Patents

Literature

51results about How to "Good mechanical bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

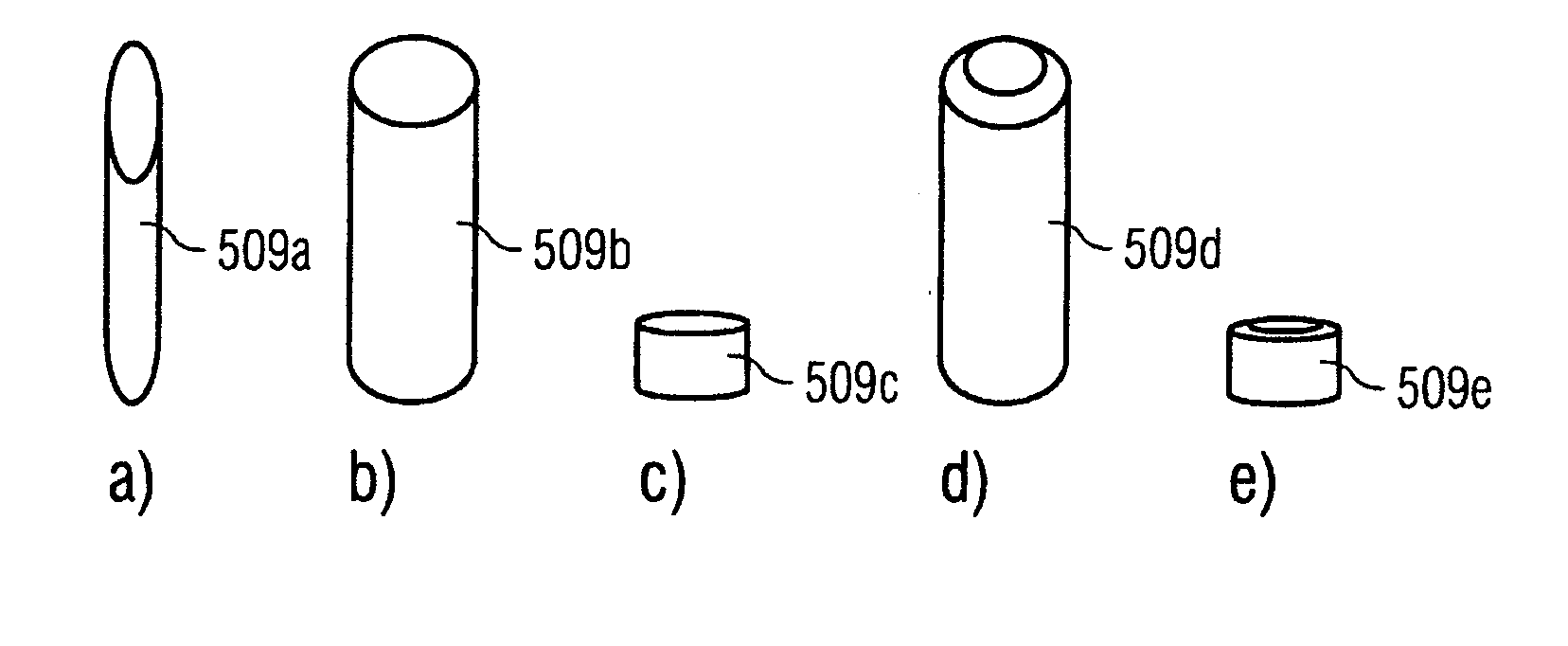

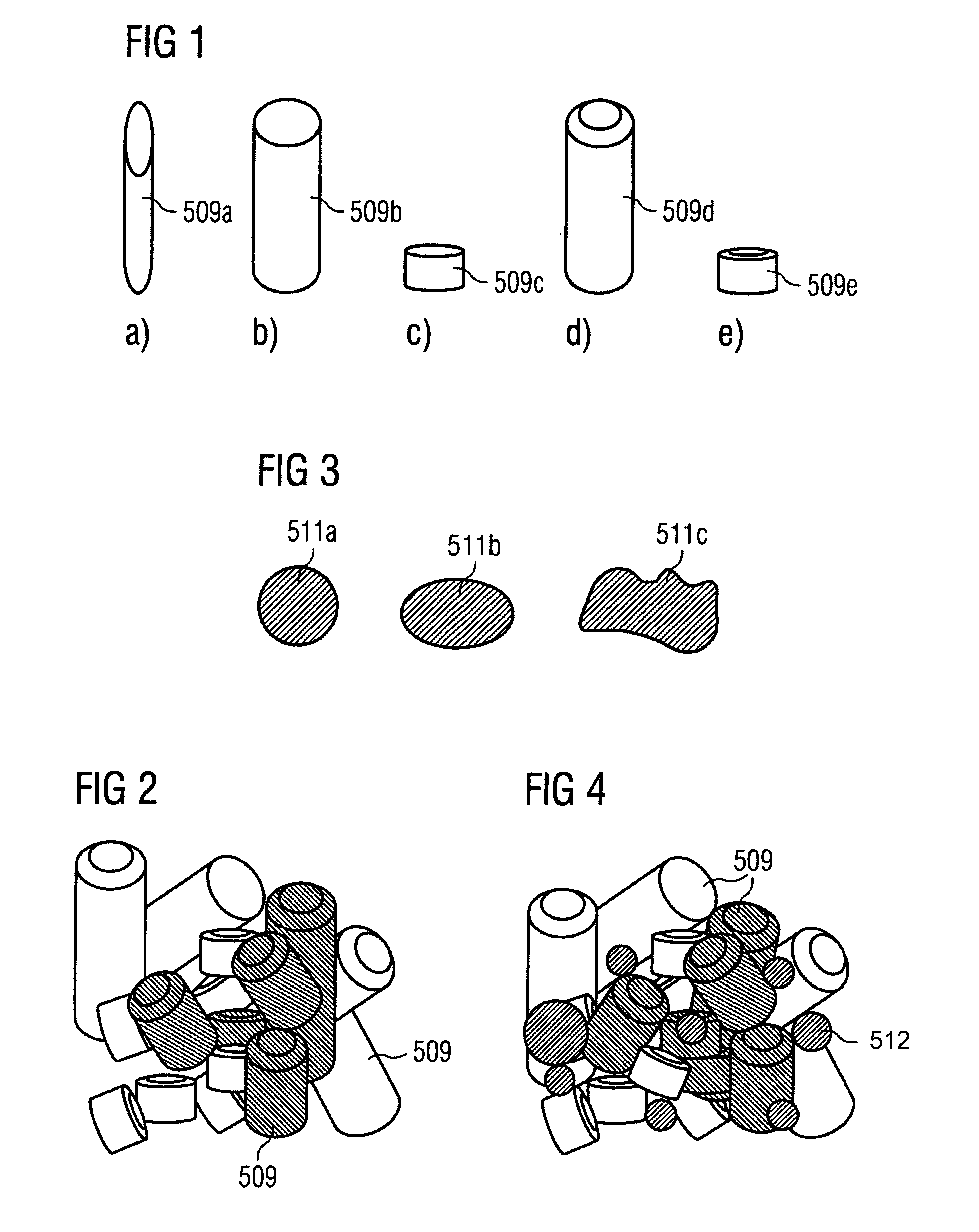

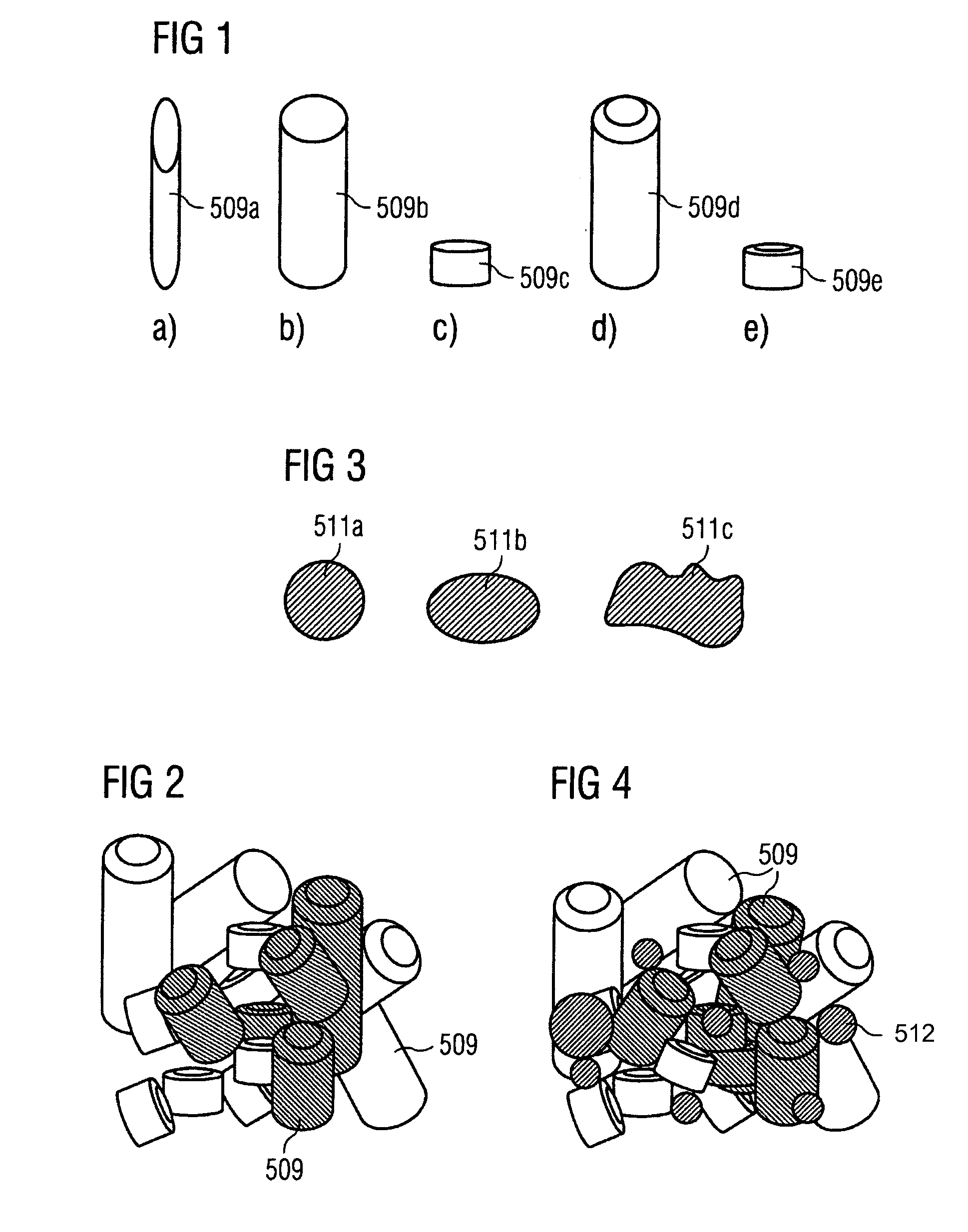

Fibers and methods for use in solid freeform fabrication

ActiveUS20110143108A1Easy to produceSpecific characteristicAdditive manufacturing apparatusSynthetic resin layered productsFiberRapid prototyping

A shaped body comprised of individual, interconnected layers may be produced from fibers in accordance with a solid freeform fabrication or rapid prototyping method. The fibers may be produced by extrusion molding a thermoplastic material.

Owner:EVONIK OPERATIONS GMBH

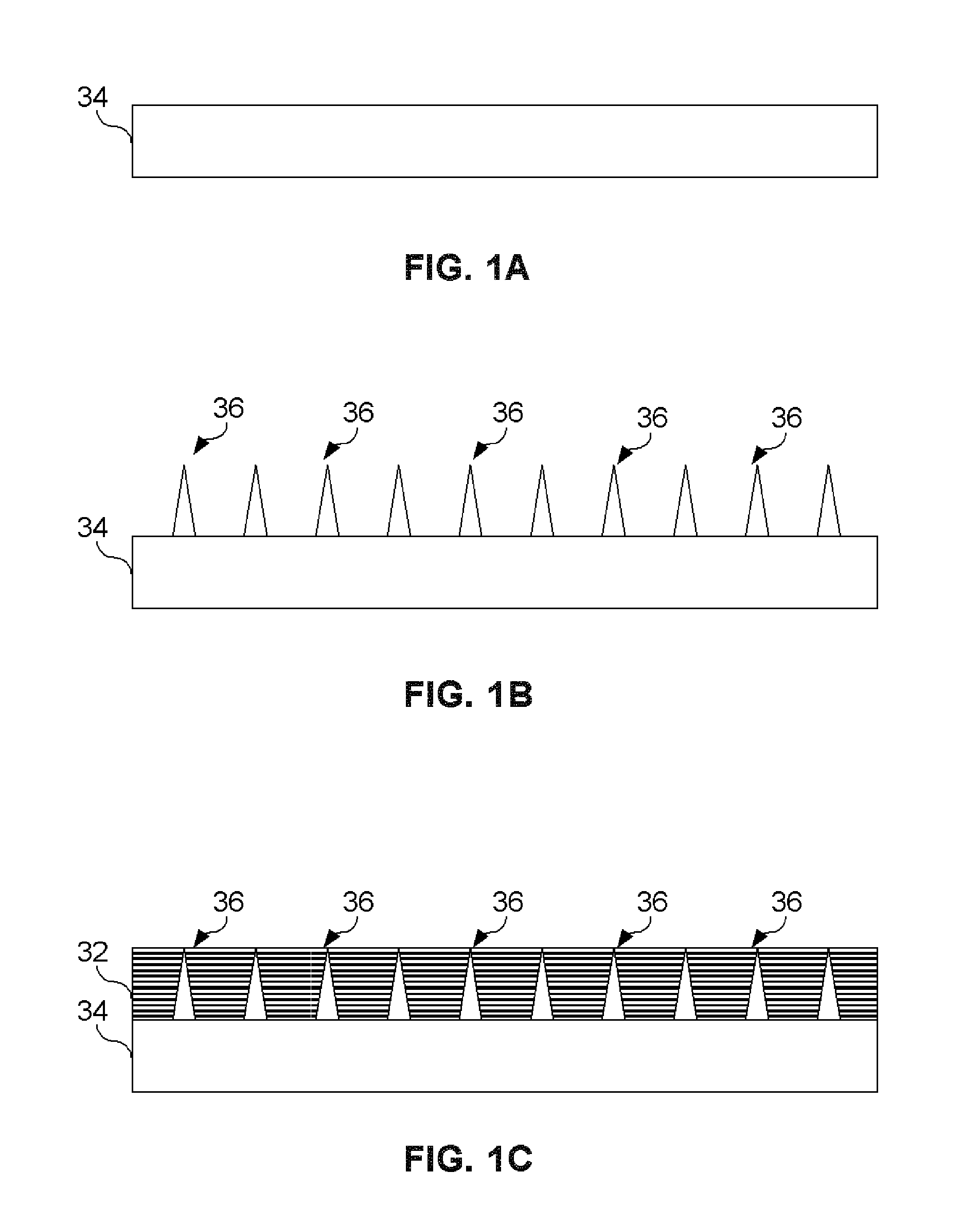

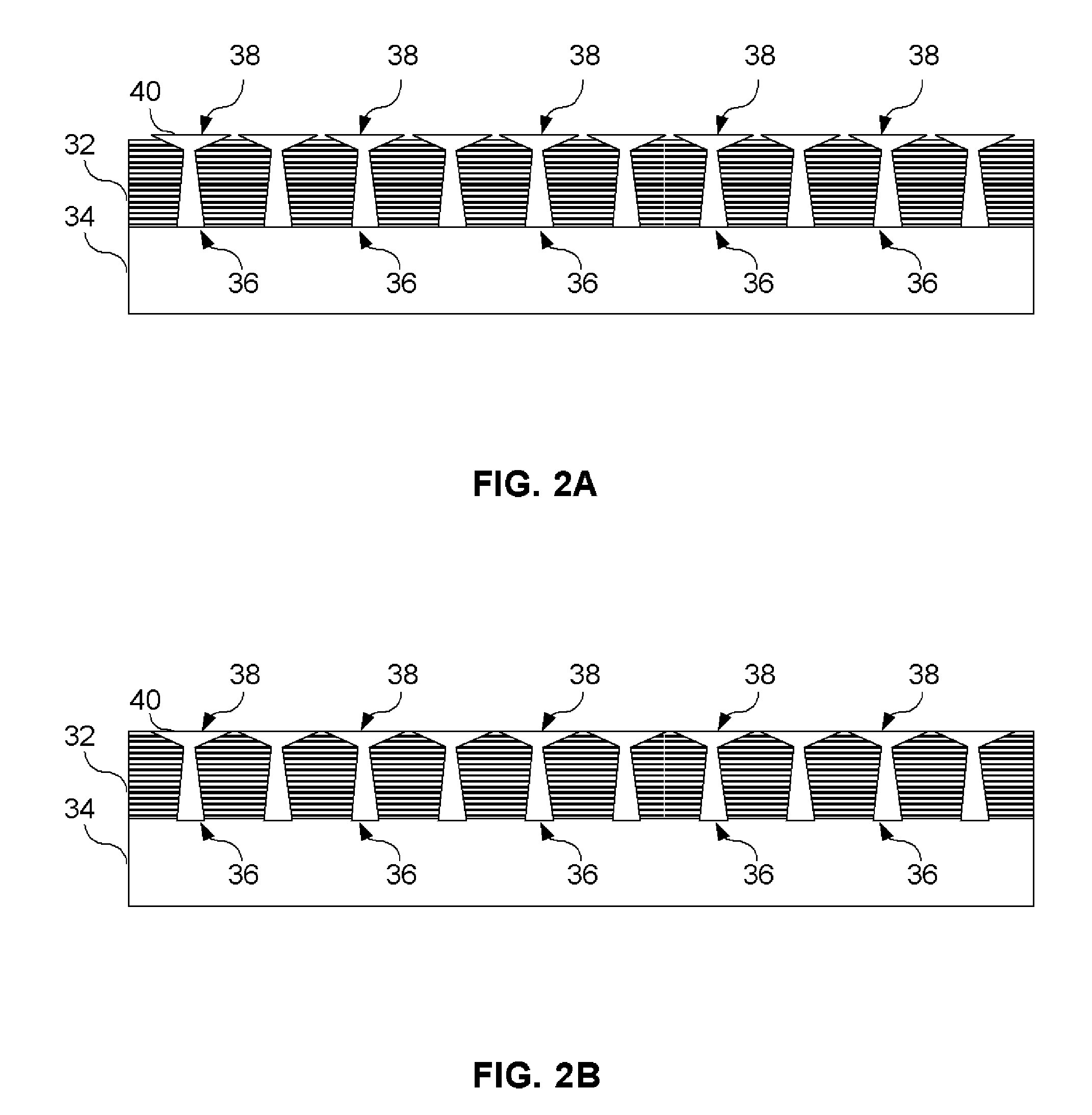

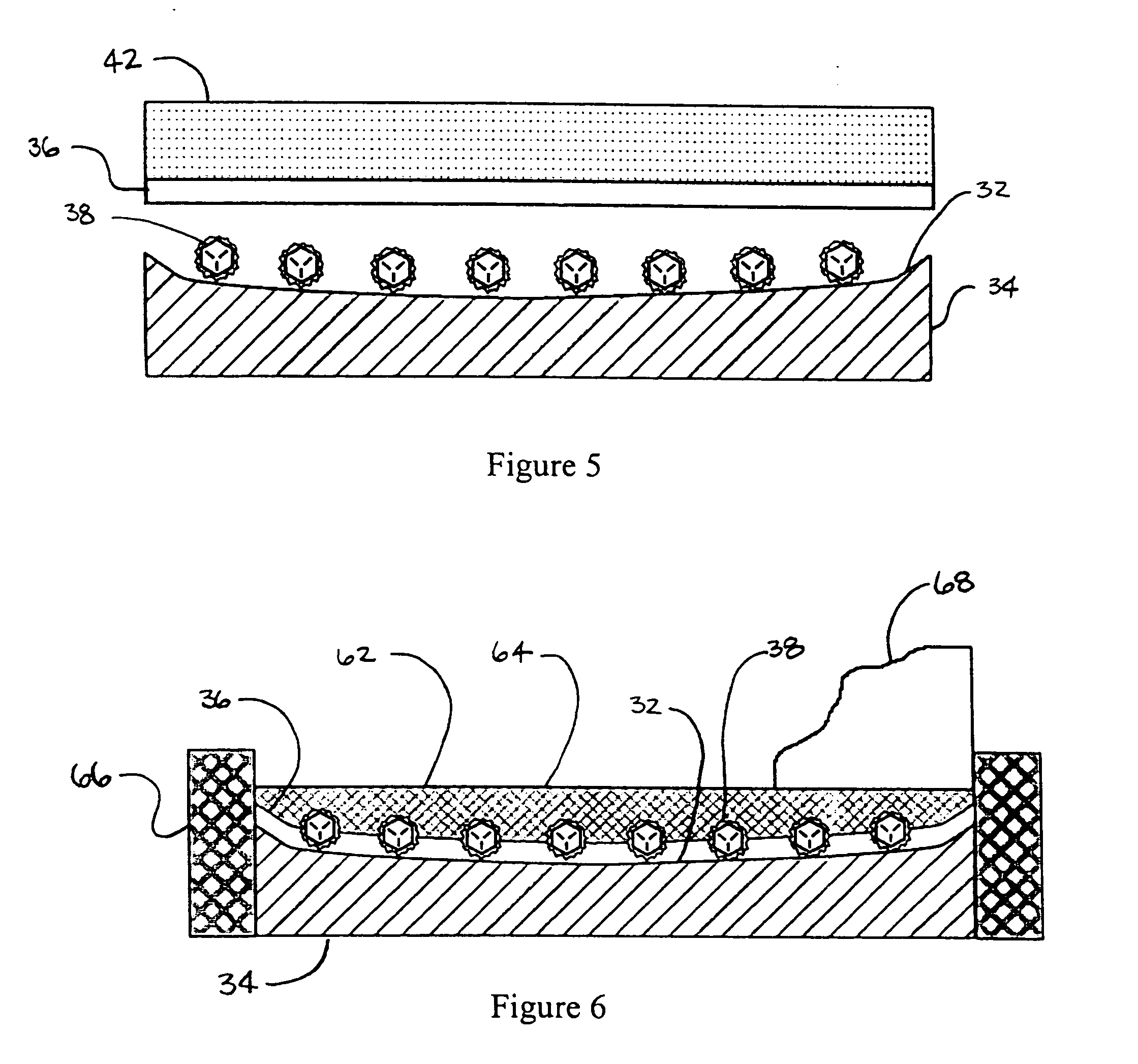

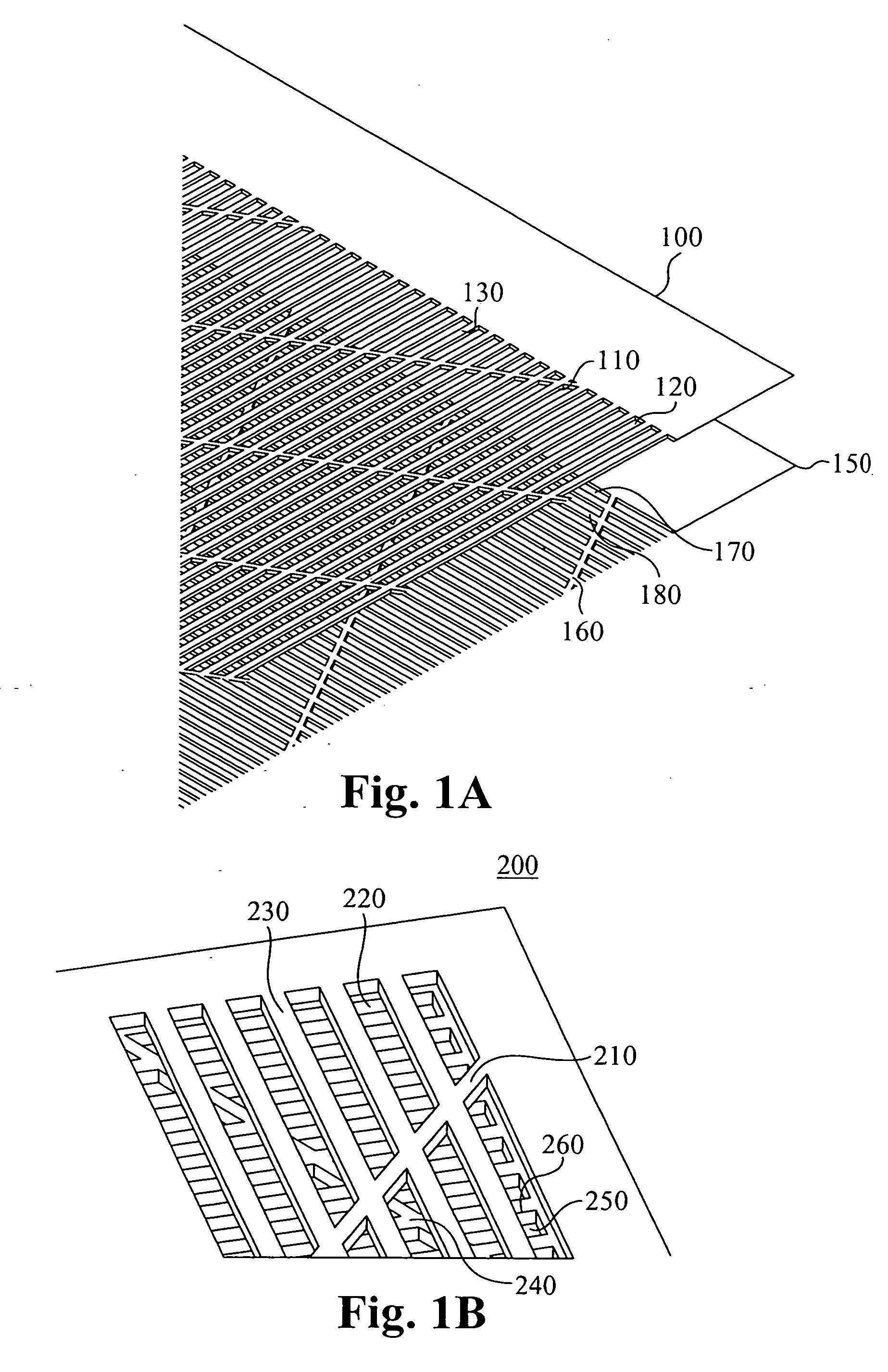

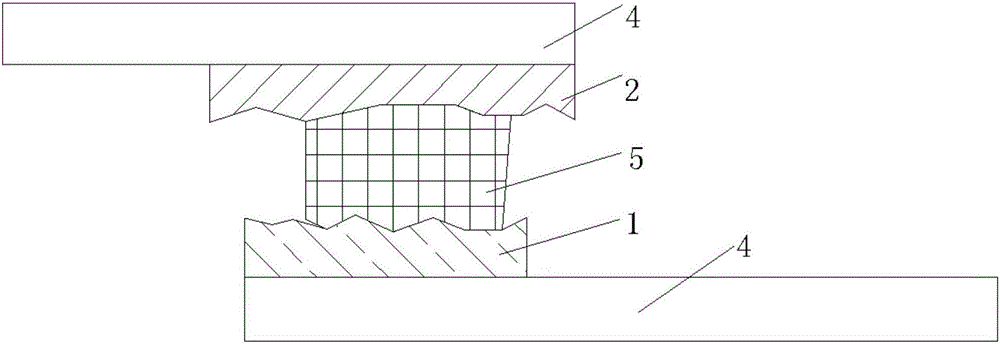

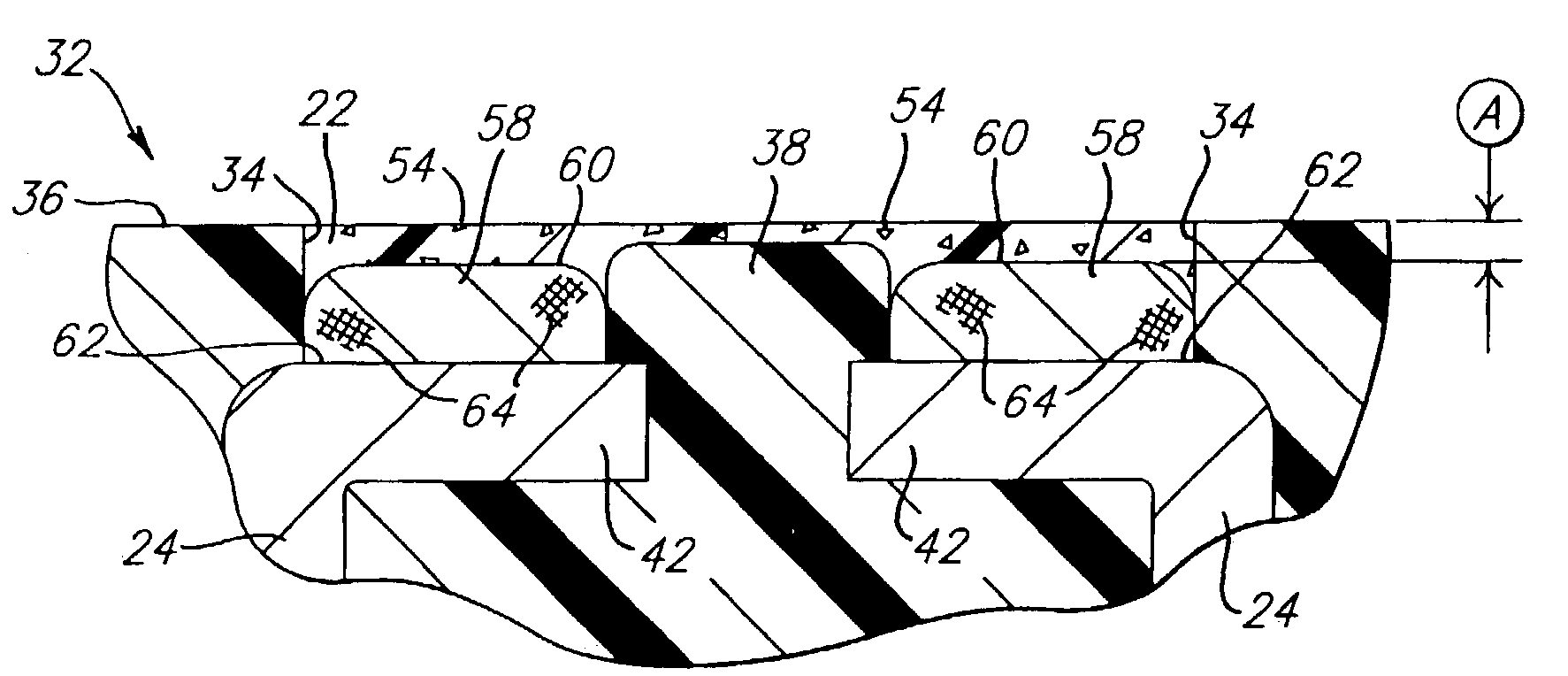

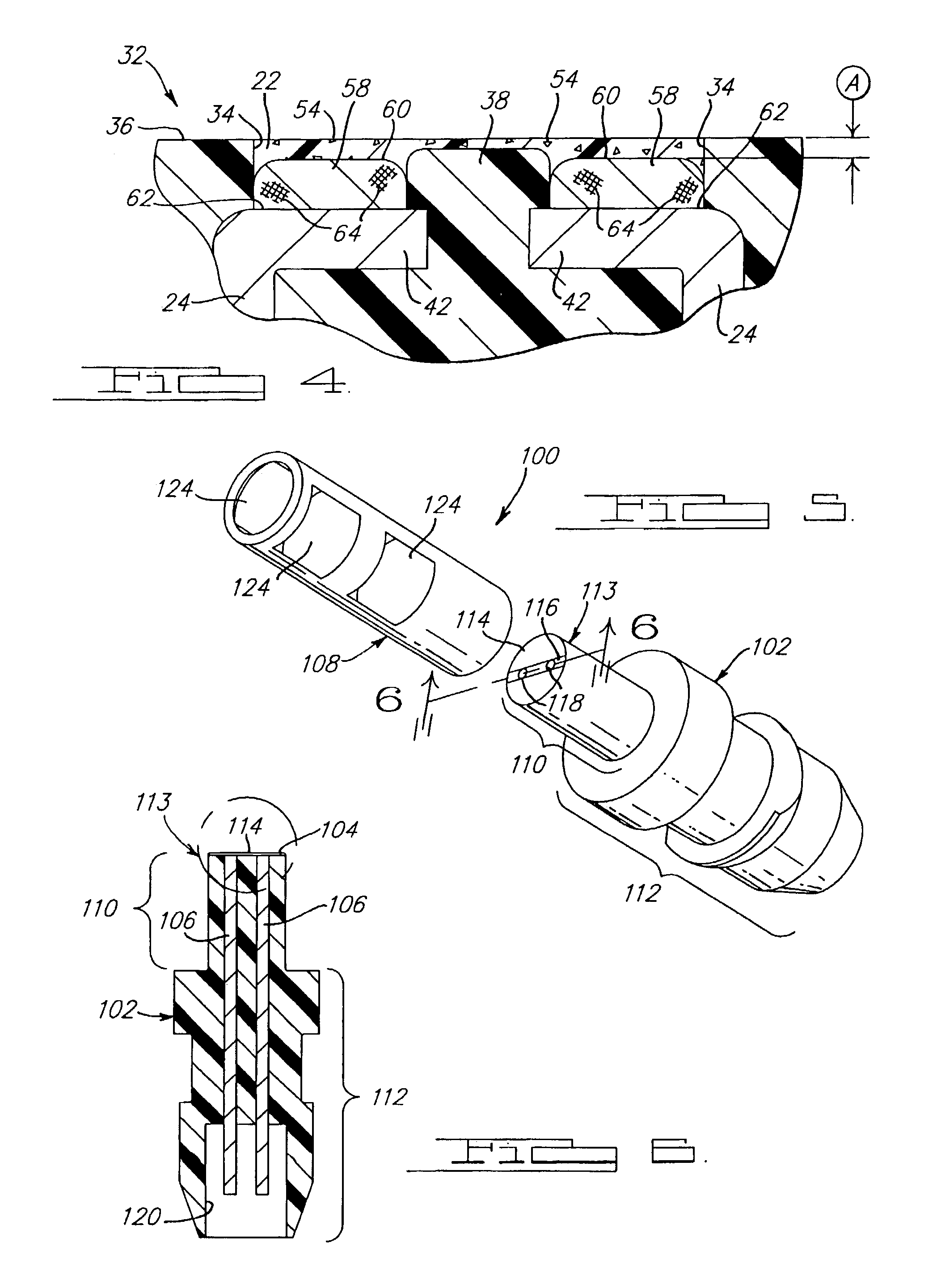

Metallic mini hooks for joining of metallic and composites

InactiveUS20080003401A1Bonding strengthGood mechanical bondLayered productsSheet joiningMetallic substrateMetal substrate

A method for joining a first structural member and a metallic substrate is provided. This method involves drawing projections from a metallic substrate using a Co-Meld or other like process. Individual plies of composite materials may be laid upon the metallic substrate and projections. These projections penetrate the individual ply or layers of the composite material. A mechanical feature that serves as a retaining device may be located at the distal end of the projections in order to prevent separation of the composite materials from the metallic substrate. The composite materials may be infused with a resin or other material to complete the formation of the composite material. Additionally, other layers of composite material may be placed over the mechanical features located at the distal ends.

