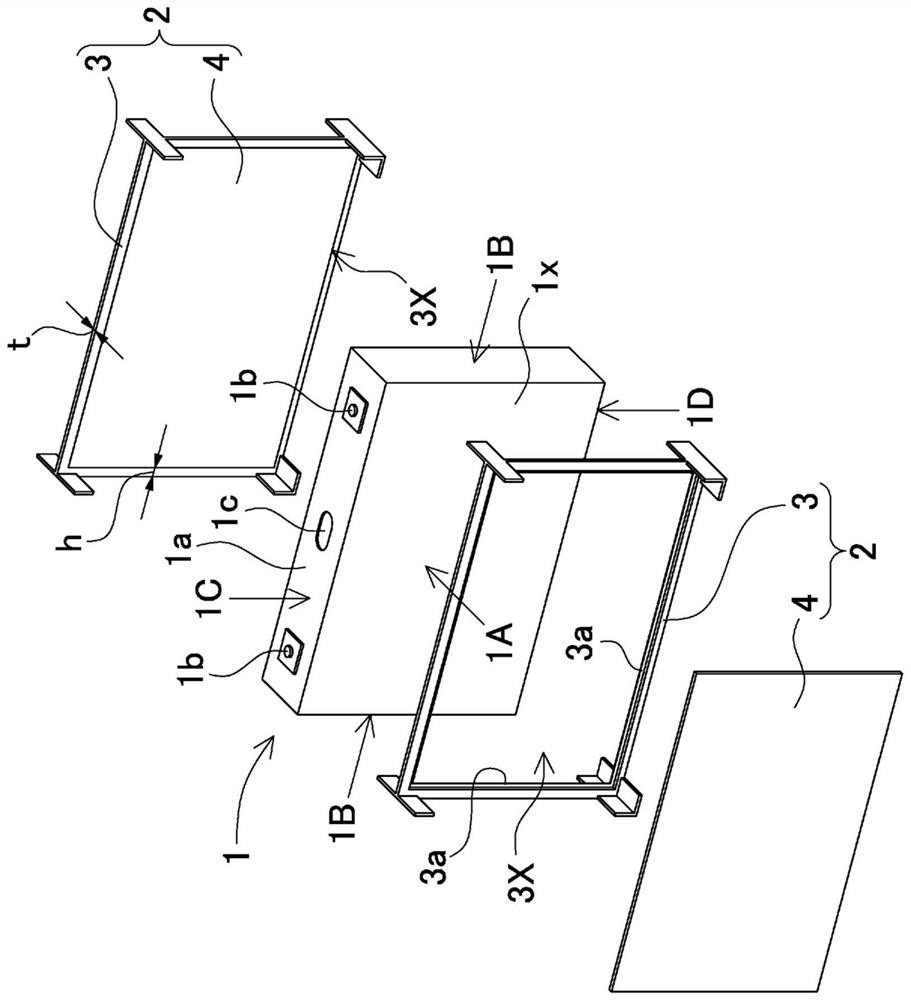

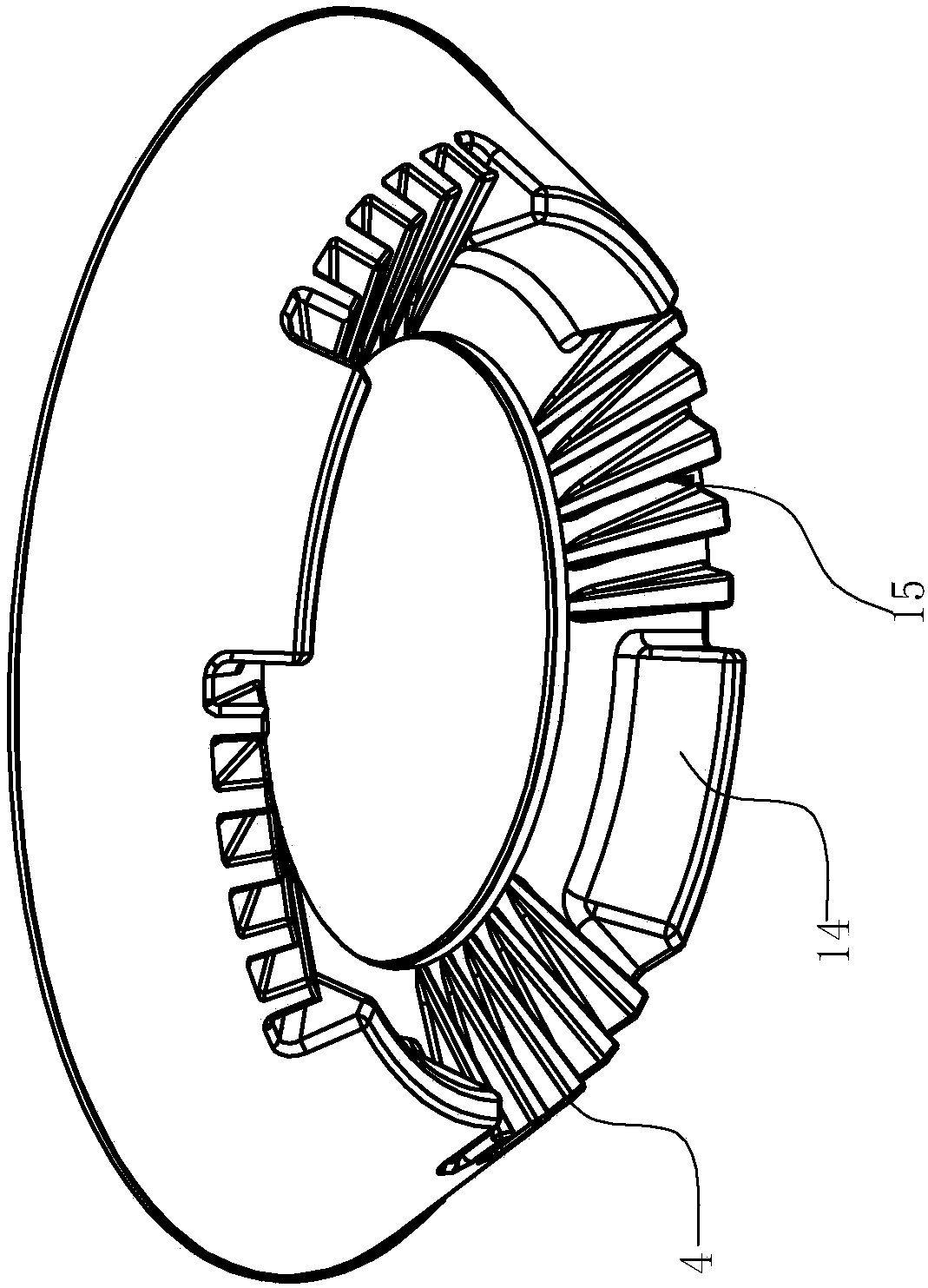

Power supply device, and electric vehicle and power storage device provided with said power supply device

InactiveCN111684618AImprove thermal insulation propertiesBattery isolationSecondary cellsElectrical batteryThermal insulation

A power storage device, while absorbing expansion of the battery cells, prevents inducing thermal runaway by blocking heat conduction between battery cells, and is provided with: a battery stack formed by stacking multiple battery cells (1); separators (2) arranged between the battery cells (1); and a fixing member for fastening the battery stack in the stacking direction. The separator (2) is formed from a perimeter frame (3) and a thermal insulation base material (4) provided in the opening (3X) of the perimeter frame (3). The perimeter frame (3) is arranged on the outer periphery of the stacking surface (1A) of the battery cell (1) and has an opening (3X) on the inside, and the thermal insulation base material (4) has flexibility that allows deformation when pressed by the expanding stacking surface (1A) of the battery cell (1). The perimeter frame (3) is more rigid than the thermal insulation base material (4), the perimeter frame (3) specifies the interval between adjacently stacked battery cells (1), and the flexible thermal insulation base material (4) has a structure that absorbs expansion of the stacking surface (1A) of the battery cell (1).

