Power transmission optical cable

A technology of optical cable and electric wire, applied in the field of optical cable structure, can solve the problems of affecting optical fiber transmission performance and not having heat insulation effect, and achieve the effects of overcoming influence, excellent thermal stability, and improving high temperature resistance and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

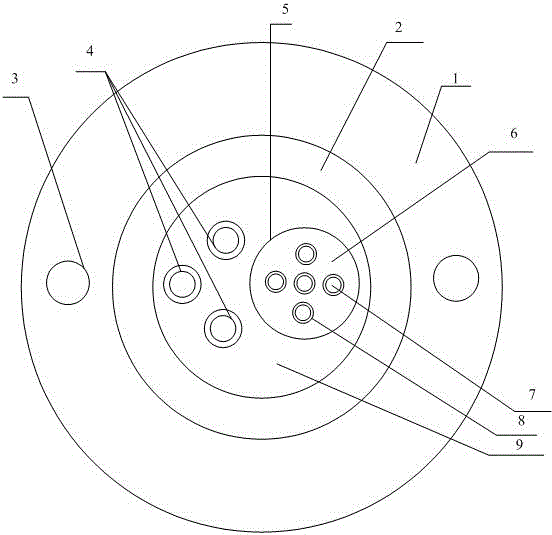

[0024] Such as figure 1 shown.

[0025] A power transmission optical cable, comprising a filling layer 9 with an optical fiber component and an electric wire 4 inside, the filling layer 9 is covered with an insulating layer 2, the insulating layer is covered with a PE outer sheath 1, and the optical fiber component includes a loose tube 5 A fiber paste layer 6 is arranged inside the loose tube, an optical fiber 7 whose outer surface is coated with an optical fiber surface coating glue 8 is arranged inside the fiber paste layer 6 , and a steel wire reinforcing rib 3 is arranged on the PE outer sheath 1 .

[0026] Optical fiber surface coating glue is composed of the following raw materials in parts by weight: silicone rubber: 25-30 parts; high molecular weight polyisobutylene: 5-10 parts; medium molecular weight polyisobutylene: 5-10 parts; 15 parts; Inorganic filler: 10-15 parts; Antioxidant: 0.5-1 part; Glass fiber: 5-10 parts; Silicate: 5-10 parts.

[0027] The coating adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com