Laser semi-solid processing preparation method of high-strength high-toughness metal material, high-strength high-toughness metal material, and application thereof

A semi-solid, tough metal technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of difficult to obtain high density, difficult to prepare semi-solid slurry, complex shape and other problems in additive manufacturing technology, and achieve good popularization and application Prospect, broad versatility and practicality, excellent performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

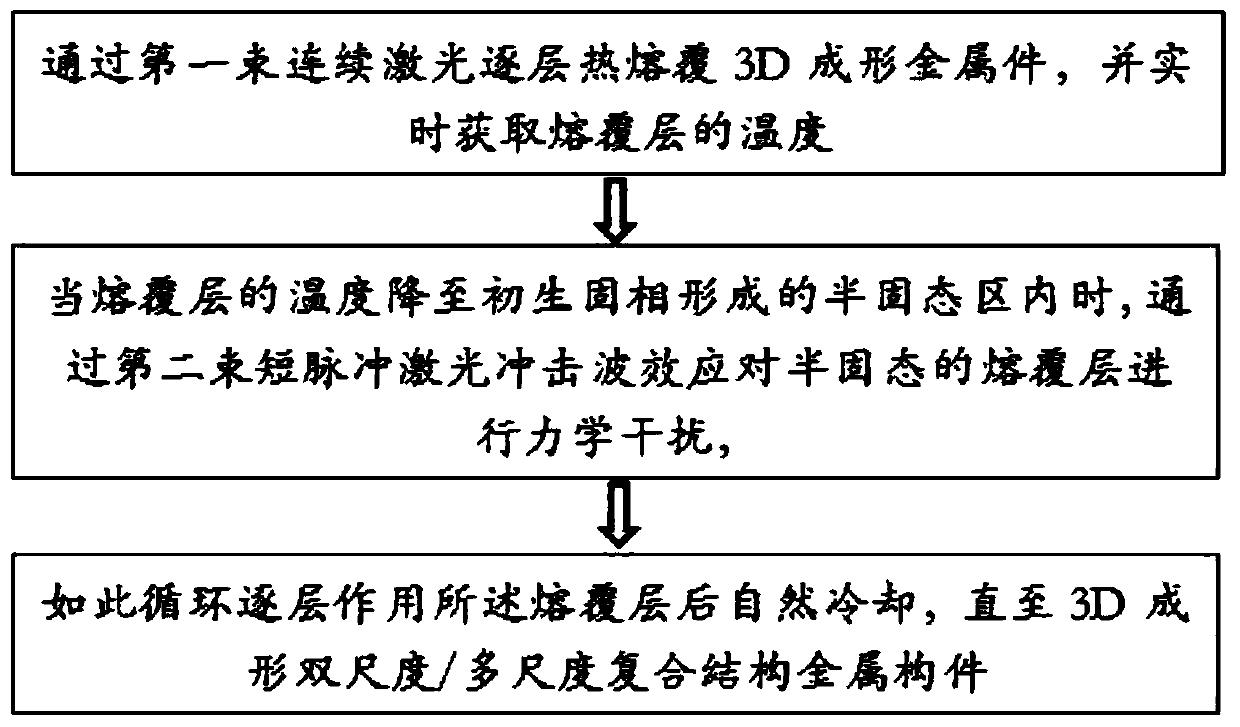

Method used

Image

Examples

Embodiment 1

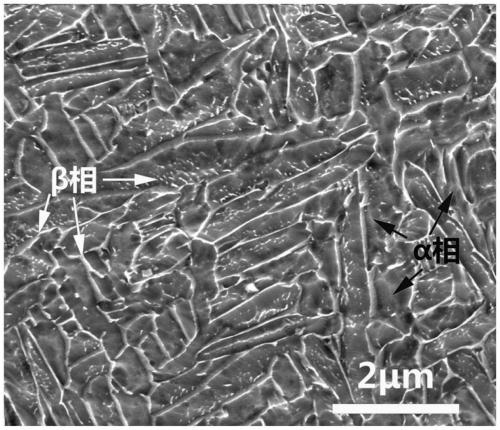

[0044] The embodiment of the present invention provides a high-strength and tough metal material and its laser semi-solid processing preparation method, which overcomes the "single structure", "quality defect", "anisotropy", " Thermal stress" and other common basic problems, while improving the comprehensive mechanical properties of metal parts.

[0045] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present inv...

Embodiment 2

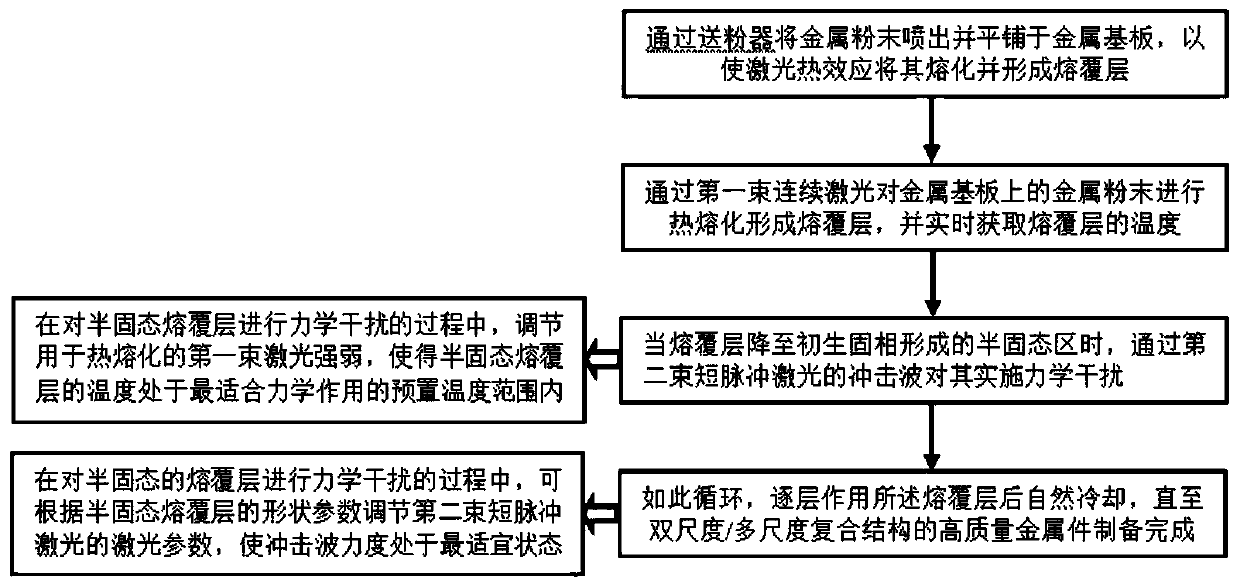

[0059] see figure 2 , another embodiment of a method for preparing a high-strength and tough metal material by laser semi-solid processing, including:

[0060] Step 1. Spray the specified Ti-6Al-4V atomized spherical powder from the nozzle through the powder feeder and spread it on the titanium alloy substrate so that it can be melted by the laser thermal effect to form a cladding layer;

[0061] In this example, in order to make the Ti-6Al-4V metal powder more optimal for laser semi-solid additive manufacturing of multi-scale composite structure metal parts, the metal powder is uniformly screened with a 200-mesh steel sieve.

[0062] Step 2. Through the first continuous laser beam, the Ti-6Al-4V metal powder sprayed by the powder feeder onto the titanium alloy substrate is thermally melted to form a cladding layer, and the temperature of the cladding layer is obtained in real time through a thermocouple temperature measuring device;

[0063] In order to monitor the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com