Owner:SANYO ELECTRIC CO LTD

Heat insulation wallpaper and preparation method thereof

InactiveCN106283859AAchieving thermal insulation propertiesImprove thermal insulation propertiesCovering/liningsSpecial paperAcrylic resinPolyvinyl chloride

The invention discloses a preparation method of a heat insulation wallpaper. The method includes the steps that 1, cyclohexanone, a dispersing agent, polyvinyl chloride, chloroform, acrylic resin, wood powder, a thickening agent and talcum powder are mixed to prepare a heat insulation coating; 2, paper is subjected to preheating treatment; 3, the heat insulation coating is applied to the paper after preheating treatment, and heating and embossing are performed to prepare the heat insulation wallpaper, wherein the weight-average molecular weight of the polyvinyl chloride is 60,000-90,000, and the average particle size of the wood powder and the talcum powder is 50-80 microns. The heat insulation wallpaper prepared by adopting the method has the characteristics of abrasion resistance and can be used for a long time.

Owner:安徽金生金世电子科技有限公司

Optical fiber surface coating adhesive preparation method

The present invention discloses an optical fiber surface coating adhesive preparation method which comprises the following steps: S1. kneading, to be more specific, high molecular weight polyisobutylene, organic silicon rubber, medium molecular weight polyisobutylene, low molecular weight polyisobutylene, an antioxidant, glass fibers and silicates are added in a rubber kneading machine for kneading, the kneading time is 30 to 50 minutes, the temperature is 120-160 DEG C; S2. mixing, to be more specific, after the completion of the kneading, an inorganic filler is added for mixing, the mixing time is 30 to 50 minutes, the temperature is 120-160 DEG C, the mixing speed is 200-280rpm; S3. extrusion, the mixed plastic material is extruded into a rubber extruder through a discharging screw, then is extruded from the rubber extruder to coat the optical fiber surface, wherein the extruder machine barrel temperature is 100-150 DEG C, and the machine head temperature is 120-140 DEG C.

Owner:成都亨通光通信有限公司

Power storage apparatus and method of operating power storage apparatus

ActiveUS9859592B2Reduce maintenance costsImprove insulation performanceCell temperature controlCell component detailsComputer moduleEngineering

A battery chamber is formed inside a sealed container. A module battery and a charging / discharging path outside a battery are housed in the battery chamber. In the module battery, an electric cell chamber and an air chamber are formed inside a heat-insulating container. The electric cell chamber and the air chamber are divided by a heat transfer wall. An electric cell of a sodium-sulfur battery, and a charging / discharging path inside a battery are housed in the electric cell chamber. An intake path starts from outside of the sealed container and leads to the air chamber. An exhaust path starts from the air chamber and leads to the sealed container. The blower generates an air flow that sequentially flows through the intake path, the air chamber and the exhaust path. In a case where the cooling of the electric cell chamber is required, the air flow is generated.

Owner:NGK INSULATORS LTD

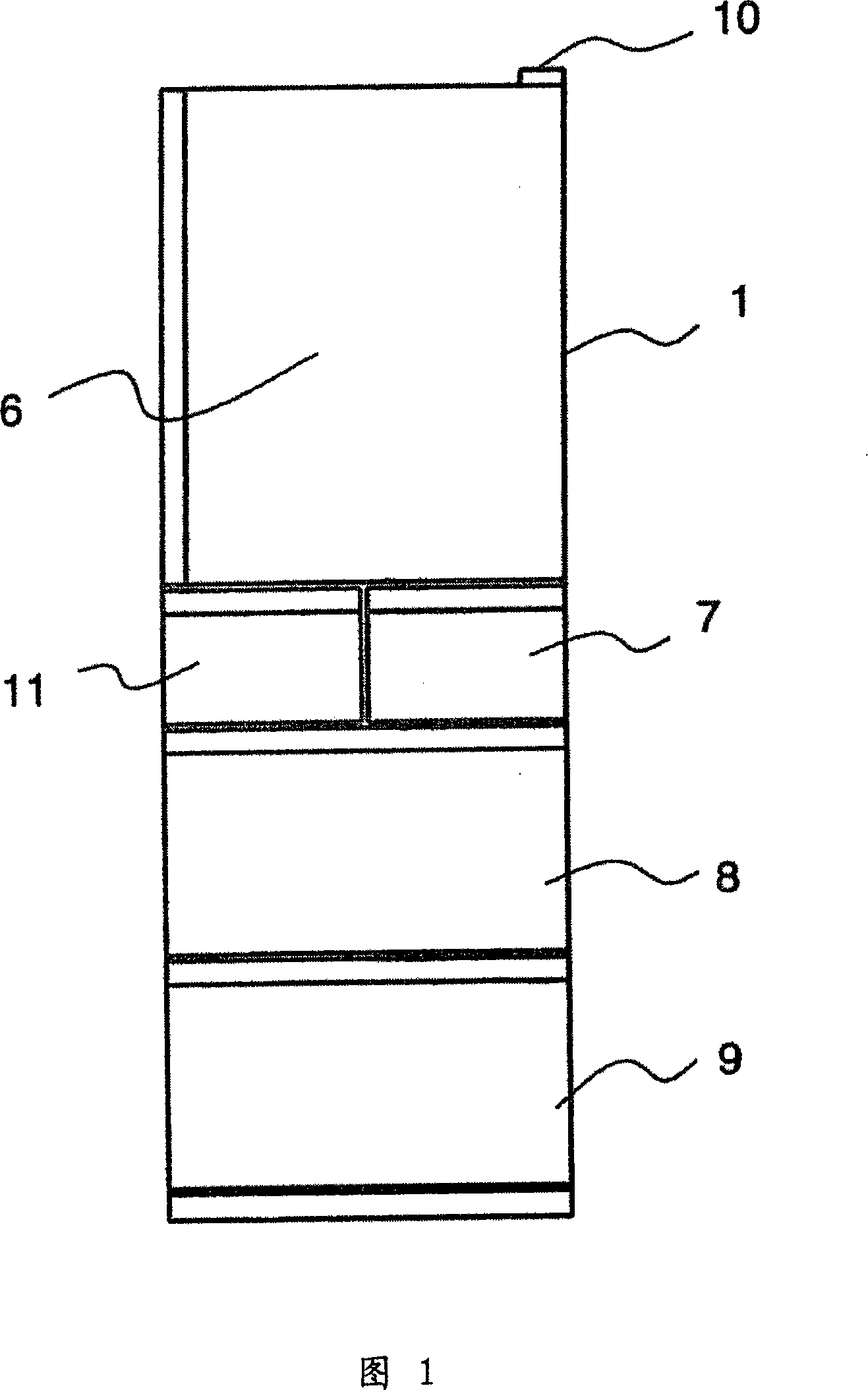

Electrical refrigeratory

InactiveCN101135532APrevent drynessImprove thermal insulation propertiesLighting and heating apparatusCooling fluid circulationCold airHeat resistance