Owner:LOCKHEED MARTIN CORP

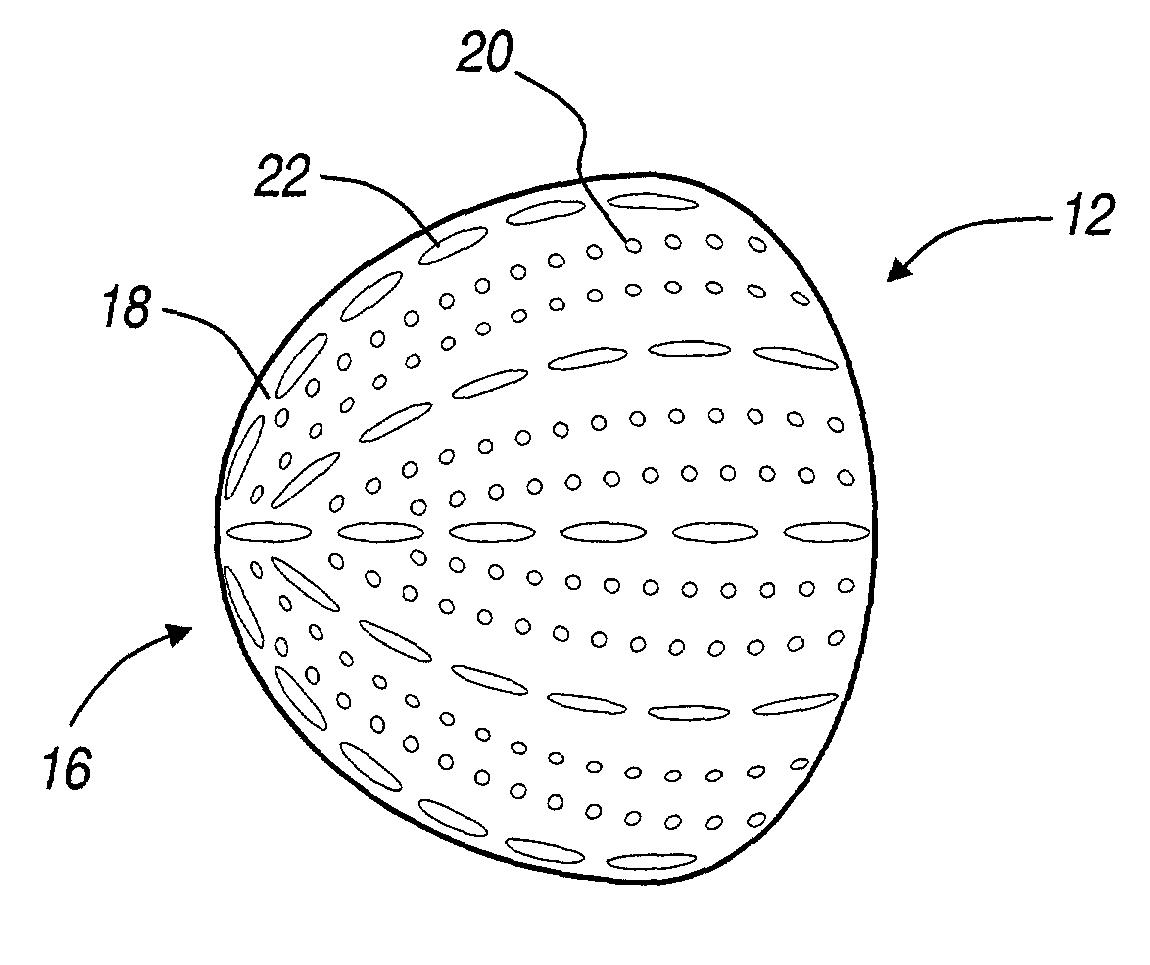

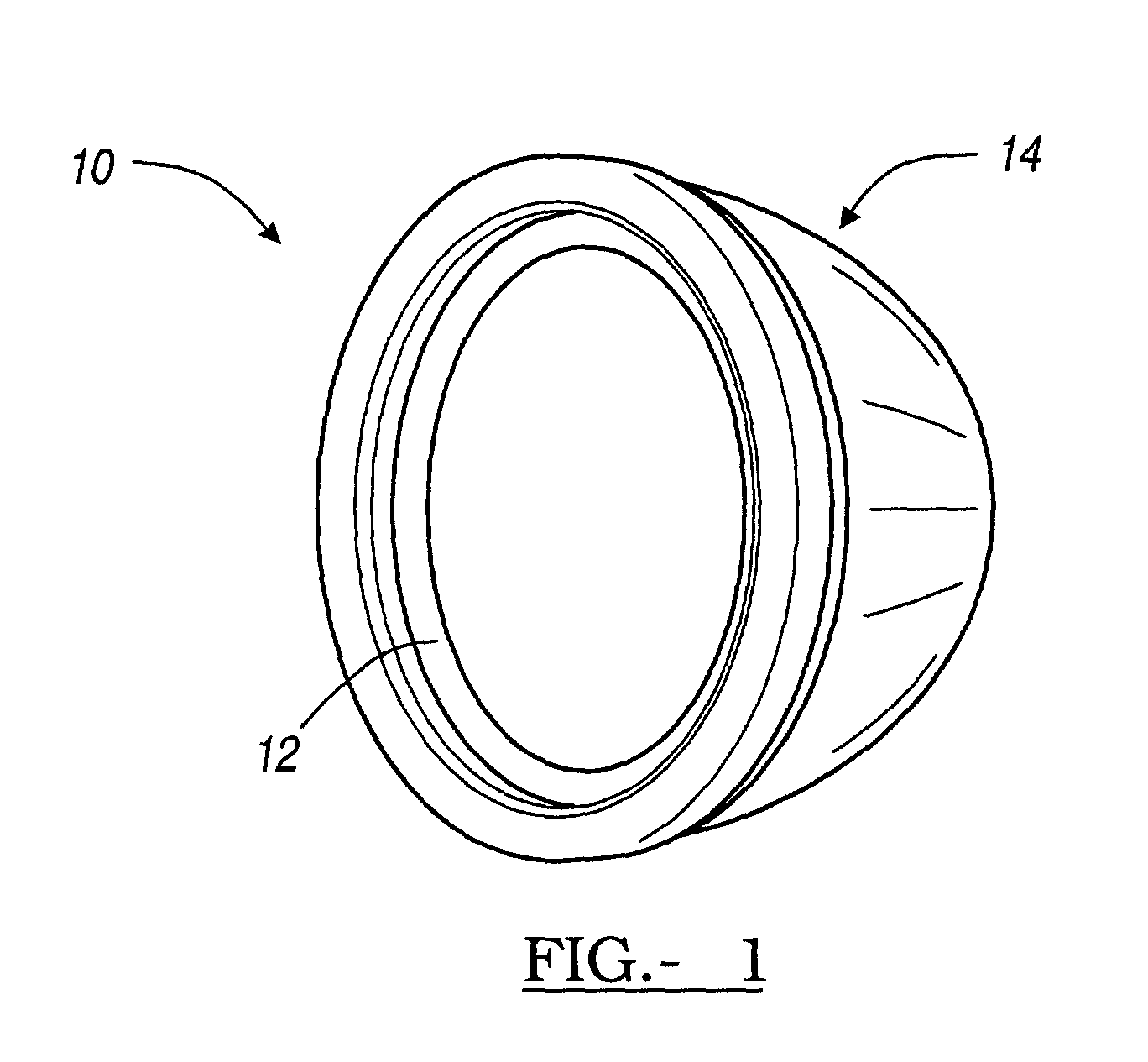

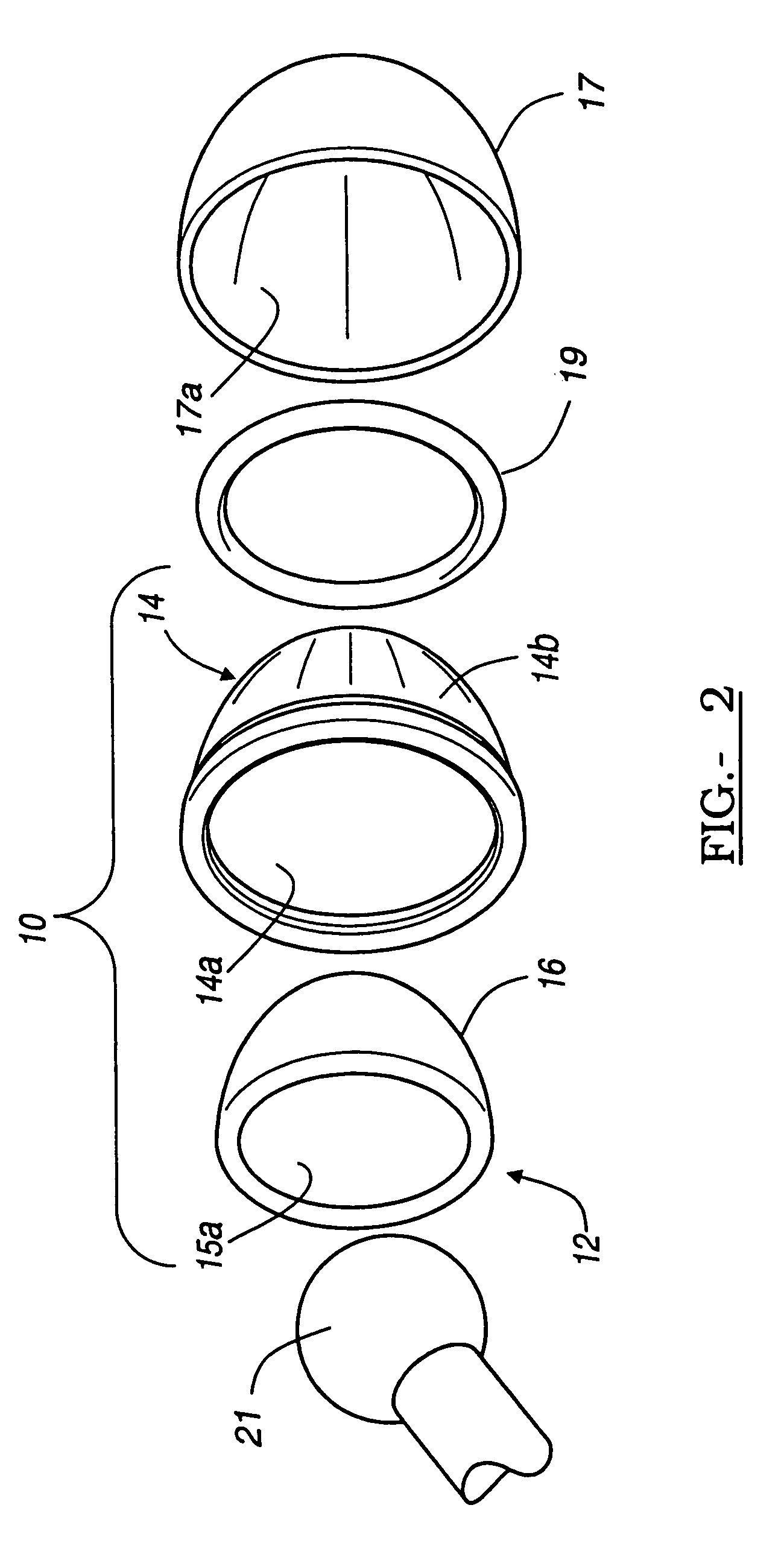

Composite acetabular component

InactiveUS6966932B1Increase mechanical bondingGood mechanical bondJoint implantsFemoral headsAcetabular componentPlastic bag

Composite acetabular components, and methods of making and using same, are described. The composites consist of a ceramic liner having a backing of plastic material, such as but not limited to ultra high molecular weight polyethylene (UHMWPE), molded around the ceramic liner. The back surface of the ceramic liner is textured to enhance the mechanical bonding strength of the plastic backing to the textured ceramic liner during the molding process.

