Flexible stress sensor with composite microstructure and preparation method thereof

A stress sensor and composite microstructure technology, applied in the field of sensors, to achieve the effects of excellent comprehensive performance, large stretching range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

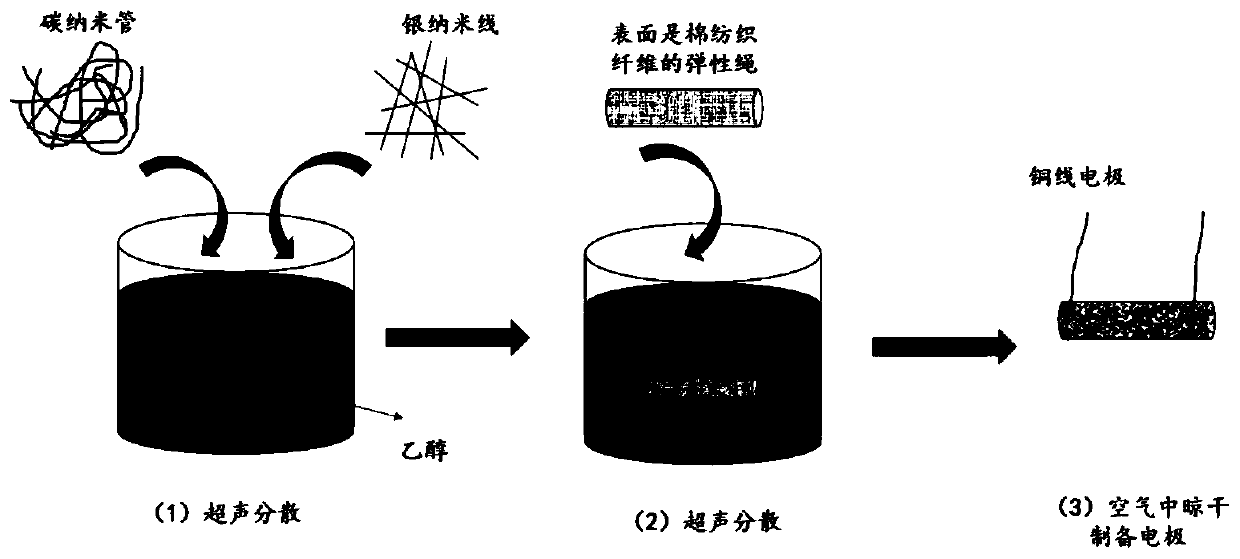

[0028] The schematic diagram of the preparation process of this embodiment is as follows figure 1 as shown,

