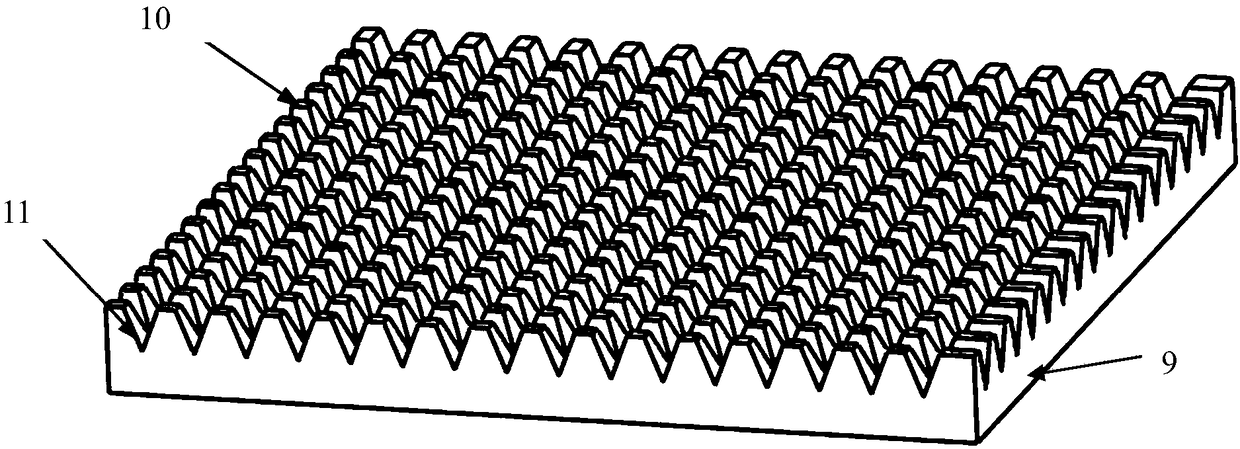

Composite microstructure current collector for lithium ion battery and preparation method of composite microstructure current collector

A composite microstructure, lithium-ion battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of excessive contact resistance between active materials and current collectors, affecting the overall performance of batteries, and low combined effective area. Achieve the effects of improving reversible capacity and capacity stability, low cost, and enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