Owner:BIOMET MFG CORP

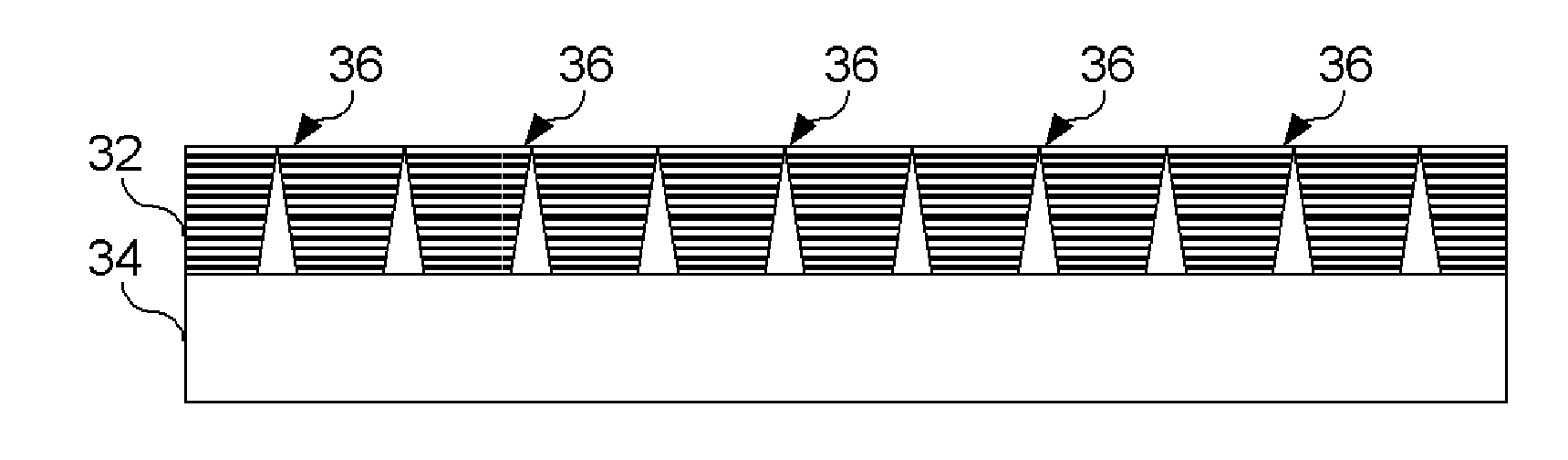

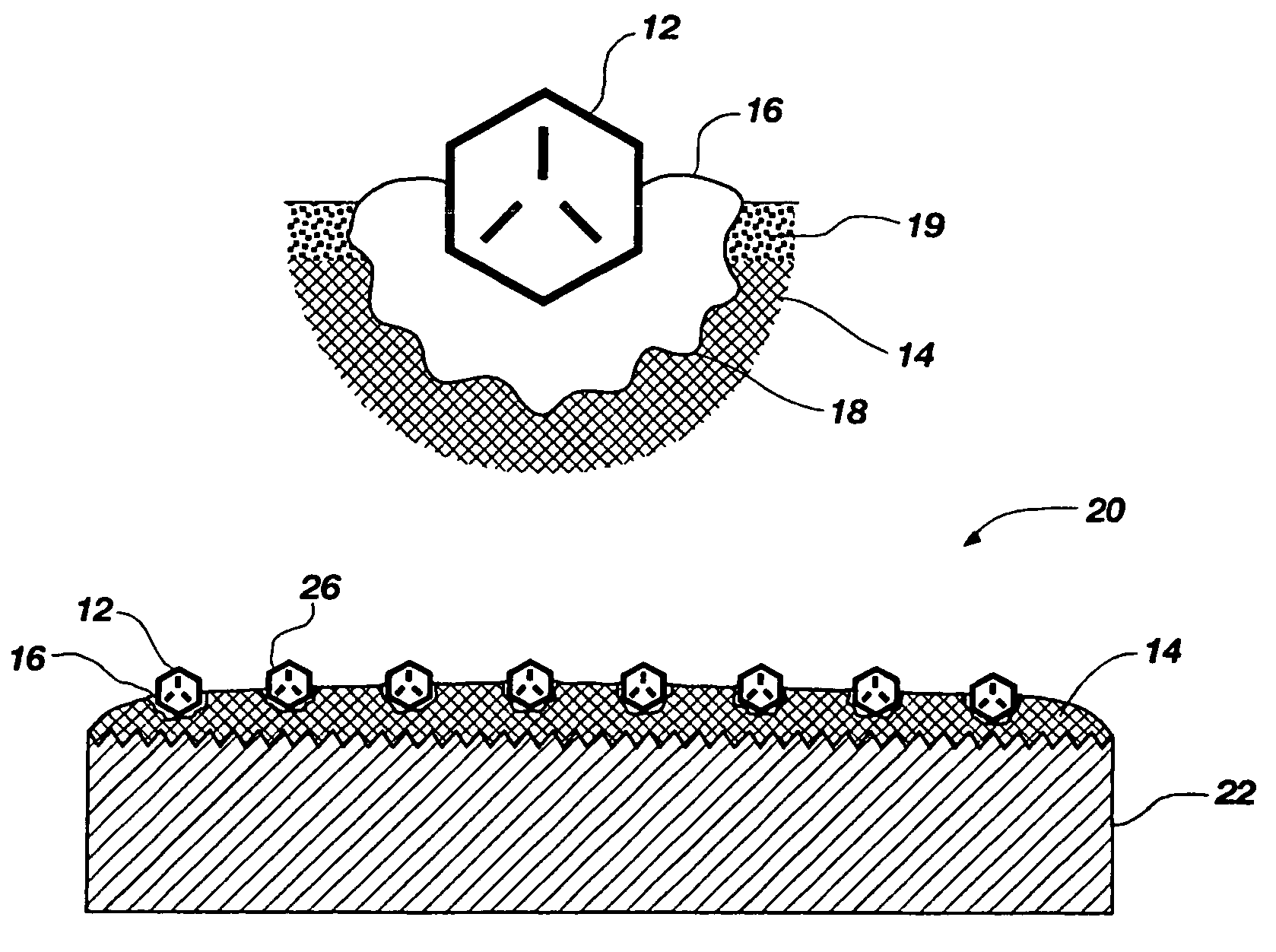

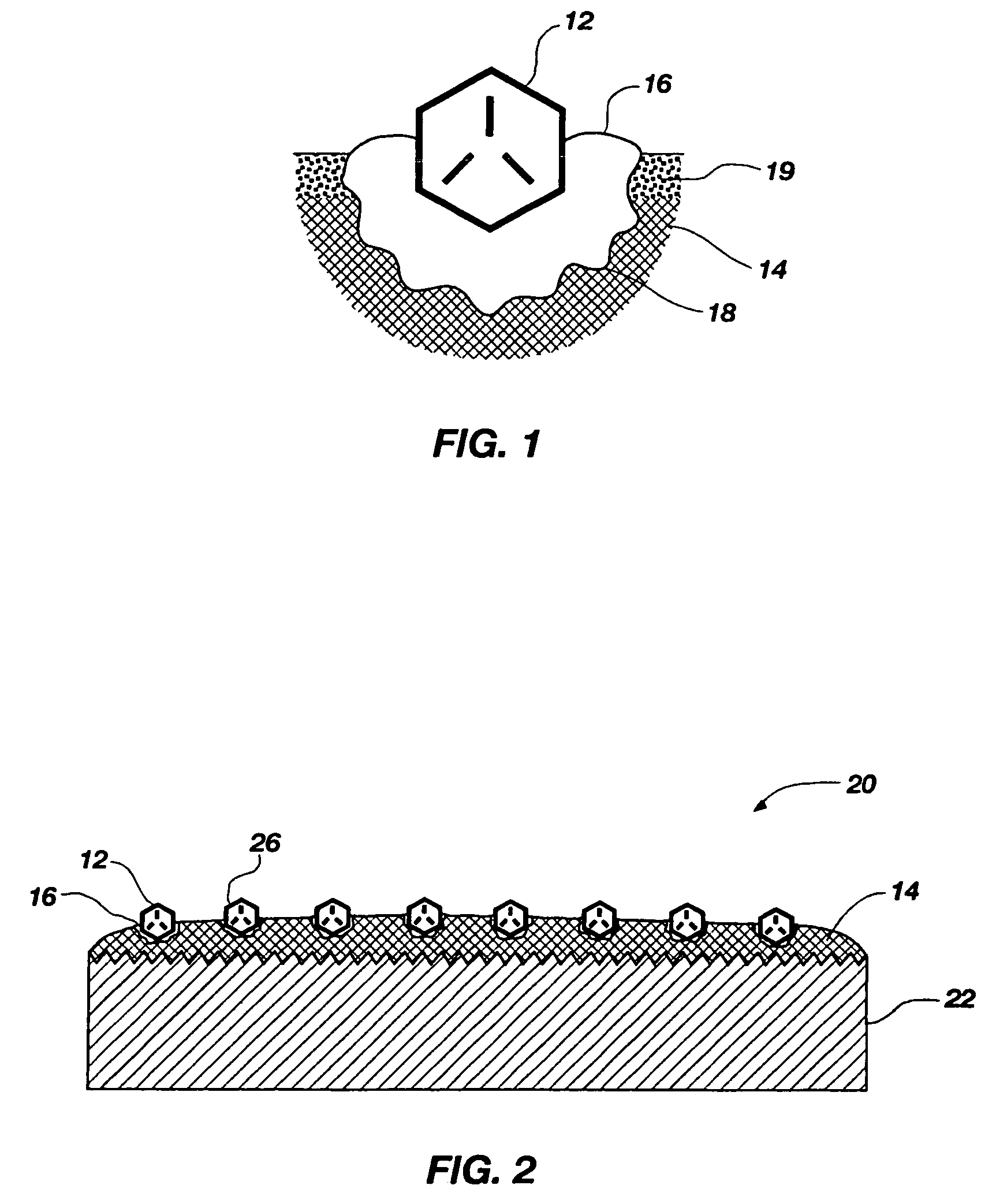

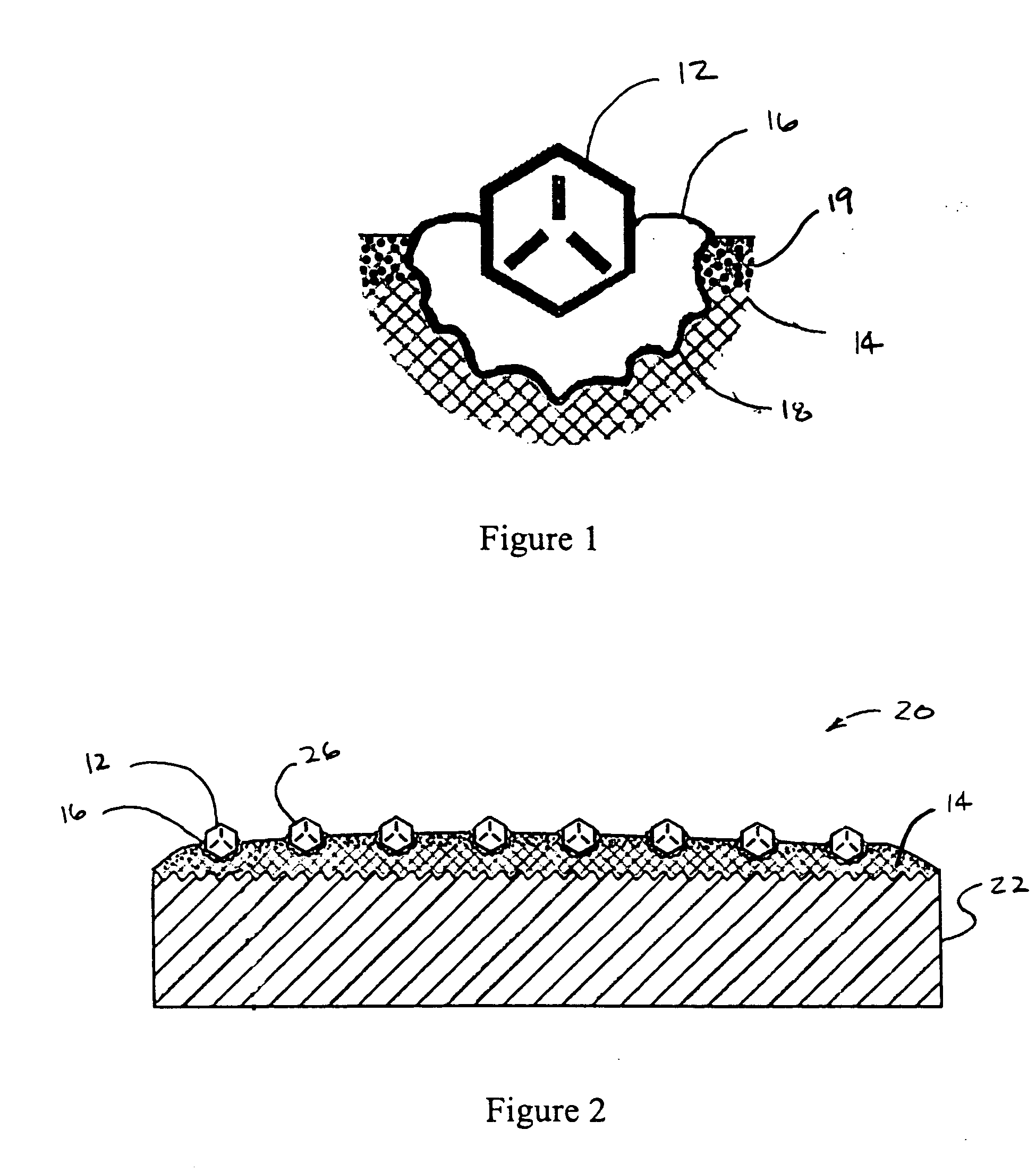

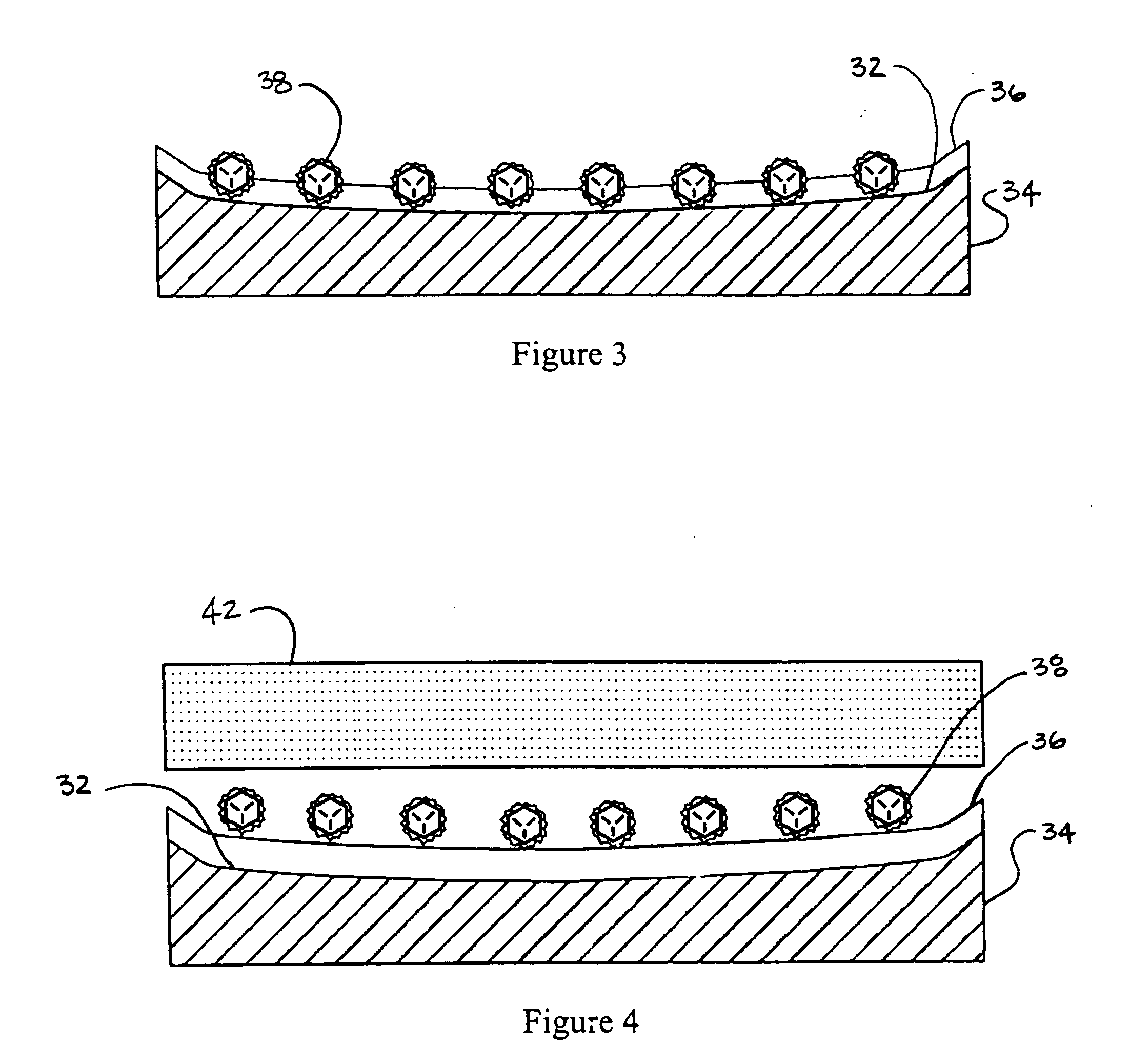

Chemical mechanical polishing pad dresser

ActiveUS7258708B2Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

Chemical mechanical polishing pad dresser

ActiveUS20060143991A1Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

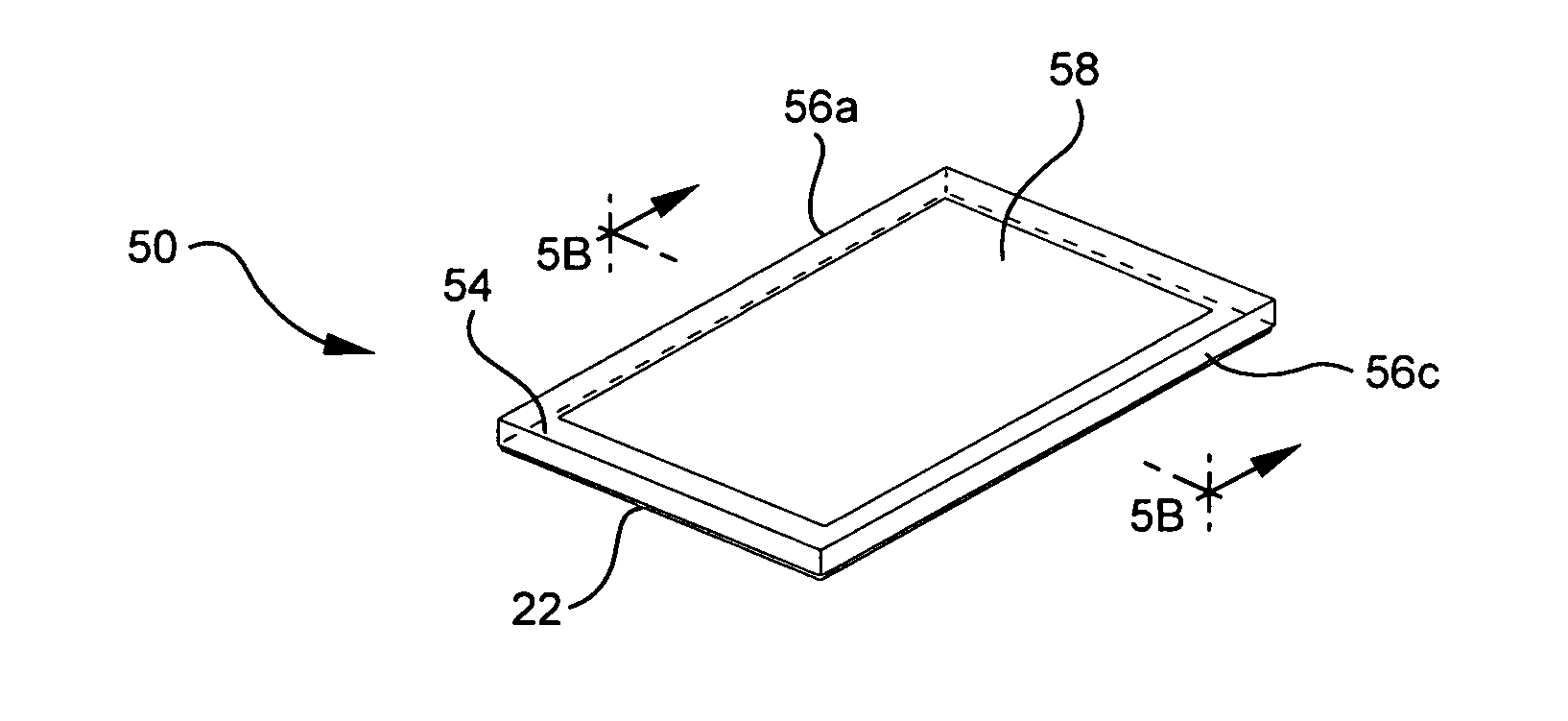

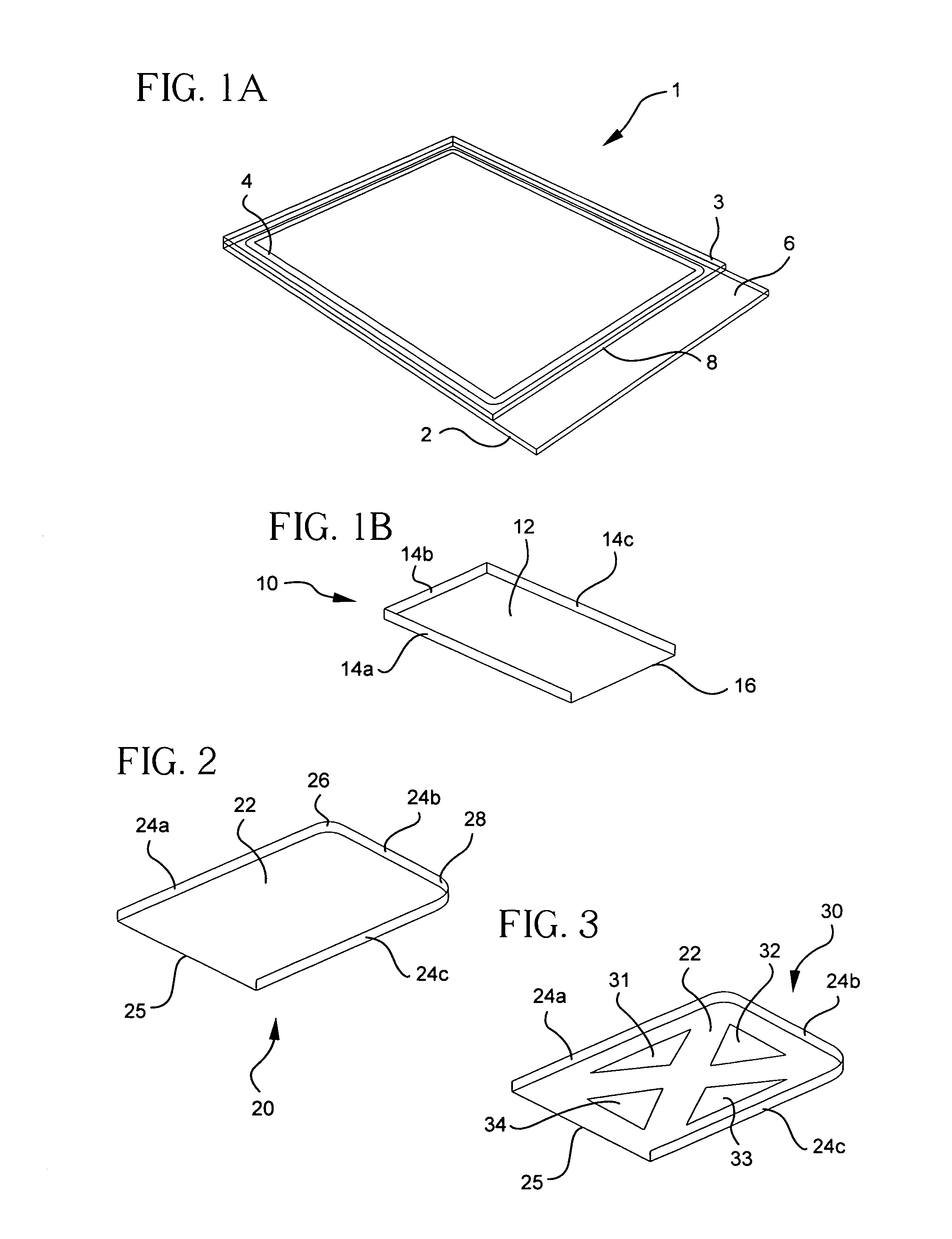

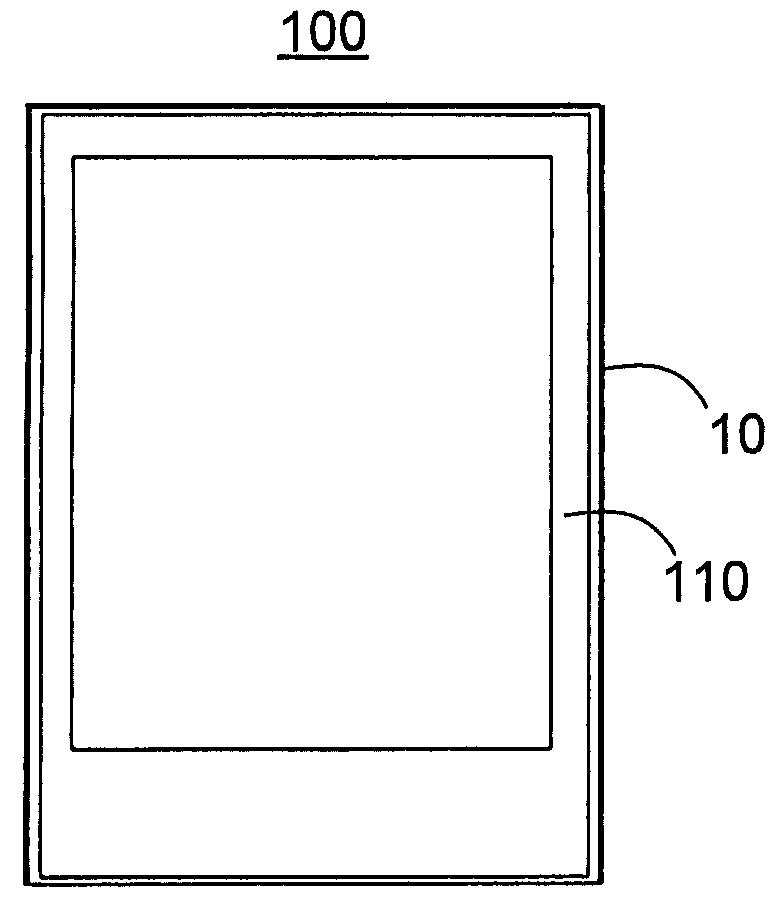

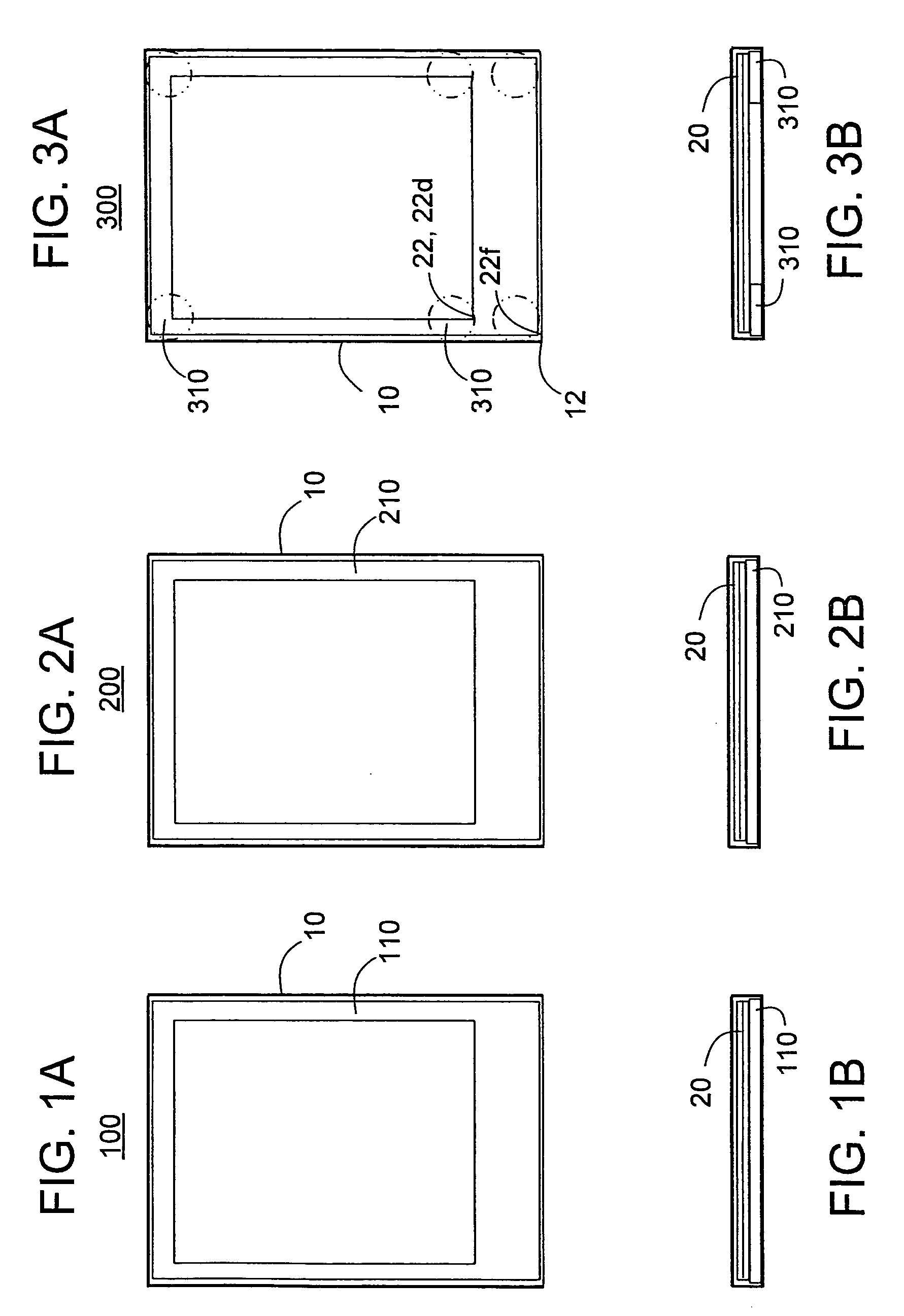

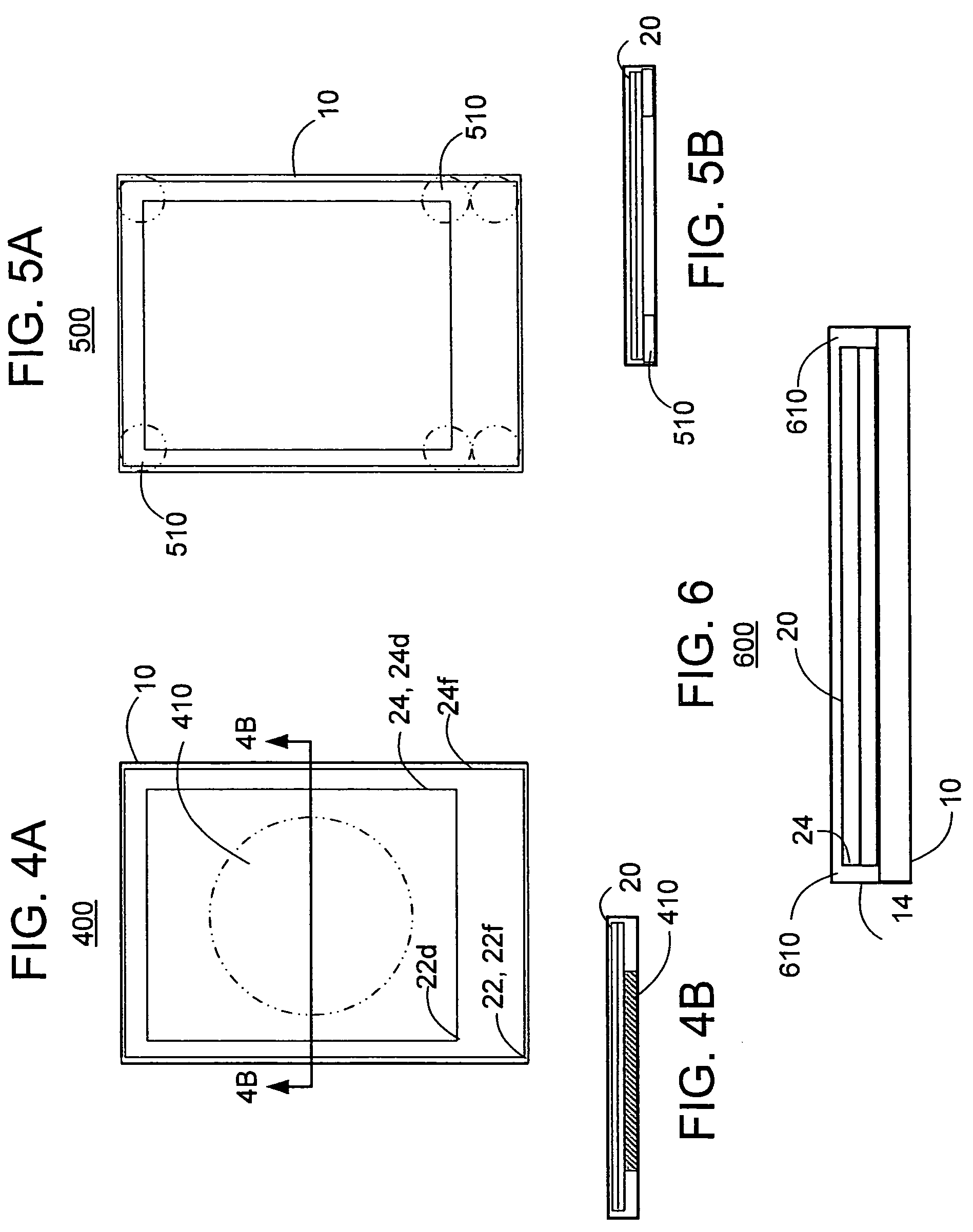

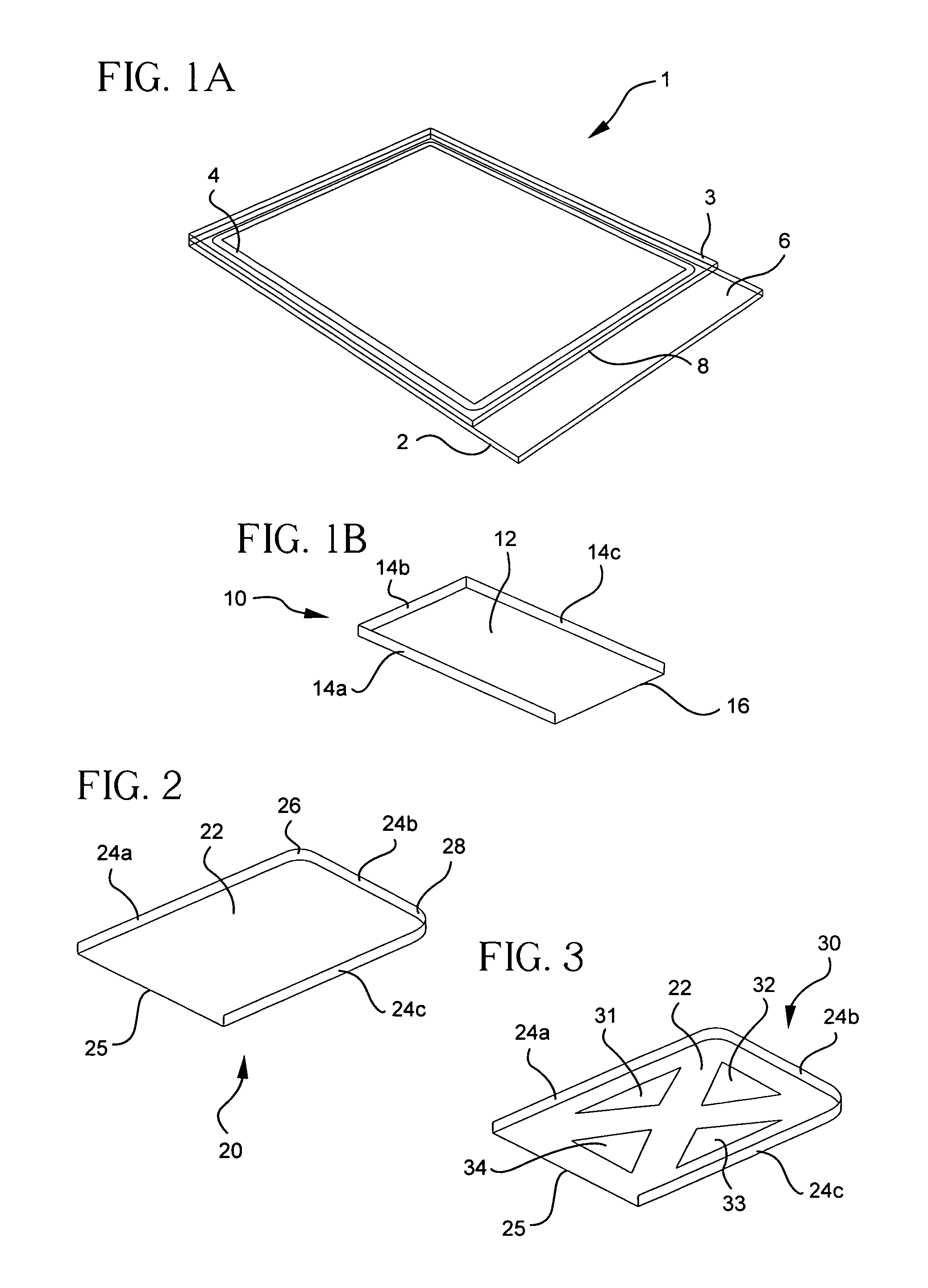

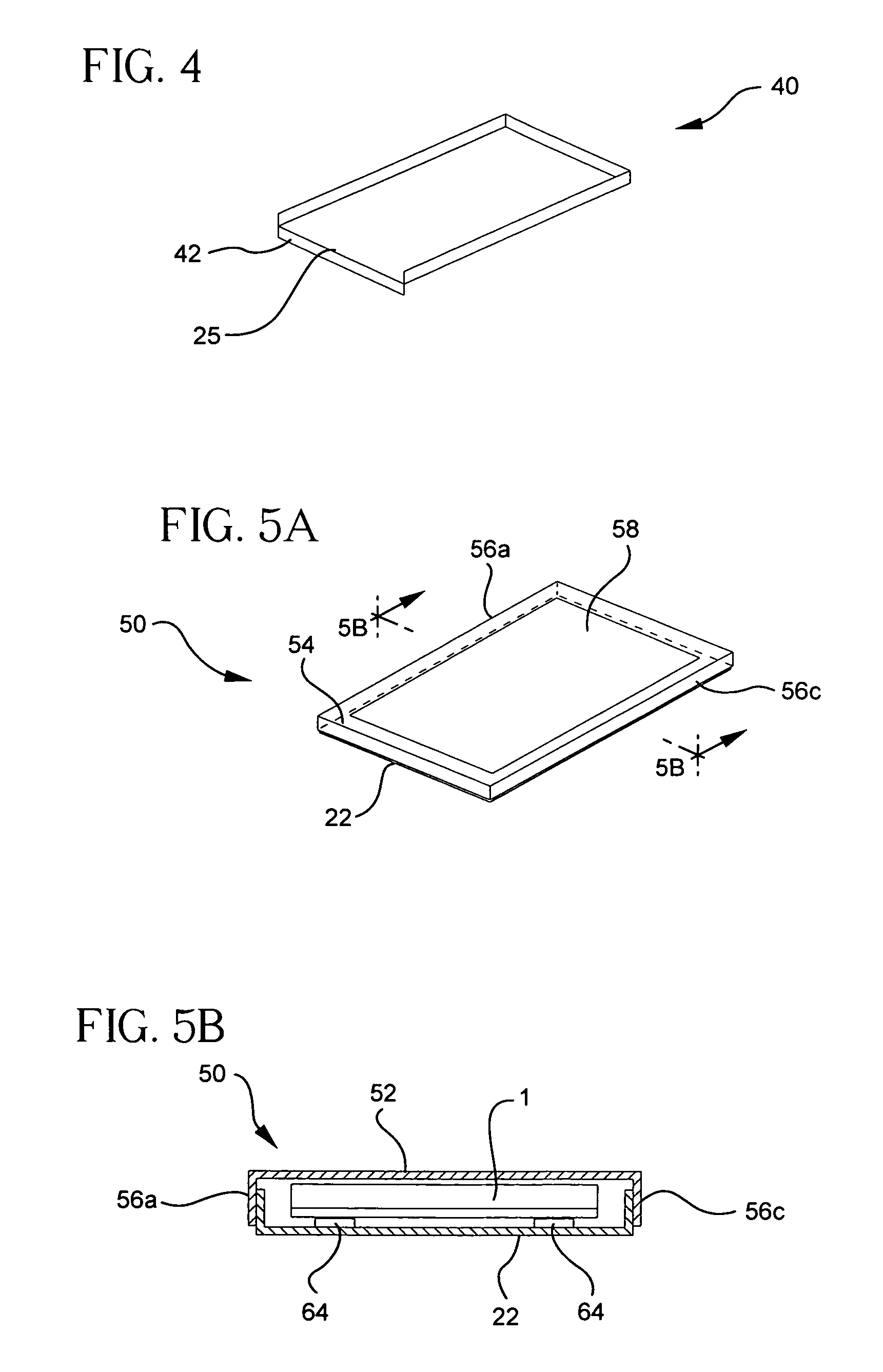

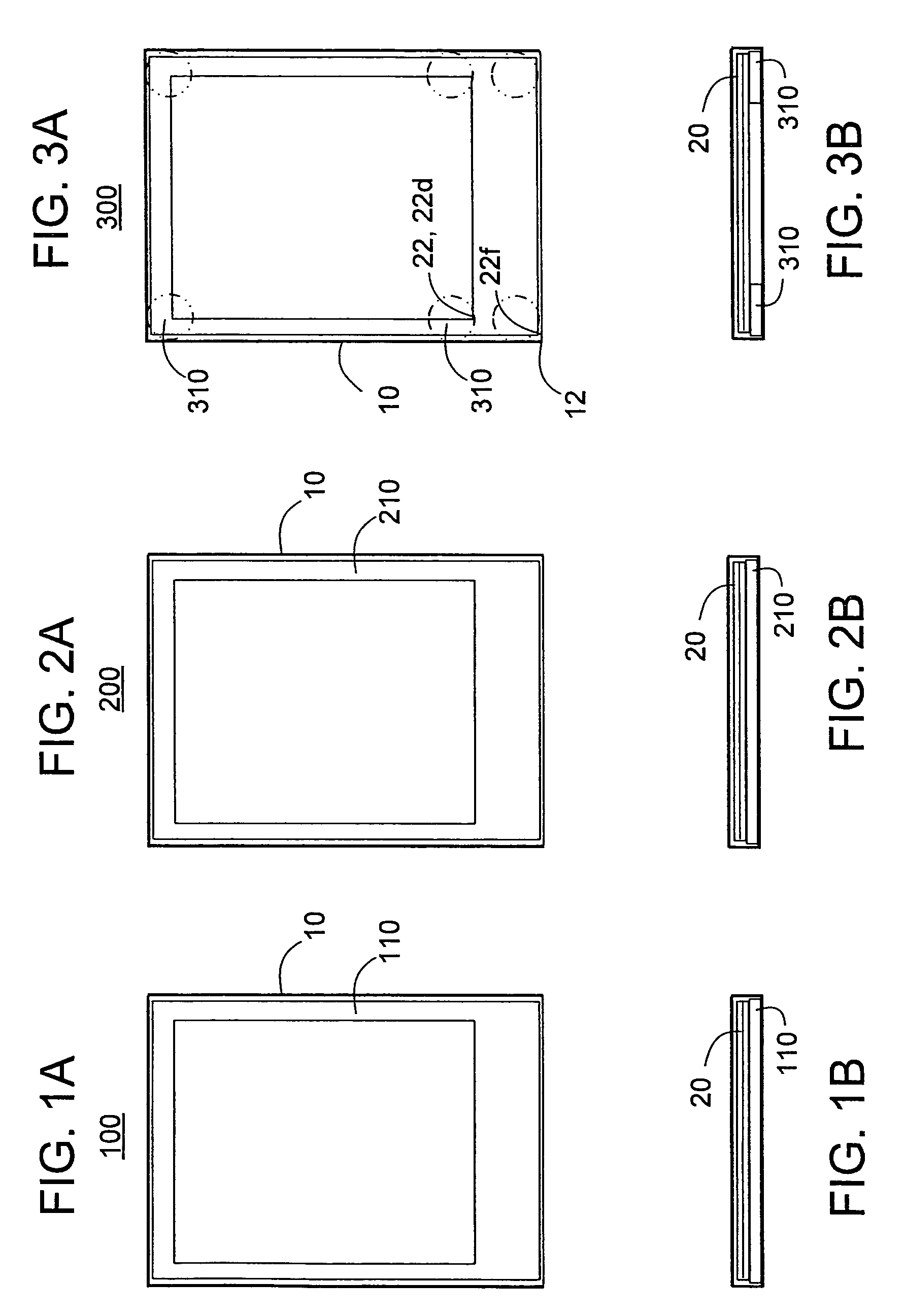

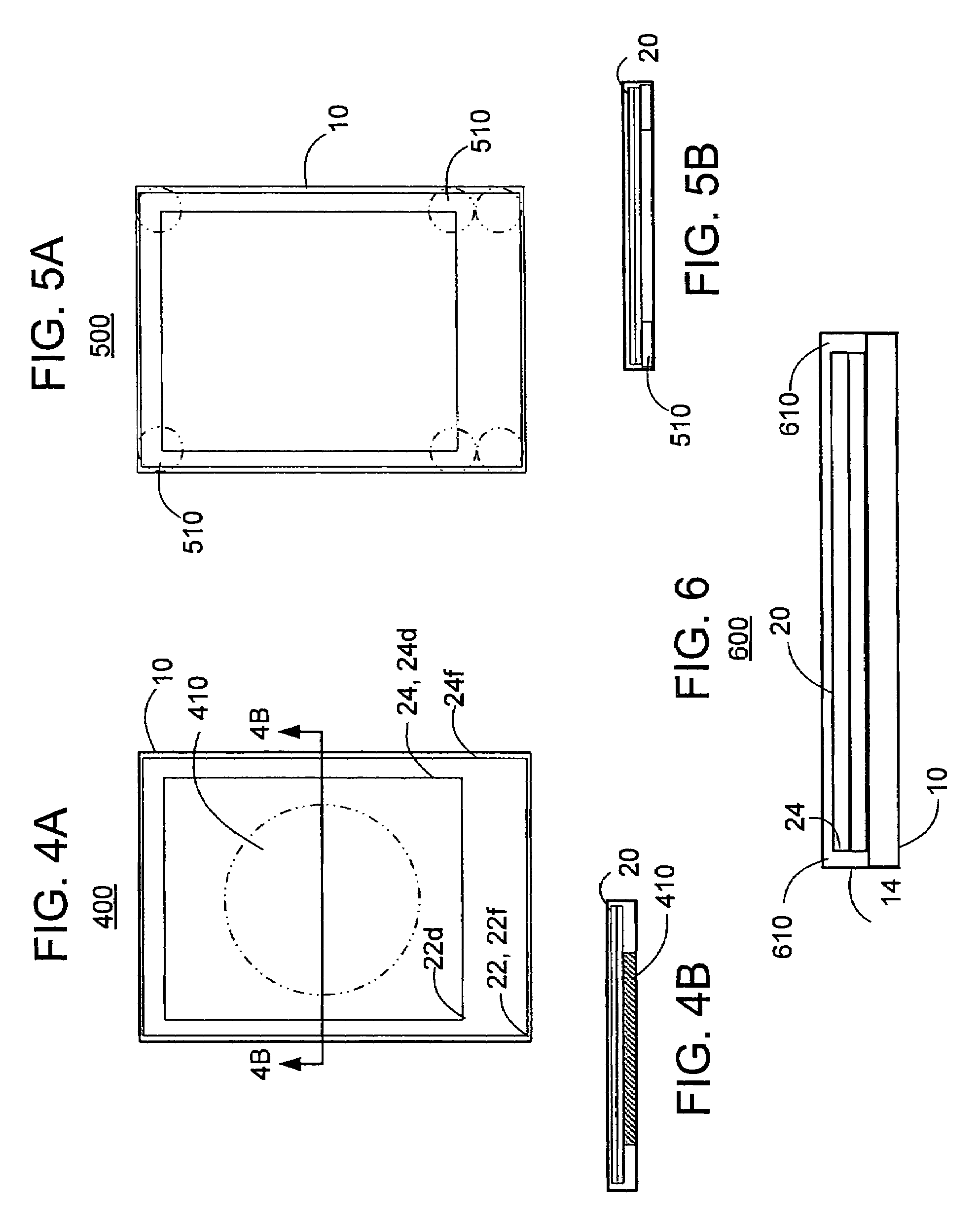

Bezel packaging for sealed glass assemblies and a glass assembly therefor

InactiveUS20110019351A1Reduce the likelihood of failureImprove integrityPlanar light sourcesStatic indicating devicesLeading edgeInter layer

Methods and assemblies related to frame or bezel packaging of a sealed glass assembly, such as a fit-sealed OLED device, such as an OLED display panel. The frame or bezel packaging may have one or more of (a) rounded or chamfered corners, (a) a cover, (b) a reinforced lead edge, (c) openings or cutouts in the back panel to conserve material and lighten the bezel, and (d) a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the back and / or sides of the frame or bezel. The frame or bezel design may include a gap between the sealed glass assembly and the back panel of the bezel. The gap may be filled at least in part with low modulus of elasticity backing material. The glass package may have one or more of (a) rounded or chamfered corners, (b) rounded or chamfered edges, (c) a low modulus of elasticity material applied around its periphery or portions of its periphery, such as on the corners only, (d) a shortened lead end, and (e) a thickened lead end.

Owner:CORNING INC

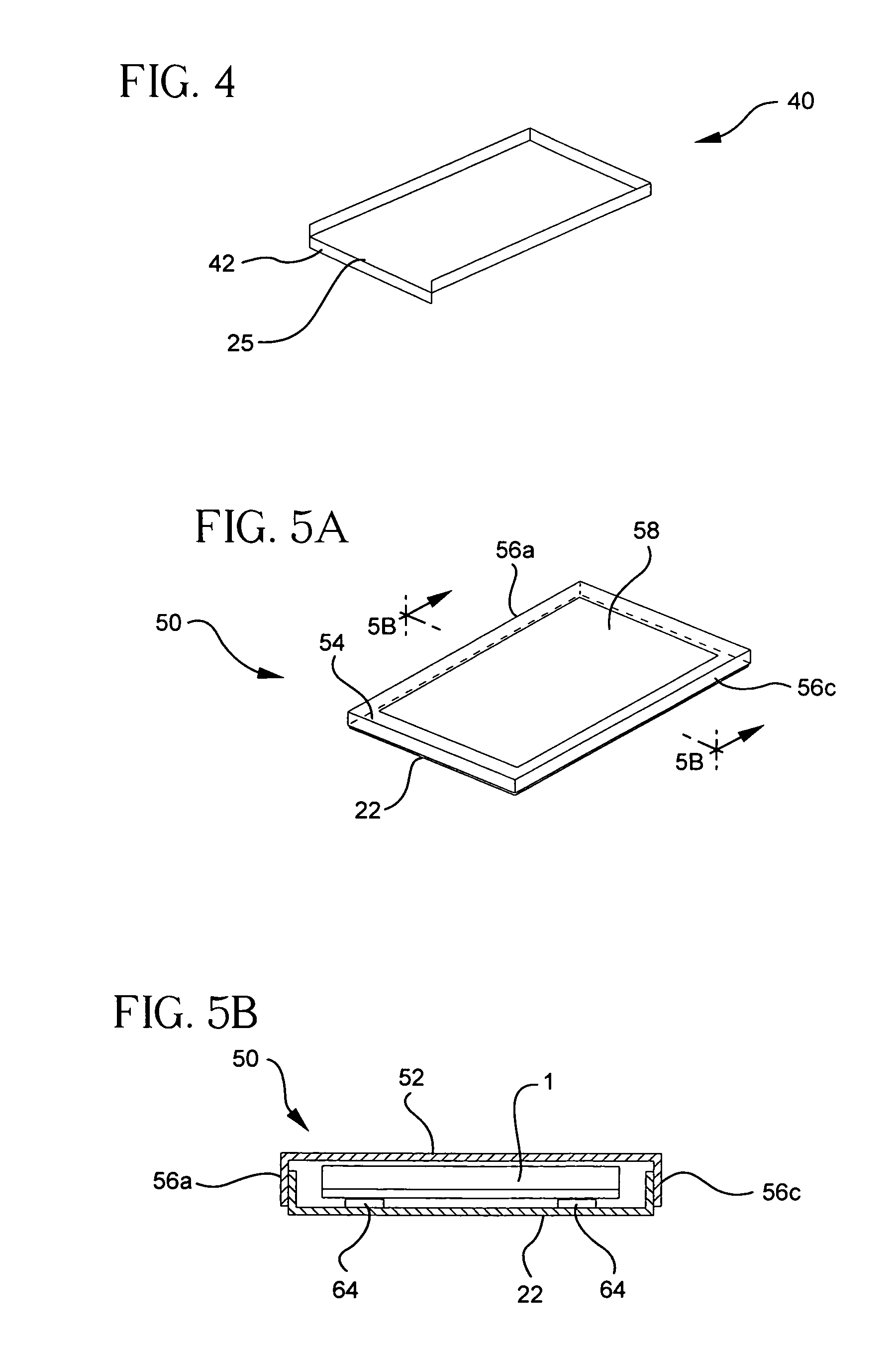

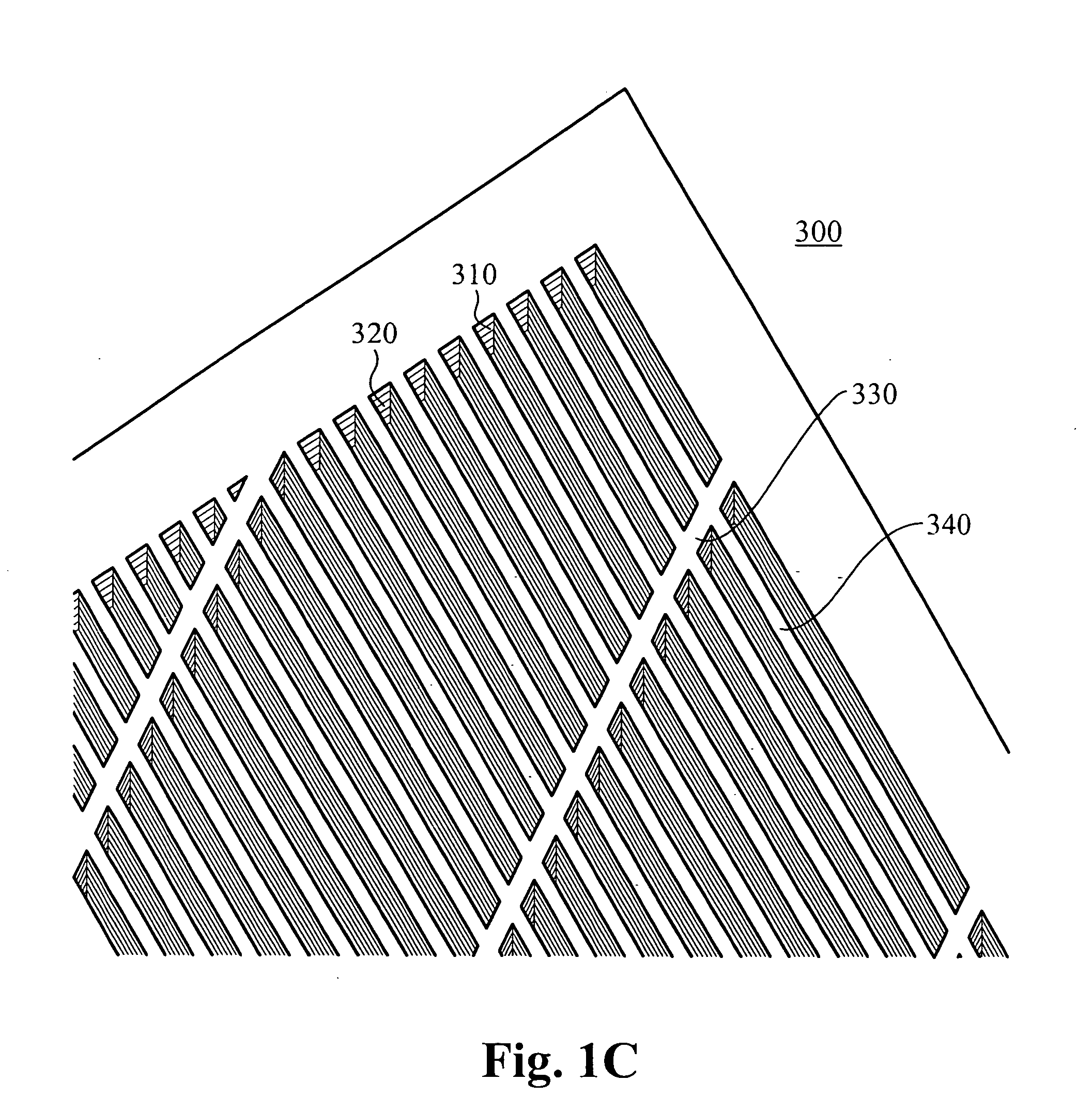

Fabrication of high surface to volume ratio structures and their integration in microheat exchangers for liquid cooling systems

ActiveUS20080210405A1Good mechanical bondExcellent thermal bondingSemiconductor/solid-state device detailsMetal-working apparatusEtchingIt integration

An structure and method of manufacturing a microstructure for use in a heat exchanger is disclosed. The heat exchanger comprises a manifold layer and an microstructured region. The manifold layer comprises a structure to deliver fluid to the microstructured region. The microstructured region is formed from multiple windowed layers formed from heat conductive layers through which a plurality of microscaled apertures have been formed by a wet etching process. The plurality of windowed layers are then coupled together to form a composite microstructure.