The object of the present invention is to provide a refrigerator which has a refrigerating chamber that can keep the frozen food wet (prevent drying) and store the food at the moisture status, and can refrigerate in short time. The refrigerator is provided with a first refrigerating chamber, a second refrigerating chamber, an ice-making chamber arranged in parallel with the second refrigerating chamber along the width direction of the refrigerating, an ice-making container arranged in the ice-making chamber, a second refrigerating chamber container arranged in the second refrigerating chamber, and a cold air forced-air circulation fan for blowing cold air to the second refrigerating chamber. The refrigerating is characterized in that the refrigerating is also provided with a cover with an opening on the top for covering the second refrigerating chamber container and a heat resistance for improving the heat insulation property of the surface contacting with the frozen food of the second refrigerating chamber container.

Owner:HITACHI APPLIANCES INC

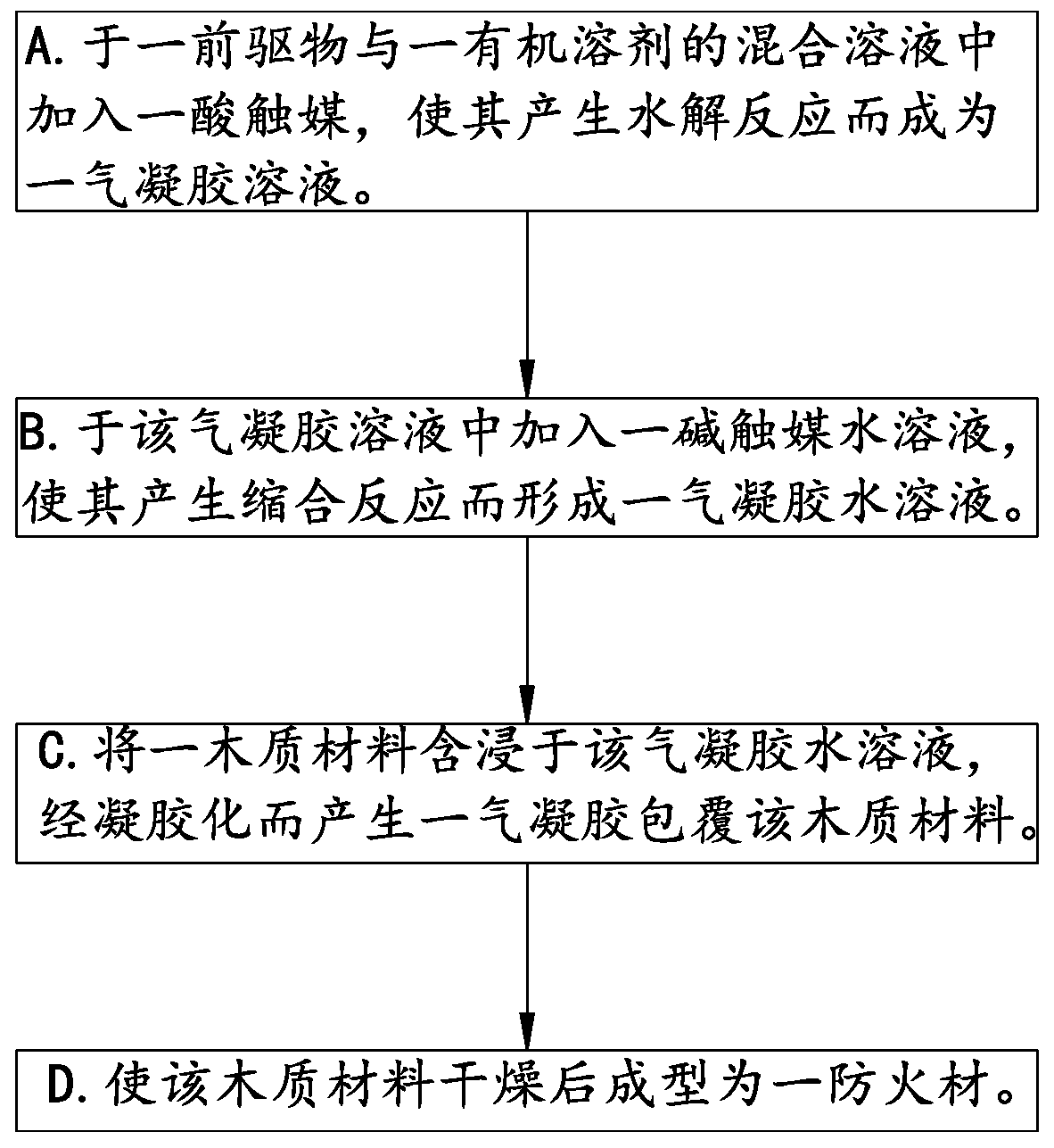

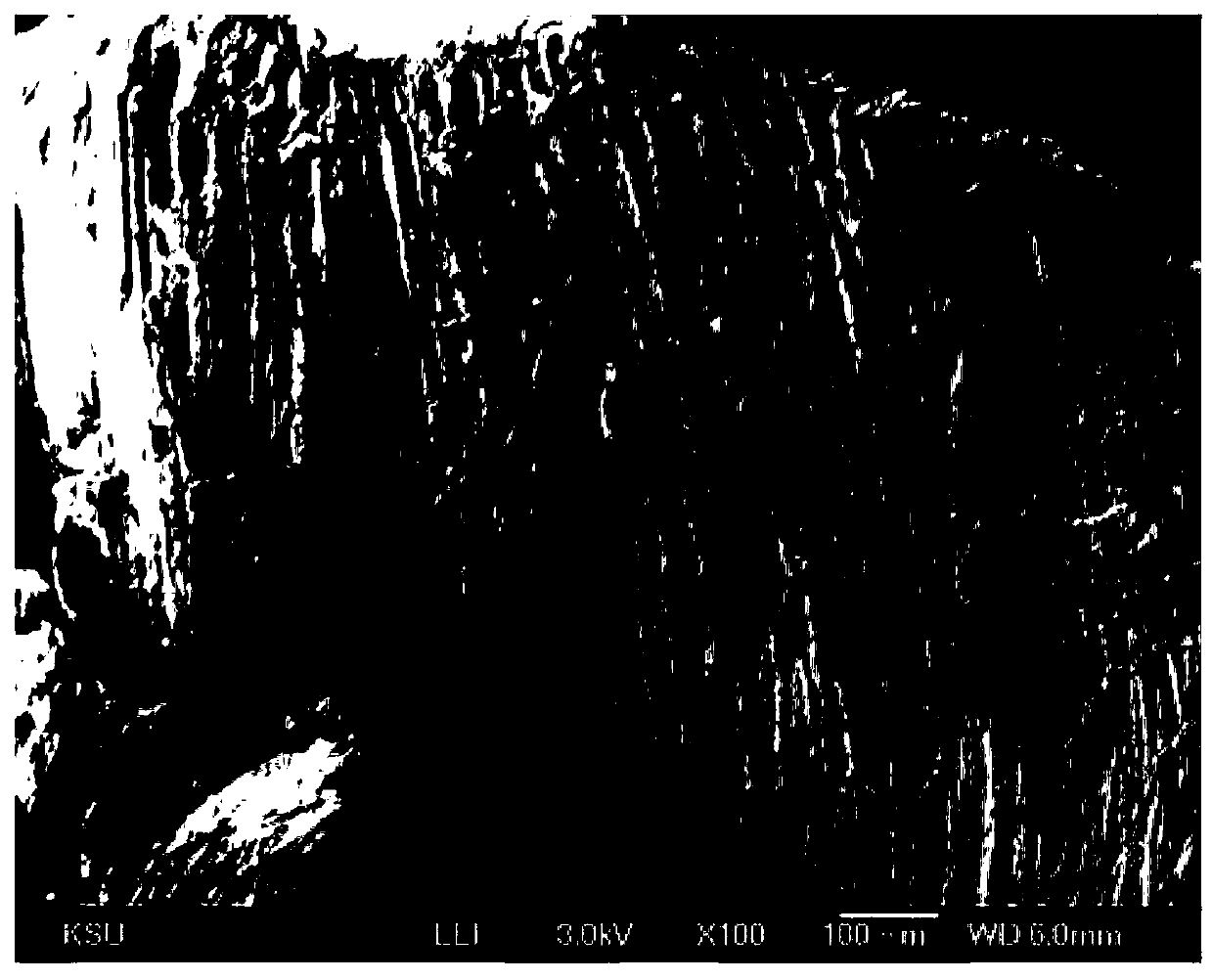

