Composite microstructure plane and sector-shaped broken tile thrust bearing and processing method thereof

A technology of thrust bearings and processing methods, which is applied in the direction of bearings, shafts and bearings, sliding contact bearings, etc., can solve the problems that have not been involved in the texture of arc grooves, and have not been involved, so as to improve the hydrodynamic lubrication effect and improve the use of Longevity and wear-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

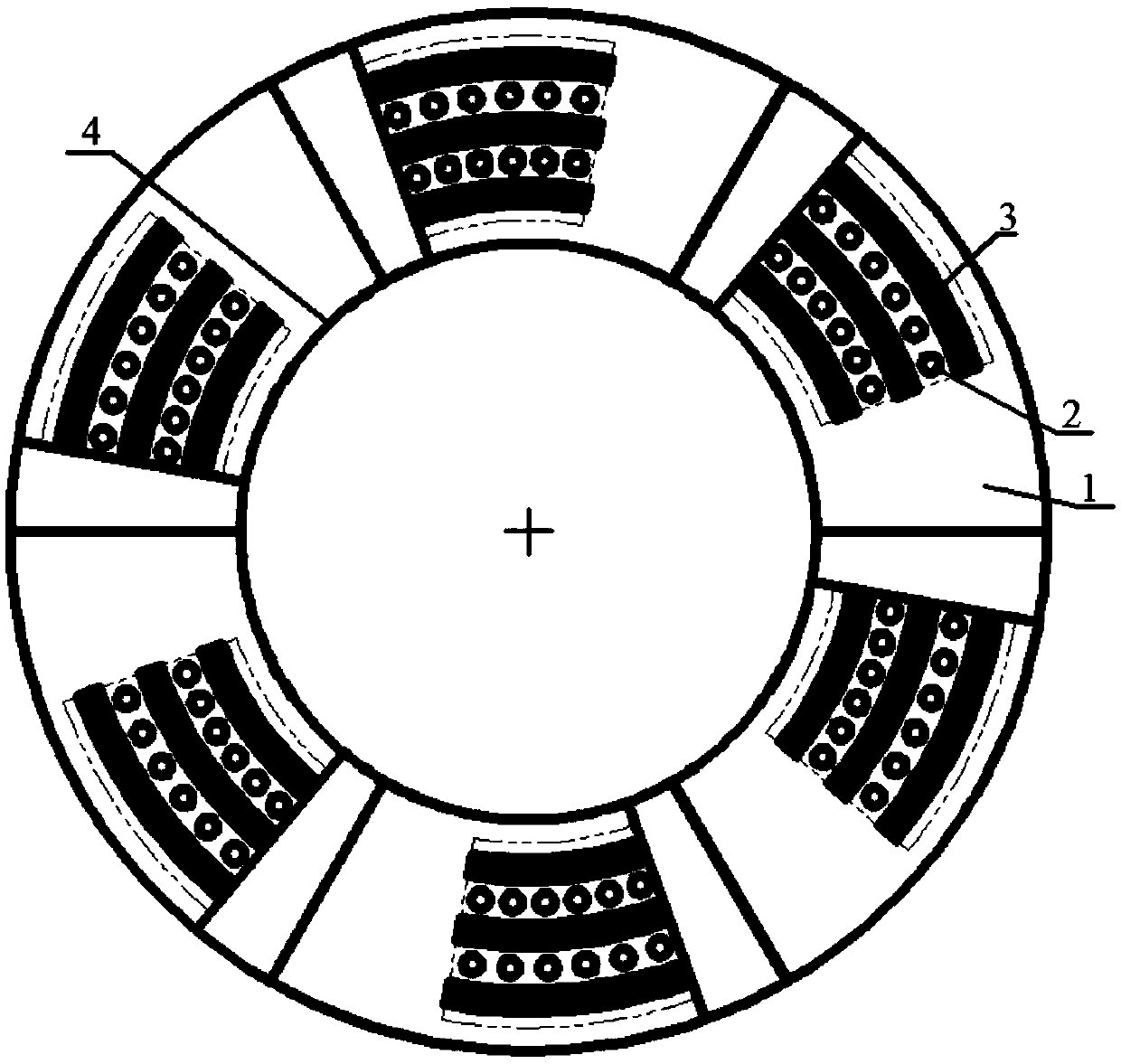

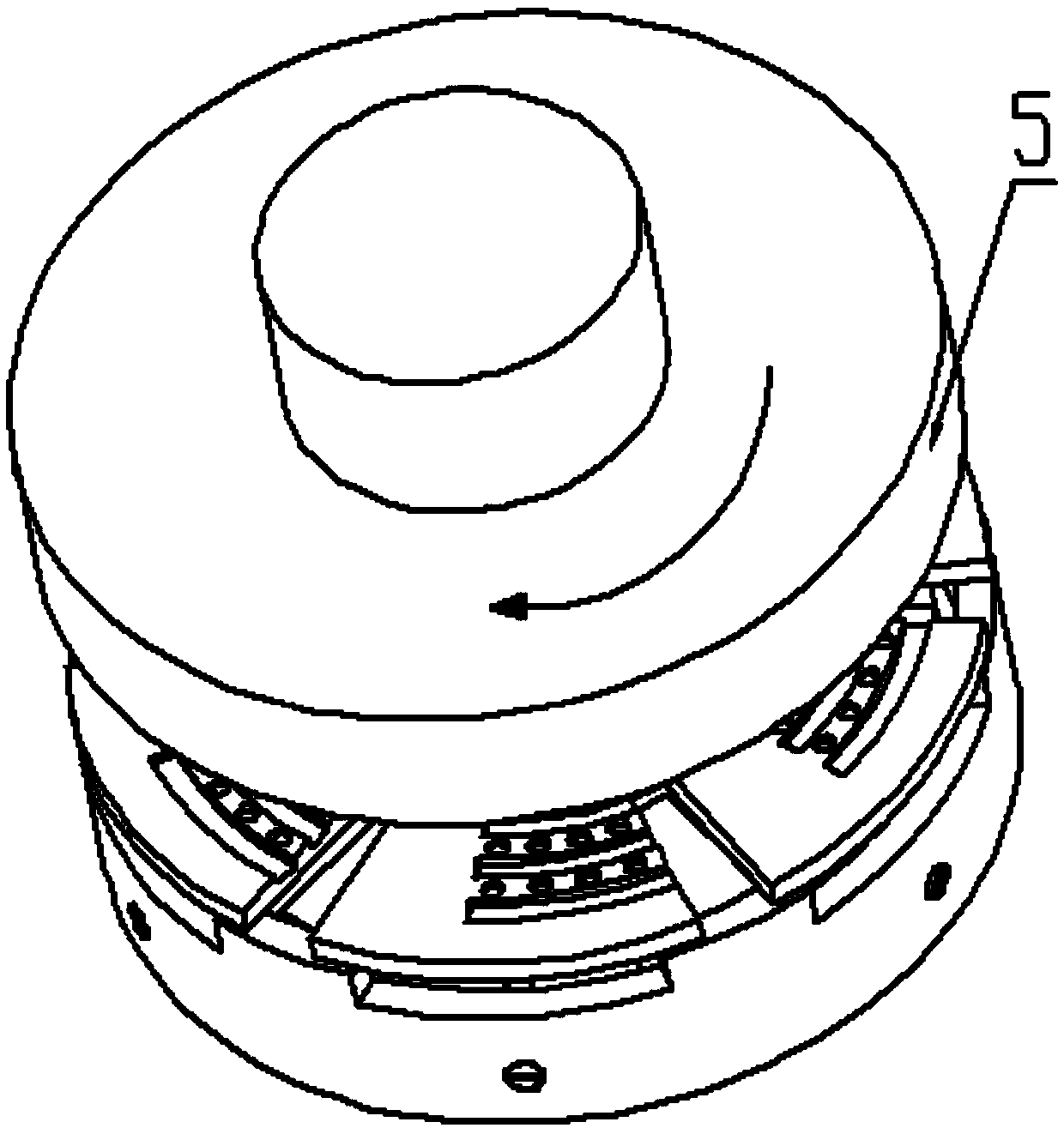

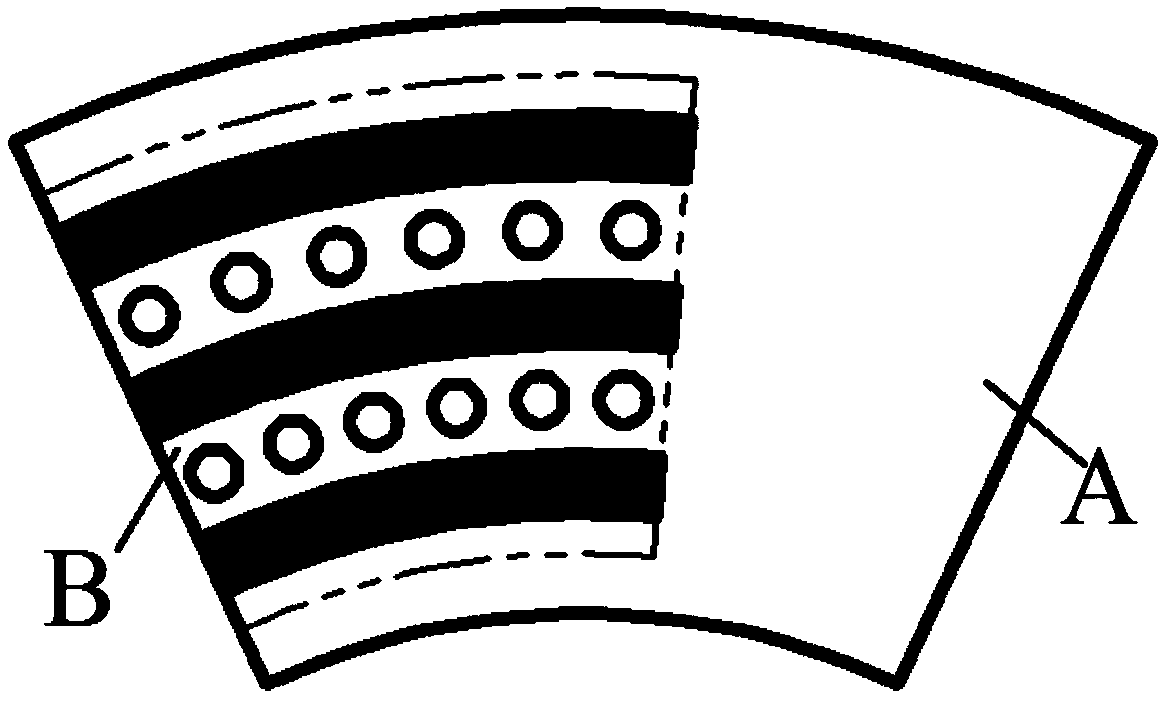

[0031] Such as figure 1 and figure 2 As shown, the composite micro-textured plane fan-shaped pad thrust bearing of the present invention includes a fan-shaped pad 1, a base ring 4 and a thrust ring 5, wherein the surface of the plane fan-shaped pad 1 is provided with a local composite micro-texture Morphology, the composite micro-texture morphology includes arc-shaped groove texture 2 and micro-pit texture 3. Such as image 3 As shown, the arc-shaped groove texture 2 and the micro-pit texture 3 are both local textures; the local texture area is located at the entrance area of the plane fan-shaped pad thrust bearing. A plurality of arc-shaped grooves 2 are provided in the entrance area of the plane sector pad 1 of the plane sector pad thrust bearing. The arc-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com