Owner:VERTIV CORP

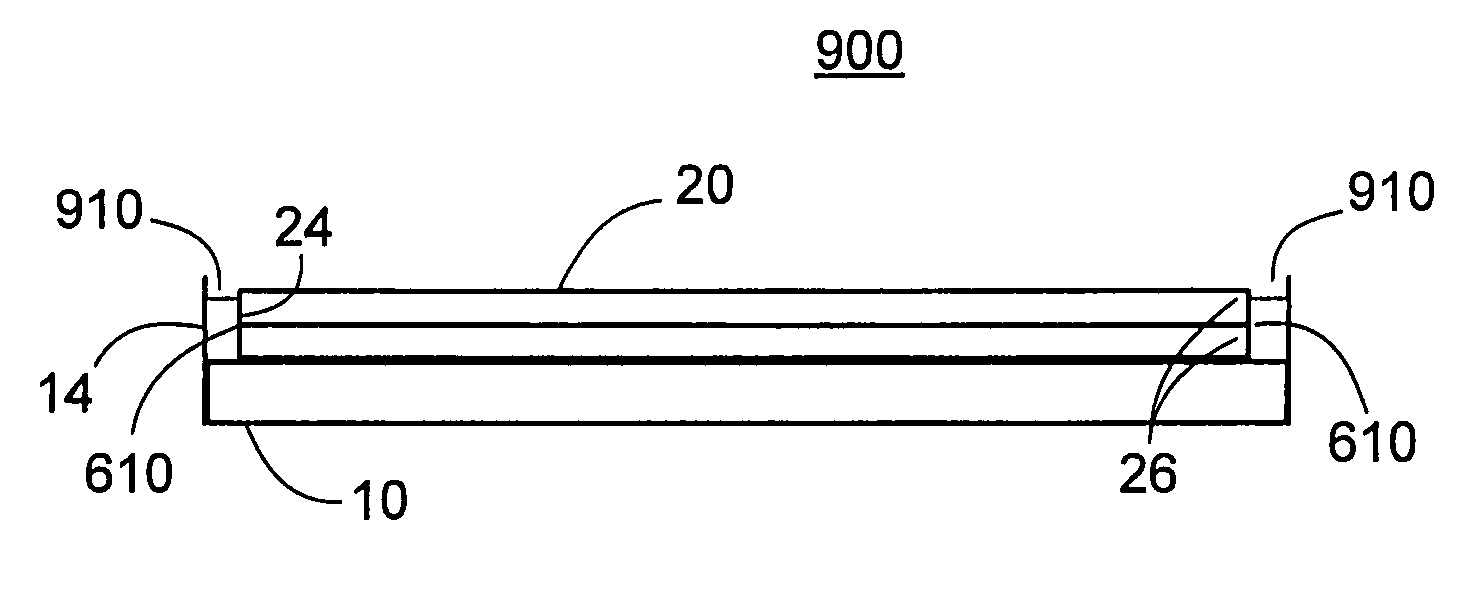

Bezel packaging of frit-sealed OLED devices

InactiveUS20080120946A1Reduce the likelihood of failureHigh mechanical reliabilityElectroluminescent light sourcesSolid-state devicesFiberInter layer

Methods and assemblies relate to bezel packaging of a sealed glass assembly, such as a frit-sealed OLED device. The bezel packaging includes a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the bezel. A bonding agent, which may include the low modulus of elasticity material and / or a separate bonding material, affixes the sealed glass assembly to the bezel. Bezel modifications may be made to stabilize the bezel. Exemplary bezel modifications include reinforced bezel side walls and supporting straps attached between bezel walls. The bezel design may include a gap between the edges of the sealed glass assembly and the bezel walls, so as to avoid direct contact therewith. The gap may be filled at least in part with low modulus of elasticity organic adhesive to provide additional shock absorbency. The low modulus of elasticity material may include foam, ceramic fiber cloth and / or a low modulus of elasticity polymeric organic coating.

Owner:CORNING INC

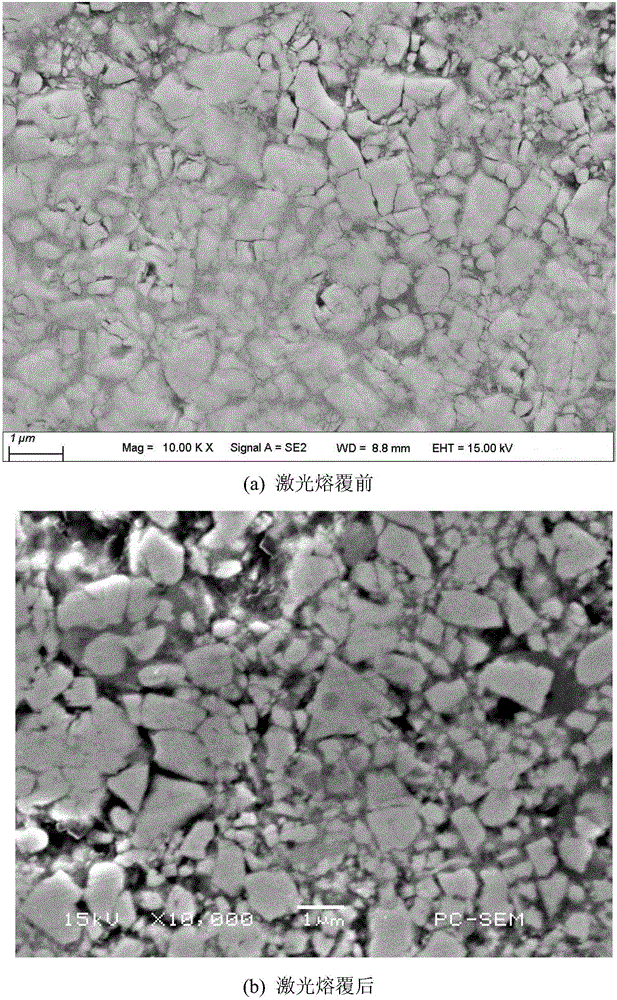

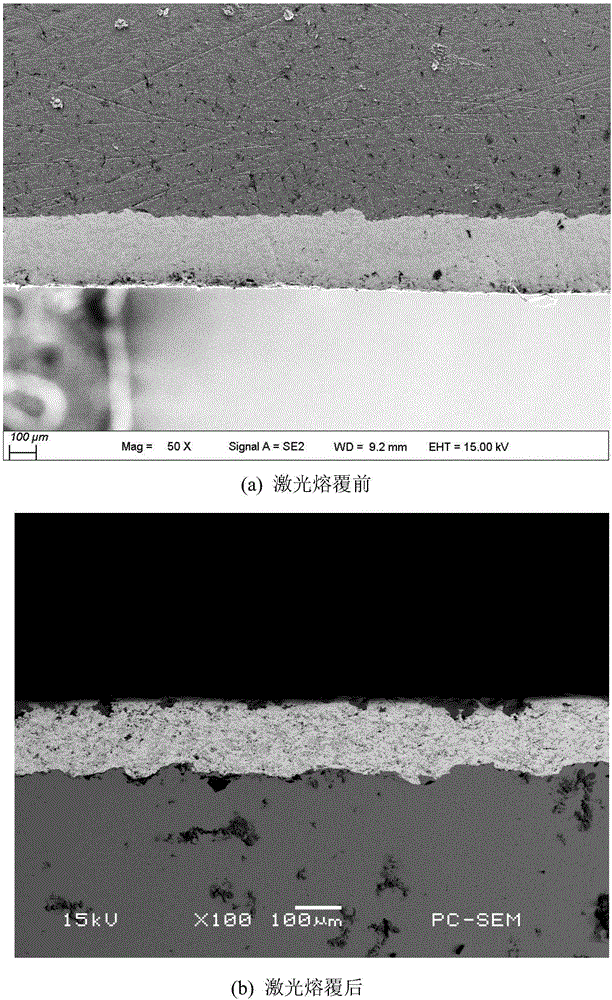

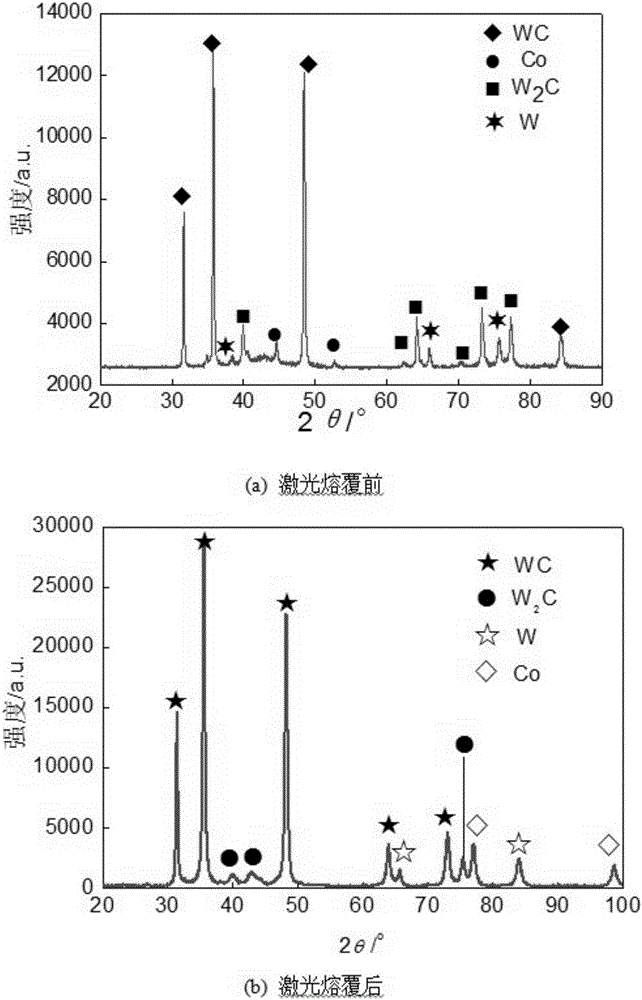

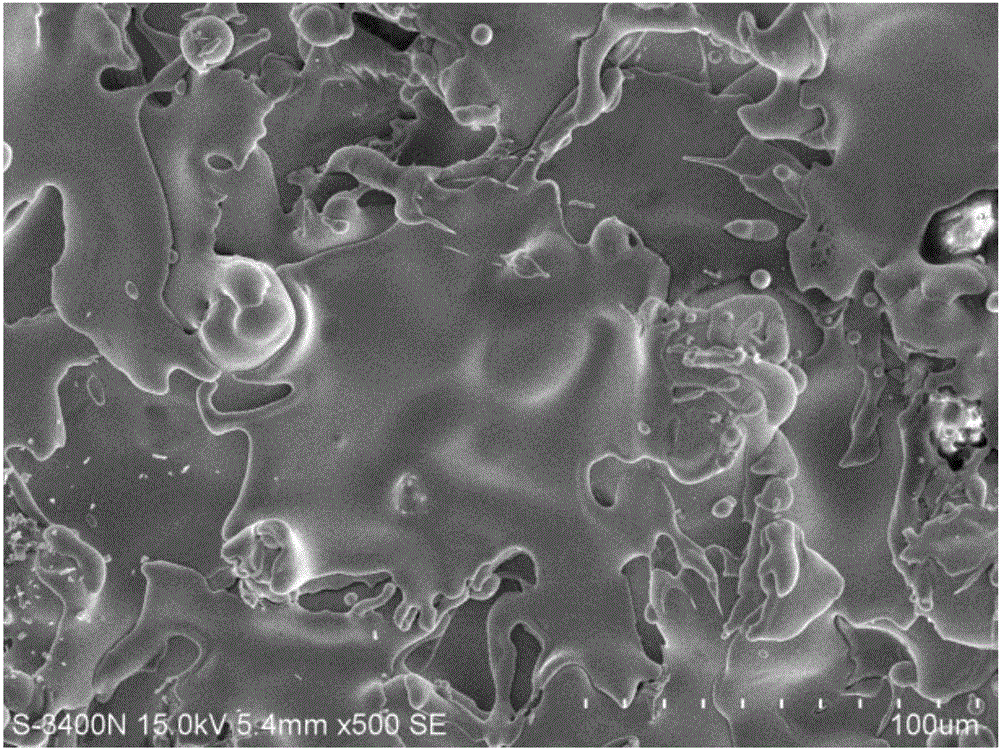

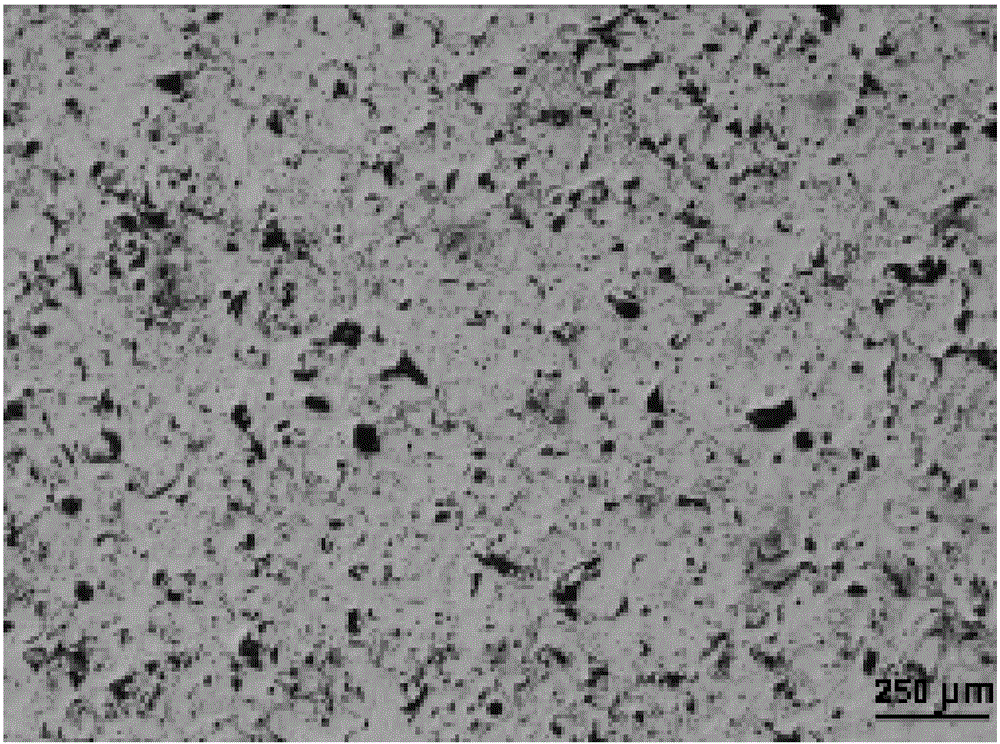

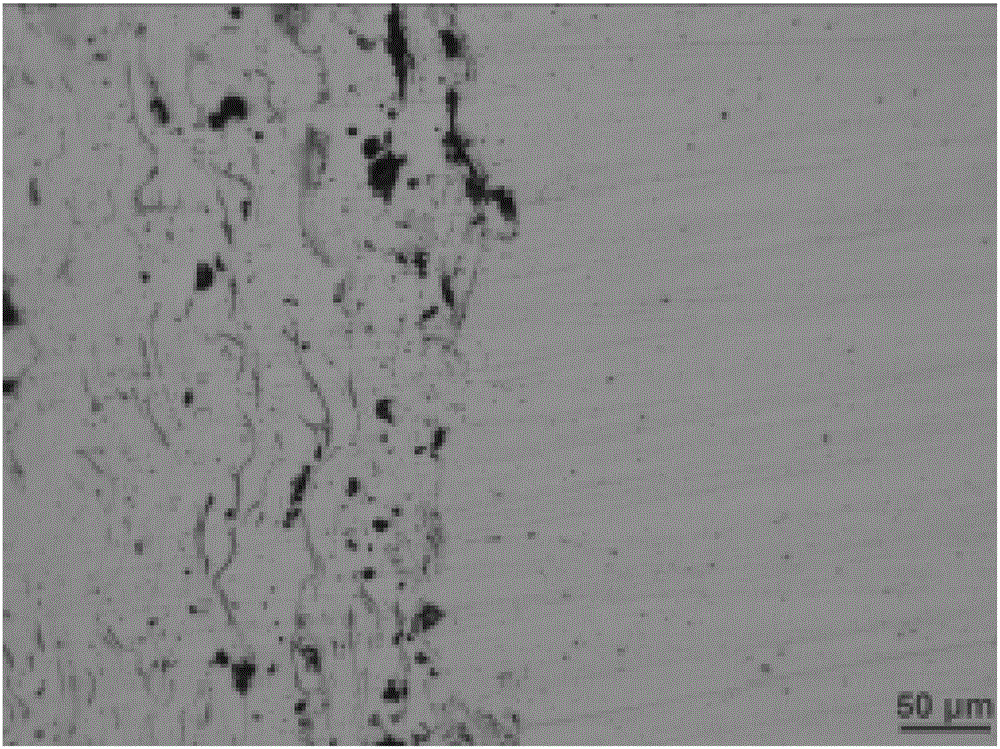

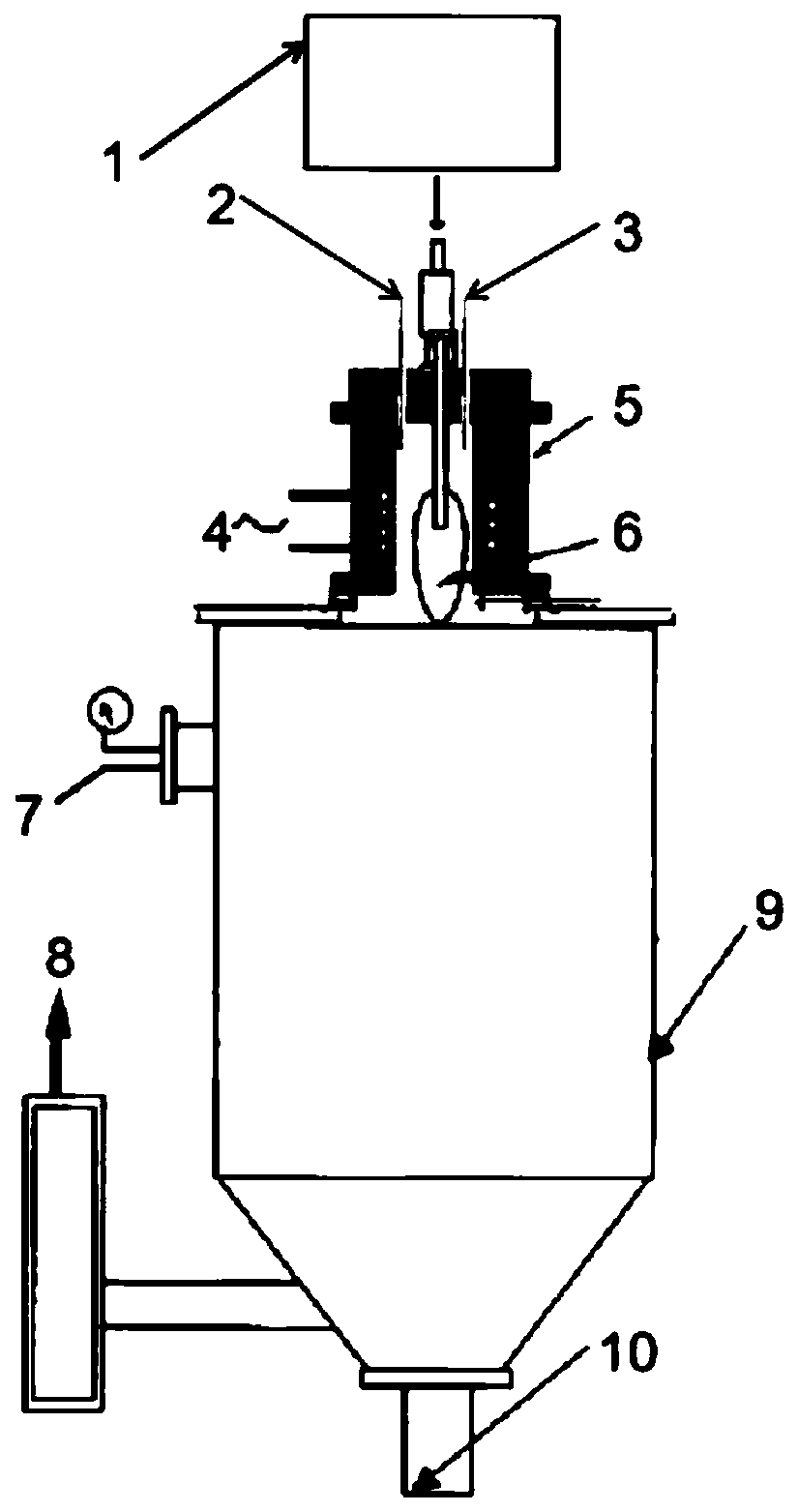

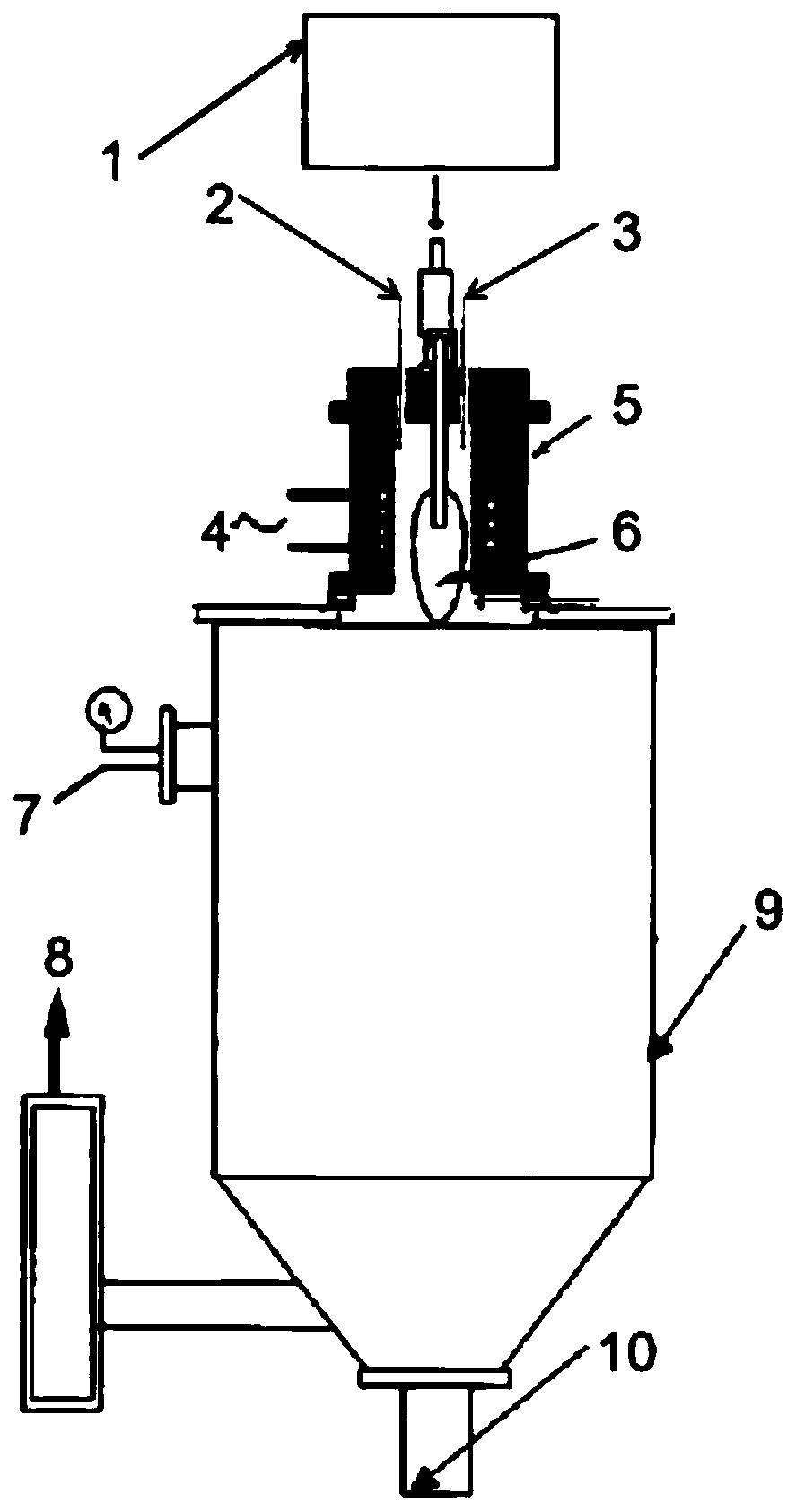

Laser remelting method for ultrasonic spraying of WC-12Co coating

ActiveCN106367707AUniform thicknessImprove bindingMolten spray coatingStructure propertySand blasting

The invention relates to the technical field of die steel surface modification treatment, in particular to a laser remelting method for ultrasonic spraying of a WC-12Co coating on the surface of H13 hot work die steel. The surface of the H13 hot work die steel is polished, cleaned and subjected to sand blasting. The laser remelting method is characterized in that the WC-12Co coating is sprayed to the surface of the H13 hot work die steel subjected to sand blasting through an ultrasonic spraying method, after heat preservation and cooling to the room temperature, laser remelting is used for remelting the WC-12Co coating and the surface of the H13 hot work die steel to achieve metallurgical bonding; and the structure property of the cooled coating is enhanced, and abrasion resistance of the coating is improved. The bonding strength of the coating and the base material is improved, and the service life of a mold is prolonged.

