Nickel-based composite powder for plasma spraying and preparation method of cladding coating

A composite powder and nickel-based alloy technology, applied in metal material coating process, coating, fusion spraying, etc., to achieve excellent fluidity, good purification effect, and the effect of inhibiting tissue loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A nickel-based composite powder for plasma spraying is prepared from the following raw materials in parts by weight: 70 parts of nickel-based alloy powder, 1 part of ceria powder, 2 parts of aluminum oxide powder, and 5 parts of silicon carbide powder.

[0032] Concrete preparation steps are:

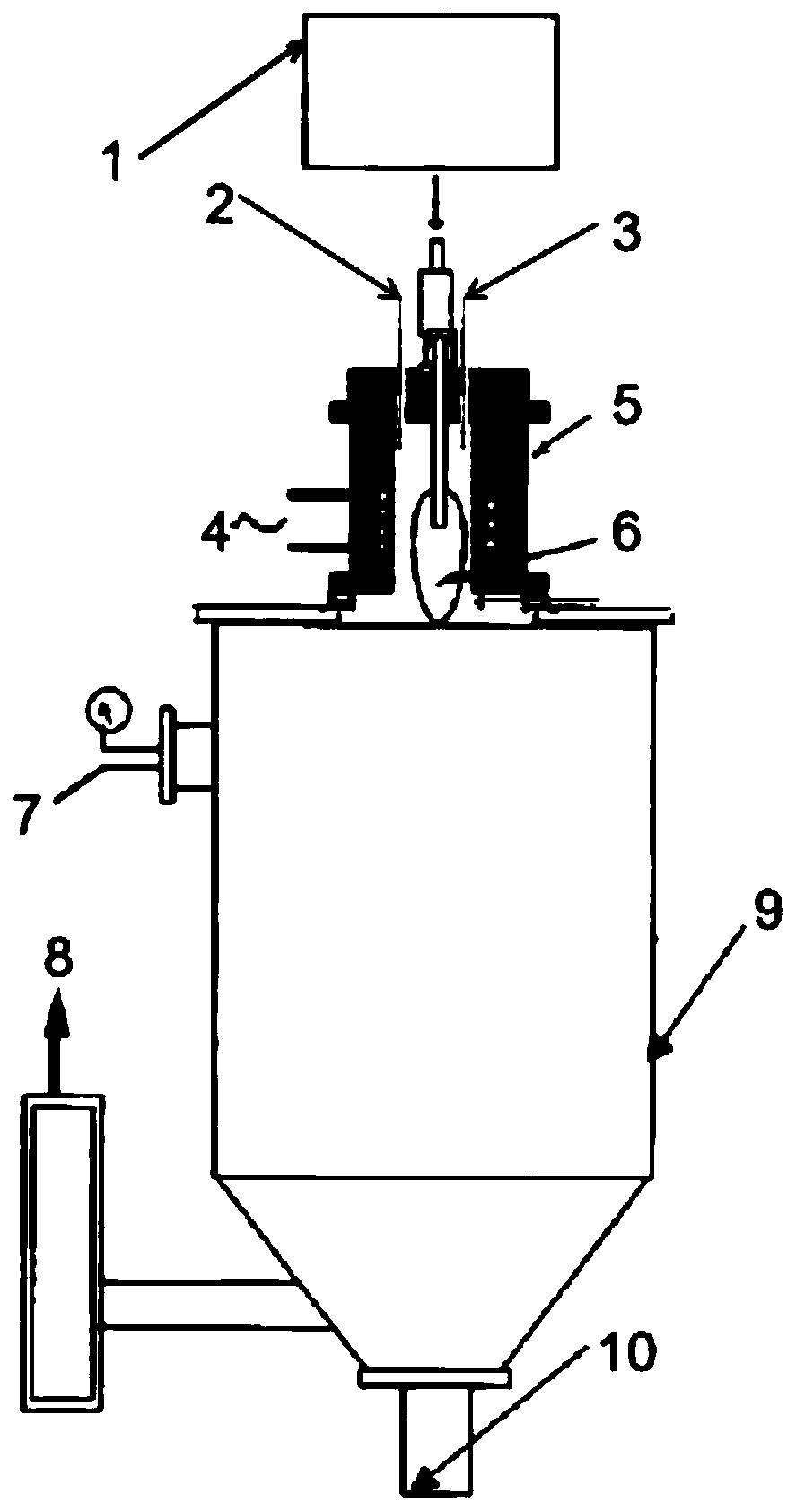

[0033] (1) Using radio frequency induction plasma spheroidization equipment, the 60μm nickel-based alloy powder Ni60A is sprayed into the plasma torch through the feeding gun with Ar as the carrier gas. The powder absorbs a large amount of heat instantly and melts and spheroidizes. The spherical droplets are rapidly cooled and solidified in the argon atmosphere, and finally the nickel-based alloy powder is collected at the bottom of the spheroidization reactor. The spheroidization parameters are center gas Ar flow rate: 10L / min, sheath gas N 2 Flow rate: 20L / min, carrier gas Ar flow rate: 30L / min, power: 10kW, powder feeding rate: 30g / min; collect nearly spherical nickel-based a...

Embodiment 2

[0045] A nickel-based composite powder for plasma spraying is prepared from the following raw materials in parts by weight: 80 parts of nickel-based alloy powder, 2 parts of cerium dioxide powder, 5 parts of aluminum oxide powder, and 10 parts of silicon carbide powder.

[0046] Concrete preparation steps are:

[0047] (1) Using radio frequency induction plasma spheroidization equipment, the 75μm nickel-based alloy powder Ni35A is sprayed into the plasma torch through the feeding gun with Ar as the carrier gas. The powder absorbs a large amount of heat instantly and melts and spheroidizes. The spherical droplets are rapidly cooled and solidified in the argon atmosphere, and finally the nickel-based alloy powder is collected at the bottom of the spheroidization reactor. The spheroidization parameters are center gas Ar flow rate: 15L / min, sheath gas N 2 Flow rate: 30L / min, carrier gas Ar flow rate: 45L / min, power: 15kW, powder feeding rate: 50g / min; collect nearly spherical nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com