Fireproof material made from organic foam combined with aerogel and manufacture method thereof

A manufacturing method and aerogel technology, which can be used in fire-resistant coatings and other directions, and can solve problems such as no disclosure yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

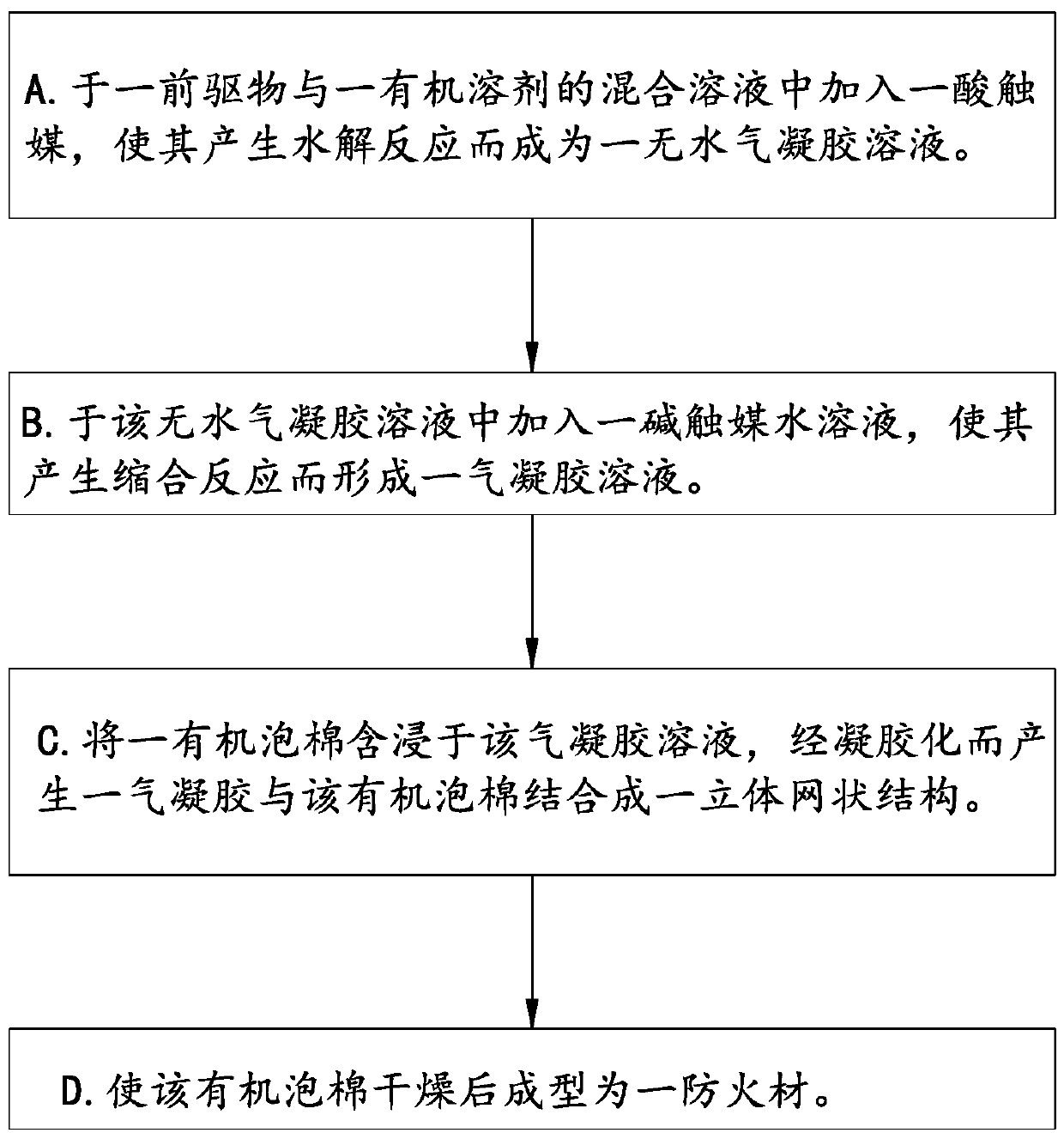

[0031] The present invention contains a kind of organic foam combined with airgel fire prevention material manufacturing method, please refer to figure 1 As shown, the embodiment of the present invention includes the following steps:

[0032]A. Add an acid catalyst to a mixed solution of a precursor and an organic solvent to cause a hydrolysis reaction to form an anhydrous airgel solution. This embodiment mainly provides a precursor of an alkoxysilane or a methyl orthosilicate, and an organic solvent mixed with water and ethanol. The alkoxysilane is tetraethylsiloxane (Tetraethoxysilane, TEOS). The mixing ratio range is that the molar ratio (mol%) of the precursor (tetraethylsiloxane) to the organic solvent ranges from 1:9 to 1:18, wherein the molar ratio of the precursor to water ranges below 1:4, then add an acid catalyst, the molar ratio of the precursor mixed with the acid catalyst ranges from 1:0.001 to 1:0.1, stir at room temperature to carry out a hydrolysis reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com