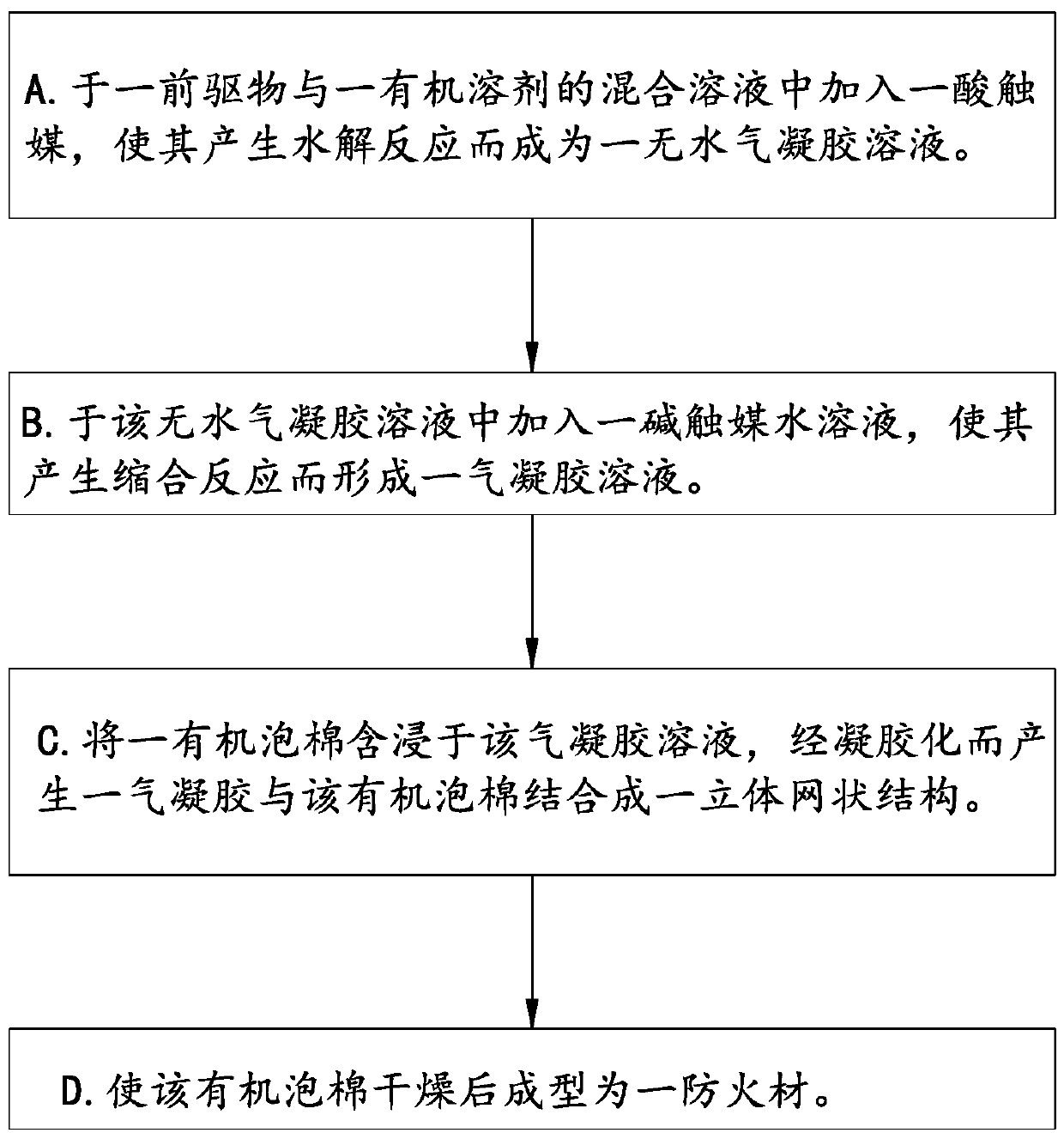

Fireproof material for combining wood material with aerogel and manufacturing method thereof

ActiveCN107775759AReduce manufacturing costSuitable for manufacturingWood treatment detailsWood impregnation detailsCombustionOrganic solvent

The invention discloses a manufacturing method of a fireproof material for combining a wood material with aerogel. The manufacturing method comprises the following steps: (A) an acid accelerant is added in mixed solution of a precursor and an organic solvent for hydrosis reaction to form aerogel solution; (B) alkali accelerant water solution is added in the aerogel solution for condensation reaction to form aerogel water solution; (C) the wood material is dipped in the aerogel water solution for gelation to generate the aerogel to coat the wood material; and (D) the wood material is dried to mold the fireproof material. The invention further discloses the fireproof material for combining the wood material with the aerogel, which is manufactured by using the steps. The fireproof material can achieve excellent fireproof effect, and can pass through a combustion lowest-oxygen-content test.

