Spherical groove joint bearing

A technology for spherical plain bearings and inner rings of bearings, applied in the field of spherical plain bearings, can solve the problems of easy plastic deformation, wear and high manufacturing costs of liners, and achieve the effects of enhanced dynamic pressure lubrication effect and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

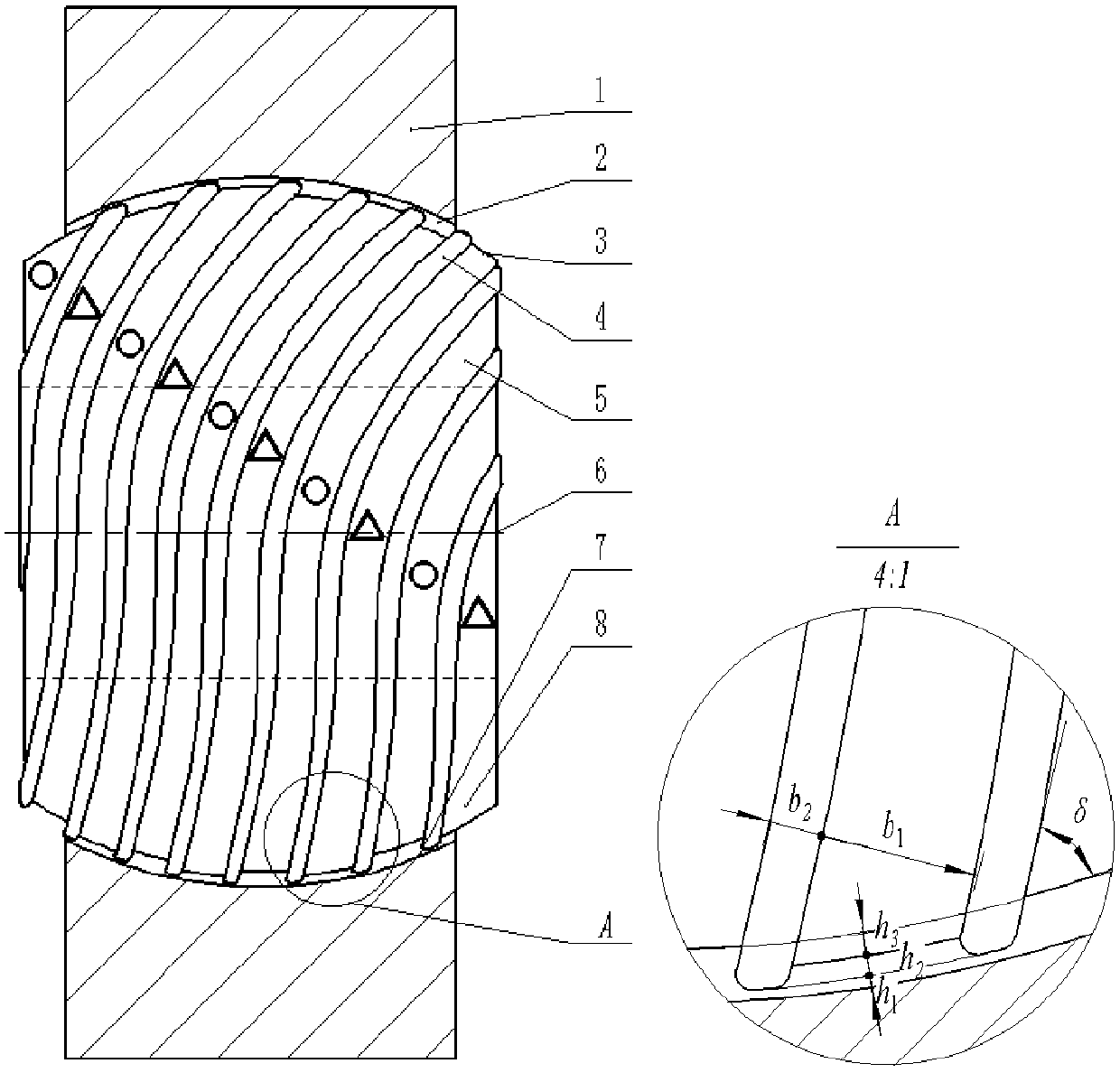

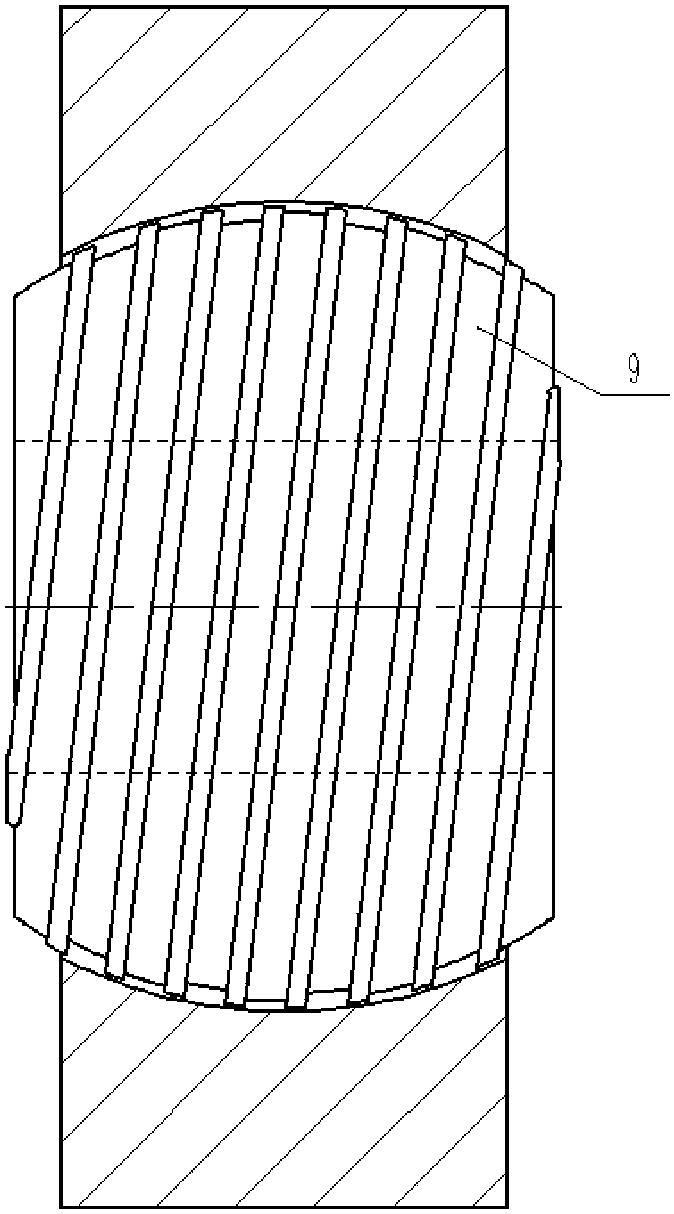

[0035] Such as figure 2 As shown, an oblique straight spiral groove 9 is used in this case.

[0036] In this case, b=0.5, h=3.6, δ=70°, and the number of slots is 9. The outer spherical surface of the inner ring is located inside the inner spherical surface of the outer ring, and can swing at any angle along the inner spherical surface of the outer ring. At the same time, under the action of the spiral groove on the outer spherical surface of the inner ring, the lubricant is retained in the bearing gap by the spiral groove to enhance the effect of dynamic pressure lubrication. And the radial bearing capacity of the bearing can be adjusted by changing the groove width ratio, groove depth ratio, helix angle and lubricating film thickness of the spiral groove.

[0037] The changing trend of the oblique straight spiral groove depth on the outer spherical surface of the bearing inner ring is different. In the same direction, the groove depth of a group of oblique linear spiral groove...

