Process for Production of a Carboxylic Acid/Diol Mixture Suitable for Use in Polyester Production

a technology of diol mixture and carboxylic acid, which is applied in the field can solve the problems of low corrosion resistance, reduced strength at high temperatures, and limited practical use of wrought magnesium alloy, and achieve excellent formability and corrosion resistance, improve elongation and anisotropy, and reduce stacking fault energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

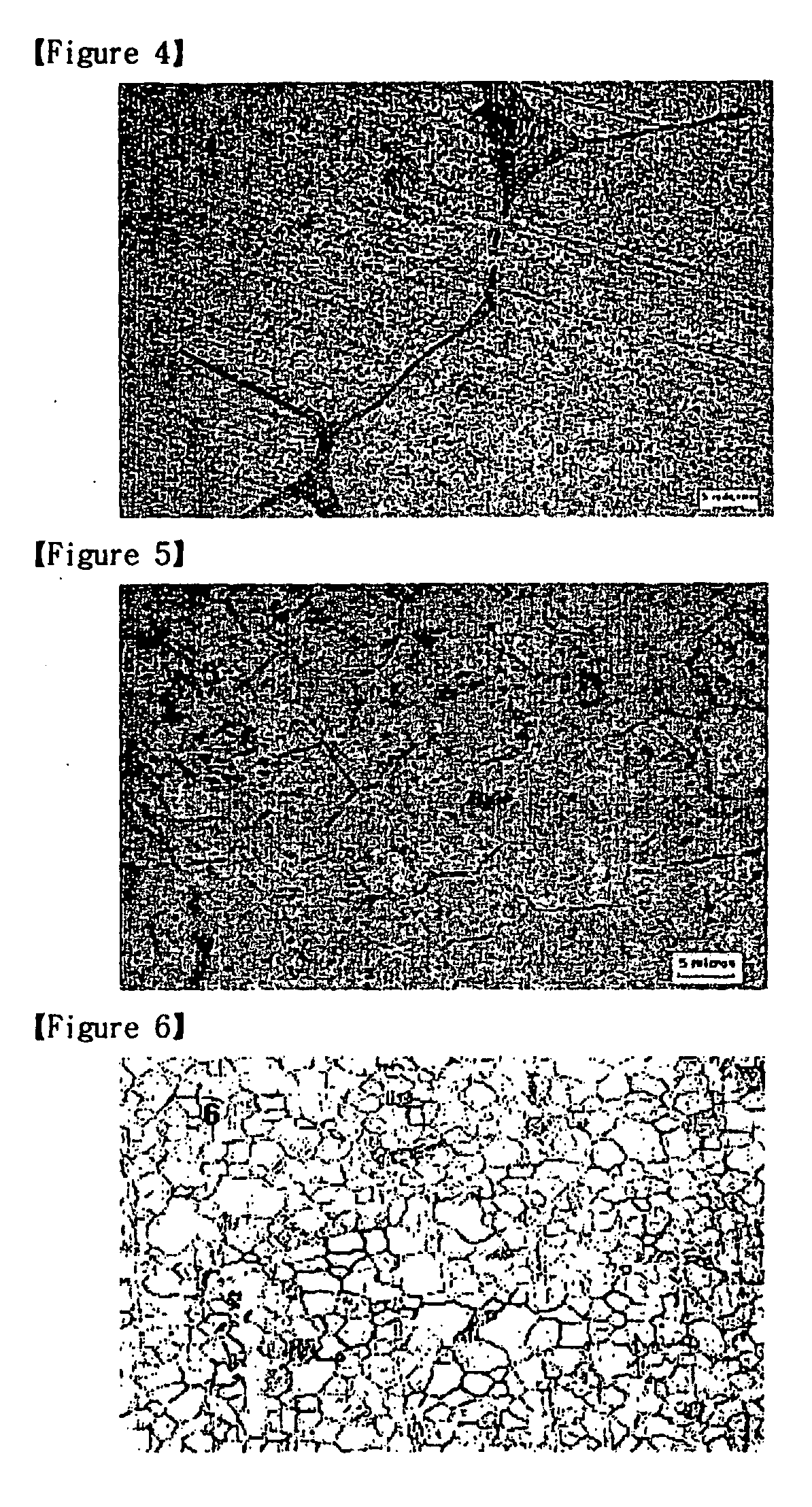

[0015]The present invention is characterized in that the fine 2nd phase precipitates, which is coherent to matrix microstructure, is formed in the solid solution microstructure having excellent ductility, thereby making grains fine and improving formability. When the grains are made fine, the strength of most materials increases. The reason is that a dislocation moves along the specific slip plane in the course of plastic deformation of the metal in such a way that the dislocation does not directly move from one grain to another grain. But direction of dislocation changes its route because of the grain boundary barrier effect. Accordingly, since the grain boundaries act as barriers in the movement of the dislocation, dislocations are pile up at a grain boundary, thereby preventing deformation. The high temperature stable phase must be capable of being formed in order to make the grain fine, and desired solid solubility must be assured at high temperatures in order to be coherent to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com