Preparation method of functional group modified aerogel particles for spinning and fiber spinning

A technology of gel particles and functional groups, which is applied in the field of preparation of functional group-modified airgel particles, which can solve the problems of easy fiber breakage during spinning and degradation of the properties of post-processing products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Based on the above technical features, the main functions of the functional group-modified airgel particles and the preparation method thereof in the embodiments of the present invention will be clearly presented in the following embodiments.

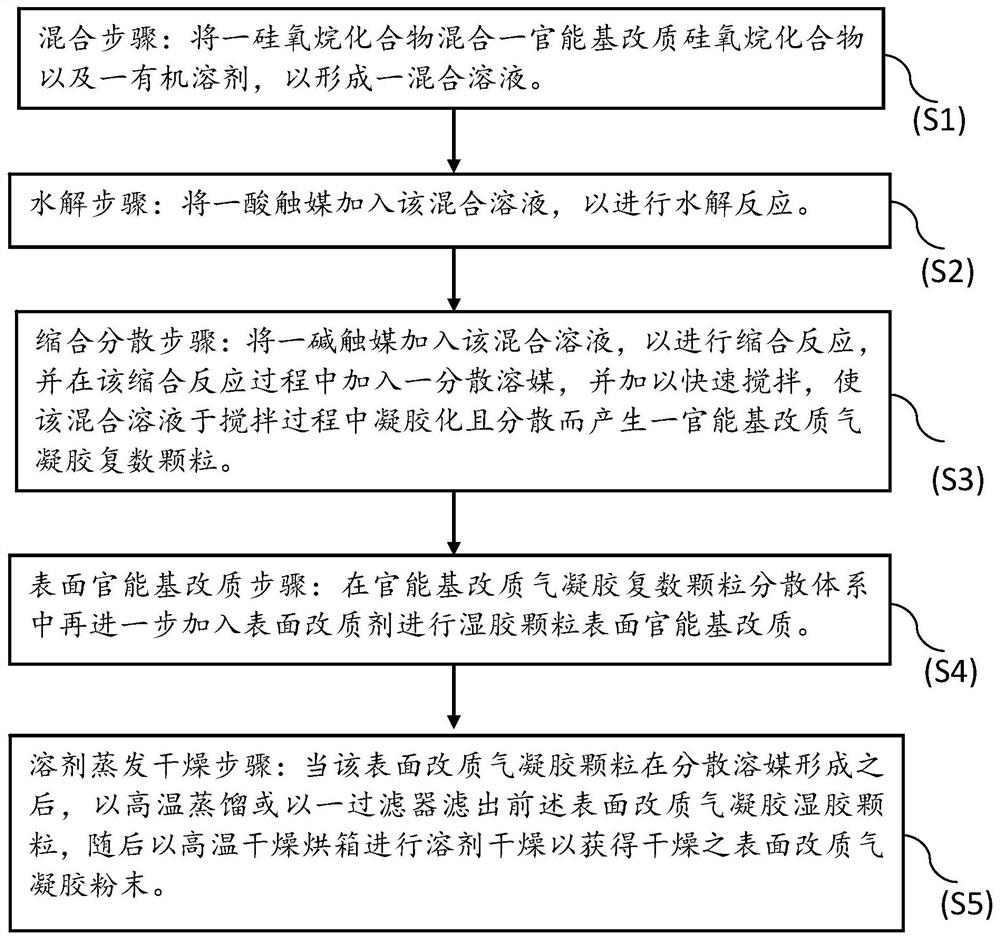

[0036] Please see first figure 1 , this figure reveals the preparation method of functional group modified airgel particles for textile and fiber spinning in the embodiment of the present invention, comprising the following steps: mixing step (S1), hydrolysis step (S2), condensation and dispersion step (S3), surface functionalization The base modification step (S4) and the solvent evaporation drying step (S5), wherein:

[0037] The mixing step (S1) is: mixing a siloxane compound with a functional group-modified siloxane compound and an organic solvent to form a mixed solution. The siloxane compound (alkoxysilane) is, for example, precursors such as tetramethoxysilane (TMOS), tetraethoxysilane (TEOS), methyl orthosilicate, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com