Embodiment 2

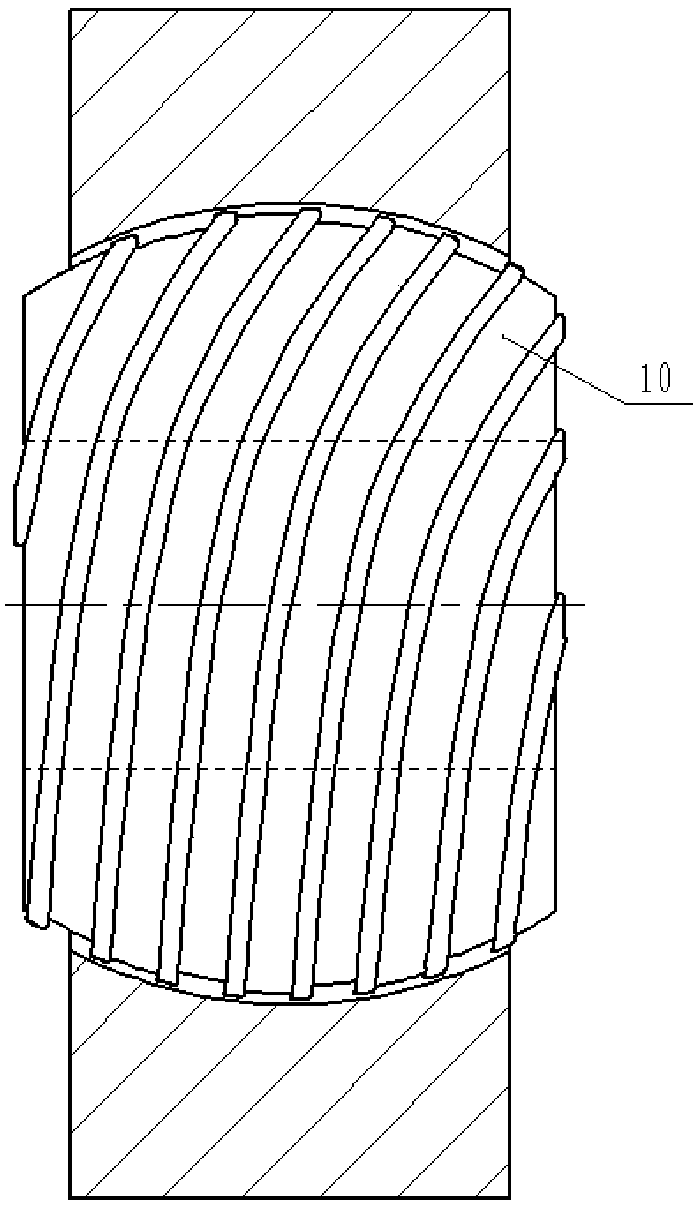

[0041] Such as image 3 As shown, in this case, a logarithmic spiral spiral groove 10 is used.

[0042] In this case, b=0.5, h=3.0, δ=70°, and the number of slots is 9. The outer spherical surface of the inner ring is located inside the inner spherical surface of the outer ring, and can swing at any angle along the inner spherical surface of the outer ring. At the same time, under the action of the spiral groove on the outer spherical surface of the inner ring, the lubricant is retained in the bearing gap by the spiral groove to enhance the effect of dynamic pressure lubrication. And the radial bearing capacity of the bearing can be adjusted by changing the groove width ratio, groove depth ratio, helix angle and lubricating film thickness of the spiral groove.

[0043] The changing trend of the depth of the logarithmic spiral spiral groove on the outer spherical surface of the bearing inner ring is different. In the same direction, the groove depth of a group of logarithmic spira...

Embodiment 3

[0047] Such as Figure 4 As shown, in this case, a circular arc slot 11 is used.

[0048] In this case, b=0.5, h=3.6, and the number of slots is 9. The outer spherical surface of the inner ring is located inside the inner spherical surface of the outer ring, and can swing at any angle along the inner spherical surface of the outer ring. At the same time, under the action of the spiral groove on the outer spherical surface of the inner ring, the lubricant is retained in the bearing gap by the spiral groove to enhance the effect of dynamic pressure lubrication. And the radial bearing capacity of the bearing can be adjusted by changing the groove width ratio, groove depth ratio, helix angle and lubricating film thickness of the spiral groove.

[0049] The changing trend of the arc groove depth on the outer spherical surface of the bearing inner ring is different. In the same direction, the groove depth of a group of circular arc grooves is changed from shallow to deep, and the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com