Owner:陈 建宏

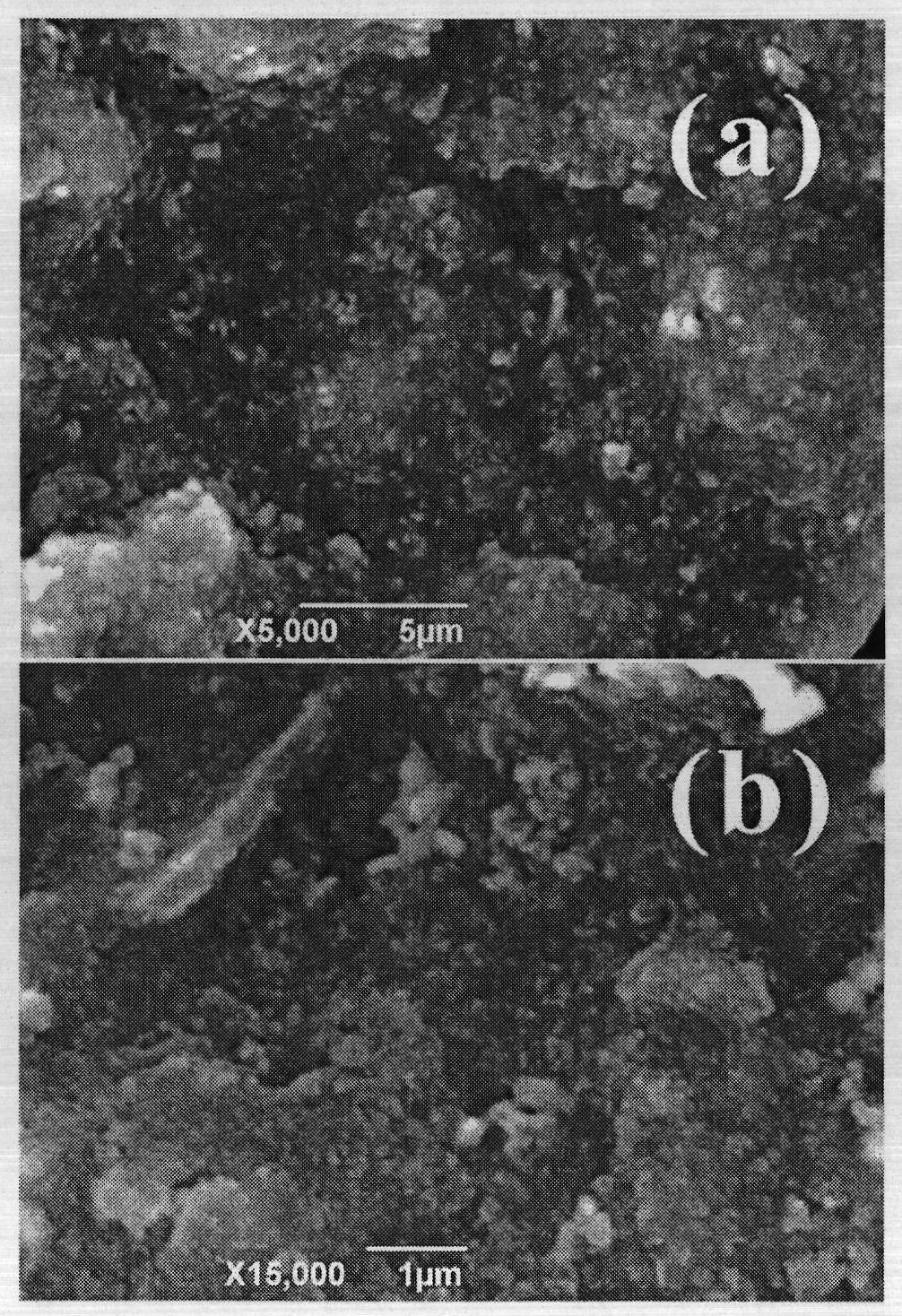

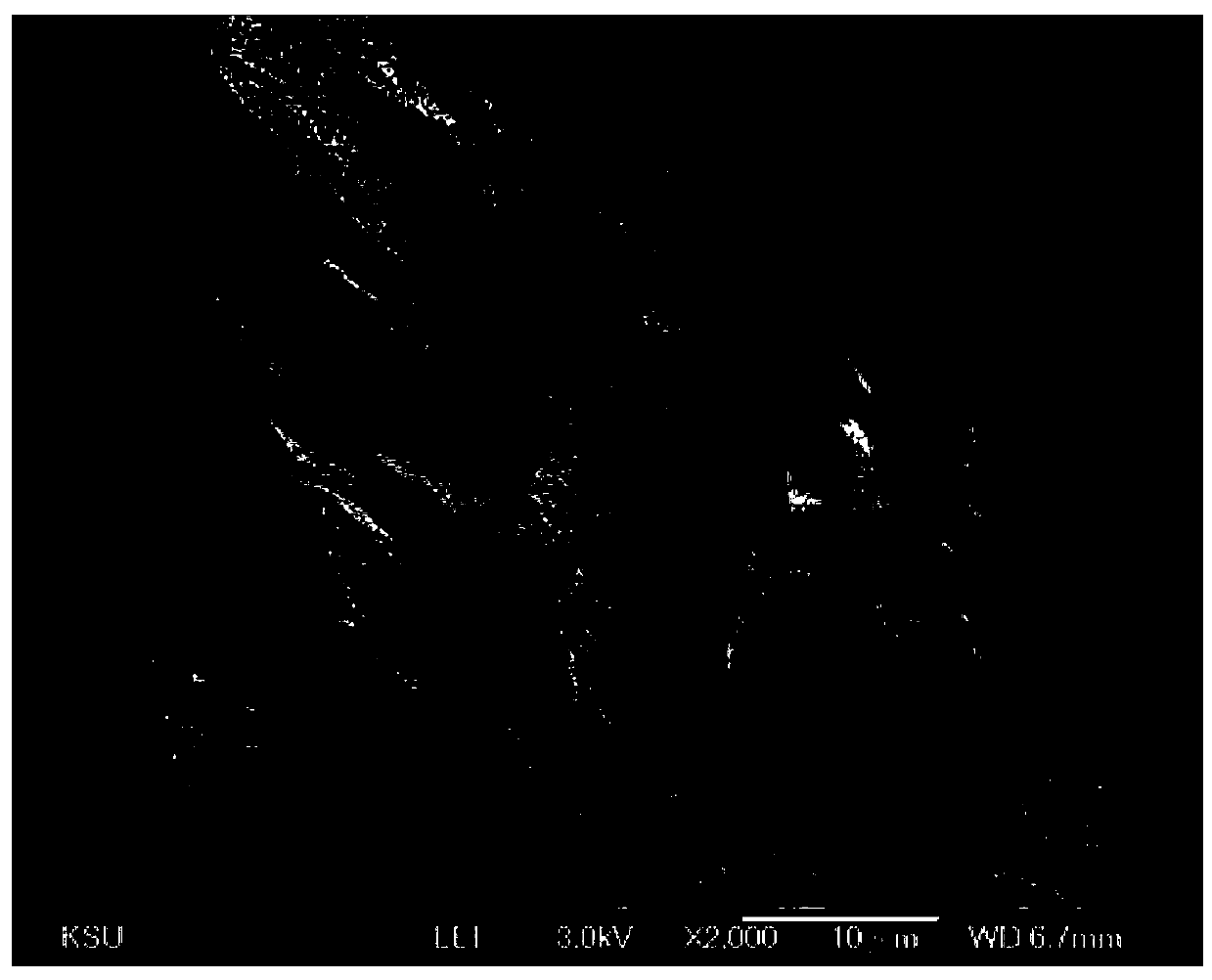

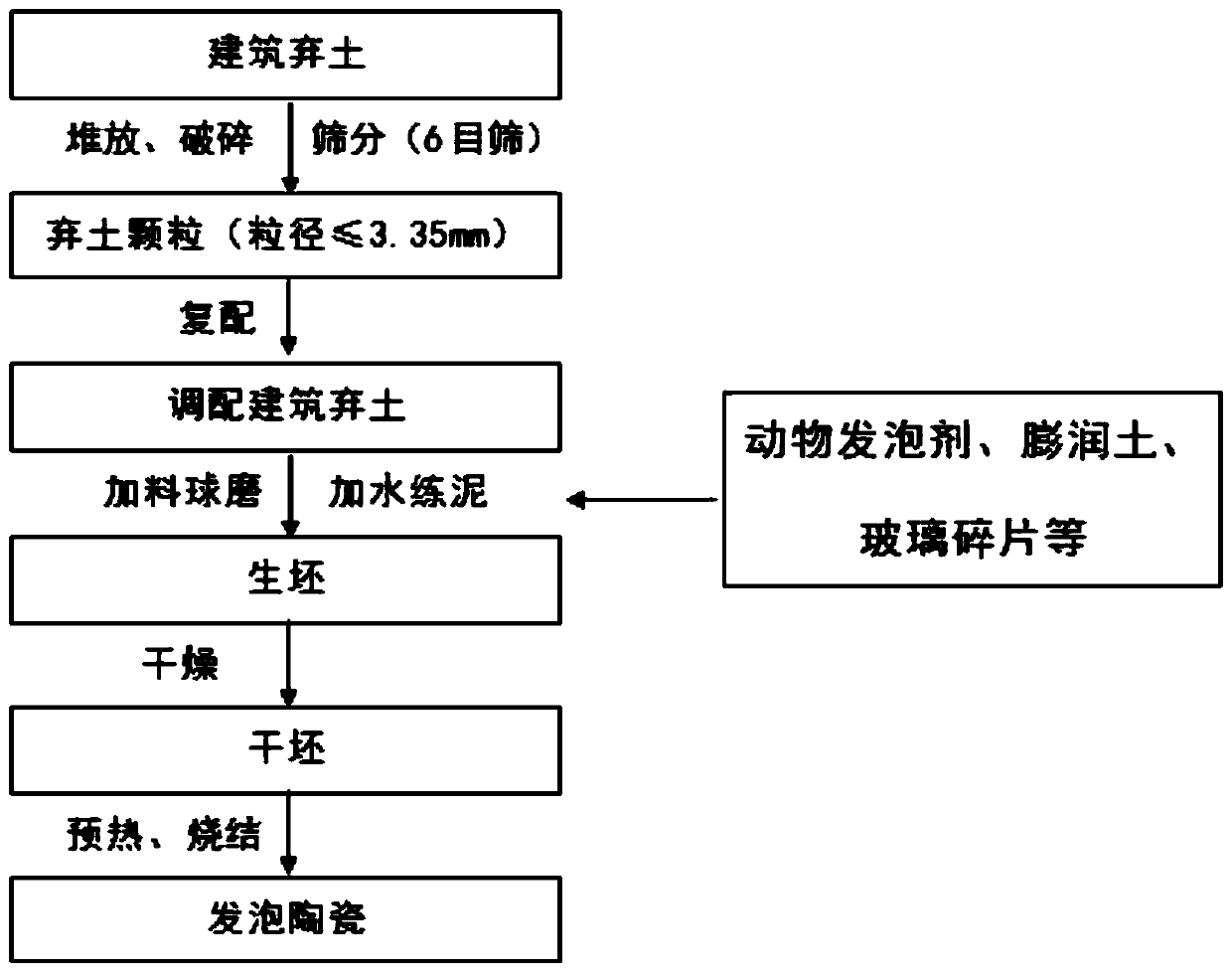

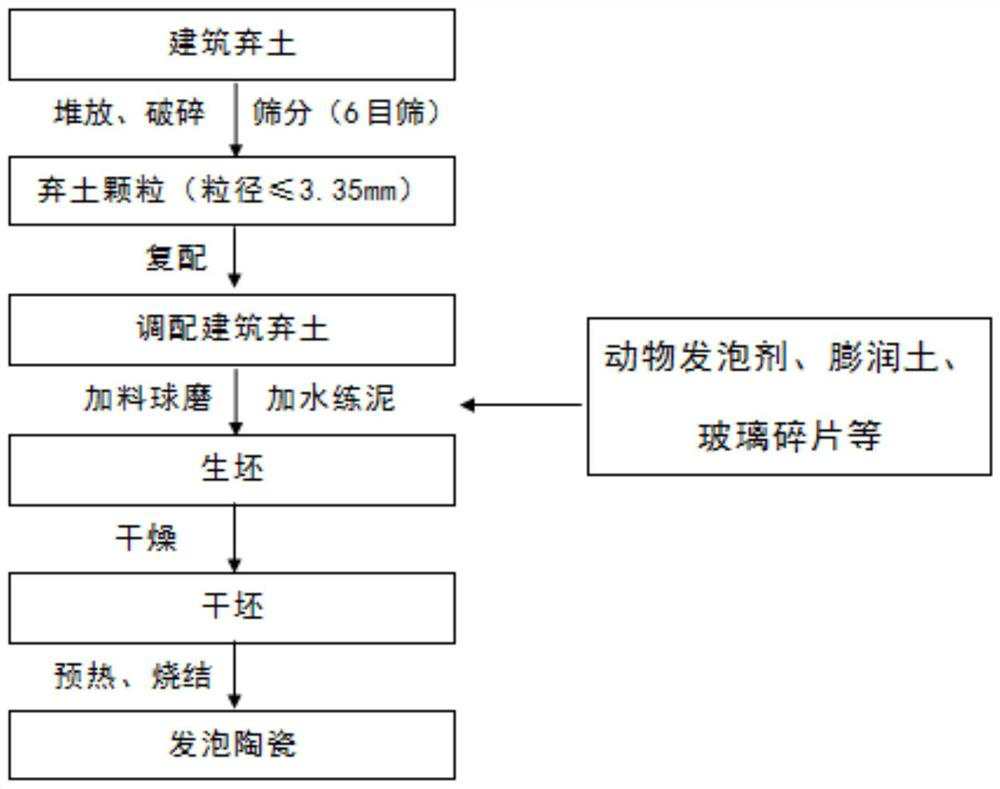

Method for sintering building spoil into foamed ceramic

ActiveCN111138166ASolve pollutionSolve resource problemsCeramic materials productionCeramicwareMuffle furnaceBall mill