Owner:CHANGZHOU UNIV

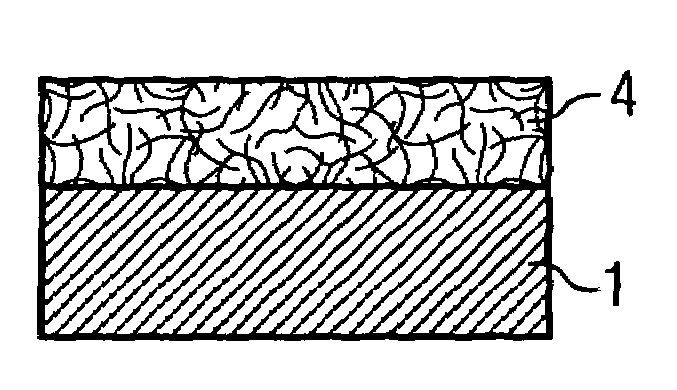

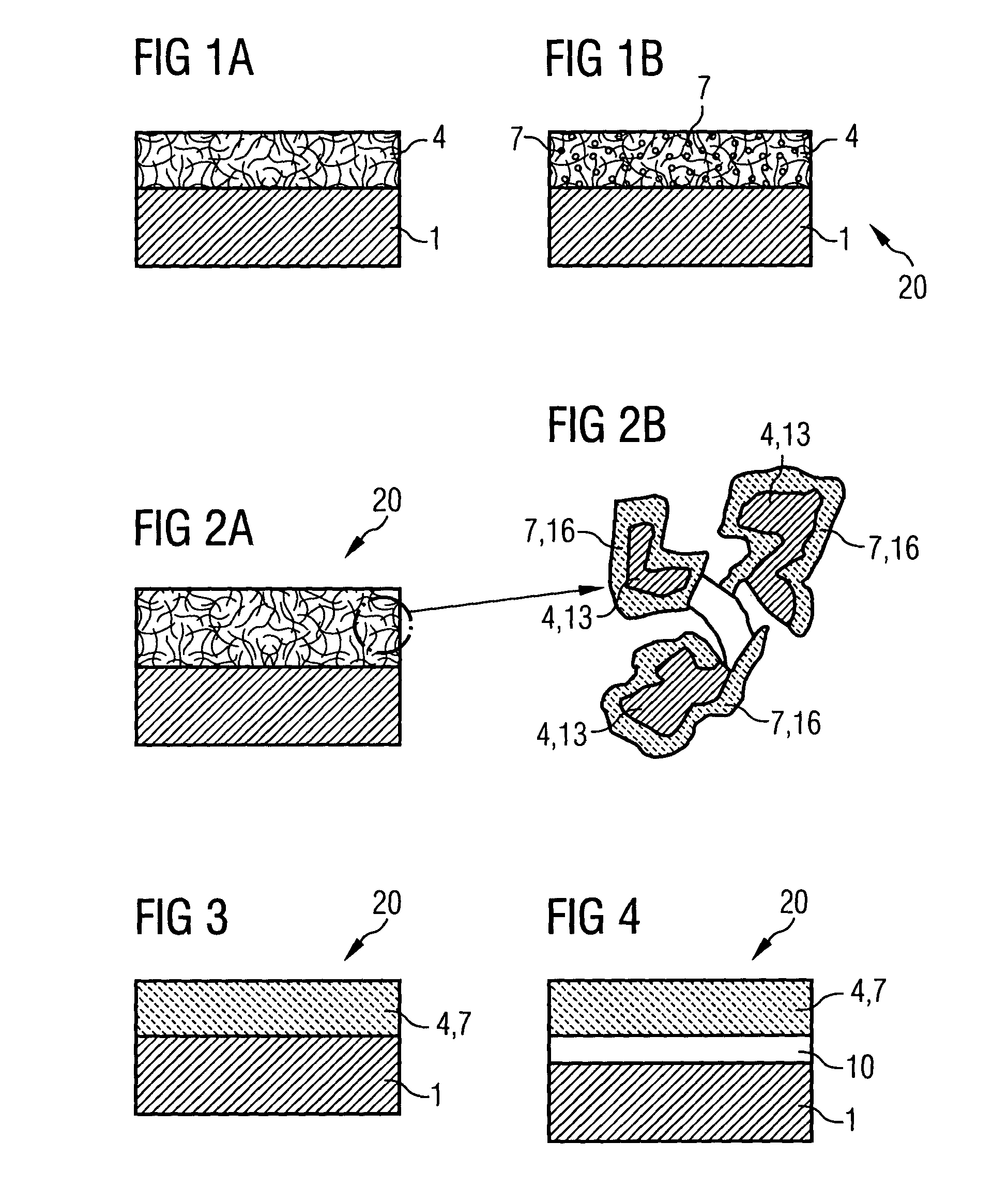

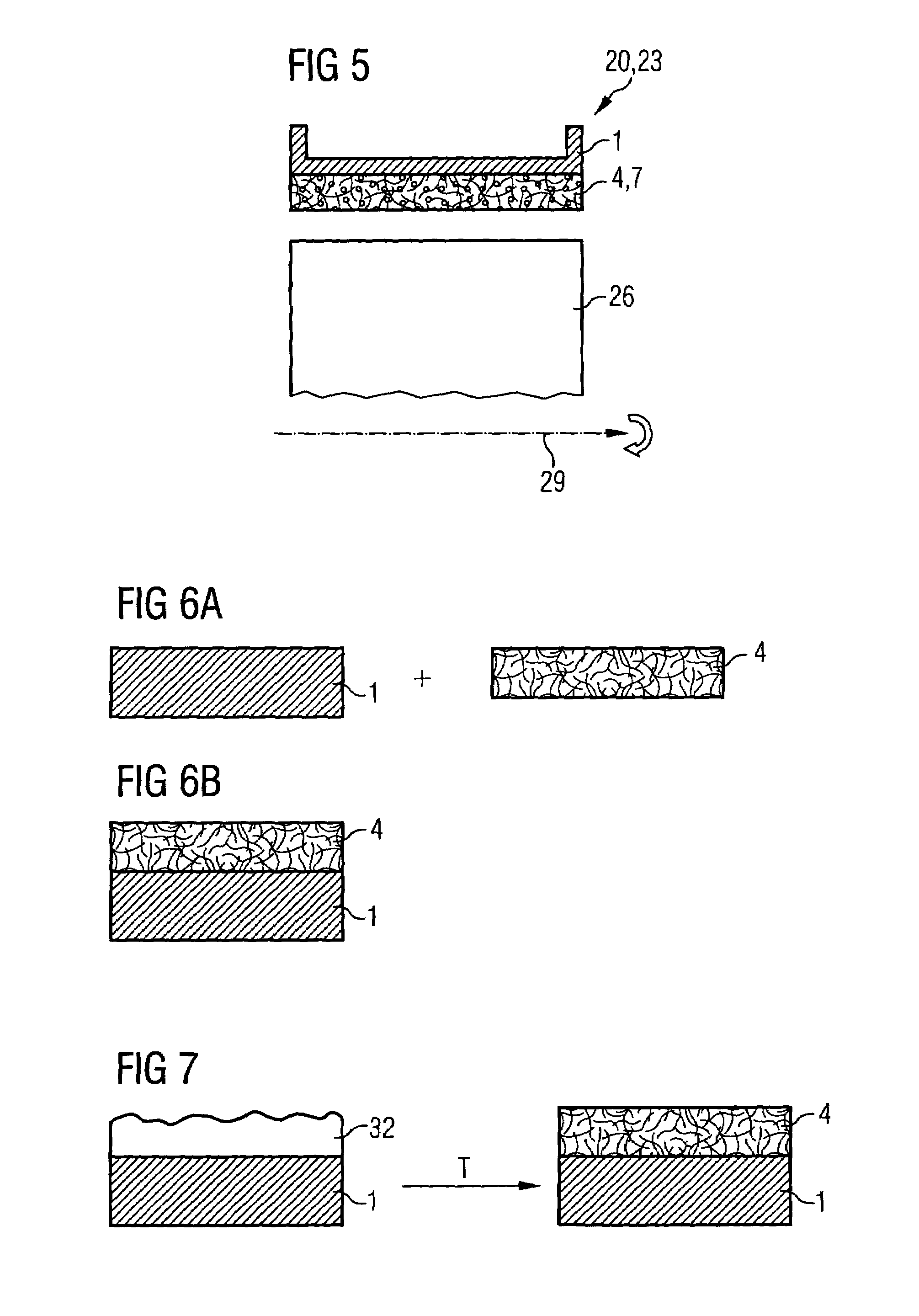

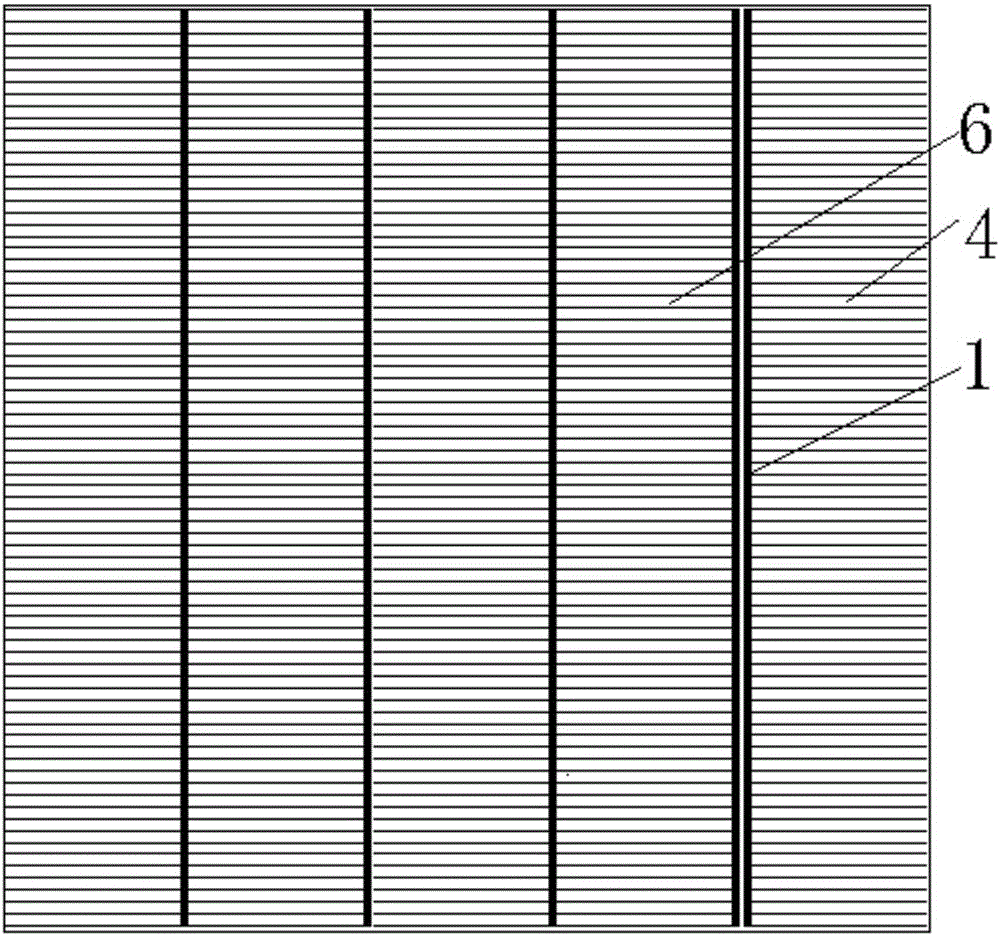

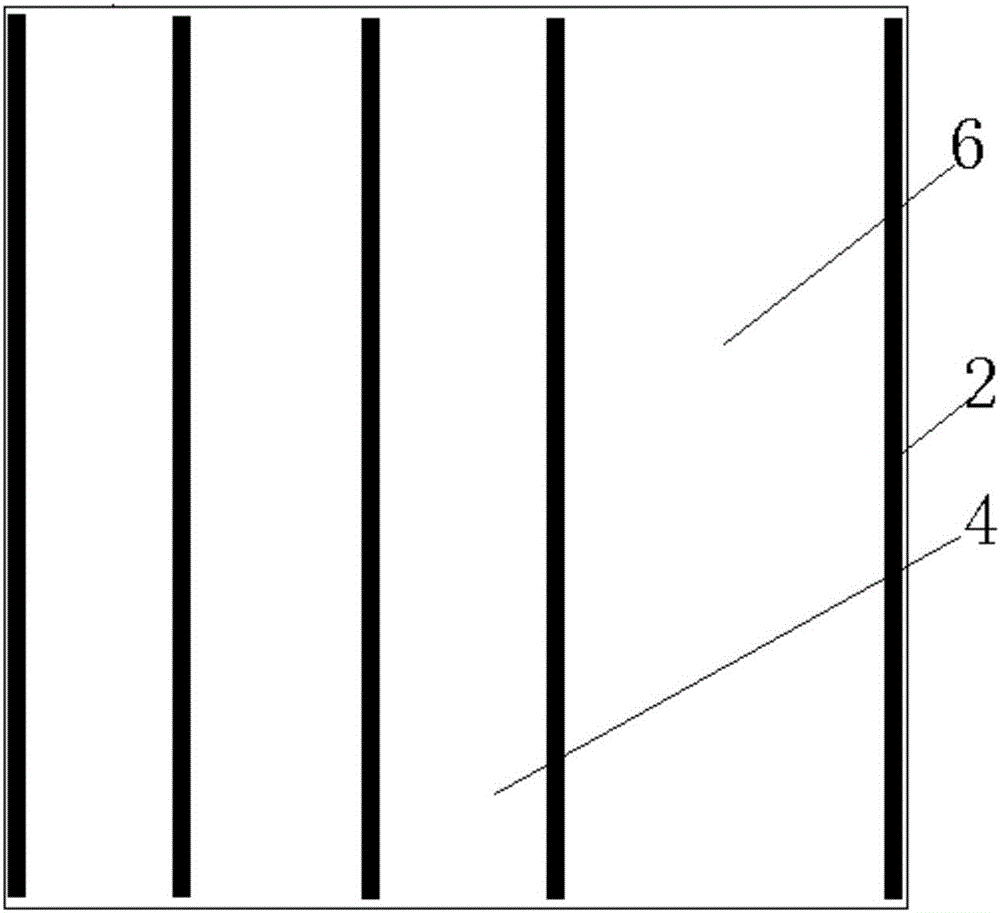

Layer system comprising a substrate, and an outer porous layer

InactiveUS7070853B2High mechanical strengthGood mechanical bondPropellersPump componentsCoating systemPorous layer

Coating systems according to the prior art, wherein a ceramic layer is applied to a metallic layer of the coating system, the connection between metal and ceramic often being poor.A coating system (20) according to the invention has a porous layer (4) in which a ceramic (7) is at least partly disposed, so that the connection between ceramic (7) and the metal of the porous layer (4) is improved.

Owner:SIEMENS AG

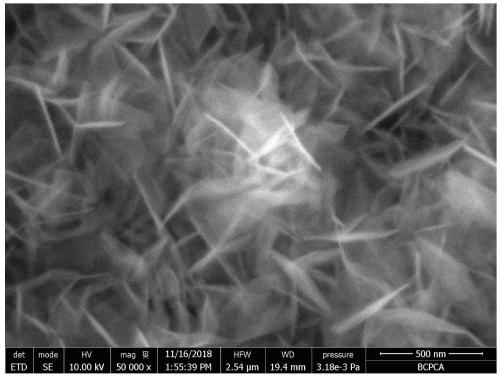

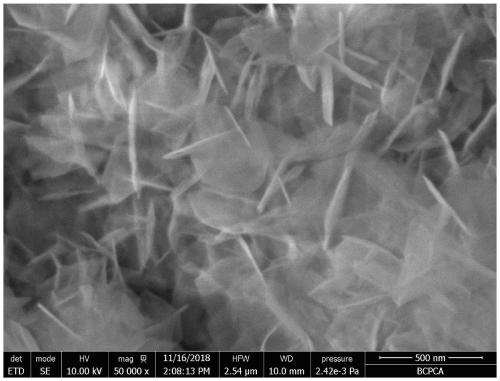

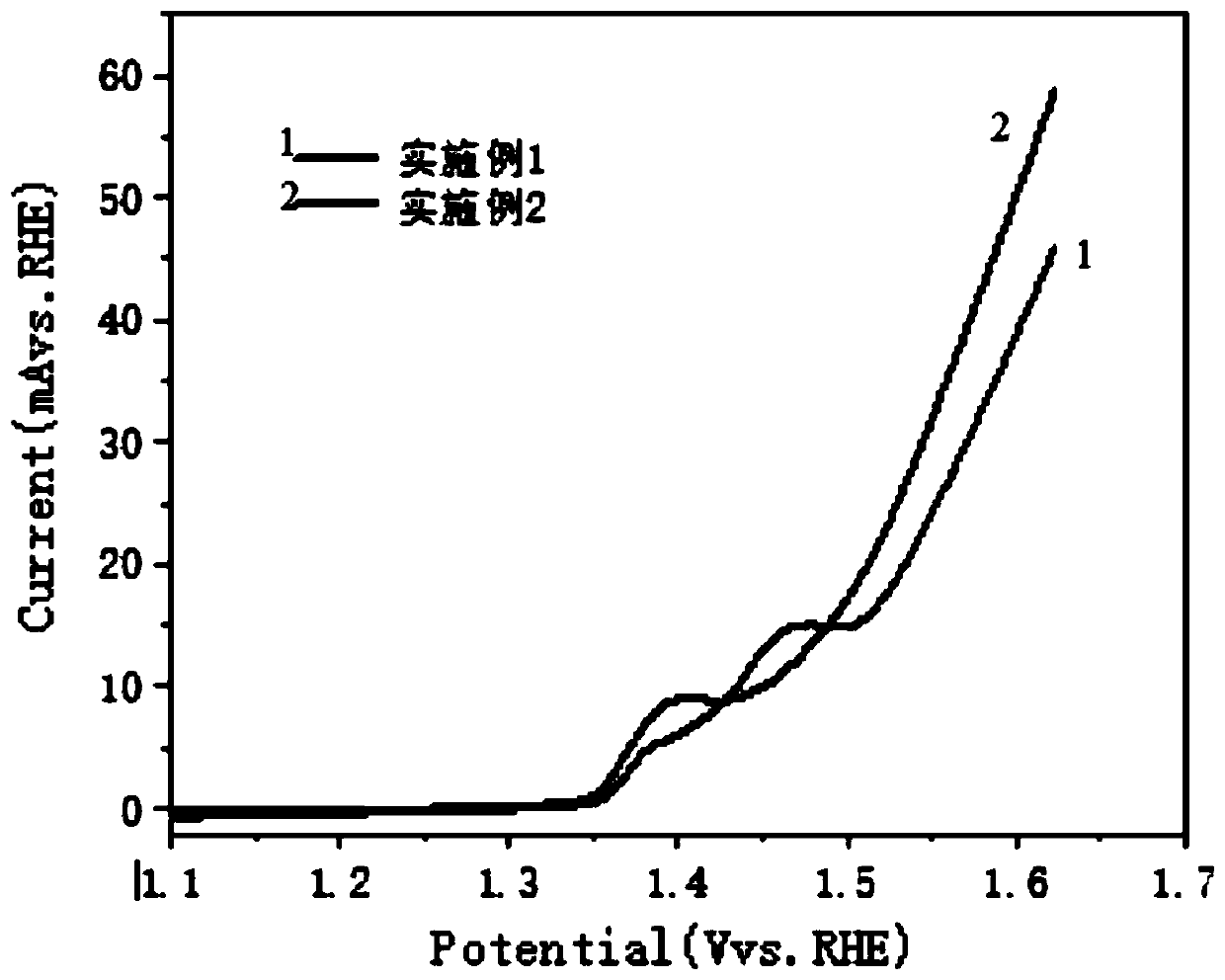

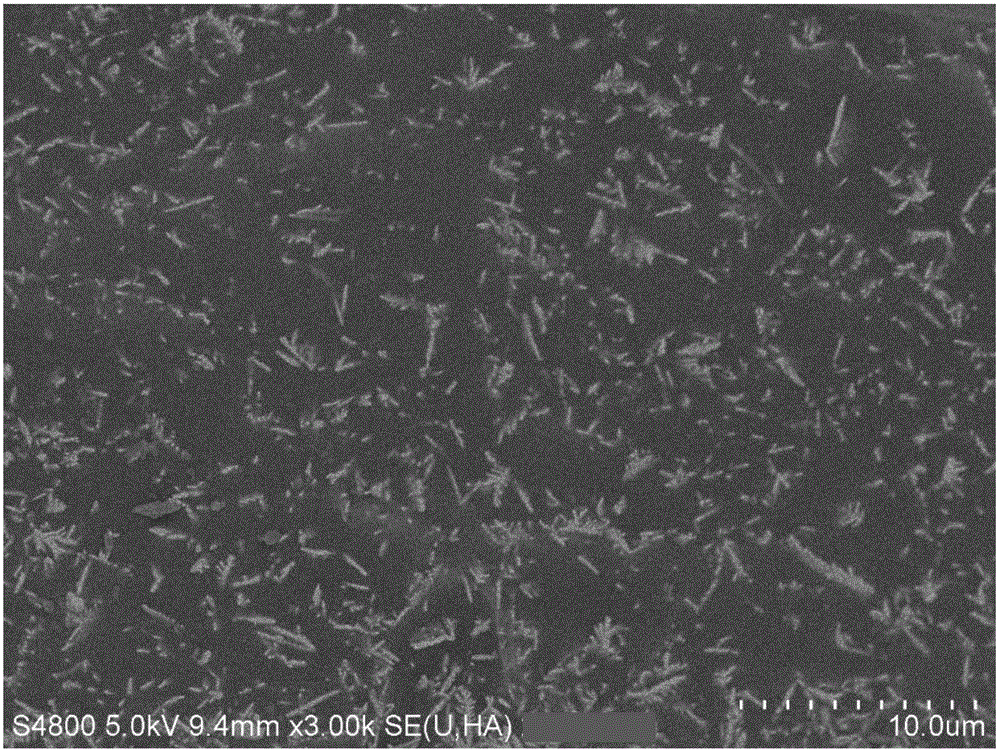

Amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material and preparation and application thereof

InactiveCN109794247AGood catalytic activityImprove uniformityElectrode shape/formsMetal/metal-oxides/metal-hydroxide catalystsBrown iron oxideOxide

The invention discloses an amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material and preparation and application thereof, and belongs to the technical field of electrochemistryenergy converting materials. The amorphous nickel-iron oxide nanometer sheet-shaped thin film material is synthesized in situ on a commercial foamed nickle matrix through a hydrothermal method, and the amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material has the advantages of a high specific surface area and many catalytic active sites. The material is applied to a 1M potassium hydroxide solution for electrolysis of water, when the current density is 10 mA.cm<-2>, the overpotential required for oxygen evolution is 206-220 mV, and the performance of the material is better than that of most currently-reported anodic oxygen evolution catalysis materials. Besides, the related preparing technology is simple, raw materials are rich and cheap, the material can replace a precious-metal-based catalyst which is expensive and scarce, and large-scale industrial application of electrolyzed water is promoted.

Owner:BEIJING UNIV OF TECH

Bezel packaging for sealed glass assemblies and a glass assembly therefor

InactiveUS8885116B2Improve integrityImprove reliabilityPlanar light sourcesStatic indicating devicesEngineeringFront edge

Methods and assemblies related to frame or bezel packaging of a sealed glass assembly, such as a fit-sealed OLED device, such as an OLED display panel. The frame or bezel packaging may have one or more of (a) rounded or chamfered corners, (a) a cover, (b) a reinforced lead edge, (c) openings or cutouts in the back panel to conserve material and lighten the bezel, and (d) a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the back and / or sides of the frame or bezel. The frame or bezel design may include a gap between the sealed glass assembly and the back panel of the bezel. The gap may be filled at least in part with low modulus of elasticity backing material. The glass package may have one or more of (a) rounded or chamfered corners, (b) rounded or chamfered edges, (c) a low modulus of elasticity material applied around its periphery or portions of its periphery, such as on the corners only, (d) a shortened lead end, and (e) a thickened lead end.

Owner:CORNING INC

Interconnection structure between solar laminated cells and solar laminated cell

ActiveCN106531829AReliable interconnectionInterconnection is stablePhotovoltaic energy generationSemiconductor devicesElectrical connectionEngineering

The present invention belongs to the technical field of solar cells, and particularly relates to an interconnection structure between solar laminated cells and a solar laminated cell. The interconnection structure is used for sequentially bonding at least two cells and forming a good electrical connection. A front electrode and / or a back electrode of the cell are / is of a hollow structure. The back electrode of the previous cell is connected with the front electrode of the next adjacent cell by using conductive glue, so that a lot of front and back electrode paste is saved, and the cost of the laminated cell is lowered. For a back fragmented hollow design, the interconnection structure also can help reduce the amount of the used conductive glue and the cost of the laminated cell.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

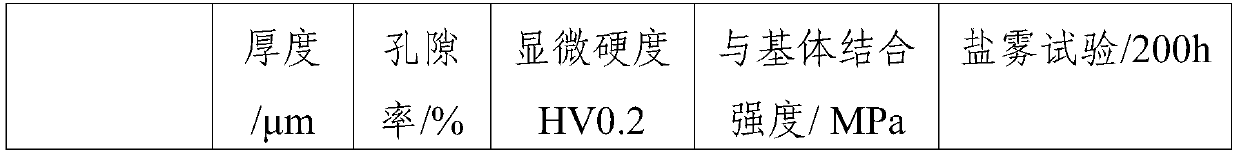

Metal wear-resisting anti-corrosion coating and electric arc spraying technology thereof

ActiveCN106756712AGood mechanical bondImprove adhesionMolten spray coatingMetal coatingCoated surface

The invention discloses a metal wear-resisting anti-corrosion coating. According to the coating, a coating wire is sprayed to a base material surface in an electric arc spraying manner, the thickness of the coating ranges from 0.5 mm to 0.8 mm, after spraying of the coating wire on the base material surface is finished, the surface of the coating is coated with a layer of hole sealing agent, and the coating is formed by mixing the coating wire comprising, by mass percent, 20% to 35% of TiAl3, 10% to 20% of Cr3C2, 5% to 15% of WC, 5% to 10% of V, 5% to 15% of Mo, 2% to 8% of Nb, 10% to 20% of Al and the balance Fe. The invention further discloses an electric arc spraying technology. The technology comprises the steps that purifying and sand blasting roughening treatment are carried out firstly, the wear-resisting anti-corrosion coating is sprayed in an electric arc manner, and finally, after spraying is finished, methyl methacrylate and a curing agent are adopted for coating and hole sealing of the surface of the coating. According to the metal wear-resisting anti-corrosion coating, the combination strength of the coating and the base material reaches more than 45 MPa, and the adhesive force of the metal coating and the base material is greatly improved.

Owner:GUANGXI UNIV +1

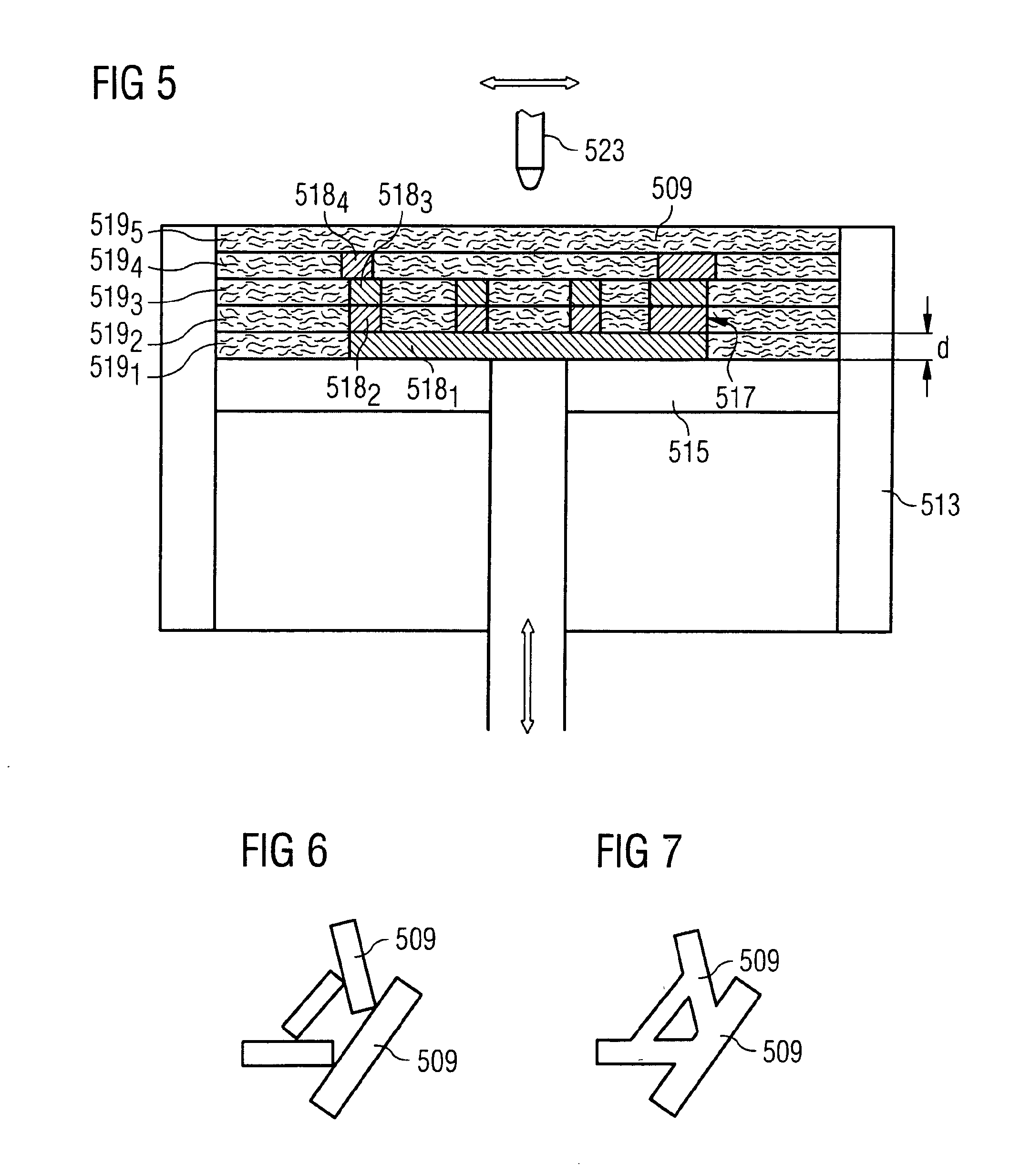

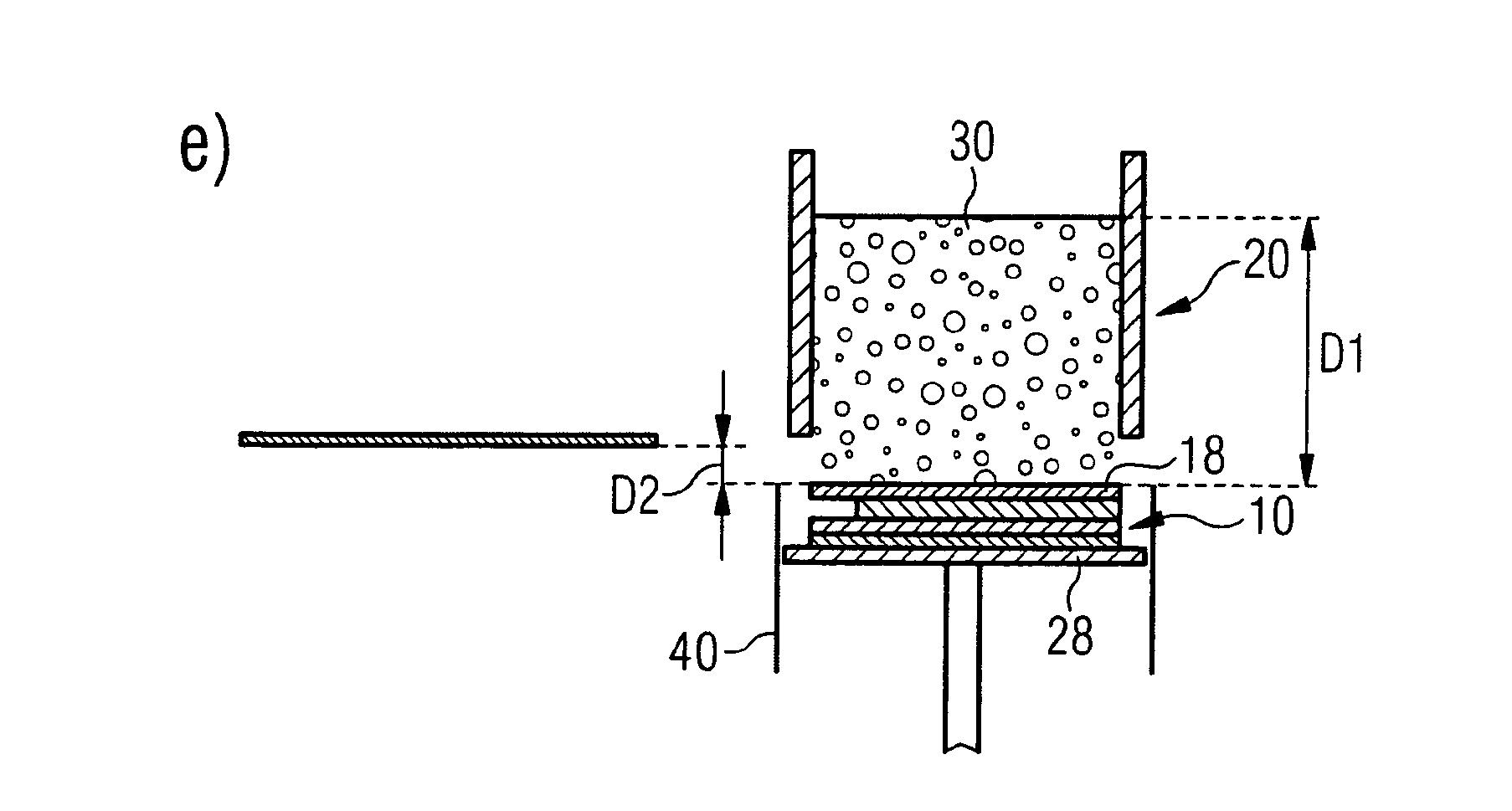

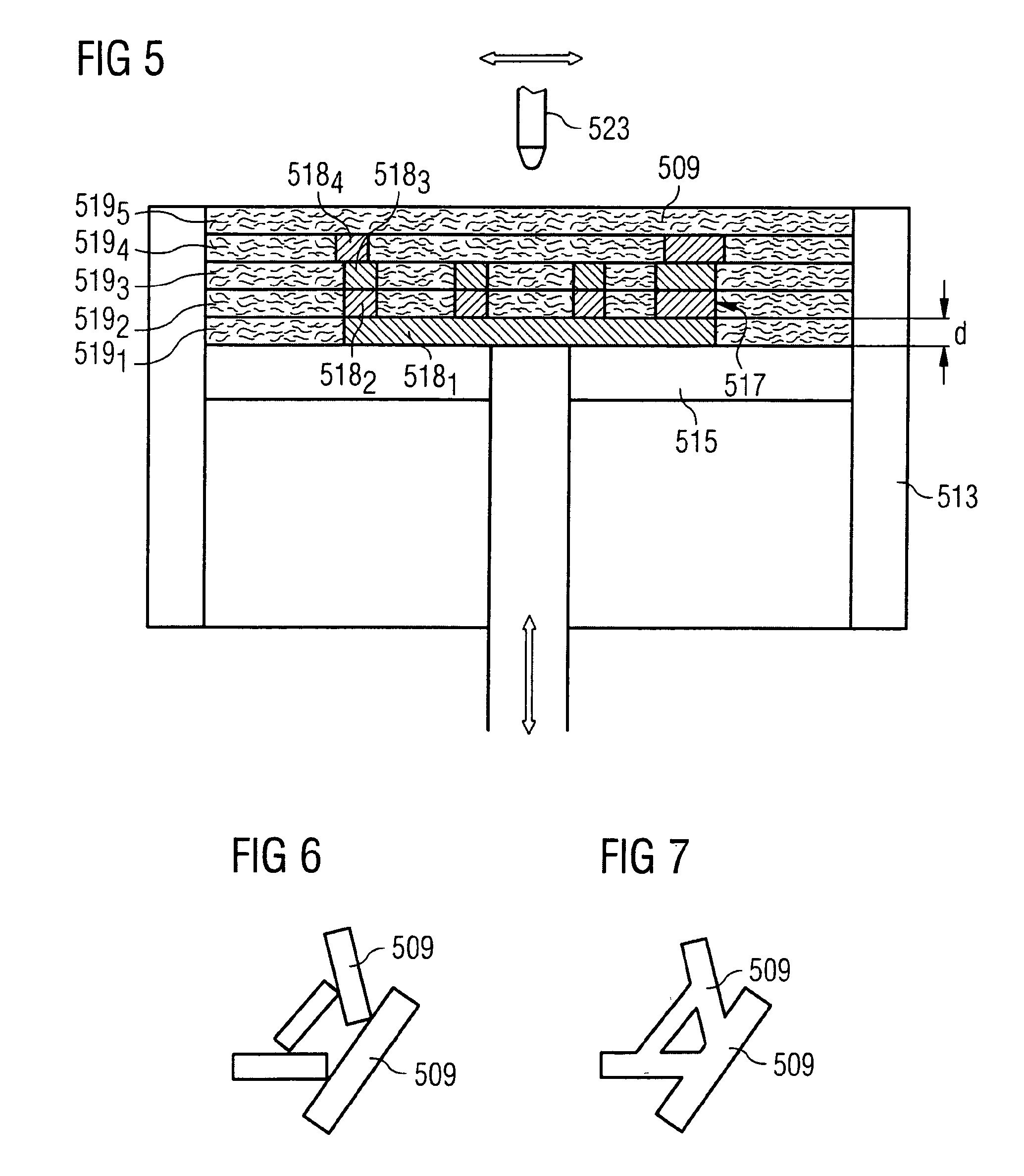

Methods and apparatus for use in solid freeform fabrication

ActiveUS20110156300A1Easy to produceSpecific characteristicMouldsConfectioneryLayer thicknessMaterials science

A method and apparatus are disclosed for producing a three-dimensional body consisting of individual solidified layers, whereby a coating material is disposed on one of a carrier plate and an already-solidified layer of the body in a first layer thickness by slidably withdrawing a bottom plate of a storage container filled with the coating material, thereby allowing coating material to descend from the storage container onto the carrier plate or already-solidified layer of the body. The first layer thickness of the coating material is then reduced to a lesser second layer thickness by re-inserting the bottom plate through the coating material disposed on the carrier plate or already-solidified layer. The coating material is then solidified at predetermined locations in order to generate a desired layer contour of one solidified layer of the three-dimensional body.