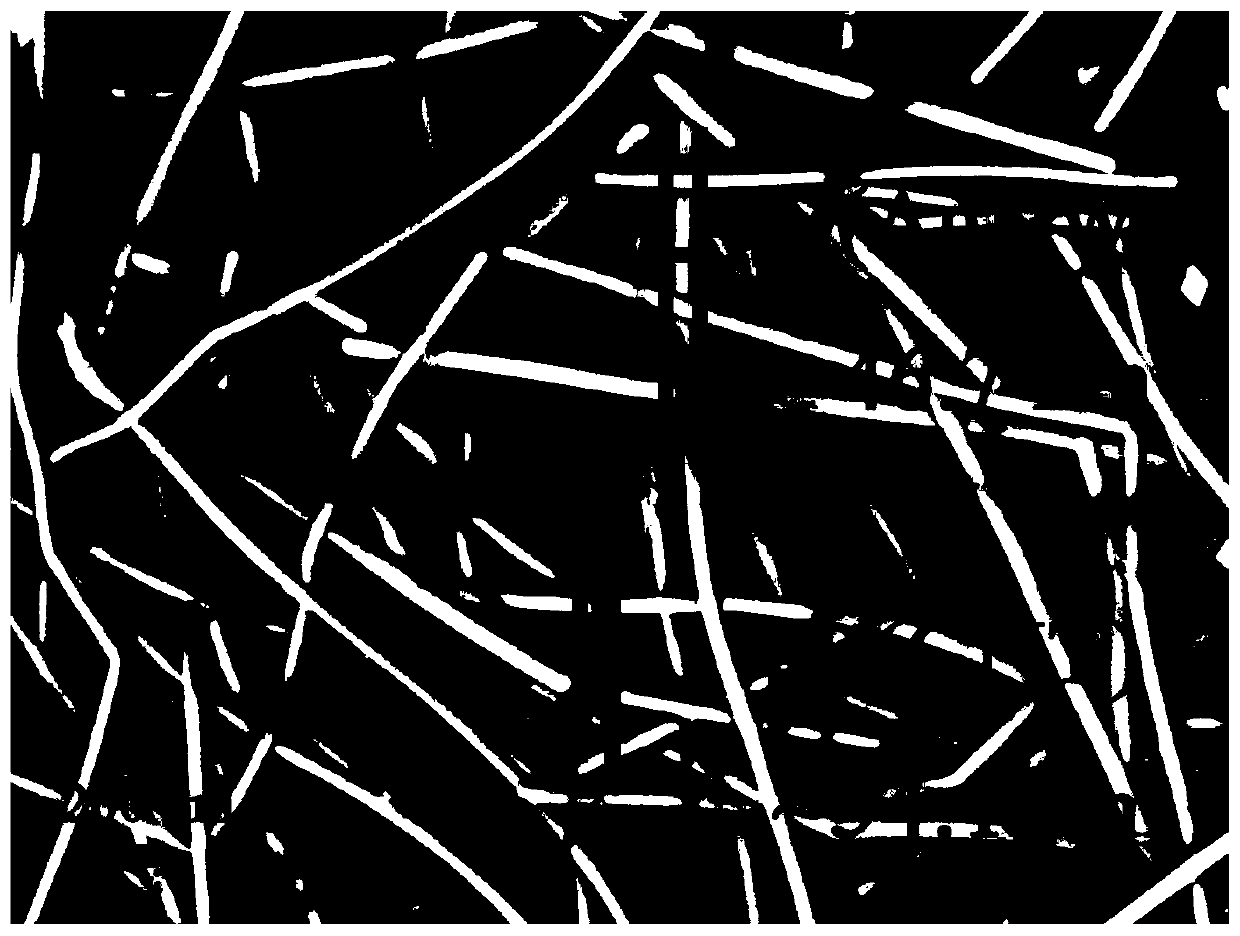

[0029] 1) Weigh 1.33 mg of multi-walled carbon nanotubes (Multi-walled carbon nanotubes, MWCNTs) powder into a test tube, add 4 mL of silver nanowires (Ag nanowires, Ag NWs)-isopropanol suspension with a concentration of 10 mg / mL, The mass ratio of MWCNTs and Ag NWs was 1:30, and the suspension of the two was stirred for 5 min and then ultrasonically dispersed for 2 h to obtain a more uniformly dispersed MWCNTs-Ag NWs hybrid material. Note that the mixture should be stirred for 5 minutes every 30 minutes of ultrasonic dispersion to ensure that MWCNTs and Ag NWs can be more uniformly dispersed;

