Binary composite structure type nickel boron alloy coating and preparation method and application thereof

A nickel-boron alloy and binary compound technology, which is applied in the direction of metal material coating technology, coating, liquid chemical plating, etc., can solve the problems of complex processing procedures, poor heat dissipation performance, environmental pollution, etc., and achieve simple processing procedures, Good adhesion and lower surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

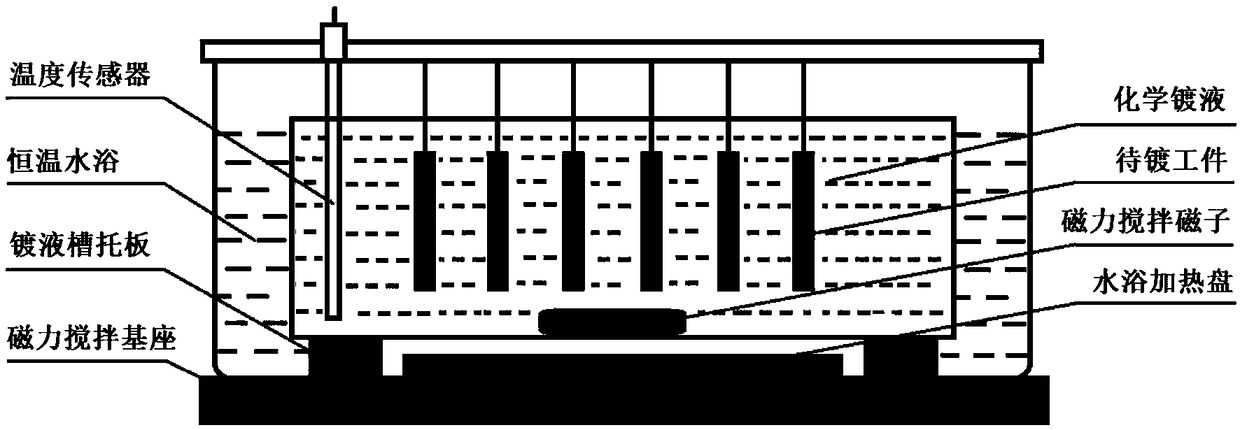

[0026] Specifically, as image 3 Shown, the preparation method of this binary composite structure nickel-boron alloy coating can comprise the following steps:

[0027] Step a, degreasing, ultrasonic cleaning and drying are performed on the workpiece to be plated to obtain a workpiece to be plated with a clean surface.

[0028] Step b. Put the workpiece to be plated with a clean surface into the chemical plating solution for chemical plating treatment, and magnetically stir the chemical plating solution through the action of the magnetic stirring base and the magnetic stirring magnet, and control the plating through a constant temperature water bath at the same time Temperature, the conditions of electroless plating are: pH value is 13-14, plating temperature is 85-95°C, and plating time is 1-5h, so as to obtain plated workpieces treated by chemical plating;

[0029] Wherein, described electroless plating solution comprises each component of following parts by weight:

[0030...

Embodiment 1

[0040] A stainless steel plate sample of 80 mm × 40 mm × 5 mm is used as the workpiece to be plated, and a binary composite structure nickel-boron alloy coating is prepared on the surface of the workpiece to be plated. The specific preparation method may include the following steps:

[0041] Step a1, degreasing, ultrasonic cleaning and drying treatment are performed on the workpiece to be plated to obtain a workpiece to be plated with a clean surface.