Owner:EVONIK OPERATIONS GMBH

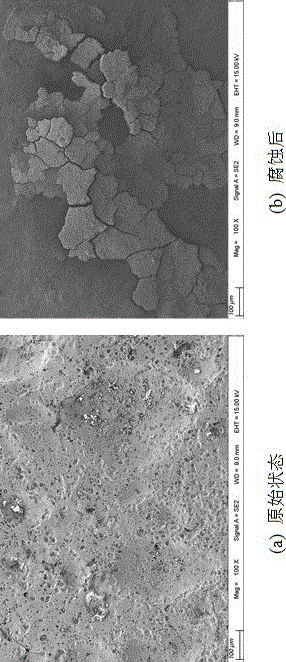

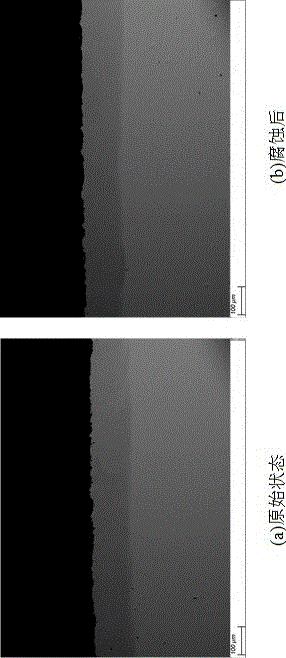

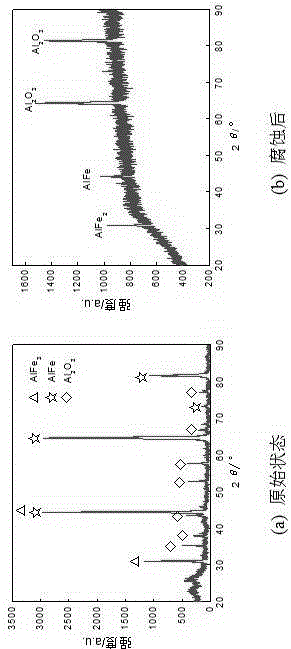

Laser remelting method for steel electric arc spraying aluminum coating layer used for ocean platform

ActiveCN104928617AGuaranteed movement speedGood mechanical bondMolten spray coatingCoated surfaceStructure property

The invention relates to the technical field of steel surface modification processing, in particular to a laser remelting method for a steel electric arc spraying aluminum coating layer used for an ocean platform, in order to solve the problem that the seawater corrosion resistant capacity of the coating layer is improved without increasing the thickness of the coating layer, and belongs to a material surface modification composite processing technology. By means of a electric arc spraying technology, a layer of the aluminum coating layer is prepared by using the surface of a steel base material on the ocean platform, then a laser remelting technology is used to iron melt the aluminum coating layer and the surface of a substrate, and after cooling is conducted, a Fe-Al alloy layer is formed; the surface of the coating layer is flat, the structure property can be improved, alloy combination is formed between the coating layer and the base material, a few amorphous state aluminum is generated in the coating layer, and the corrosion resistant performance of the coating layer can be improved.

Owner:CHANGZHOU UNIV

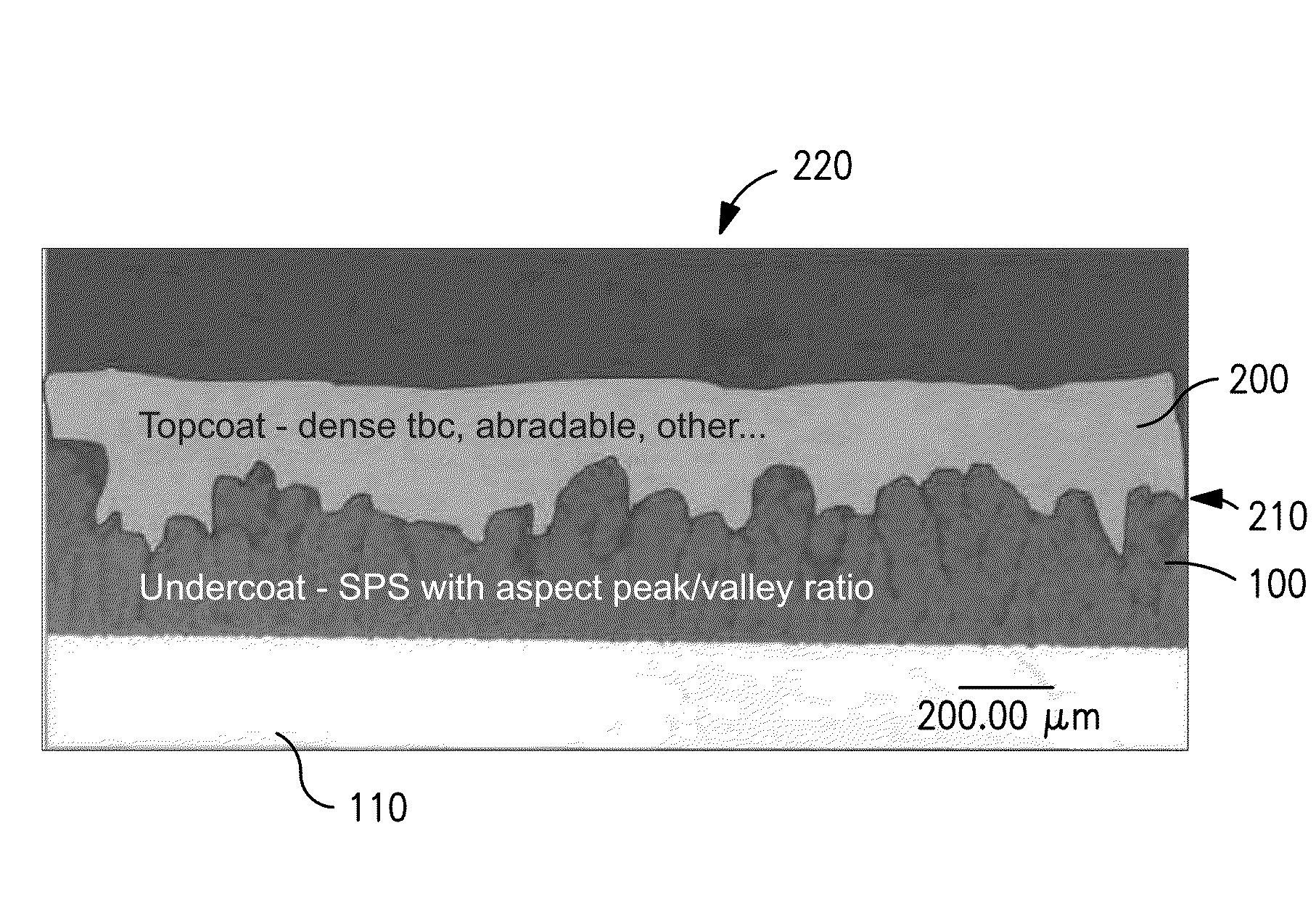

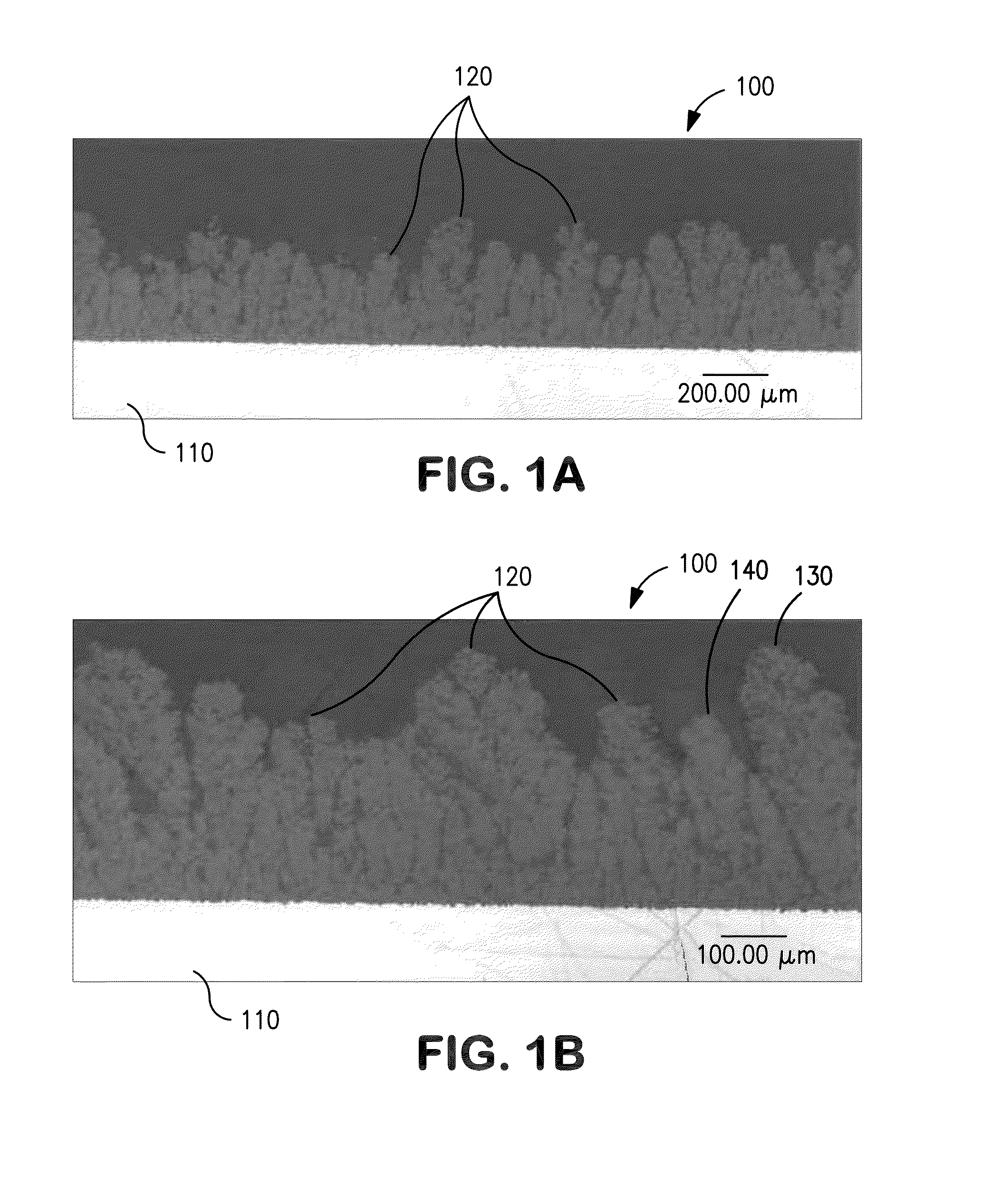

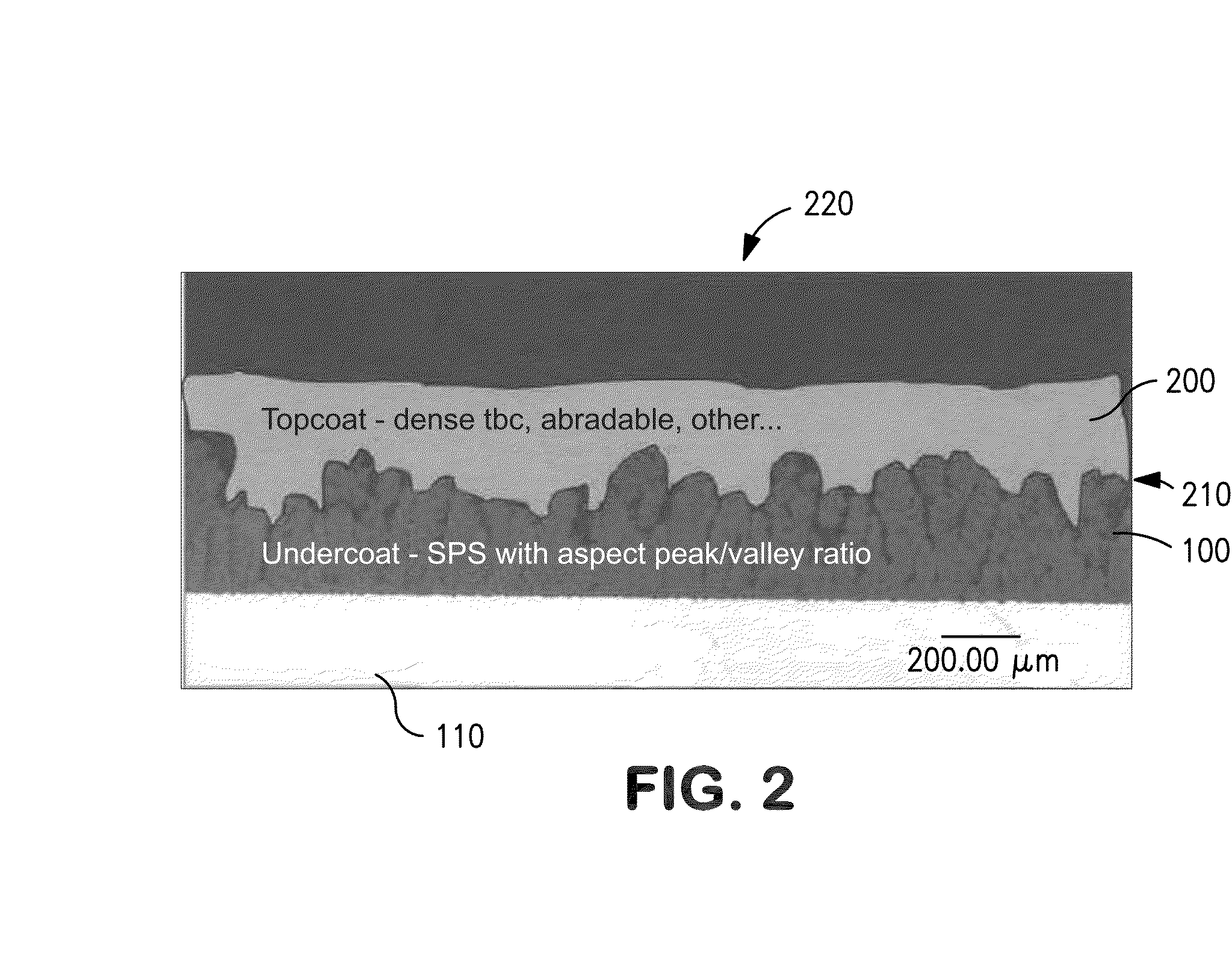

Modified thermal barrier composite coatings

InactiveUS20150147524A1Good mechanical bondReduce porosityMolten spray coatingLayered productsMetallurgyCoating system

A novel coating system is provided that allows for a single coating structure to exhibit properties previously considered mutually exclusive. A unique approach for tailoring specific properties of a coating structure as a function of location within the coating is provided with a specially designed undercoat having a columnar macrostructure and a second coating layer that is selected to be compatible with and complement the undercoat. The resultant composite coating system can maintain thermocomechanical compliance while improving various bulk and / or free surface properties of the composite coating system.

Owner:PRAXAIR ST TECH INC

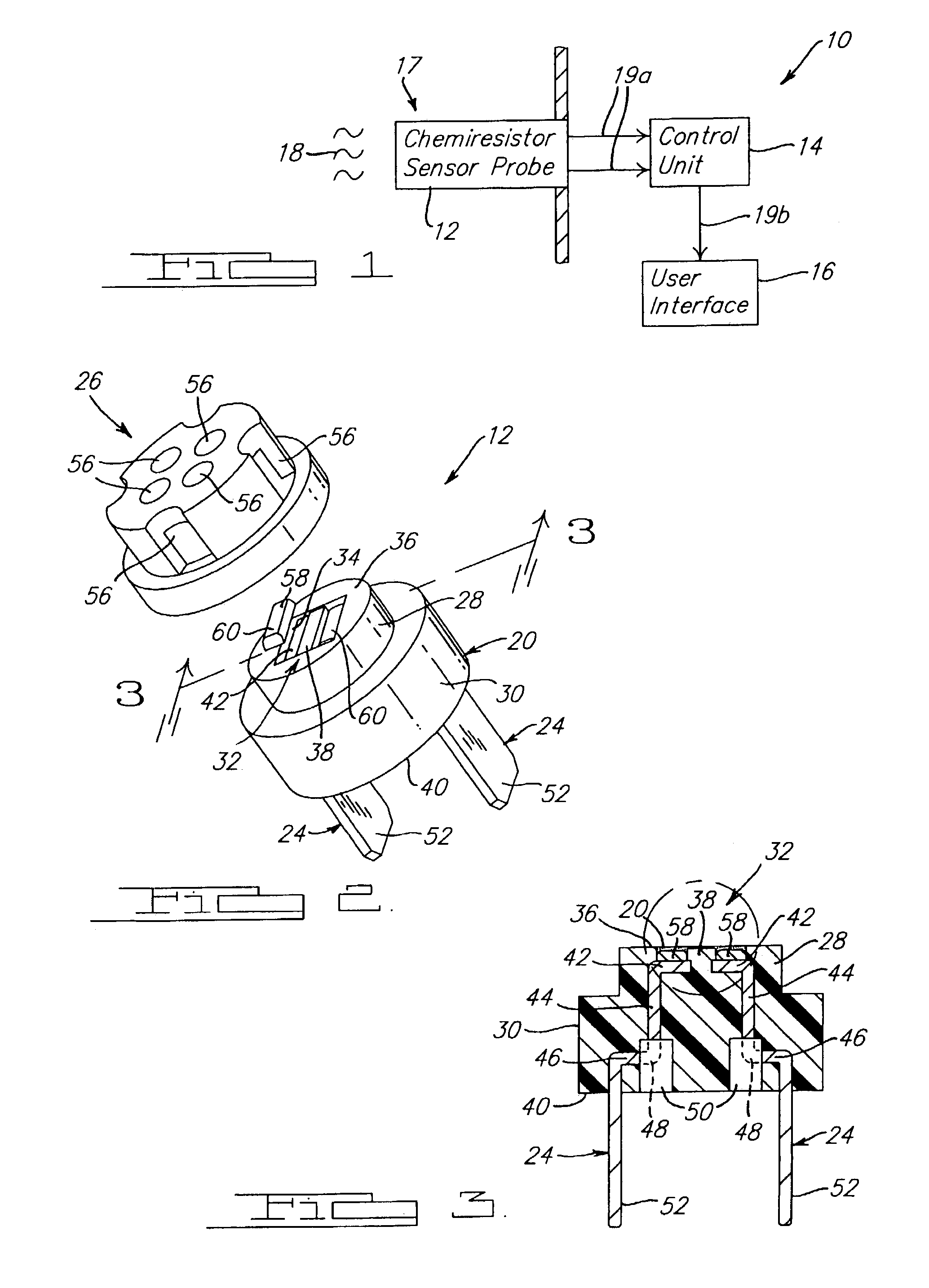

Robust chemiresistor sensor

InactiveUS7112304B2Reliable electrical connectionImprove responsivenessImmobilised enzymesBioreactor/fermenter combinationsElectrical resistance and conductanceAnalyte

A chemiresistor sensor probe for detecting target analytes. The probe includes a body having a first control surface and a second control surface recessed within the first. A sensor film comprises numerous conductive particles disposed upon the second surface. The film swells upon absorbing one or more analytes for which it has an affinity, thus causing the conductive particles to become more dispersed and increasing the resistance between the particles. The thickness of the film is equal to the distance between the first surface and the second surface, thus permitting the thickness to be controlled by varying the distance between the control surfaces. The robustness of the sensor probe is enhanced by placing a porous or mesh electrode along with, or in place of, a chemical binding agent between the film and the terminals. The robustness is also improved by placing a diode in series with the sensor circuit.

