A method for sintering foamed ceramics with construction spoil

A technology of construction spoil and ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., and can solve the problem that construction spoil has not been properly disposed of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

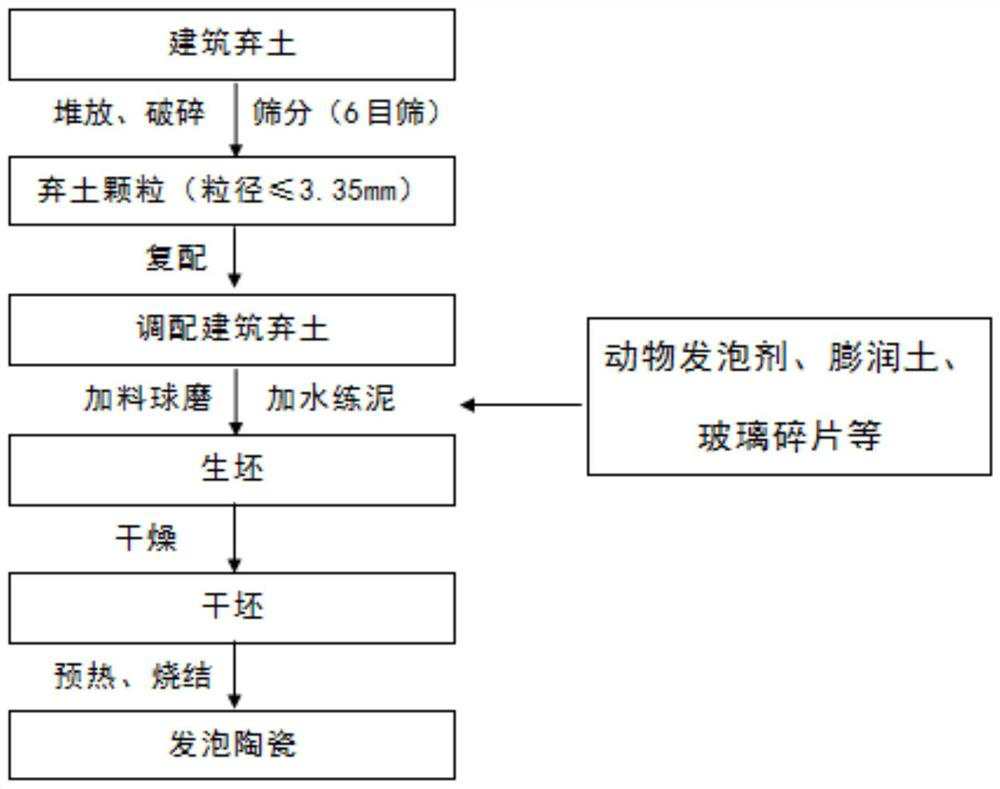

Method used

Image

Examples

Embodiment 1

[0078] The construction spoil is excavated with earth and stone, and the spoil is blended with fly ash.

[0079] Follow the steps below to implement:

[0080] Collect earthwork excavation spoil, put earthwork excavation spoil into mobile crusher, crush it, pass through 6-mesh sieve, and screen to obtain construction spoil raw materials with a particle size not greater than 3.35mm. Add fly ash to the earth and stone excavation spoil, by weight, take 50 parts of earth and stone excavation spoil particles, 25 parts of fly ash, put the raw materials into a horizontal ribbon mixer, and stir for 20 minutes to obtain sintered bone material.

[0081] In parts by weight, 80 parts of the above sintered aggregate, 5 parts of animal hoof horn foaming agent, 5 parts of sodium bentonite, 5 parts of ordinary silicate glass shards and 60 parts of tap water are taken. Put the above-mentioned materials weighed into a ball mill, ball mill for 1 hour, add water to refine the mud, and inject it ...

Embodiment 2

[0088] The construction spoil is made of muddy construction spoil and prepared with diatomaceous earth.

[0089] Follow the steps below to implement:

[0090] Collect the silty construction spoil, and stack the silty construction spoil for 15 days, pass through a 6-mesh sieve, and screen to obtain construction spoil raw materials with a particle size not greater than 3.35mm. Add diatomite to the silty construction spoil, by weight, take 70 parts of earthwork excavation spoil particles, 25 parts of diatomite, put the raw materials into a horizontal ribbon mixer, and stir for 20 minutes to obtain sintered bone material.

[0091]In parts by weight, 80 parts of the above-mentioned sintered aggregate, 7 parts of animal hoof horn foaming agent, 7 parts of sodium bentonite, 7 parts of ordinary silicate glass shards and 20 parts of tap water are taken. Put the above-mentioned materials weighed into a ball mill, ball mill for 1 hour, add water to refine the mud, and inject it into a ...

Embodiment 3

[0098] For construction spoil, earthwork excavation spoil and silty construction spoil can be used in a mixed ratio of 1:1, without compounding.

[0099] Follow the steps below to implement:

[0100] Collect earth and stone excavation spoil, put the earth and stone excavation spoil into the mobile crusher, and crush it; collect muddy construction spoil, and pile up muddy construction spoil for 15 days. Pass the preliminarily treated construction spoil through a 6-mesh sieve to obtain construction spoil raw materials with a particle size not greater than 3.35mm.

[0101] In terms of parts by weight, 35 parts of excavation spoil for earth and stone; 35 parts of muddy construction spoil; 5 parts of animal hoof horn foaming agent; 7 parts of sodium bentonite; 5 parts of ordinary silicate glass fragments; 40 parts of tap water. Put the above-mentioned materials weighed into a ball mill, ball mill for 1 hour, add water to refine the mud, and inject it into a mold with a size of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com