The invention relates to a method for sintering building spoil into foamed ceramic. The method comprises the following steps: (1) collecting the building spoil, and treating the building spoil so as to prepare sintered aggregate; (2) preparing materials according to the following formula: 70-80 parts of the sintered aggregate, 5-7 parts of an animal foaming agent, 5-7 parts of bentonite, 5-7 partsof glass fragments and 20-60 parts of water; (3) putting the components in the step (2) into a ball mill for ball milling, adding water for pugging, injecting an obtained material into a mold, carrying out pressure molding, and carrying out demolding so as to obtain a green body; and (4) drying the green body so as to obtain a dried green body, then placing the dried green body into a muffle furnace, and carrying out sintering so as to prepare the foamed ceramic. Compared with the prior art, the method provided by the invention has the following advantages: the building spoil which is difficult to be utilized is treated and compounded, so the building spoil can be used as a raw material for sintering the foamed ceramic; meanwhile, the performance of traditional foamed ceramic is improved.

Owner:TONGJI UNIV

A method for sintering foamed ceramics with construction spoil

ActiveCN111138166BSolve pollutionSolve resource problemsCeramic materials productionCeramicwareFoaming agentMuffle furnace

The invention relates to a method for sintering building spoils into foamed ceramics, comprising the following steps: (1) collecting building spoils, and processing the building spoils to prepare sintered aggregate; (2) preparing materials according to the following formula, and sintering 70-80 parts of aggregate, 5-7 parts of animal foaming agent, 5-7 parts of bentonite, 5-7 parts of glass fragments, 20-60 parts of water; (3) Put the components of step (2) into a ball mill for ball milling , adding water to smelt the mud, pouring it into a mold, forming it under pressure, and demoulding to obtain a green body; (4) drying the green body to obtain a dried green body, and then putting the dried green body into a muffle furnace for sintering to prepare foamed ceramics. Compared with the prior art, the invention processes and recombines the difficult-to-use building waste soil so that it can be used as raw material for sintered foamed ceramics, and at the same time improves the performance of traditional foamed ceramics.

Owner:TONGJI UNIV

A flexible direct-lit backlight source and display device thereof

ActiveCN109597242BImprove flexibilityLarge curvatureNon-linear opticsLiquid-crystal displayFlexible circuits

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

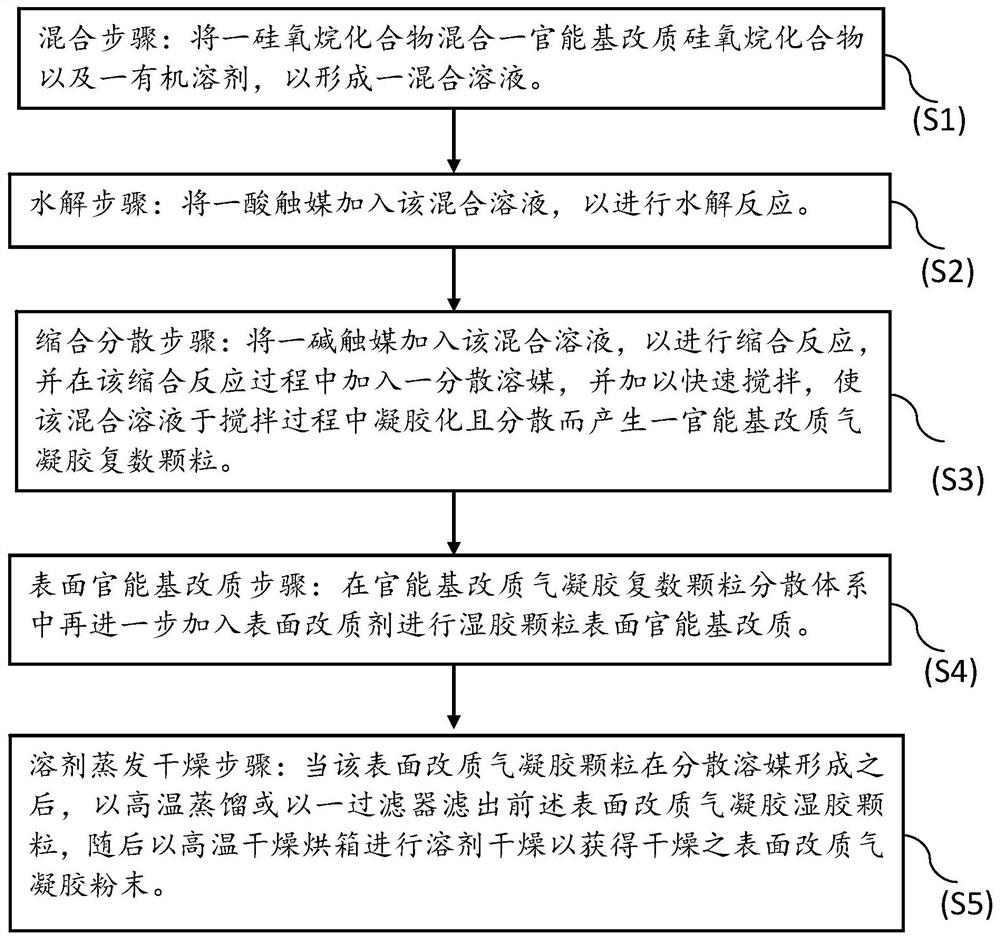

Preparation method of functional group modified aerogel particles for spinning and fiber spinning

ActiveCN112850723AImprove spinning propertiesImprove practicalityNanotechnologySilicon compoundsSolvent evaporationCold resistance

The invention provides a preparation method of functional group modified aerogel particles for spinning and fiber spinning. The functional group modified aerogel particles are prepared by the following steps: (1) mixing, (2) hydrolyzing, (3) condensing and dispersing, (4) further modifying surface functional groups, and (5) evaporating and drying a solvent. The surface functional group modified aerogel powder can be continuously produced or produced in batches, the manufacturing process is simple and convenient, and the manufacturing speed is high. According to the invention, the excellent acting force formed between the functional group modified aerogel powder and various plastics can be obviously improved, the composite mixing efficiency between the aerogel and the plastics is improved, and the dispersion of the functional group modified aerogel powder in the plastics is improved, so that the functionality of the aerogel composite material and the spinnability of subsequent fiber spinning are improved; the product can improve the special functions of heat insulation, cold resistance, light weight, fire resistance, molten drop resistance and the like of the plastic composite material and the spinning fiber.