Owner:THERM O DISC

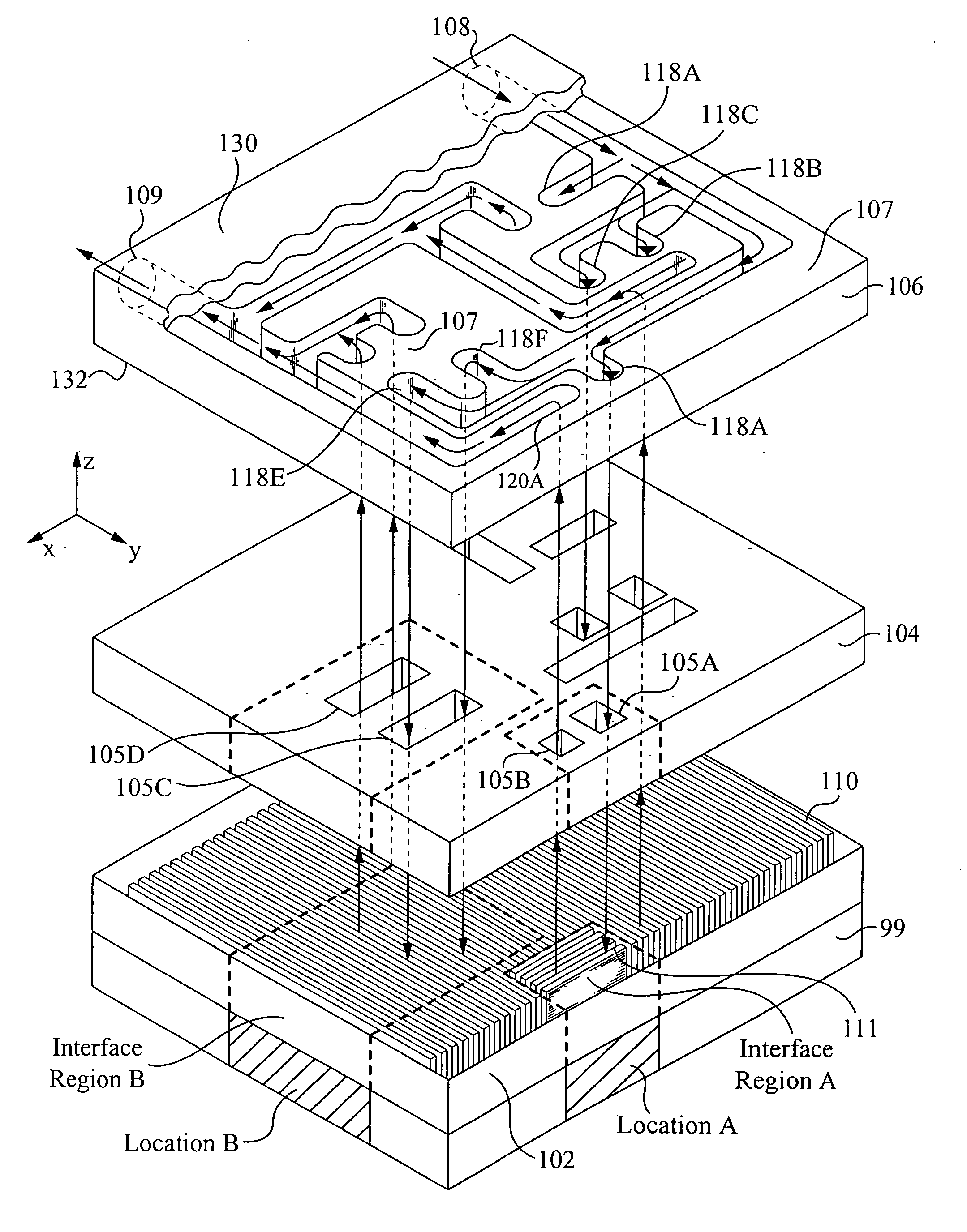

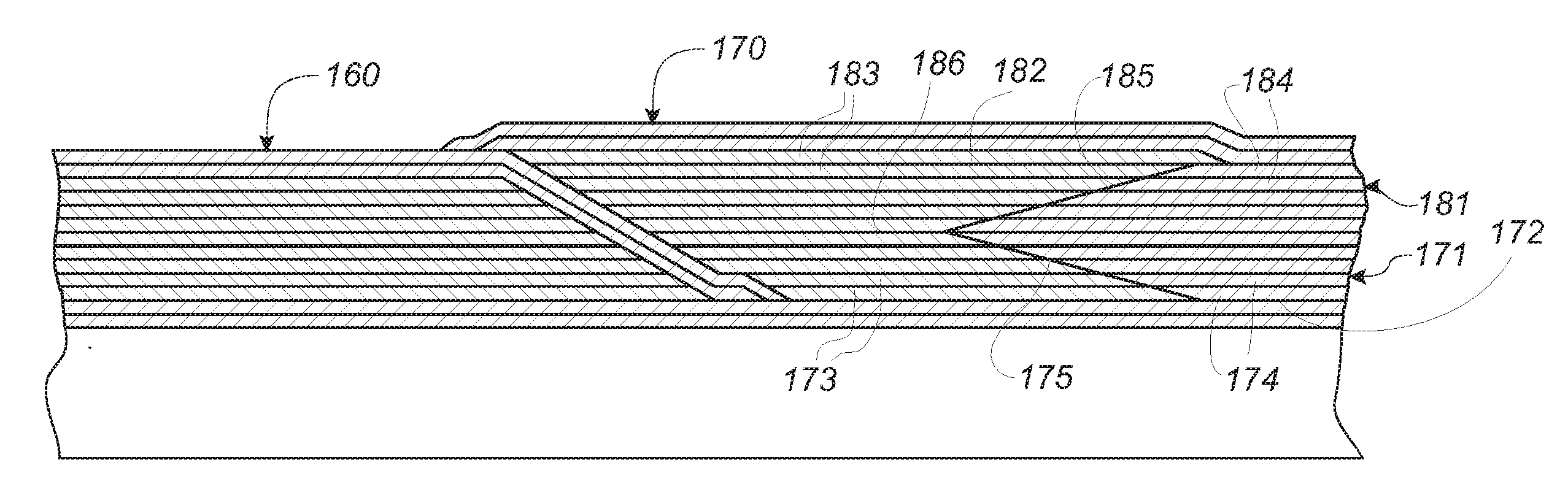

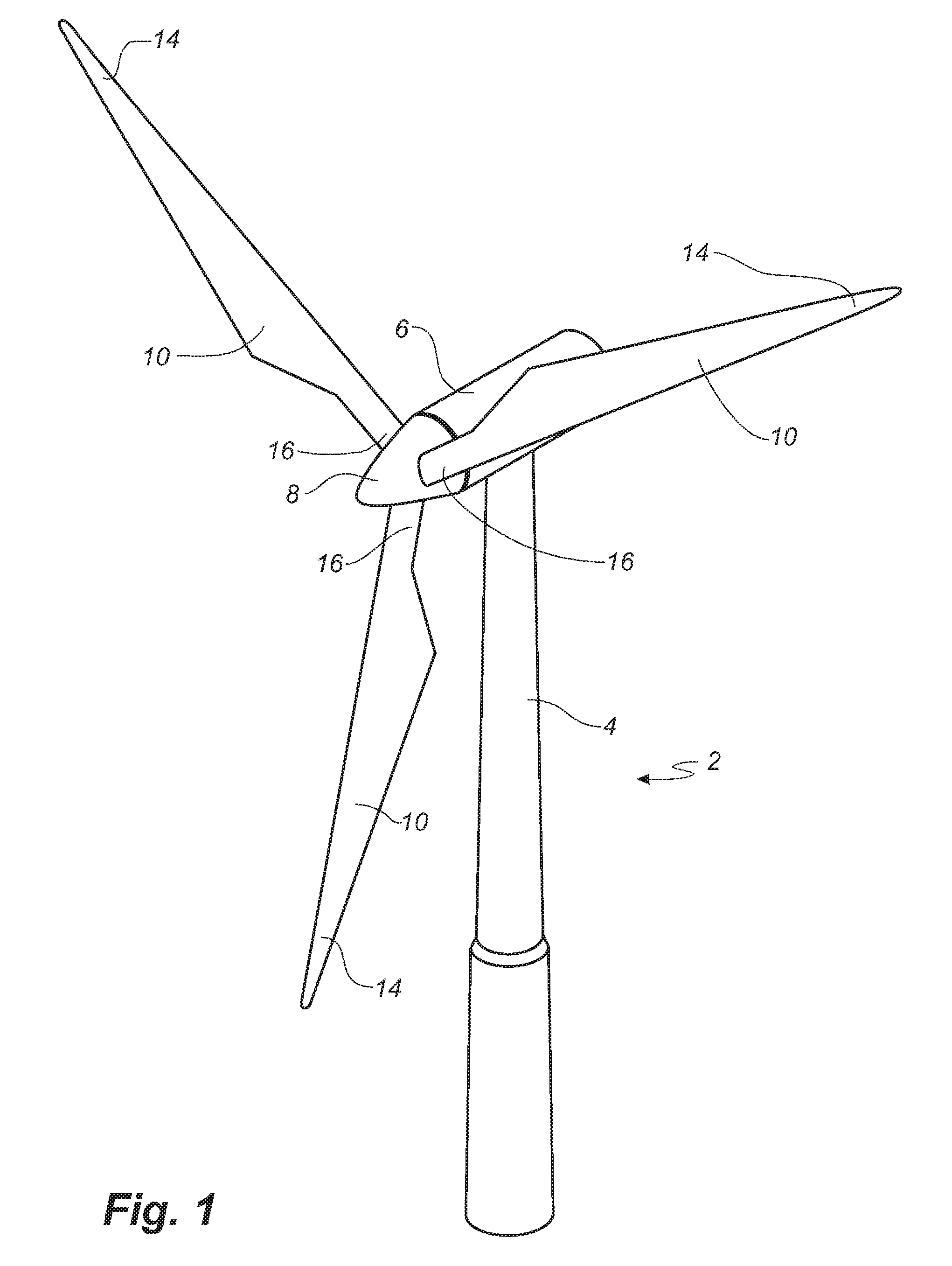

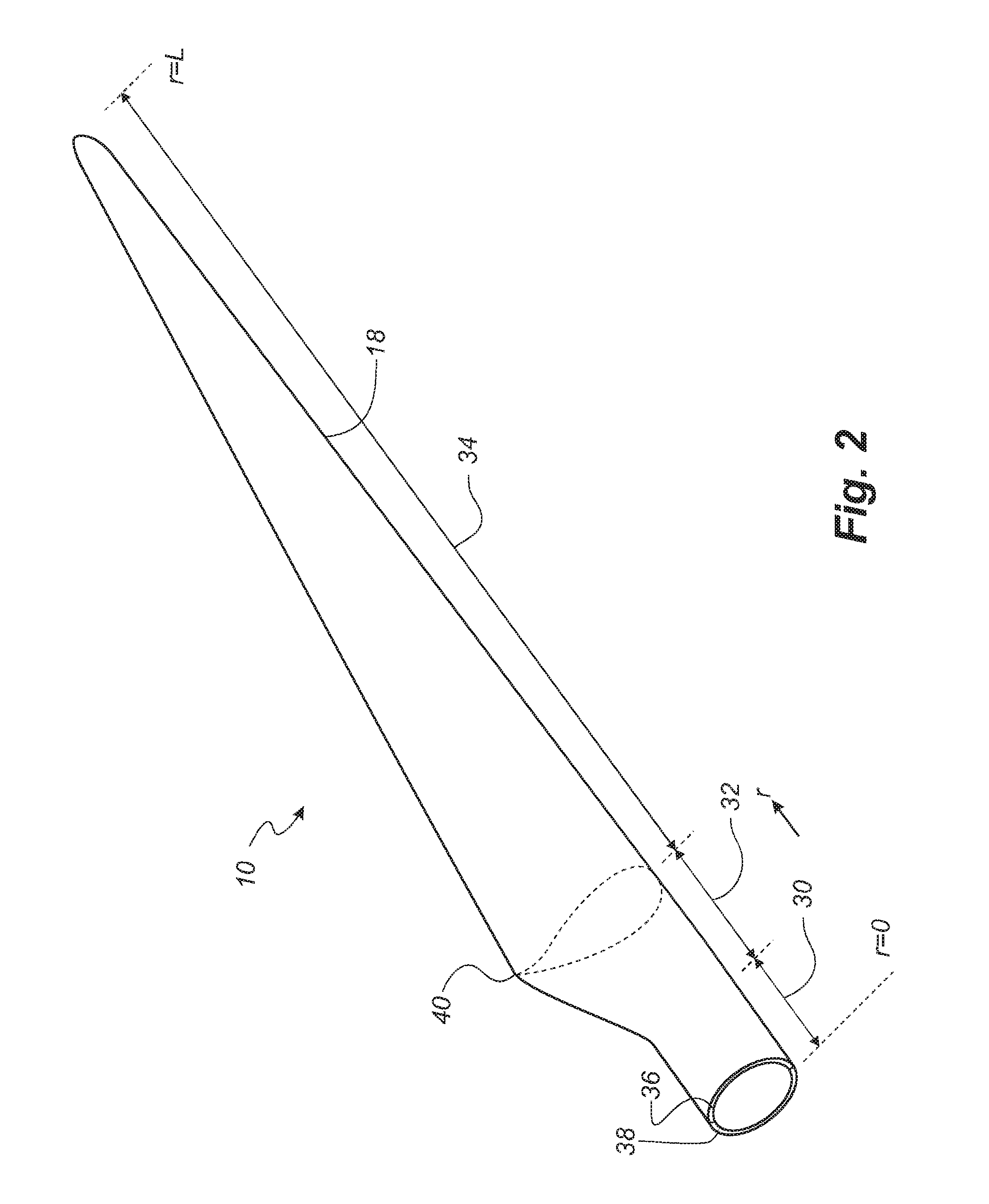

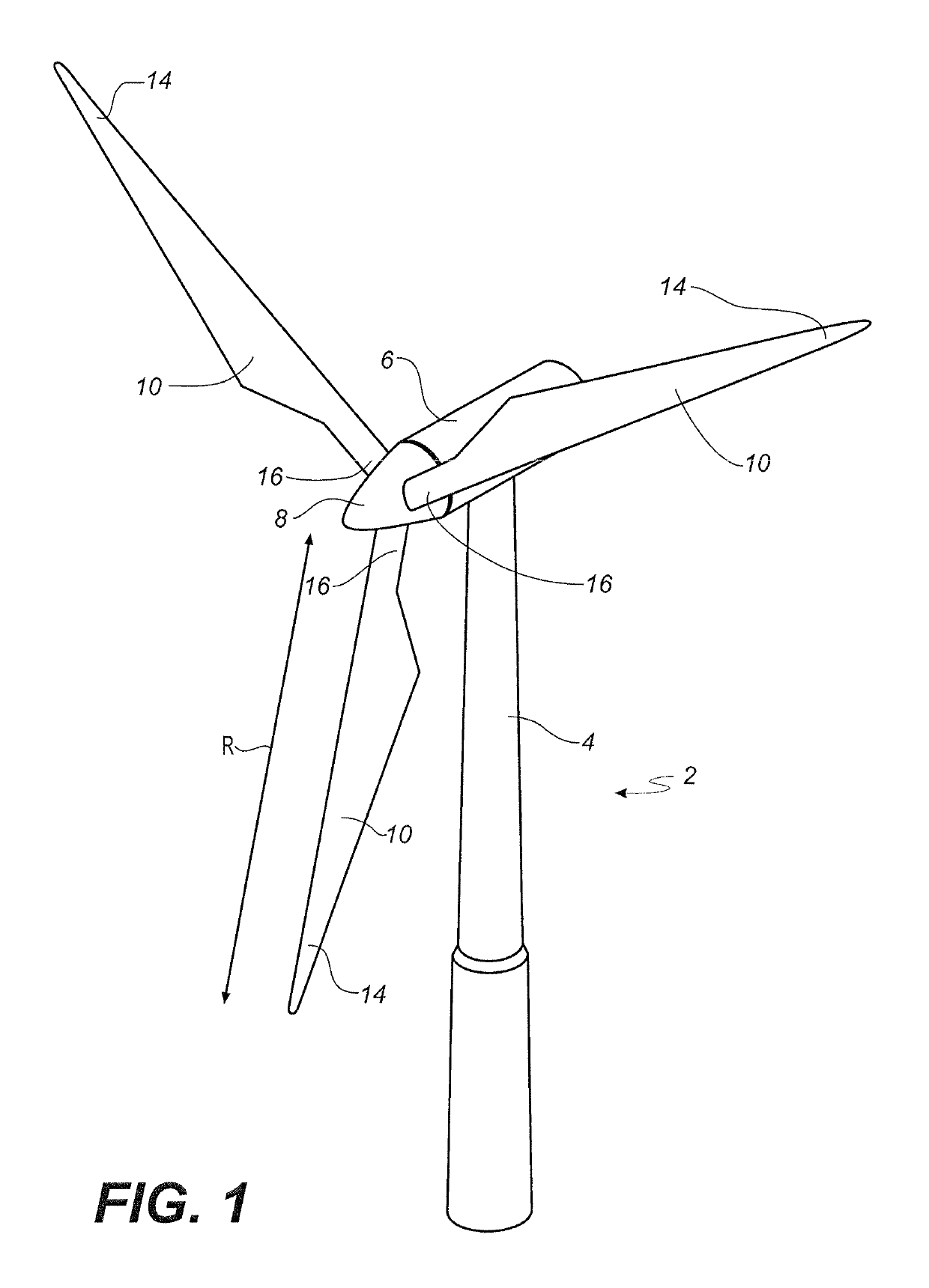

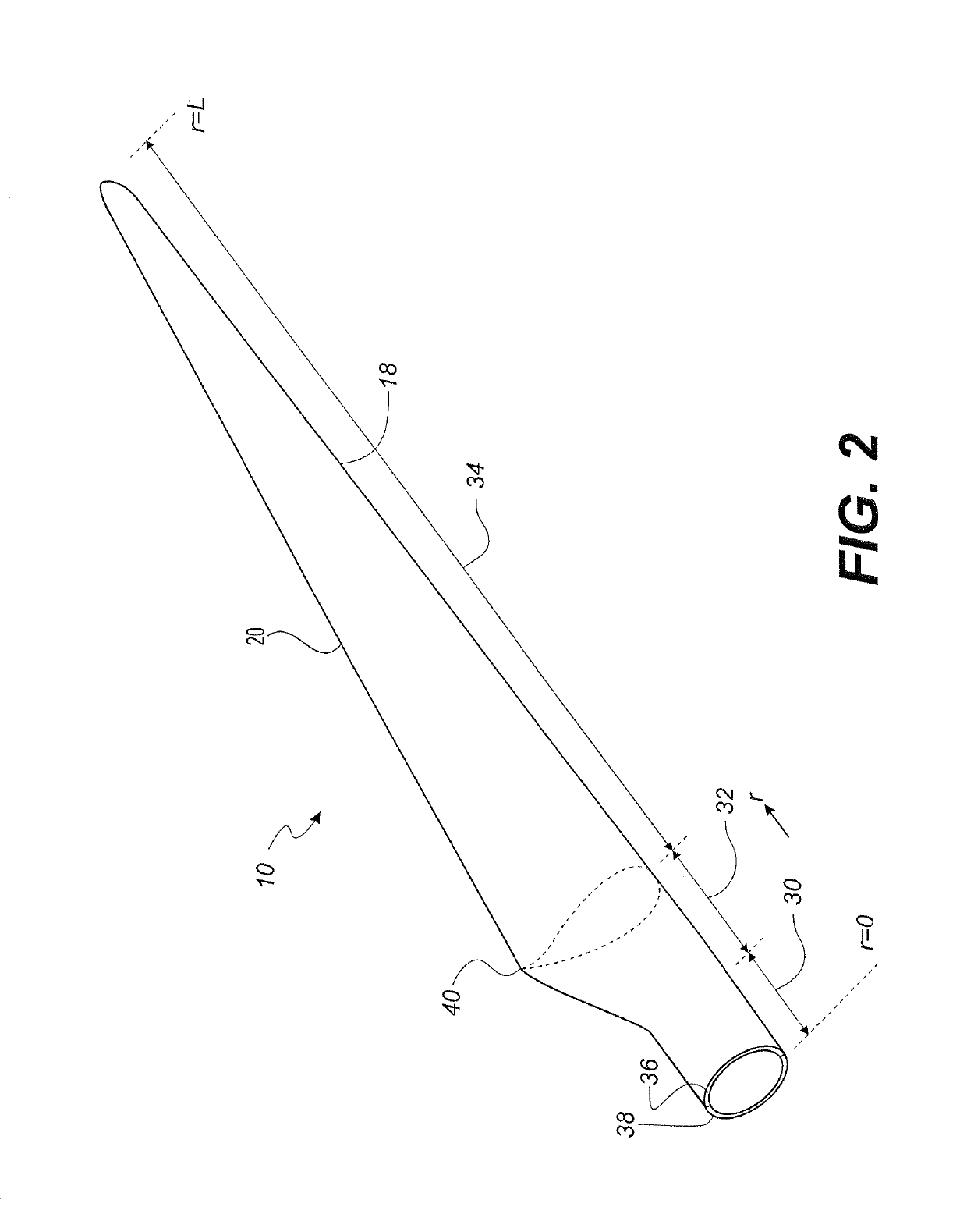

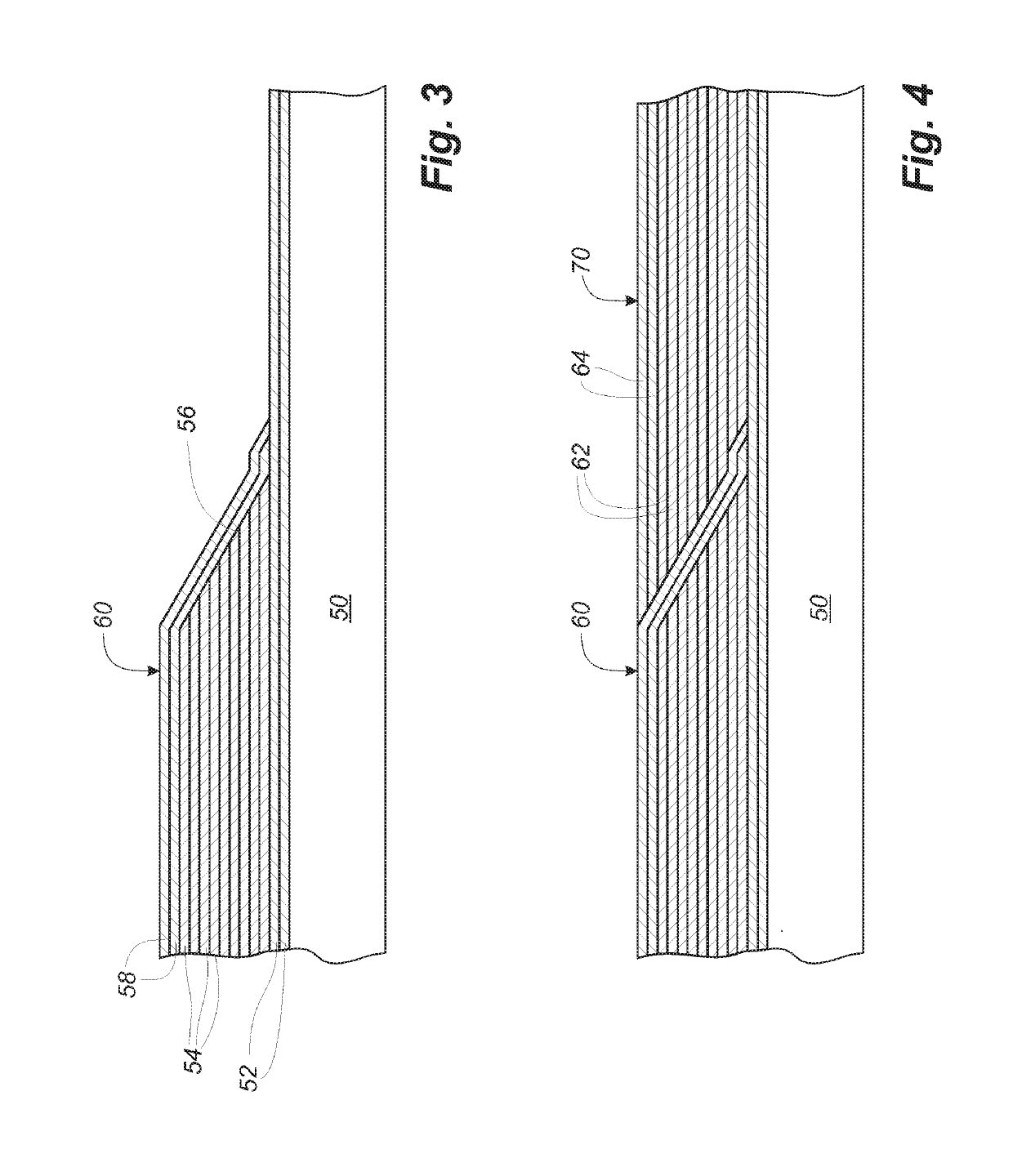

Wind turbine blade with improved fibre transition

ActiveUS20160341178A1Increased complexityStrong stiffness transitionEngine manufactureFinal product manufactureFiberFibre type

A wind turbine blade having a transition between two reinforcement fibre types is described. A gradual transition is provided by a combined double-tapered thickness section with first type reinforcement fibres sandwiched between second type reinforcement fibres or vice versa. The double-tapering is provided during layup and that the reinforcement material is impregnated with a polymer resin and then cured or hardened so that the two types of reinforcement fibres are embedded in a common polymer matrix.

Owner:LM WP PATENT HLDG

Bezel packaging of frit-sealed OLED devices

InactiveUS7786559B2High mechanical reliabilityImprove the immunitySemiconductor/solid-state device detailsElectroluminescent light sourcesFiberAdhesive

Methods and assemblies relate to bezel packaging of a sealed glass assembly, such as a frit-sealed OLED device. The bezel packaging includes a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the bezel. A bonding agent, which may include the low modulus of elasticity material and / or a separate bonding material, affixes the sealed glass assembly to the bezel. Bezel modifications may be made to stabilize the bezel. Exemplary bezel modifications include reinforced bezel side walls and supporting straps attached between bezel walls. The bezel design may include a gap between the edges of the sealed glass assembly and the bezel walls, so as to avoid direct contact therewith. The gap may be filled at least in part with low modulus of elasticity organic adhesive to provide additional shock absorbency. The low modulus of elasticity material may include foam, ceramic fiber cloth and / or a low modulus of elasticity polymeric organic coating.

Owner:CORNING INC

Hot melt pressure sensitive adhesive composition that includes vegetable wax and articles including the same

The invention provides a hot melt pressure-sensitive adhesive composition that includes thermoplastic polymer, tackifying agent, plasticizer oil, and from at least 5 % by weight to about 25 % by weight vegetable wax.

Owner:HB FULLER CO

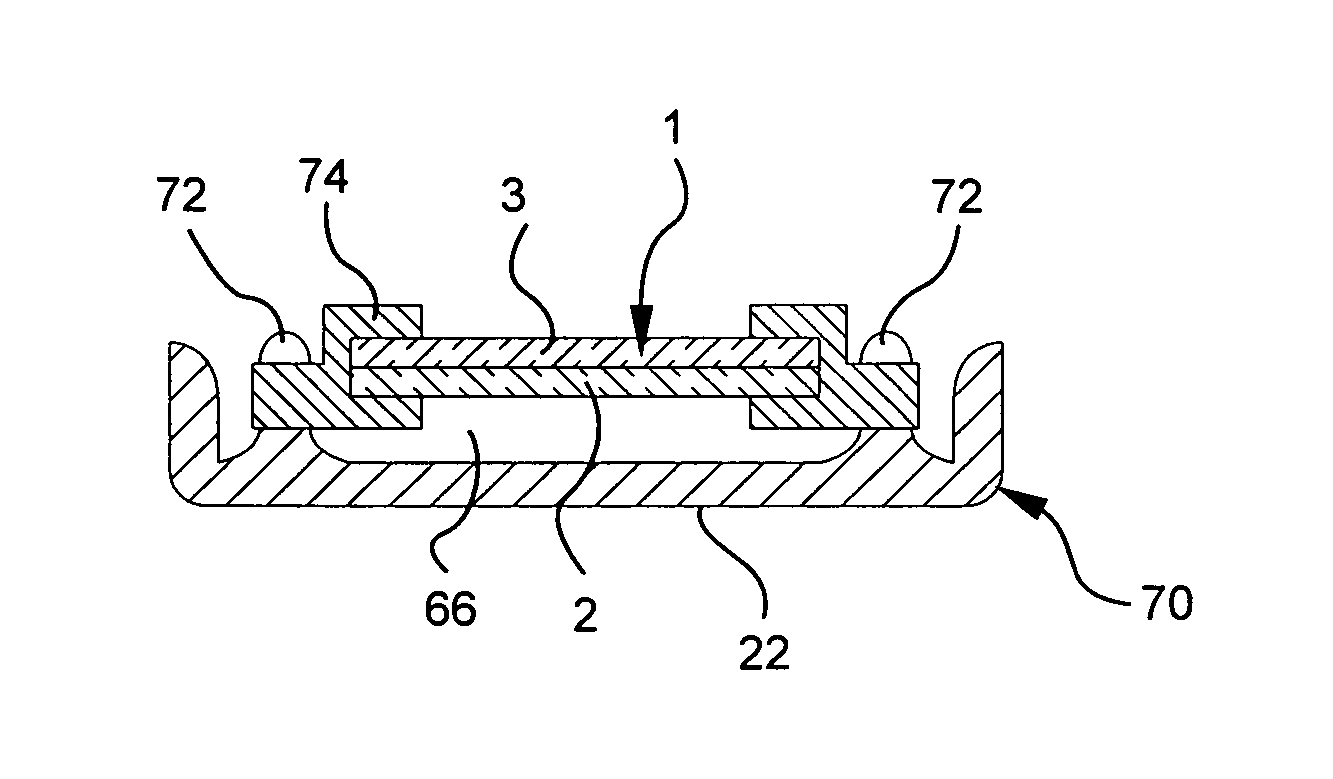

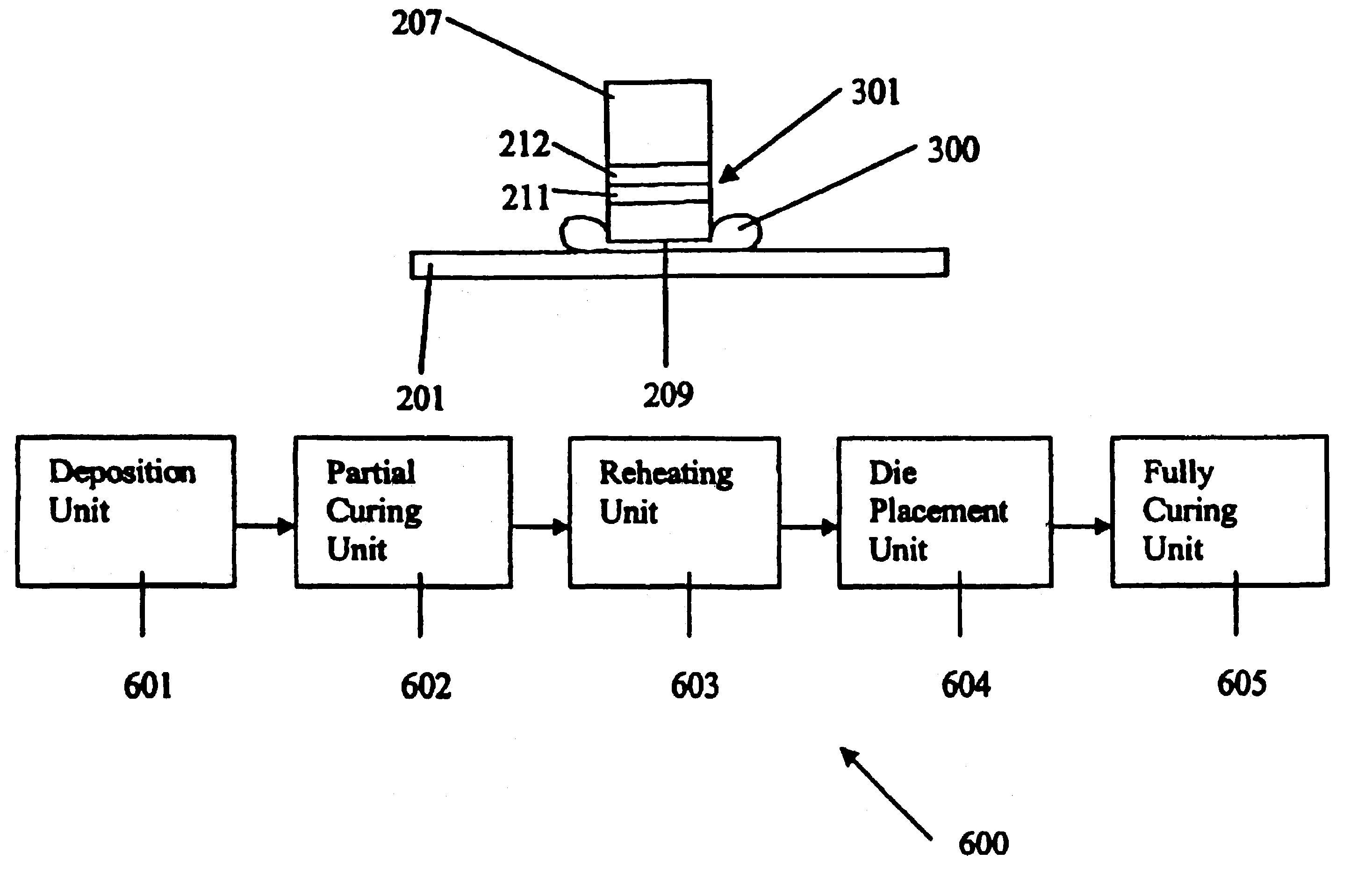

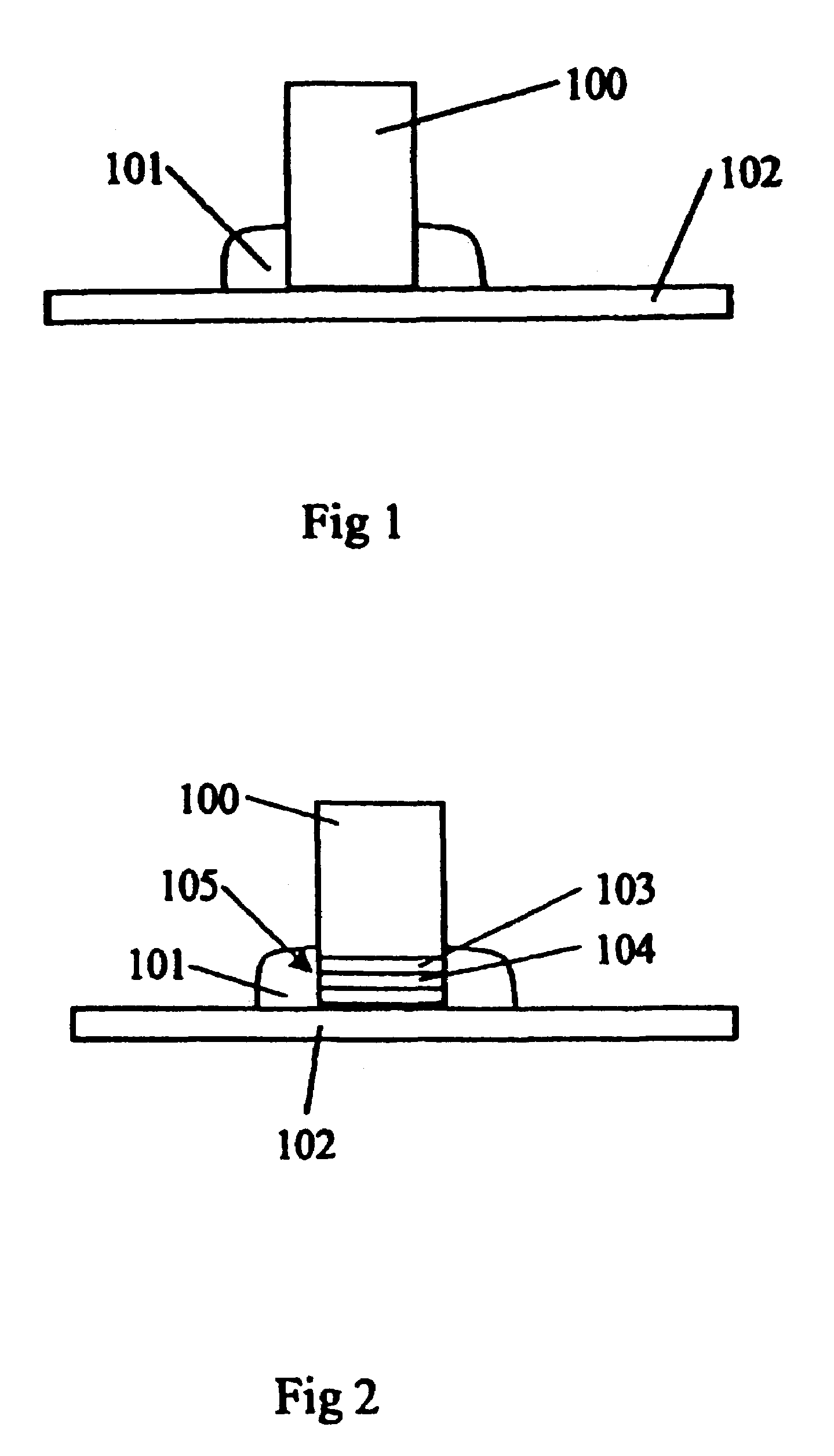

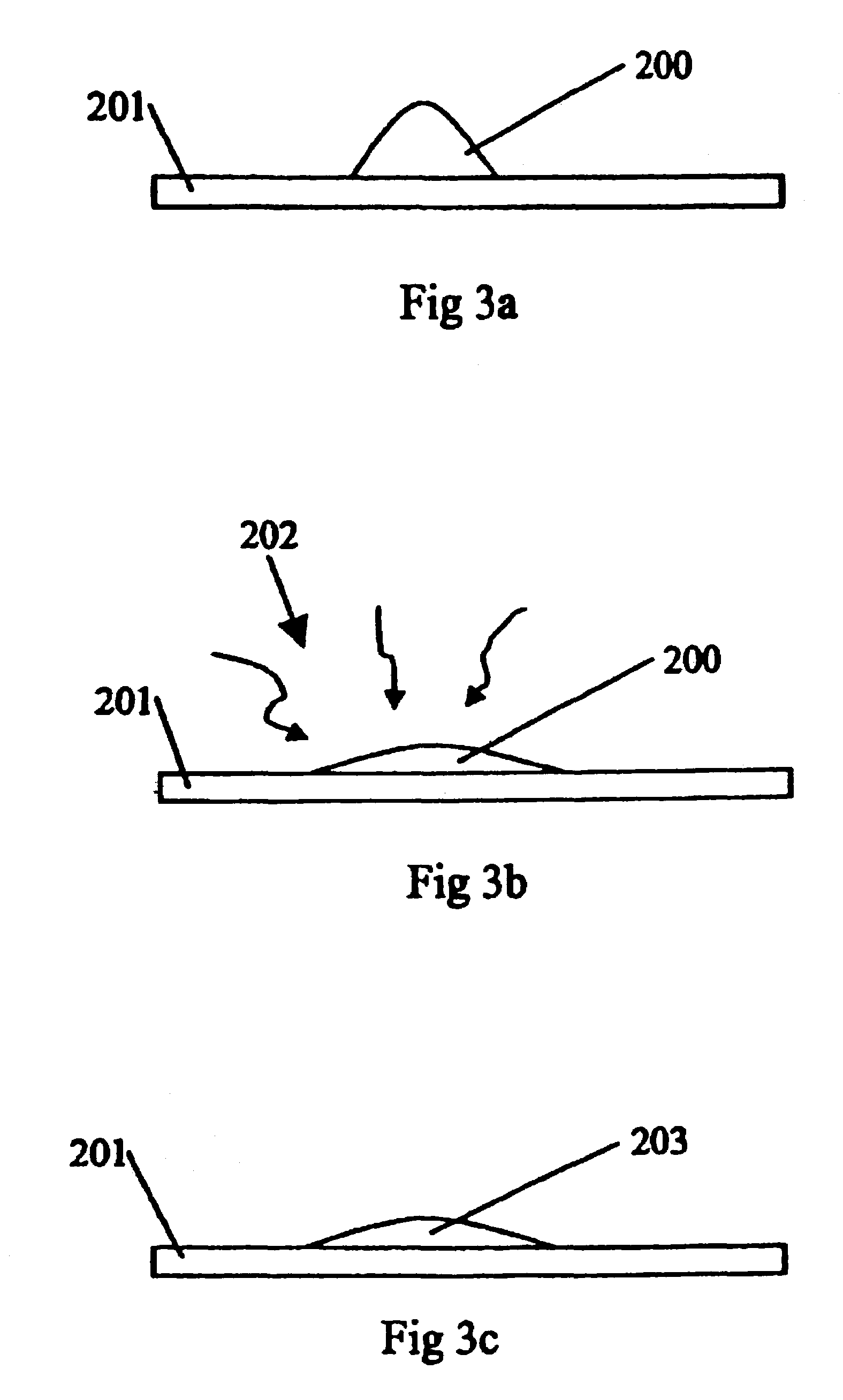

Adhesive die attachment method for a semiconductor die and arrangement for carrying out the method

InactiveUS6967123B2Easy to controlGood mechanical bondSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention relates to an adhesive attaching method for attaching a semiconductor die to a substrate in which an adhesive is deposited onto the substrate, the deposited adhesive is partially cured and / or dried, the partially cured and / or dried adhesive is reheated and a semiconductor die is placed onto the reheated adhesive, after which the adhesive is fully cured so that the semiconductor die is bonded, both electrically and mechanically, to the substrate.

Owner:BENCH WALK LIGHTING LLC

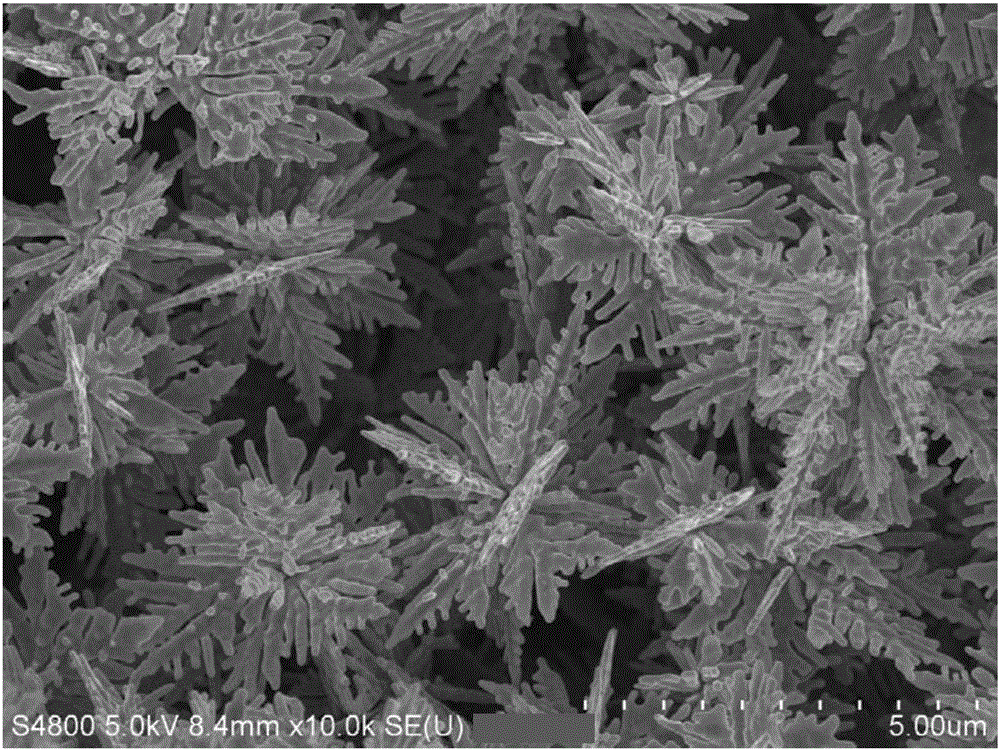

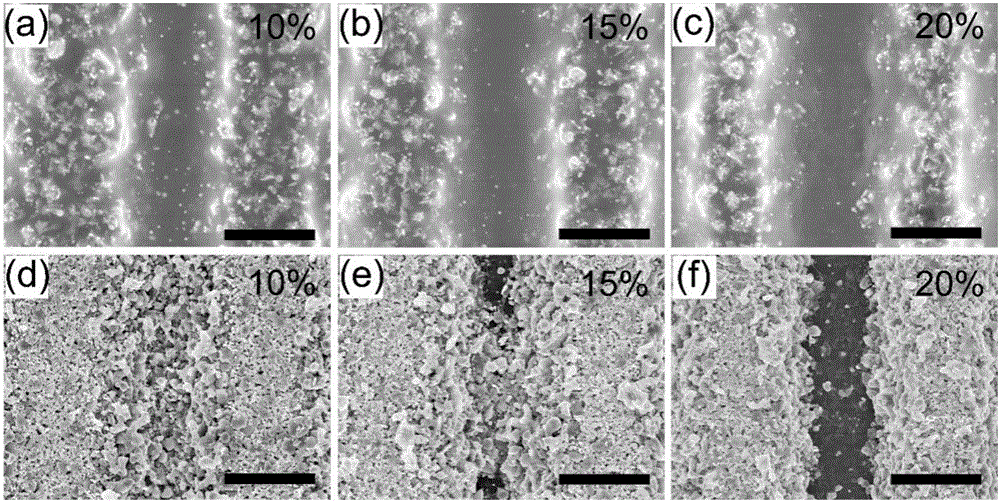

Conductive composite material and preparation method thereof, and preparation method for conductive line

ActiveCN105006270AReduce energy transferSmall thermal deformationNon-conductive material with dispersed conductive materialPrinted circuit manufactureLaser etchingPolymer resin

The invention discloses a conductive composite material and a preparation method thereof, and a preparation method for a conductive line. The conductive material comprises a substrate, and metal particles uniformly dispersed in the substrate, the diameter of the metal particles is from 100 nm to 10 <mu>m, the substrate is polymer resin, and the metal particles are metal particles with three-dimensional fractal layered structures. The conductive material is used for laser etching, the micro-nano metal particles with the three-dimensional fractal layered structures are employed as the conductive filling material, the unique geometric shapes of the metal particles are employed so that ablation occurs more easily under the effect of laser compared with conventional filling material particles, and finer wiring effect can be realized under low laser power; the same conductivity is reached by adopting less metal particles than the conventional filling material particles so that the required laser etching energy is less; and the content of the metal particles is less so that the bonding force in conductive slurry and the bonding force between the conductive slurry and a matched insulation substrate can be both greatly increased.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