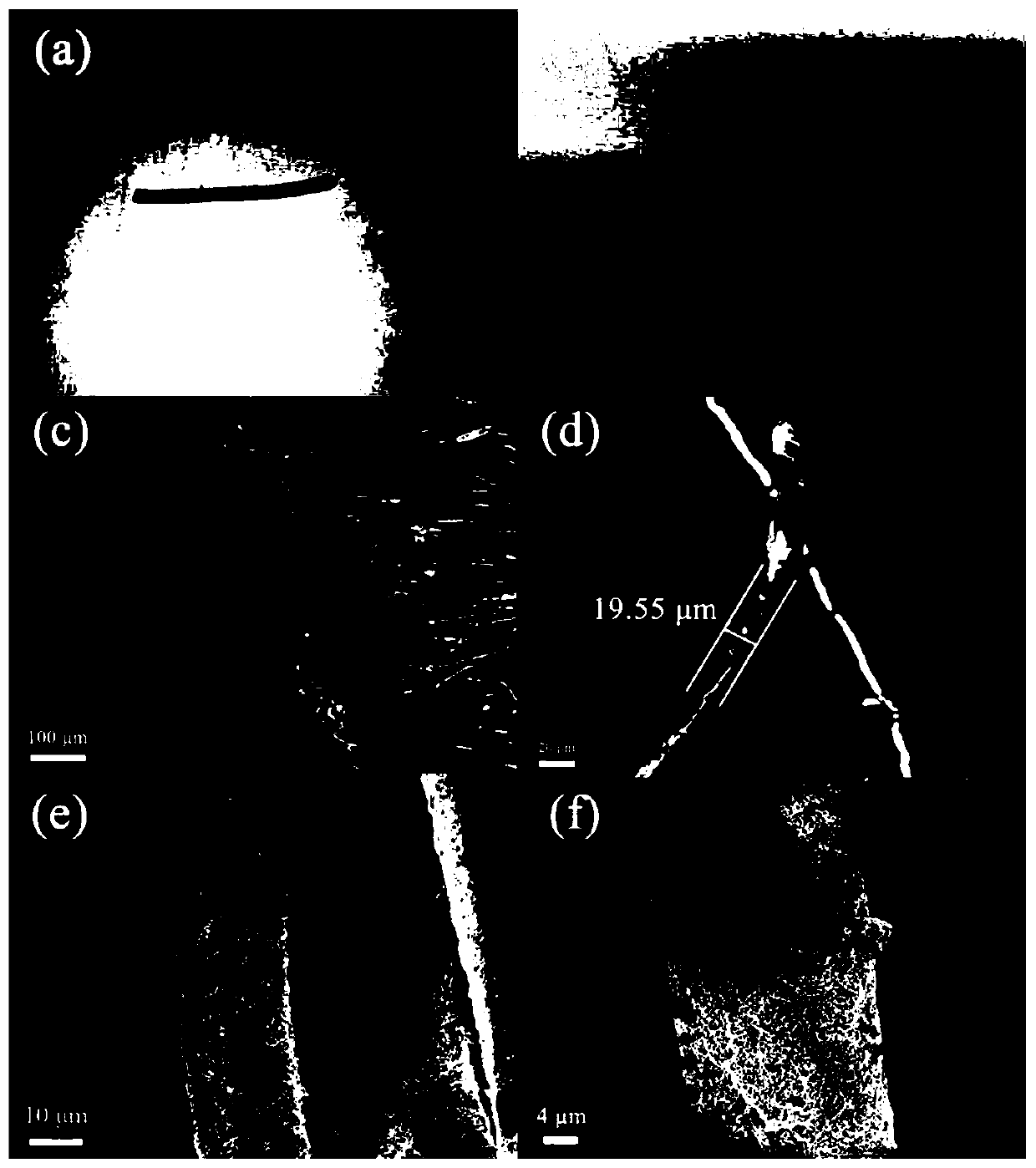

[0030] 2) The elastic rope whose surface is cotton textile fiber is cut into a small section with a length of 20 mm, cleaned with ethanol and deionized water, and cleaned with N 2 Blow dry, then immerse in the suspension of the MWCNTs-Ag NWs hybrid material prepared in 1), ul...

Embodiment 2

[0036] 1) Weigh 1.60mg of carbon nanofiber powder into a test tube, add 5mL of copper nanowires (Cuanowires, Cu NWs)-isopropanol suspension with a concentration of 10mg / mL, stir the suspension of the two for 5min and then ultrasonically disperse for 2h , to obtain a more uniformly dispersed carbon nanofiber-Cu NWs hybrid material. Note that the mixture should be stirred for 5 minutes every 30 minutes of ultrasonic dispersion to ensure that the carbon nanofibers and Cu NWs can be more uniformly dispersed;

[0037] 2) the surface is that the elastic rope of nylon textile fiber is cut into the segment that length is 30mm, cleans up with ethanol and deionized water, uses N 2 Blow dry, and then immerse in the suspension of the carbon nanofiber-Cu NWs hybrid material prepared in 1), ultrasonic 2h makes the carbon nanofiber-Cu NWs hybrid material more evenly adhere to the nylon fiber surface of the outer layer of the elastic rope;

[0038] 3) Take out the elastic rope, put it in the...

Embodiment 3

[0040]1) Weigh 2.0mg of carbon nanofiber powder into a test tube, add 5mL of gold nanowires (Aunanowires, Au NWs)-isopropanol suspension with a concentration of 20mg / mL, stir the suspension of the two for 5min and then ultrasonically disperse for 2h , to obtain a more uniformly dispersed carbon nanofiber-Au NWs hybrid material. Note that the mixture should be stirred for 5 minutes every 30 minutes of ultrasonic dispersion to ensure that the carbon nanofibers and Cu NWs can be more uniformly dispersed;

[0041] 2) the surface is that the elastic rope of nylon textile fiber is cut into the segment that length is 30mm, cleans up with ethanol and deionized water, uses N 2 Blow dry, and then immerse in the suspension of the carbon nanofiber-Cu NWs hybrid material prepared in 1), ultrasonic 2h makes the carbon nanofiber-Cu NWs hybrid material more evenly adhere to the nylon fiber surface of the outer layer of the elastic rope;

[0042] 3) Take out the elastic rope, put it in the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com