Biochemical automatic control device

An automatic control device, biochemical technology, applied in the direction of water treatment parameter control, grease/oily substance/suspton removal device, chemical instrument and method, etc., can solve problems such as large labor investment, increased environmental protection of enterprises, hidden dangers, etc., and achieve sewage The effect of good purification degree, accelerated separation speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

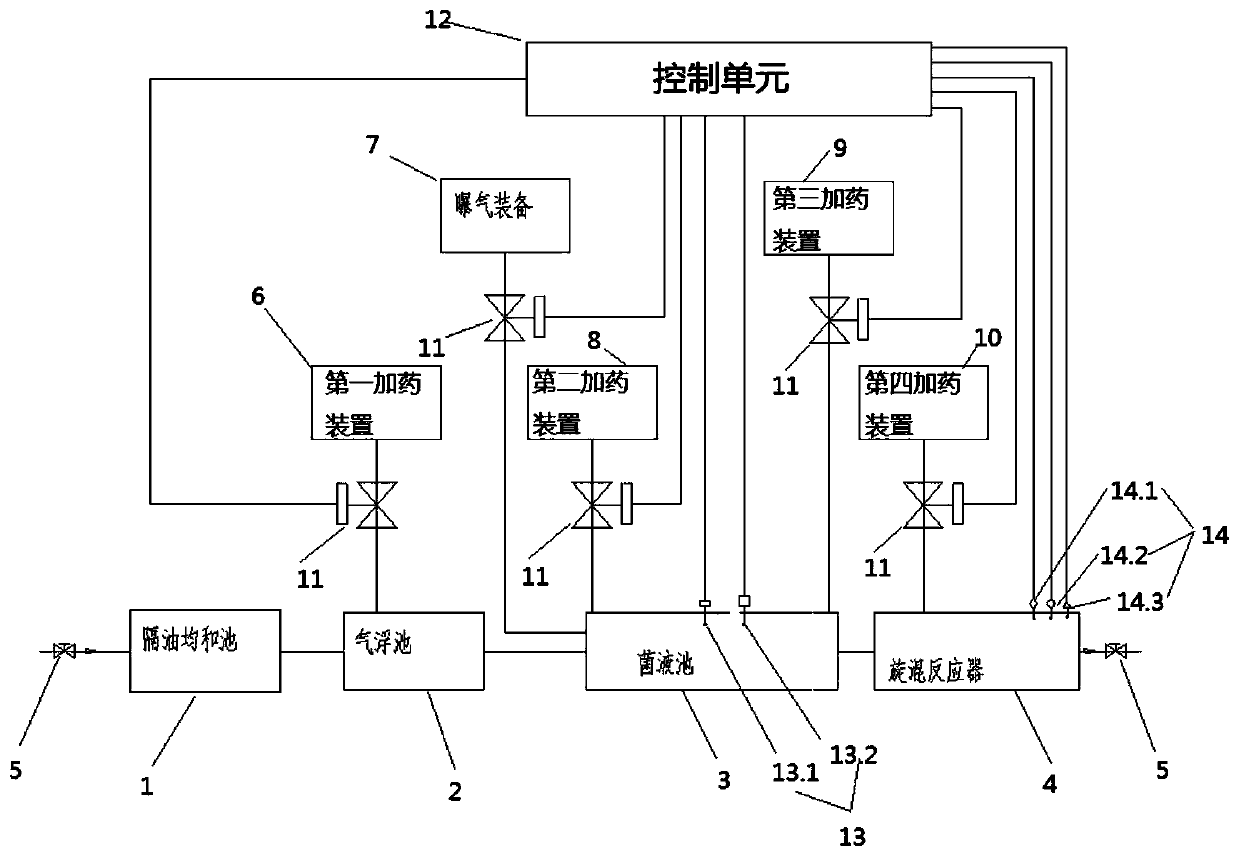

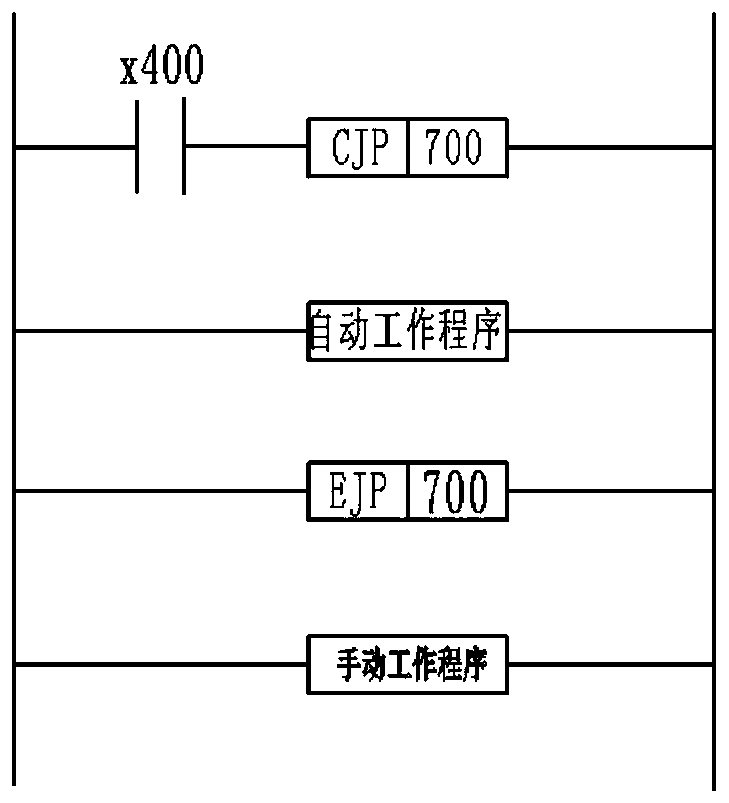

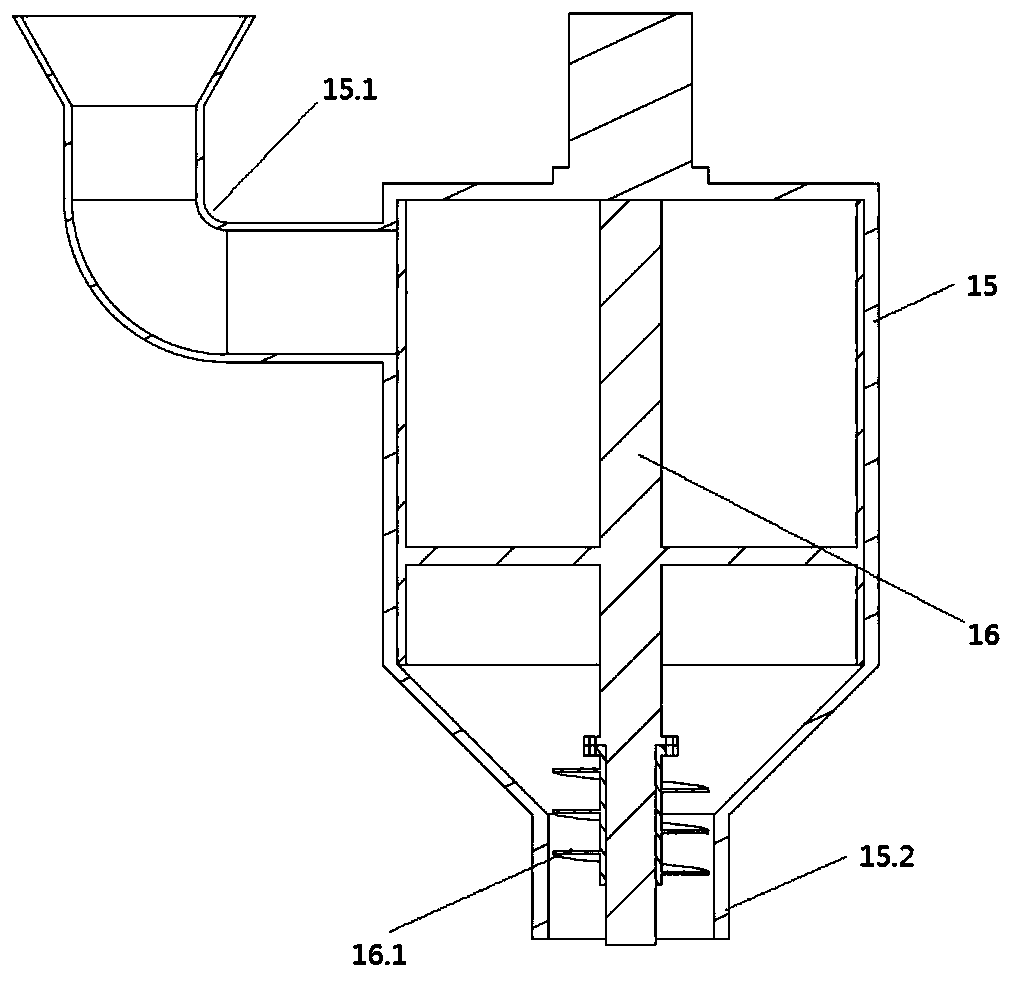

[0021] as attached Figures 1 to 6 The described automatic biochemical control device comprises an oil-separation homogeneous tank 1, an air flotation tank 2, a bacterial liquid pool 3 and a cyclone reactor 4 which are sequentially connected; The pipeline between the reactor 4 and the dosing equipment is connected with an automatic switch 11. In this embodiment, the automatic switch 11 is a solenoid valve, and there are 5 of them, which are respectively arranged between the first dosing device 6 and the air flotation tank. on the passage between the aeration equipment 7 and the bacterial liquid pool 3, on the passage between the second dosing device 8 and the bacterial liquid pool 3, between the third dosing device 9 and the bacterial liquid pool on the passage; the on-off of the solenoid valve is controlled by the control unit 12, the control unit 12 described in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com