Environment friendly polyester polycondensation catalyst and method for preparing polyester by using the same

A polycondensation catalyst, an environmentally friendly technology, applied in the field of polyester, can solve the problems of unsatisfactory catalytic activity and catalytic speed, no report on the preparation method of aluminum catalyst, and yellow hue of titanium catalyst polyester, and achieve excellent catalytic speed and excellent catalytic activity. , the effect of fast catalytic polycondensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

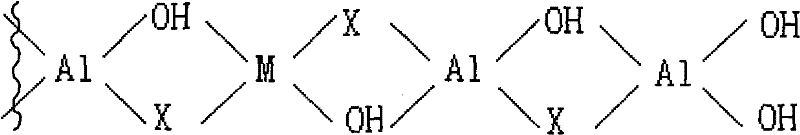

[0020] Dissolve 10 grams of aluminum trichloride in 90 grams of ethylene glycol, heat the solution to 90°C, continue to stir at this temperature for 10 minutes, add 10 grams of 15% zinc acetate aqueous solution, and stir at 90°C for 30 minutes. Raise the temperature to 110°C, continue to stir for 50 minutes, then cool to room temperature, add 1.6 grams of phosphoric acid and stir evenly to prepare an environmentally friendly polyester polycondensation catalyst for future use; its structural formula is as follows:

[0021] where X is Cl - , M is Zn.

[0022] Add 350 grams of terephthalic acid, 220 grams of ethylene glycol, and 1 gram of the liquid aluminum catalyst prepared by the above method into a 2L reactor, and perform esterification at 200-250°C and a pressure of 0.25 MPa (gauge pressure). When the effluent reaches 95% of the theoretical effluent, the esterification is completed, the pressure of the reactor is released to normal pressure, and the pressure is gradually ...

Embodiment 2

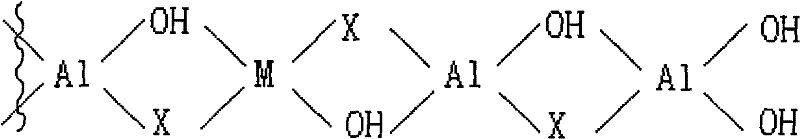

[0024] Dissolve 10 grams of aluminum acetate (one or more of monoacetate, aluminum diacetate, aluminum triacetate) in 90 grams of ethylene glycol, heat the solution to 90 ° C, continue stirring at this temperature for 10 minutes, then add 5 gram of zinc acetate aqueous solution of 15% concentration, 3 grams of sodium acetate 15% solution, 1 gram of lithium acetate 15% aqueous solution, after stirring at 90 DEG C for 35 minutes, heat up to 110 DEG C, continue to stir and cool to room temperature after 30 minutes, add 2 gram of trimethyl phosphate is stirred evenly, and the environment-friendly polyester polycondensation catalyst is prepared, and it is standby; its structural formula is as follows:

[0025]

[0026] where X is CH 3 COO - , M is Zn, Na, Li.

[0027] Add 350 grams of terephthalic acid, 220 grams of ethylene glycol, and 1 gram of the liquid aluminum catalyst prepared by the above method into a 2L reactor, and perform esterification at 205-250°C and a pressure ...

Embodiment 3

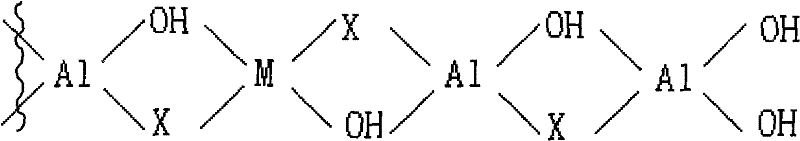

[0029] Dissolve 10 grams of aluminum ethylene glycol in 90 grams of ethylene glycol, add 5 grams of 15% calcium acetate aqueous solution and 5 grams of cobalt acetate 15% solution after heating the solution to 90°C, stir at 90°C for 30 minutes, then heat up To 100 DEG C, after continuing to stir for 30 minutes, cool to room temperature and add 2.2 grams of phenylphosphoric acid to prepare an environmentally friendly polyester polycondensation catalyst for subsequent use; its structural formula is as follows:

[0030]

[0031] where X is HOCH 2 CH 2 o - , M is Ca or Co.

[0032]Add 350 grams of terephthalic acid, 220 grams of ethylene glycol, and 1 gram of the liquid aluminum catalyst prepared by the above method into a 2L reactor, and perform esterification at 203-255°C and a pressure of 0.25 MPa (gauge pressure). When the effluent reaches 95% of the theoretical effluent, the esterification is completed, the pressure of the reactor is released to normal pressure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com