A flexible direct-lit backlight source and display device thereof

A direct type, backlight technology, applied in the direction of nonlinear optics, optics, instruments, etc., can solve the problem that the backlight cannot meet the large curvature and free bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

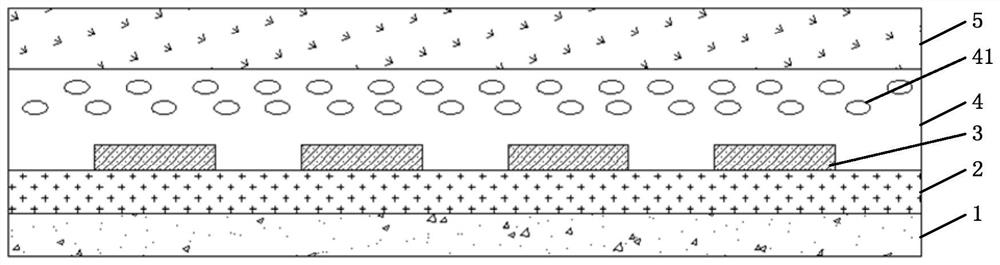

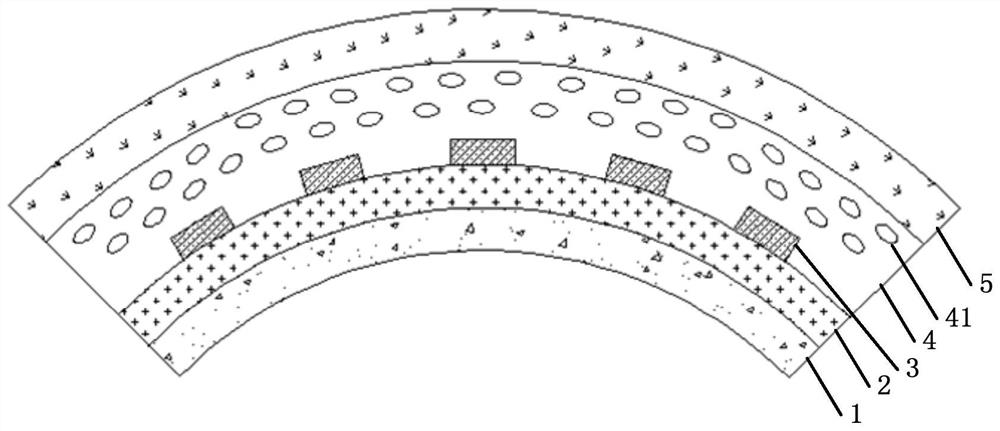

[0028] Such as figure 1 As shown, the present invention provides a flexible direct backlight, which includes a graphene heat dissipation coating 1, a flexible circuit board 2, a mini LED 3, an air bubble glue layer 4 and an optical film layer 5 arranged in sequence.

[0029] Wherein the composition material Graphene (Graphene) of described graphene heat dissipation coating 1 is a kind of by carbon atom with sp 2 The hybrid orbitals form a hexagonal two-dimensional carbon nanomaterial with a honeycomb lattice. Since graphene has very good thermal conductivity, it can well transmit the heat generated by the backlight to the outside.

[0030] Wherein the flexible printed circuit board 2 (English full name: Flexible Printed Circuit, FPC for short) is disposed on the graphene heat dissipation coating 1 . The flexible circuit board 2 is made of polyimide or polyester film as the base material. Therefore, the flexible circuit board 2 has the characteristics of high wiring density,...

Embodiment 2

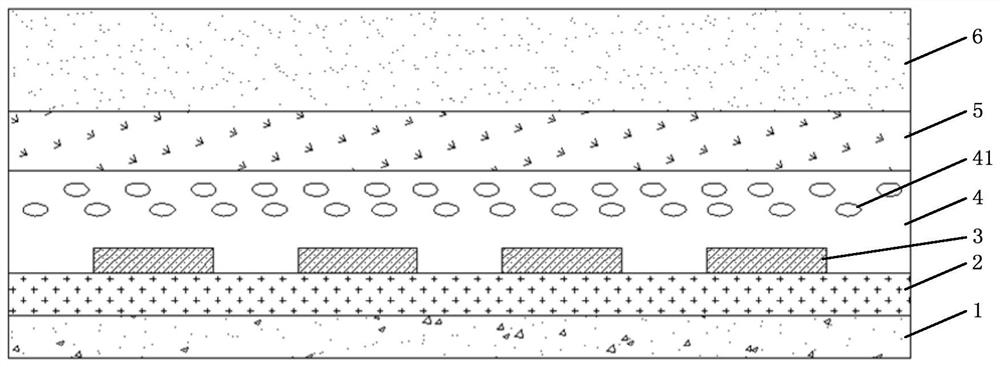

[0037] In the following, only the differences between the present embodiment and the first embodiment will be described, and the similarities will not be repeated here.

[0038] Such as image 3 As shown, the present invention also provides a display device, including the above-mentioned flexible direct backlight and a flexible liquid crystal screen 6 . The flexible liquid crystal screen 6 is pasted on the flexible direct-type backlight through an adhesive.

[0039] The constituent materials of the adhesive include at least one of silica gel, epoxy glue and acrylic, and at least one of UV light curing agent, inorganic particles and inert gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com