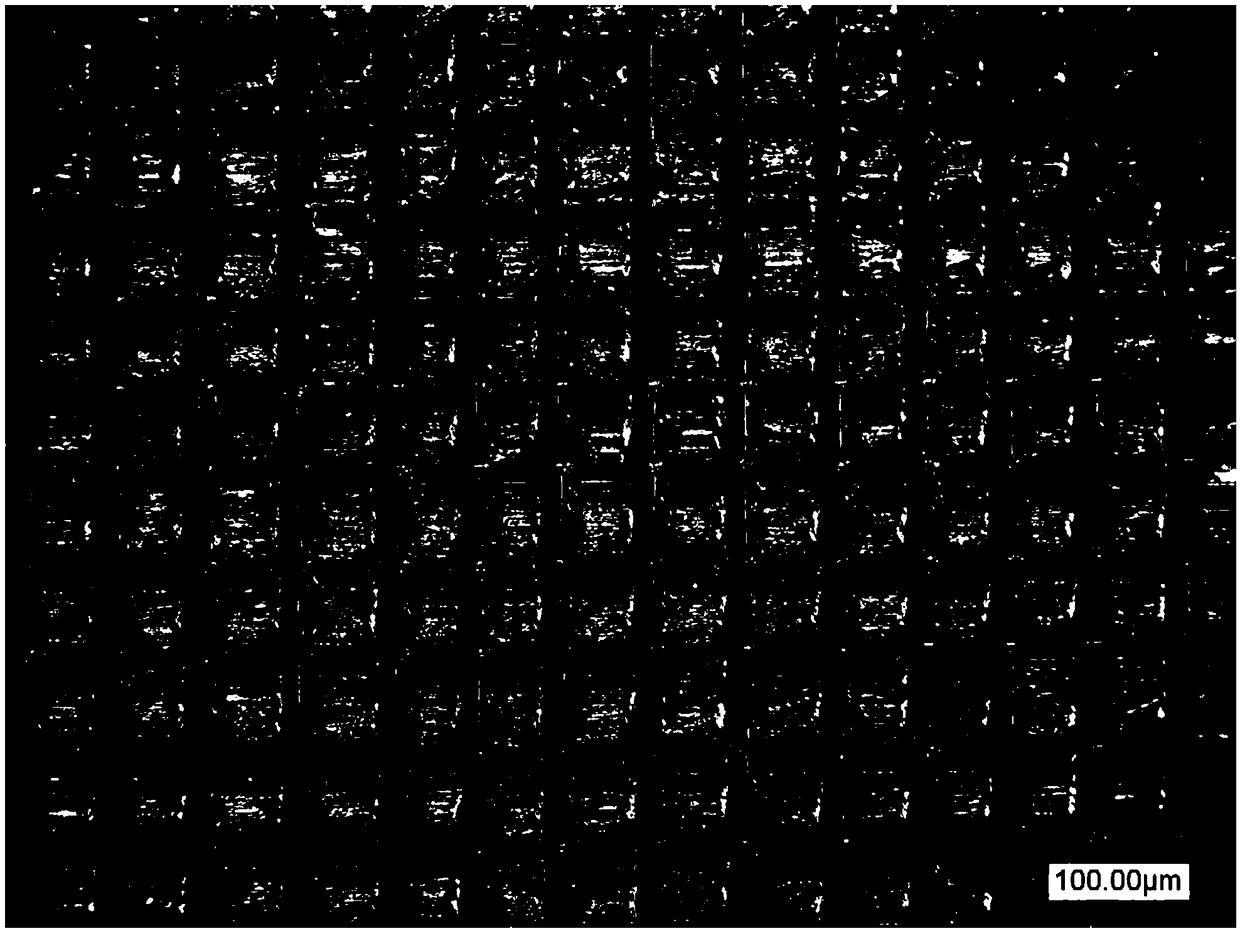

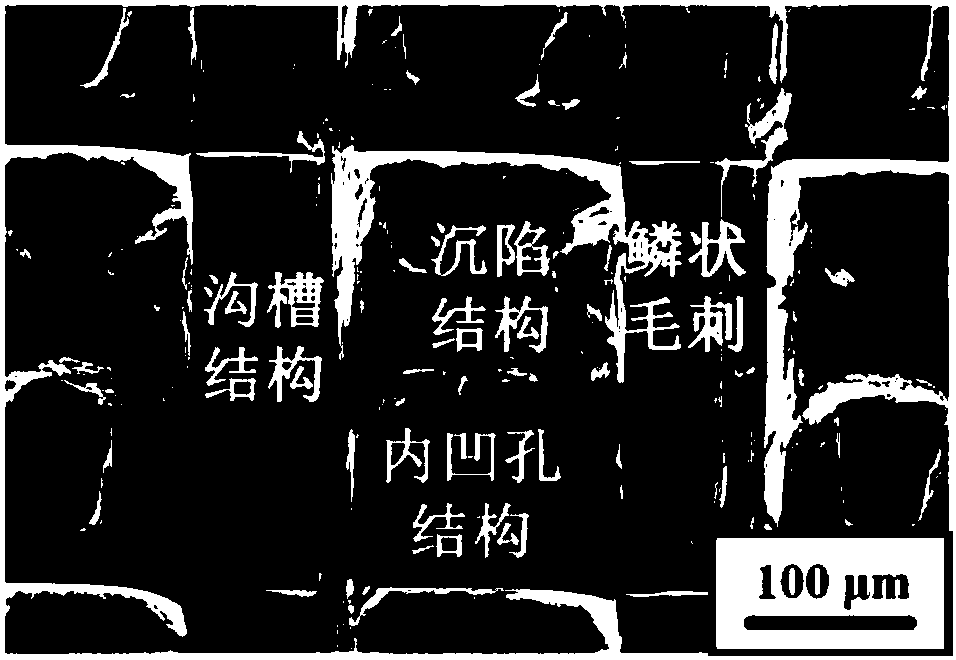

Examples

Embodiment 1

[0039] A composite microstructure current collector for lithium-ion batteries and a preparation method thereof, comprising the steps of:

[0040] (1) Design of the tool: The material of the tool is W18Cr4V. The main tool angles include: rake angle α =40°, relief angle kappa =20°, extrusion blade inclination angle β =30° and forming angle θ =20°. Other tool parameters include tool width B 0 =20mm and thickness L t =4mm (see Figure 4 ).

[0041] (2) Surface pretreatment of the circular copper sheet: use sandpaper to polish the 0.5mm thick copper sheet to make both surfaces smooth. Then soak the copper sheet in the cleaning agent for the surface of the copper clad laminate and stir continuously for 5 minutes to make the two surfaces of the copper sheet smooth.

[0042] (3) Tool clamping and workpiece fixing: Clamp the plow cutting tool on the planer, adhere the round copper sheet to the stainless steel square table with metal 502 glue, then fix the square table on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com