Owner:TAIWAN AEROGEL TECH MATERIAL CO LTD

Fireproof material made from organic foam combined with aerogel and manufacture method thereof

InactiveCN107779208AIncrease softnessImprove thermal insulation propertiesFireproof paintsCombustionOrganic solvent

The invention discloses a manufacture method of a fireproof material prepared from organic foam combined with aerogel. The method comprises the following steps: A, adding an acid accelerant into a mixed solution of a precursor and an organic solvent, so as to ensure that the mixed solution is subjected to hydrolysis reaction to form an anhydrous aerogel solution; B, adding an alkali accelerant aqueous solution into the anhydrous aerogel solution, so as to ensure that the anhydrous aerogel solution is subjected to condensation reaction to form an aerogel solution; C, soaking organic foam into the aerogel solution, producing aerogel through gelatinization, and combining the aerogel with the organic foam to form a stereochemical network structure; D, drying the organic foam to form a fireproof material. The invention further discloses a fireproof material prepared from organic foam combined with aerogel, which is manufactured through the steps. The fireproof material has an excellent fireproof effect, and passes a combustion minimum oxygen content test.

Owner:陈 建宏

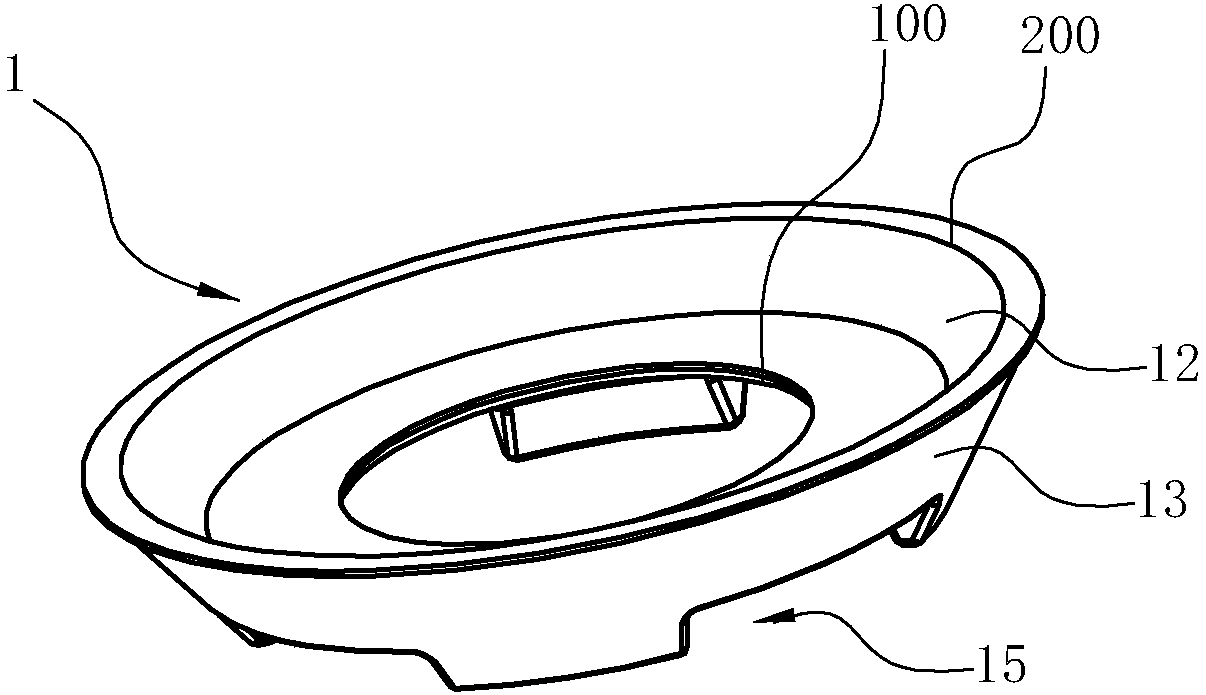

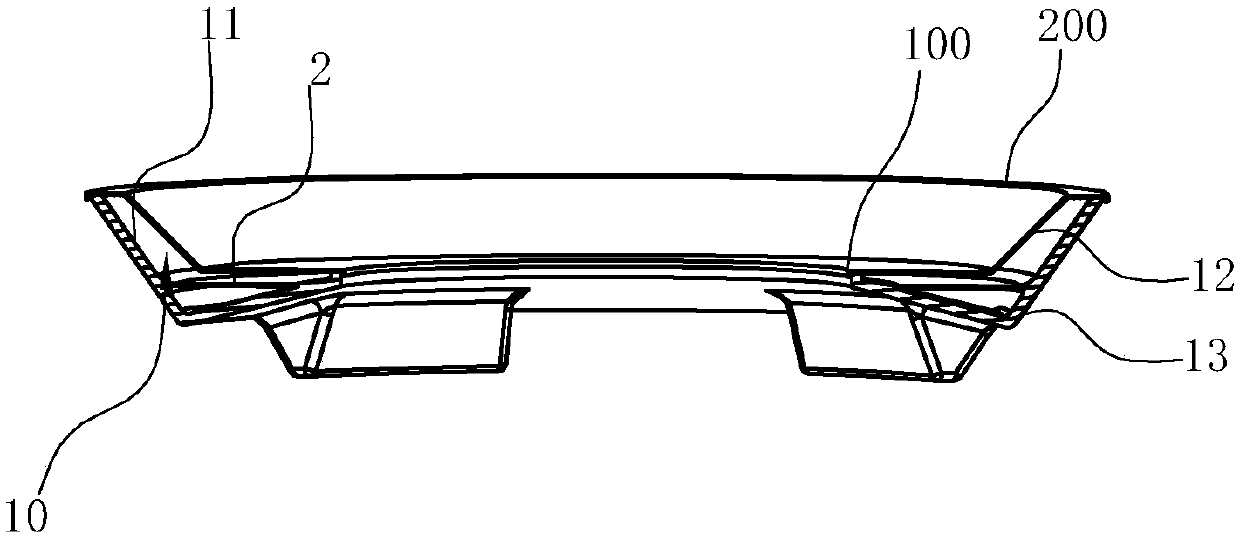

Heat-insulating cover for stove and stove applying heat-insulating cover for stove

PendingCN109869766AIncrease profitImprove thermal insulation propertiesDomestic stoves or rangesLighting and heating apparatusHearthEngineering

The invention relates to a heat-insulating cover for a stove. The heat-insulating cover comprises an annular cover body, and is characterized in that the cover body is of a double-layer structure composed of an upper-layer cover and a lower-layer cover, a hollow cavity is formed between the upper-layer cover and the lower-layer cover, a separating piece is further arranged in the hollow cavity, and the edge of the periphery of the separating piece abuts against the inner wall of the hollow cavity so as to divide the hollow cavity into at least two sub-hollow cavities. Compared with the prior art, the heat-insulating cover for the stove has the advantages that the heat-insulating cover for the stove is additionally arranged on the basis of an existing gas stove, the heat-insulating cover isof the double-layer structure and is provided with the hollow cavity, the separating piece is further arranged in the hollow cavity, so that the hollow cavity of the heat-insulating cover is dividedinto the plurality of sub-hollow cavities with relatively independent closed spaces so as to effectively reduce convection heat exchange of air in the hollow cavity and further reduce convection heatexchange of air in the hollow cavity and air outside the hollow cavity, the invention further discloses the stove applying the heat-insulating cover, secondary air supplementing grooves of the cover body can be arranged aligned with secondary air inlets of a gas mixing chamber of a combustor one by one so that secondary air can be effectively supplemented.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com