Tubular member and exhaust system

A technology of exhaust system and tubular body, which is applied in the field of tubular body, can solve the problems that the exhaust system is susceptible to high temperature fluctuations, poor coating durability, and increased component weight, etc., to achieve light weight, small required space, and high durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

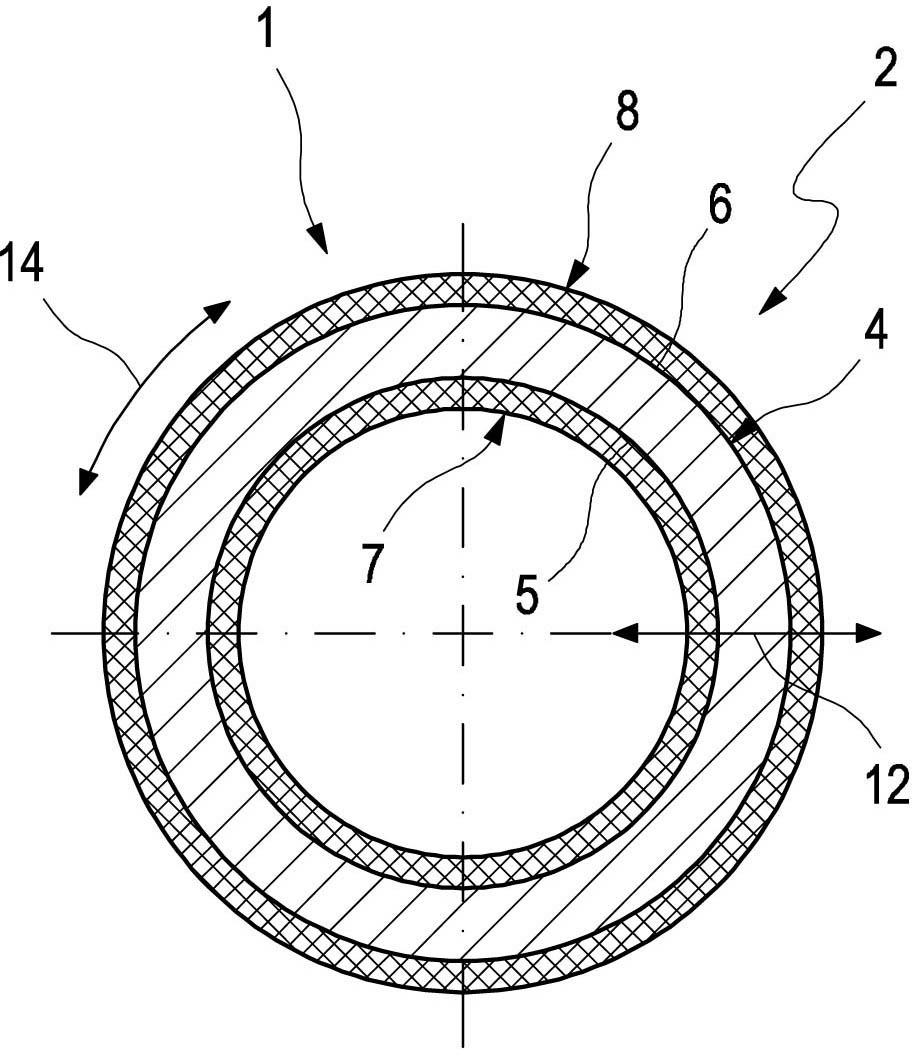

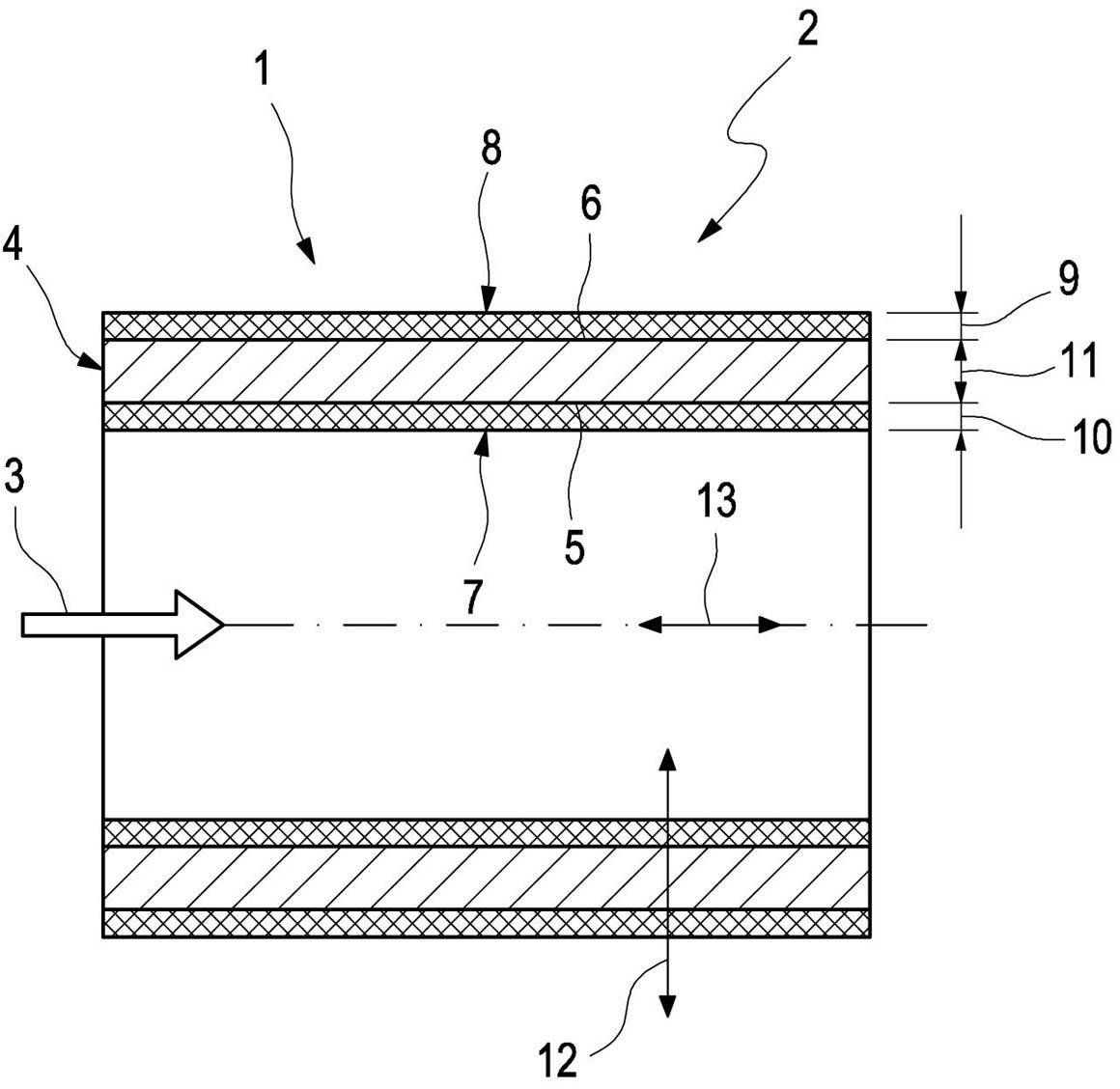

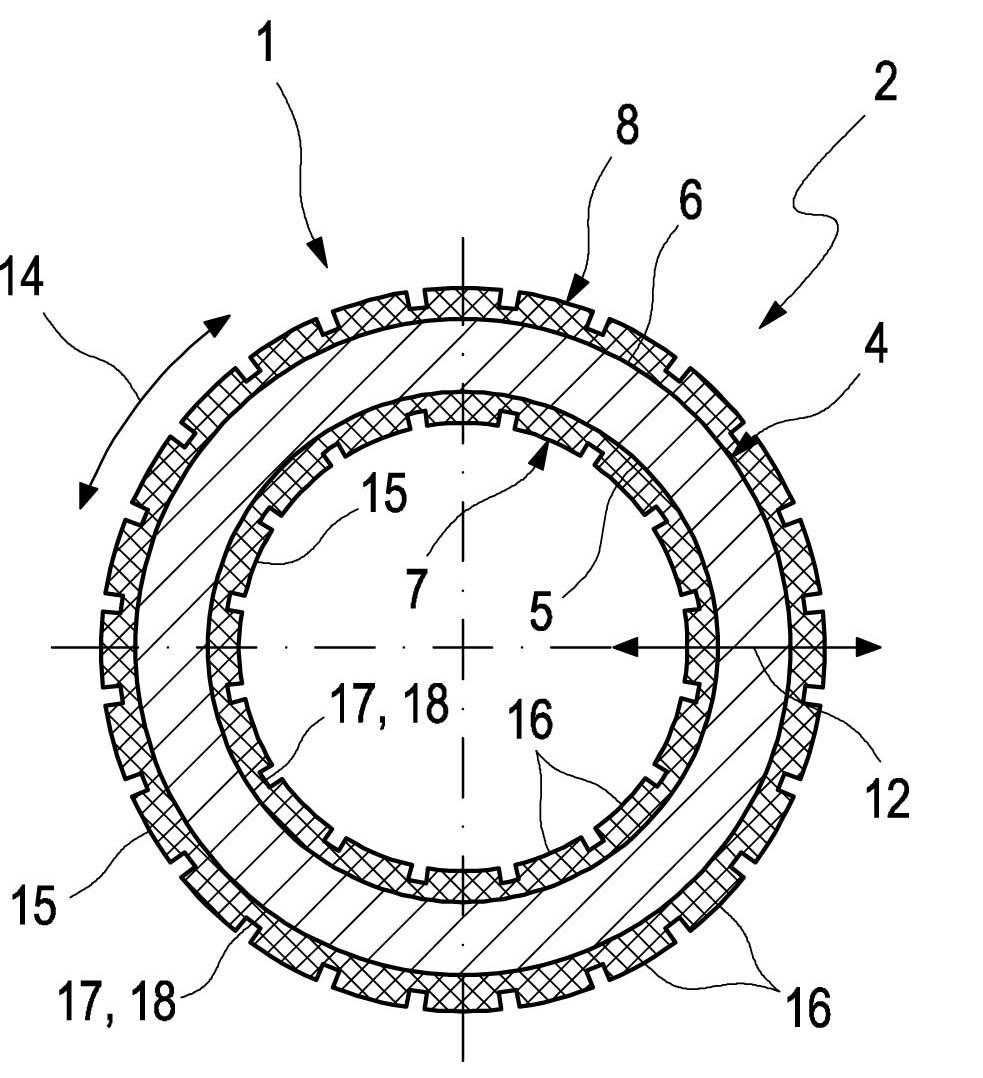

[0026] Figures 1 to 4 in shows the cross-section and longitudinal section of the tubular body 1, respectively. The tubular body 1 preferably forms part of an exhaust system 2 not shown here, so that the exhaust system 2 contains at least one such tubular body 1 . The exhaust system 2 here can obviously also comprise two or more such tubular bodies 1 .

[0027] The exhaust system 2 is suitable for exhausting exhaust gases of an internal combustion engine, which in particular may be arranged in a motor vehicle. The tubular body 1 is therefore also suitable for treating exhaust gases. exist figure 2 and 4 In , the corresponding exhaust gas flow is indicated by an arrow and reference 3.

[0028] exist Figures 1 to 4 In the embodiment, the tubular body 1 is configured as a circular cross-section. Obviously, other cross-sections are also possible in principle. This can be another circular cross-section or any desired geometrical cross-section.

[0029] The tubular body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com