Amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material and preparation and application thereof

An electrocatalytic material and nano-sheet technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, electrode shapes/types, etc., can solve complex processes, various raw materials, and difficult Large-scale industrial application and other issues, to achieve the effect of simple preparation process, low cost of raw materials, and strong conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

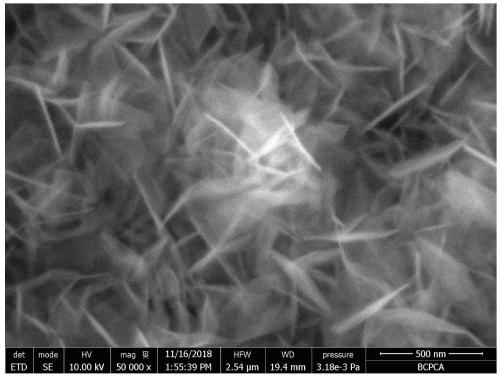

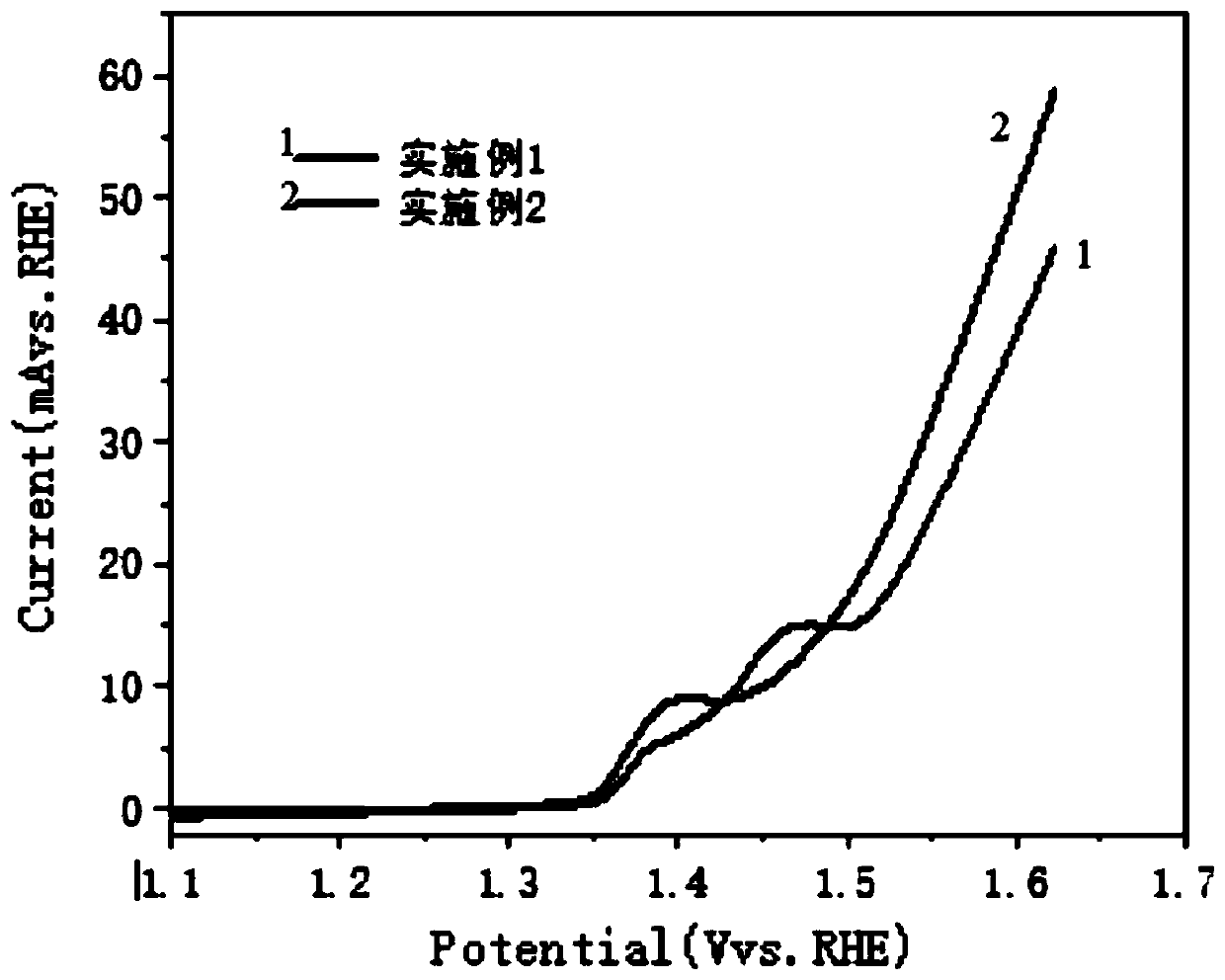

Embodiment 1

[0026] Put a piece of 2×4cm 2 Nickel foam, thickness 1.6mm, placed in a beaker filled with 3M hydrochloric acid solution for ultrasonication for 5 minutes, then rinsed repeatedly with deionized water, and then placed the foamed nickel in a beaker filled with ethanol for 5 minutes to remove foam Oxide, oil and other impurities on the nickel surface. Dissolve 0.0916g nickel nitrate hexahydrate, 0.1616g ferric nitrate nonahydrate and 0.48g urea in 35mL deionized water to form a hydrothermal solution, stir with a magnetic stirrer for 10min to mix the solution evenly, then transfer it to a 50mL polytetrafluoroethylene In the vinyl fluoride liner, the foamed nickel substrate is placed in the solution at an angle of 60°, and then the polytetrafluoroethylene liner with the foamed nickel substrate and the solution is placed in a stainless steel autoclave and sealed. Heated at 120°C for 12 hours, and finally cooled to room temperature to obtain nickel-iron salt and take it out, rinse i...

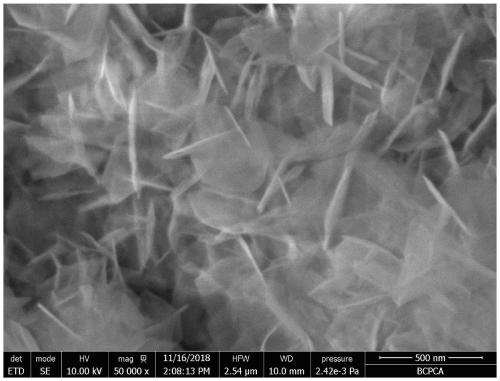

Embodiment 2

[0028] Put a piece of 2×4cm 2 Nickel foam with a thickness of 1.6mm was placed in a beaker filled with 3M hydrochloric acid solution for 8 minutes, then rinsed repeatedly with deionized water, and then the nickel foam substrate was placed in a beaker filled with ethanol for 8 minutes to remove Oxide, oil and other impurities on the surface of nickel foam. Dissolve 0.1862g nickel nitrate hexahydrate, 0.0646g ferric nitrate nonahydrate and 0.50g urea in 42mL deionized water to form a hydrothermal solution, stir with a magnetic stirrer for 8min to mix the solution evenly, and transfer it to 50mL polytetrafluoroethylene In the ethylene liner, place the nickel foam matrix in the solution at an angle of 60°, then place the polytetrafluoroethylene liner with the nickel foam matrix and the solution in a stainless steel autoclave and seal it, in an electric blast drying oven, Keep the temperature at 120°C for 12 hours, and finally cool to room temperature to obtain the nickel-iron sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com