Heat-insulating cover for stove and stove applying heat-insulating cover for stove

A technology for heat shields and stoves, applied in the field of stoves, which can solve problems such as flameout, slippery pots, overflow of cooking soup, swinging flames of gas stoves, etc., to improve heat insulation characteristics, improve gas utilization, Reduce the effect of convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

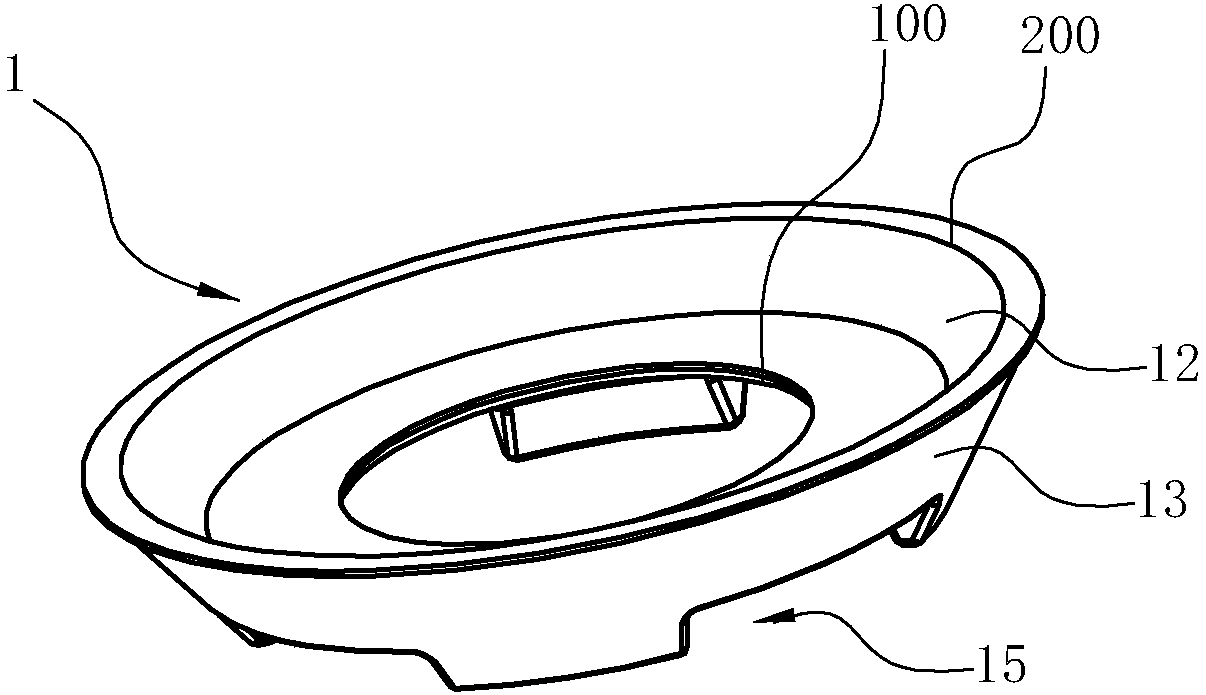

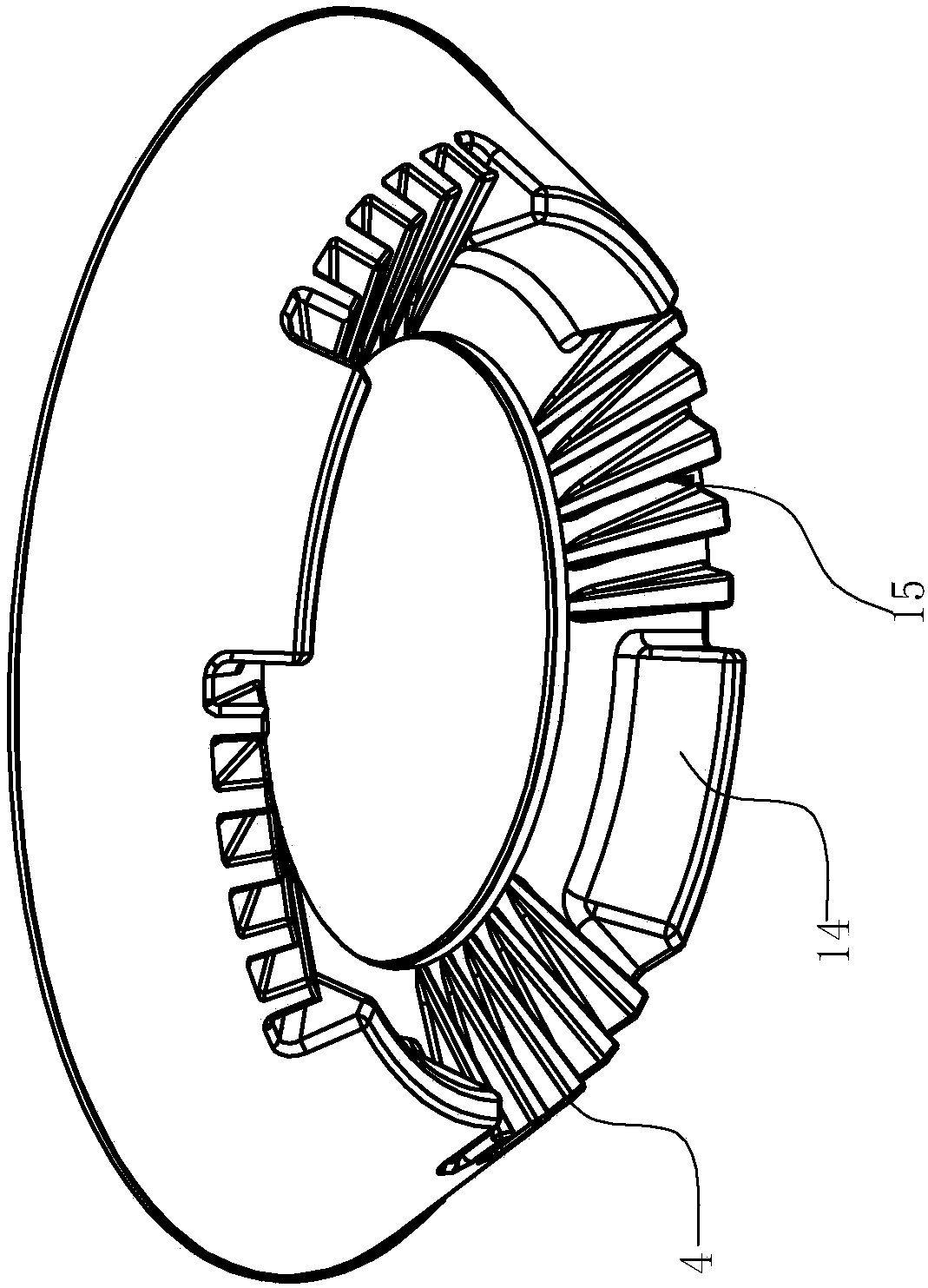

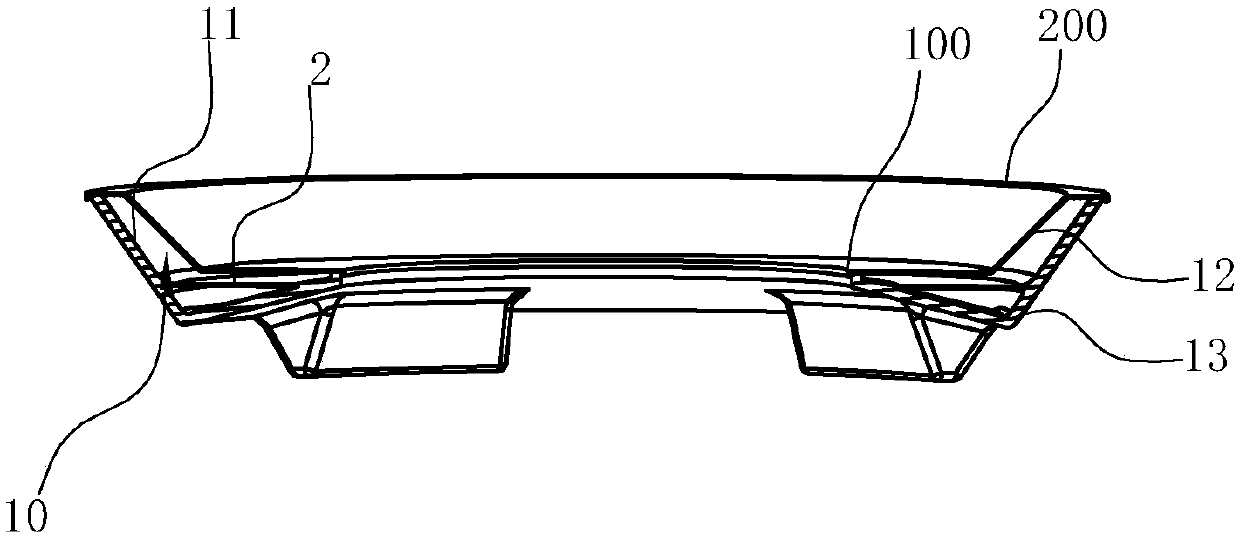

[0026] Such as Figure 1~4 As shown, the stove heat shield in this embodiment includes an annular cover body 1, the cover body 1 is a double-layer structure and forms a cavity 10, a partition is also arranged in the cavity 10, and the edge of the periphery of the partition It is against the inner wall of the cavity 10 to divide the cavity 10 into at least two sub-cavities 11 , wherein the partition is a horizontal partition 2 , and the cavity 10 is divided into two sub-cavities 11 distributed up and down.

[0027] Wherein, the cover body 1 is a double-layer structure composed of an upper cover 12 and a lower cover 13, and the cavity 10 formed between the upper cover 12 and the lower cover 13 is filled with air, and the poor heat transfer performance of air is used as a thermal insulation. The thermal effect achieves the purpose of high temperature inside the upper cover 12 and low temperature outside the lower cover 13, thereby achieving the effect of highly concentrated heat ...

Embodiment 2

[0032] Such as Figure 5 As shown, the structure is basically the same as that of Embodiment 1, and the difference is that the separator is a vertical partition 3, which is arranged along the radial direction of the cover body 1, and the cavity 10 is divided into at least two along the circumference. To the distributed sub-cavity 11.

Embodiment 3

[0034] Such as Figure 6 As shown, the structure is basically the same as that of Embodiment 1, the difference is that the partition includes at least one horizontal partition 2 arranged along the horizontal direction of the cover 1 and at least one horizontal partition 2 arranged along the radial direction of the cover 1 The vertical partition 3, the horizontal partition 2 and the vertical partition 3 divide the energy-gathering cavity into a plurality of independent closed sub-cavities 11. The diameter is 10.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com