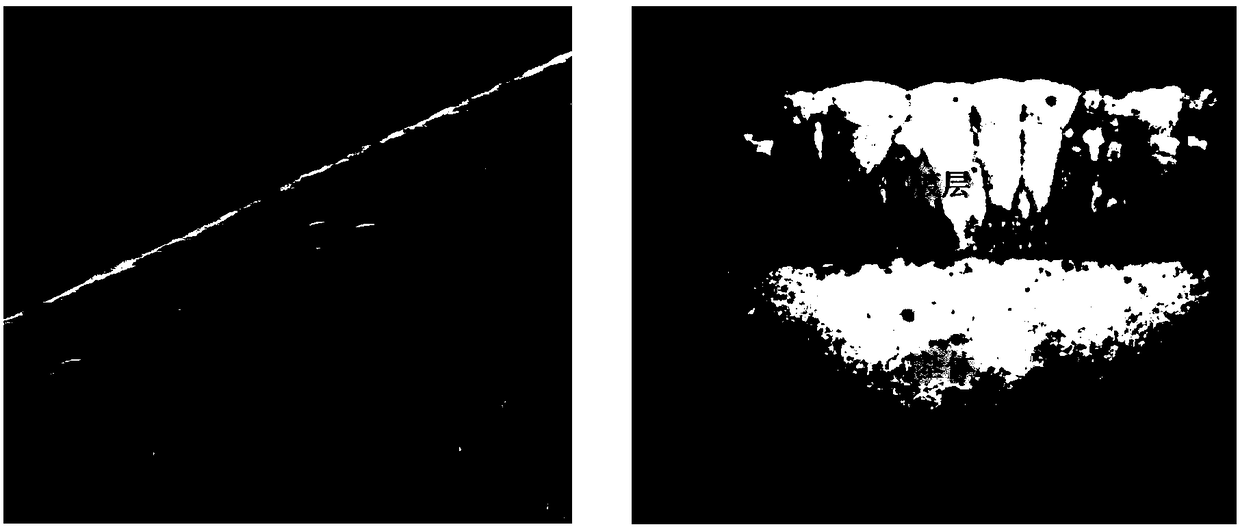

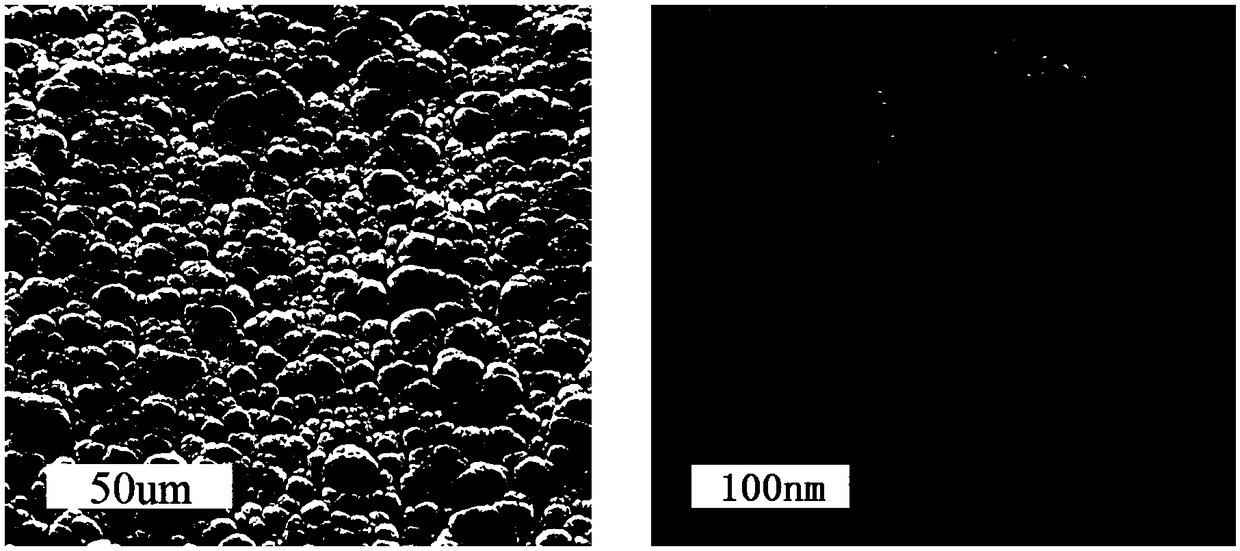

[0042] Step b1, put the workpiece to be plated with a clean surface into the chemical plating solution with a pH value of 13 for chemical plating treatment, and magnetically stir the chemical plating solution to eliminate the concentration polarization of the chemical plating solution and uniform solution composition , improve the uniformity of the coating, and at the same time control the coating temperature to 90±1°C and the coating time to 1h through a constant temperature water bath, so as to obtain the coated workpiece afte...

Embodiment 2

[0049] A circular saw blade of Ф180 mm × 1.1 mm for cutting red oak is used as the workpiece to be plated, and a binary composite structure nickel-boron alloy coating is prepared on the surface of the workpiece to be plated. The specific preparation method may include the following steps:

[0050] In step a2, degreasing, ultrasonic cleaning and drying are performed on the workpiece to be plated to obtain a workpiece to be plated with a clean surface.

[0051] Step b2, put the workpiece to be plated with a clean surface into the chemical plating solution with a pH value of 14 for chemical plating treatment, and magnetically stir the chemical plating solution to eliminate the concentration polarization of the chemical plating solution and uniform solution composition , improve the uniformity of the coating, and at the same time control the coating temperature to 85±1°C and the coating time to 3.5 hours through a constant temperature water bath, so as to obtain the coated workpiec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com