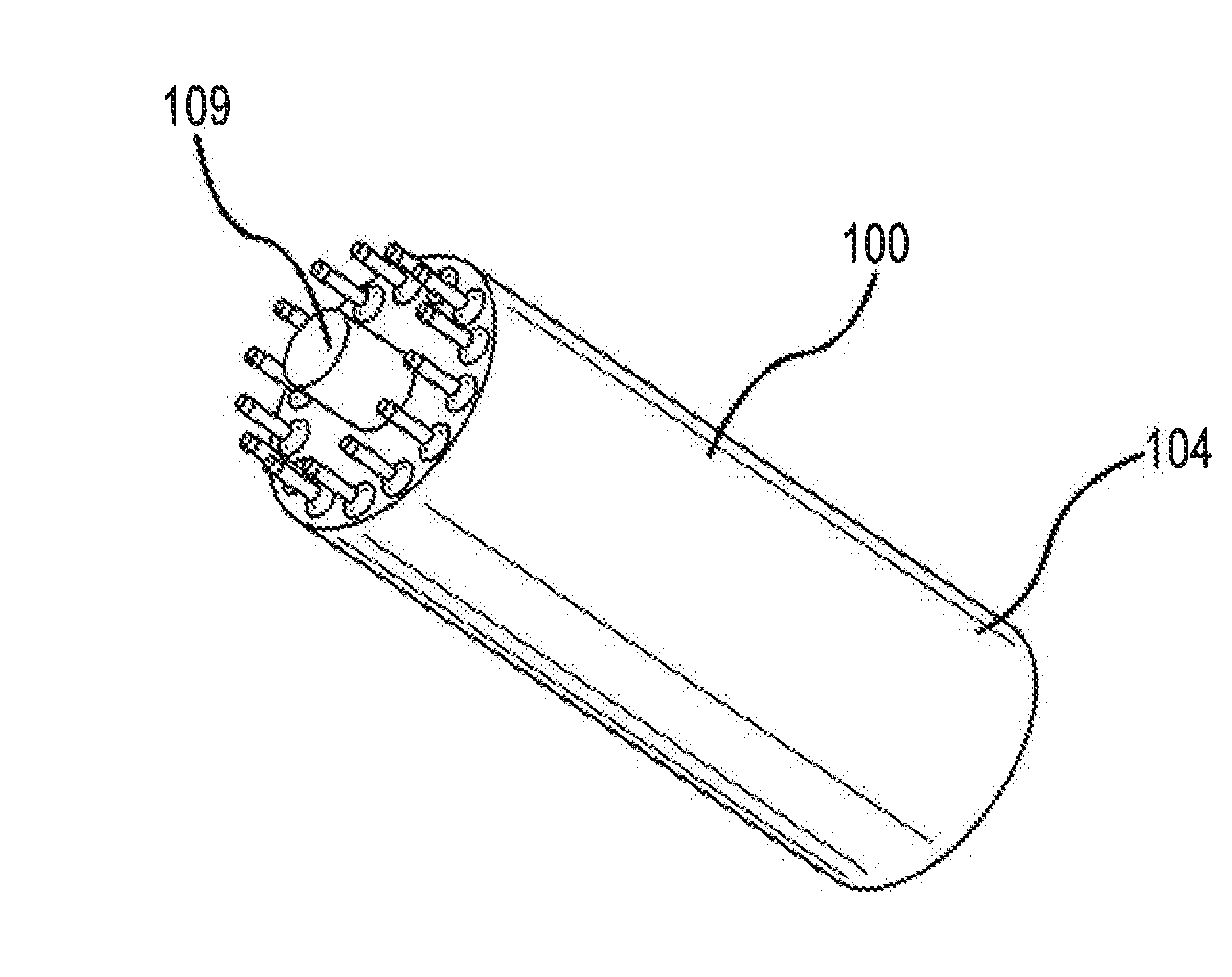

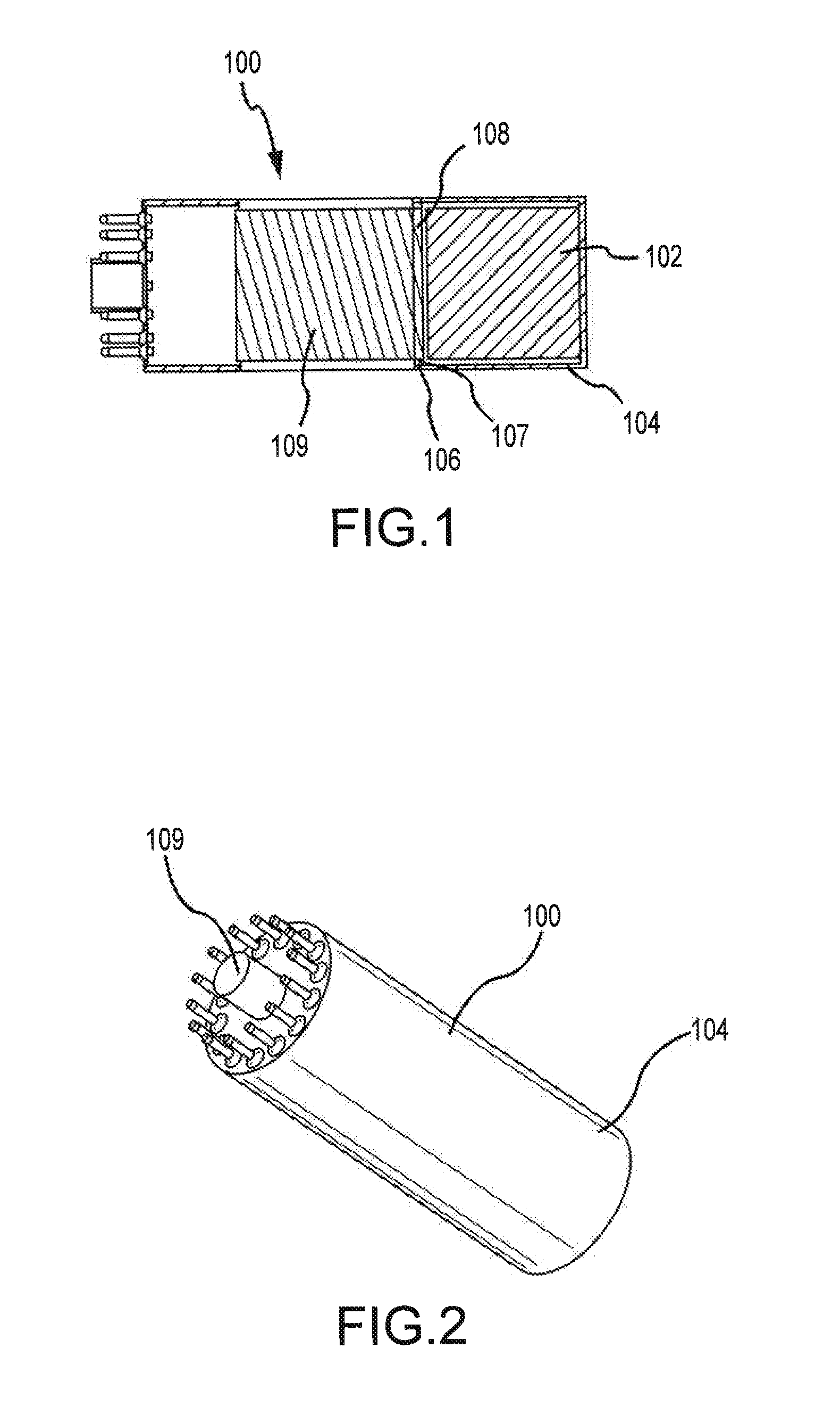

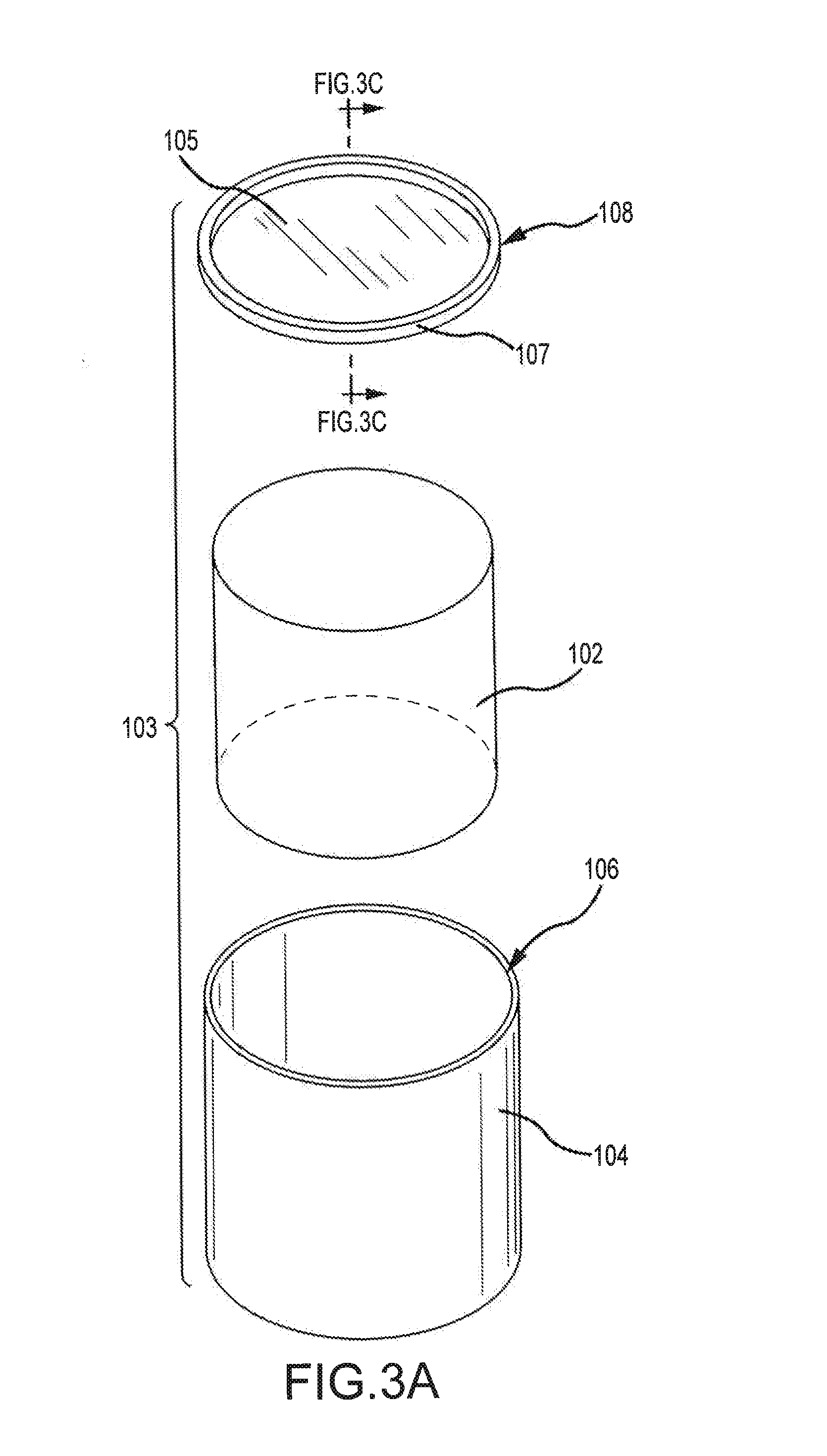

Scintillation detector assembly

InactiveUS20140097345A1Avoid exposurePrevent moisture intrusionPhotometryFluorescence/phosphorescenceCrystalline materialsGlass window

A scintillation detector assembly sealed via a compression fit without the use of epoxy or other sealant is disclosed. The assembly includes a scintillator composition and a photomultiplier tube optically coupled to the scintillator. A hermetically sealed scintillator container assembly in accordance with the present disclosure includes a cup shaped container sized to receive and hold a scintillator composition. This container has an open end. A metal rim compressively forms a mechanical hermetic seal around a glass window placed over the open end to preclude moisture intrusion into the container and thus prevent exposure of the scintillator crystalline material to degrading moisture. The metal rim is in turn welded to the container.

Owner:SCINTITECH

Wind turbine blade with improved fibre transition

ActiveUS10330074B2Increased complexityStrong stiffness transitionEngine manufactureMachines/enginesPolymer resinTurbine blade

A wind turbine blade having a transition between two reinforcement fiber types is described. A gradual transition is provided by a combined double-tapered thickness section with a first type of reinforcement fibers sandwiched between a second type of reinforcement fibers or vice versa. The double-tapering is provided during layup and the reinforcement material is impregnated with a polymer resin and then cured or hardened so that the two types of reinforcement fibers are embedded in a common polymer matrix.

Owner:LM WP PATENT HLDG

PANI/Go/PAN nanofiber membrane composite potassium air battery negative electrode and preparation method thereof

ActiveCN110247060AImprove electrochemical performanceInhibit migrationFuel and primary cellsCell electrodesPotassiumDendrite

The invention relates to a PANI / Go / PAN nanofiber membrane composite potassium air battery negative electrode and a preparation method thereof, and the potassium air battery negative electrode is prepared by pressing a porous potassium sheet into an electrode sheet, coating the surface of the electrode sheet with a PANI / Go / PAN nanofiber membrane, and mechanically pressing the electrode sheet into the potassium air battery negative electrode. The preparation method comprises the following steps: adding polyacrylonitrile into a solvent to obtain a colloidal solution, adding aniline and camphorsulfonic acid into the colloidal solution, stirring, adding ammonium persulfate, refrigerating, adding graphene oxide to obtain a spinning solution, and carrying out electrostatic spinning to obtain a nanofiber membrane; pressing a punctured metal potassium sheet and a current collector nickel net into an electrode sheet, coating the surface of the electrode sheet with the nanofiber membrane, and pressing to obtain the potassium air battery negative electrode. The negative electrode has the advantages that formation of potassium dendrites can be inhibited; corrosion and invalidation of the negative electrode can be slow down; and the negative electrode can be applied to a potassium air battery, thereby improving the performance of the potassium air battery and prolonging the cycle life of the potassium air battery.

Owner:HARBIN INST OF TECH

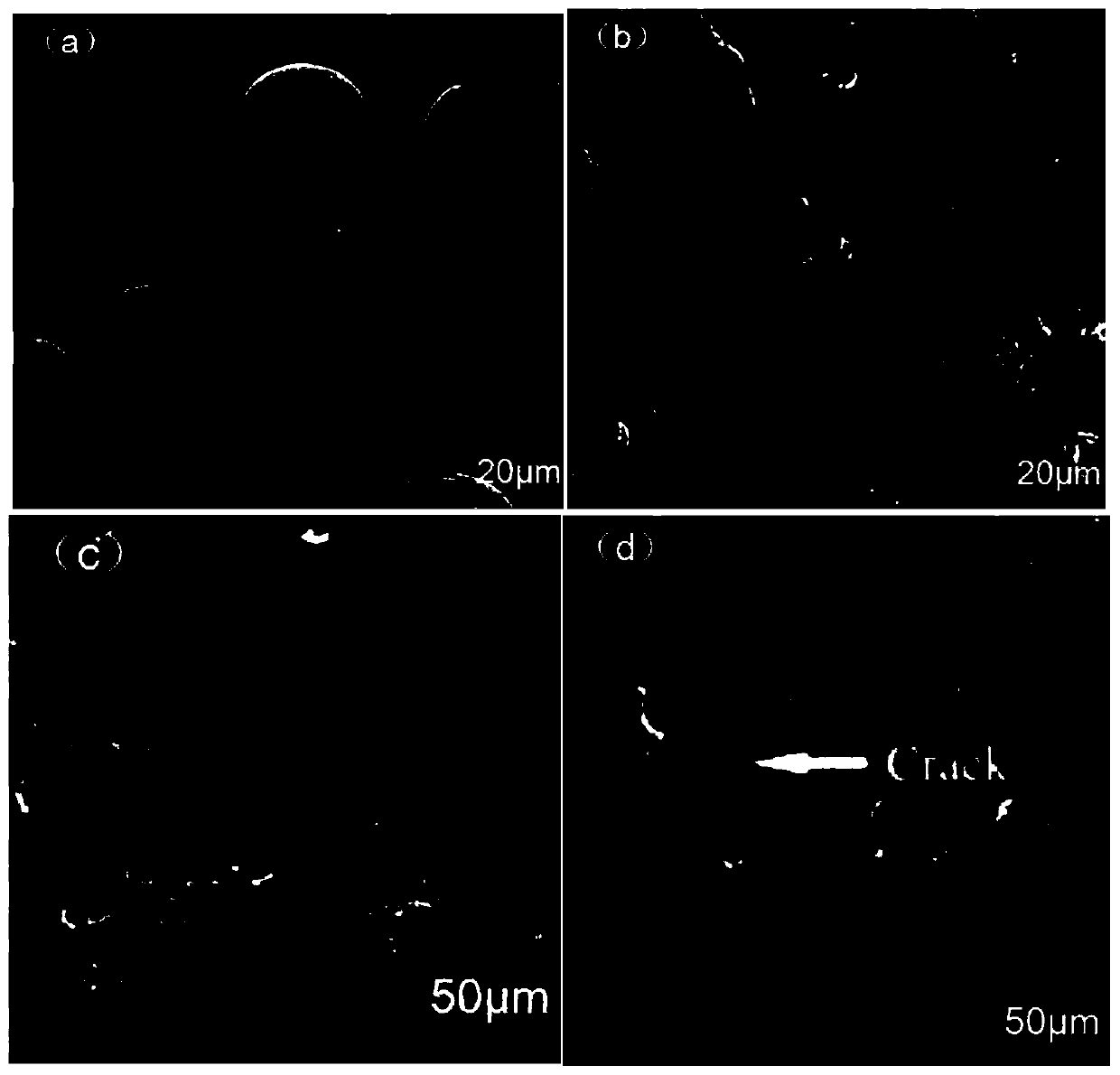

Cobalt-based alloy composite powder for plasma spray and preparation method of fusion covering coating

ActiveCN110923610AHigh hardnessImprove wear resistanceMolten spray coatingTransportation and packagingChromium carbideAlloy composite

The invention relates to cobalt-based alloy powder for plasma spray. The cobalt-based composite powder is prepared from the following raw materials in parts by weight: 90-120 parts of cobalt-based alloy powder, 3-5 parts of yttria powder, 7-12 parts of titanium boride powder and 10-15 parts of chromium carbide powder; the powder is mechanically and uniformly mixed after being treated by radio frequency induced plasma balling equipment to obtain subsphaeroidal cobalt-based composite powder; and the invention further discloses a method for manufacturing a hydraulic prop piston rod fusion covering coating by plasma spray. High bonding strength and hardness, good abrasive resistance and corrosion resistance and reduced cracking sensibility of the fusion covering coating are obtained through the treatment of the radio frequency induced plasma balling equipment and the optimization of plasma spray technological parameters; and the service life of a hydraulic prop piston rod is prolonged. Meanwhile, the cobalt-based composite powder can further be applied to the protection of other parts.

Owner:王爱平

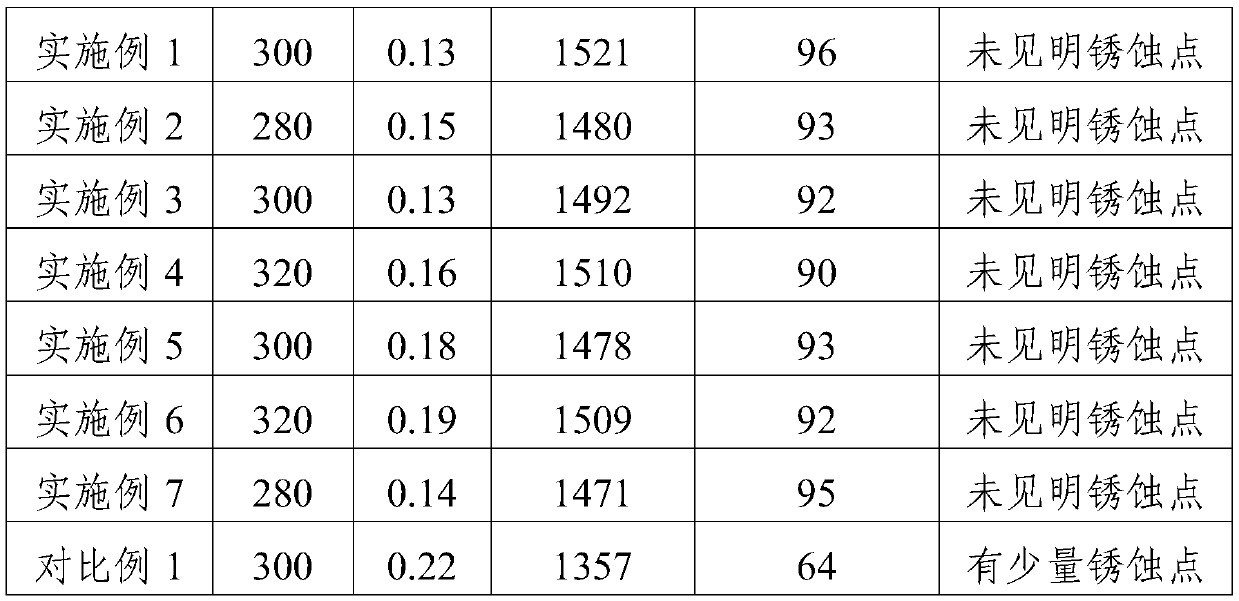

Preparation method of high-wear-resistance and high-corrosion-resistance protective layer of hot work die steel

InactiveCN111004991AGood protectionEnhanced goodMolten spray coatingSolid state diffusion coatingTemperingHot work

The invention provides a preparation method of a high-wear-resistance and high-corrosion-resistance protective layer of hot work die steel, and relates to the technical field of die steel. The preparation method of the protective layer comprises the following steps: (1) carrying out surface purification treatment and surface roughening treatment; (2) carrying out preheating treatment, then spraying a coating by adopting a hypersonic flame spraying method, carrying out compressed air cooling, and the spraying powder being prepared from the following components in percentage by weight: 55 to 64percent of WC, 12 to 18 percent of TaC, 3 to 4.5 percent of VC, 0.8 to 1.5 percent of nano rare earth oxide and the balance of NiCr; and (3) carrying out carburizing treatment, quenching and tempering. According to the method, the hot work die steel is subjected to surface roughening treatment, hypersonic flame spraying, carburizing treatment, quenching and tempering, so that a high-wear-resistance and high-corrosion-resistance coating can be formed on the surface of the hot work die steel, the bonding strength between the coating and a base body is high, and excellent surface protection and strengthening can be formed on the hot work die steel.

Owner:安徽旭通网络科技有限公司

Nickel-based composite powder for plasma spraying and preparation method of cladding coating

ActiveCN110904361AGood purificationStrong affinityMolten spray coatingCarbide siliconCorrosive substance

The invention relates to nickel-based composite powder for plasma spraying. The nickel-based composite powder is prepared from the following raw materials in parts by weight: 70-80 parts of nickel-based alloy powder, 1-2 parts of cerium dioxide powder, 2-5 parts of aluminum oxide powder and 5-10 parts of silicon carbide powder. The powder is treated by radio frequency induction plasma spheroidizing equipment and then is mechanically and uniformly mixed to obtain the nearly spherical nickel-based composite powder. The invention further discloses a method for manufacturing a cladding coating ofa hydraulic prop piston rod by plasma spraying. Through treatment of the radio frequency induction plasma spheroidizing equipment and optimization of plasma spraying process parameters, the bonding strength and hardness are high, the wear resistance and corrosion resistance are good, and the cracking sensitivity of the cladding coating is reduced; and the service life of the hydraulic prop pistonrod is prolonged. Meanwhile, the method can also be applied to protection of other parts.

Owner:BEIJING JUNSHAN SURFACE TECH ENG

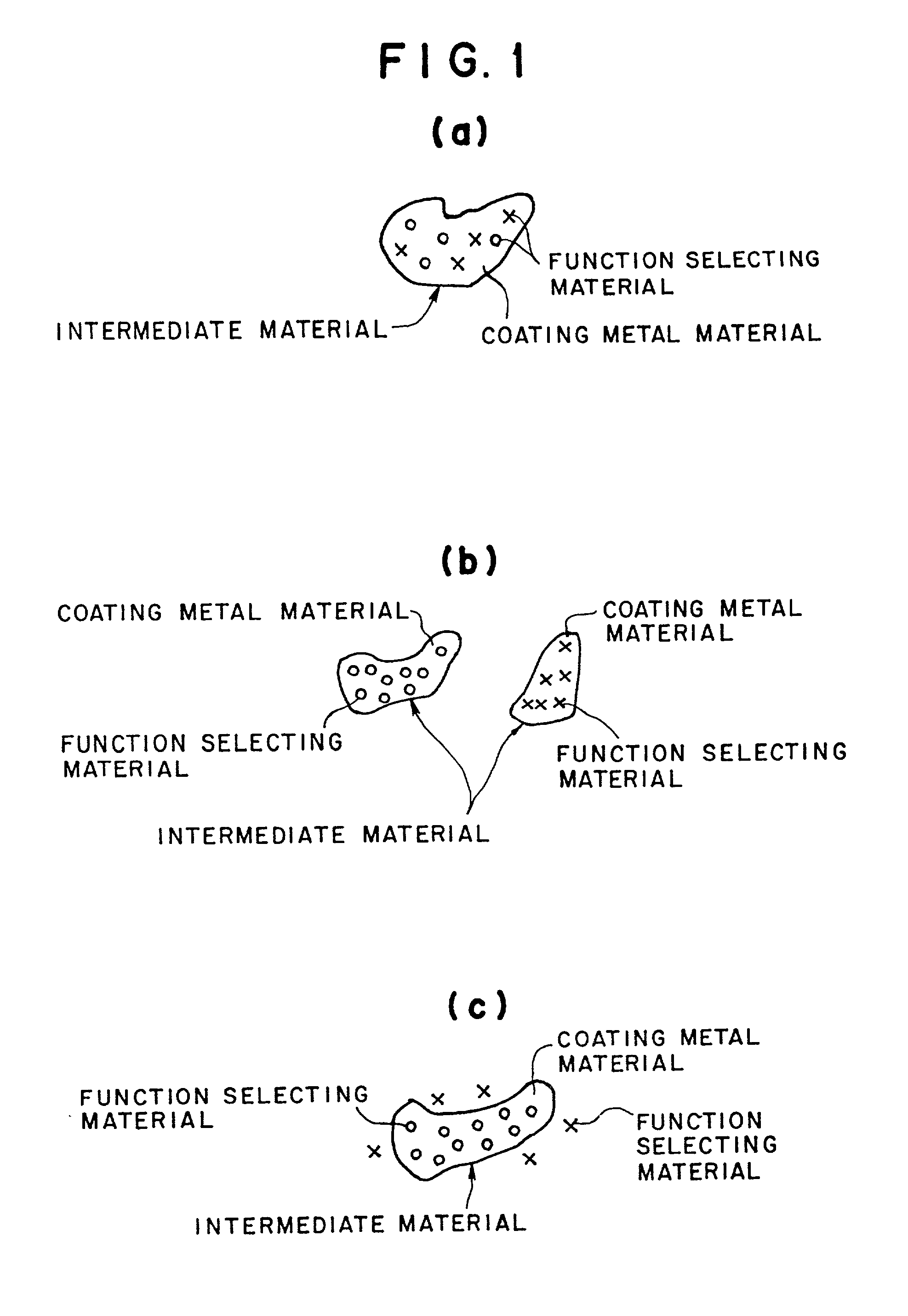

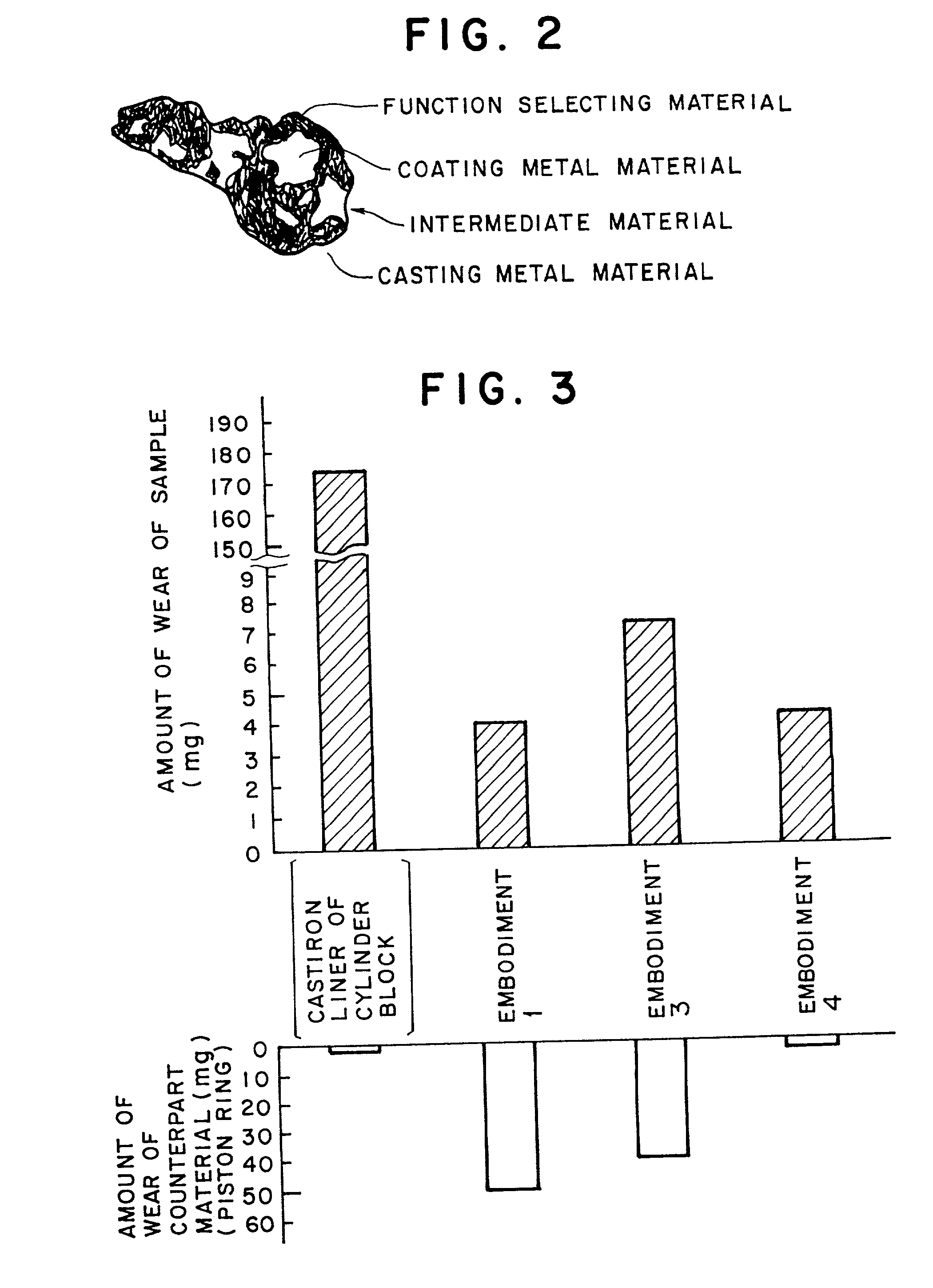

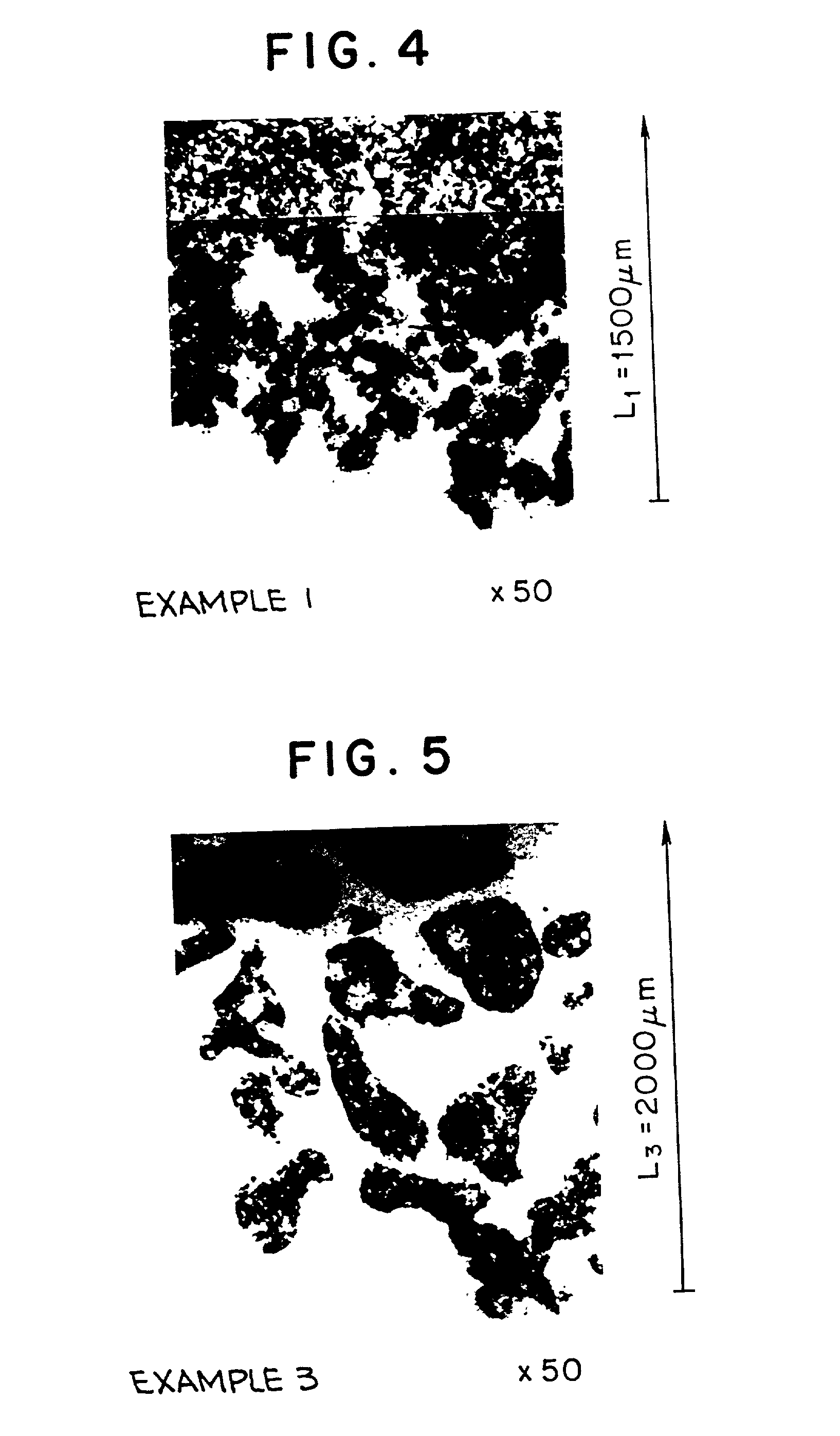

Method of casting a product

InactiveUS20010013401A1Easily and inexpensively formedImprove machinabilityGearingCylindersMetalMaterials science

An intermediate material is formed by coating at least a half of the surface of a function selecting material having at least one of physical property values that are different from those of a casting metal material forming a cast product with a coating metal material and the casting metal material is cast together with the intermediate material to form a composite body in casting the product.

Owner:AHRESTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com