High-efficiency catalyst for degrading water body COD (Chemical Oxygen Demand) by ozone and preparation method thereof

A technology for ozone degradation and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve problems such as a large amount of waste gas, complex preparation process, and environmental pollution , to avoid pollution, improve stability and reduce metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

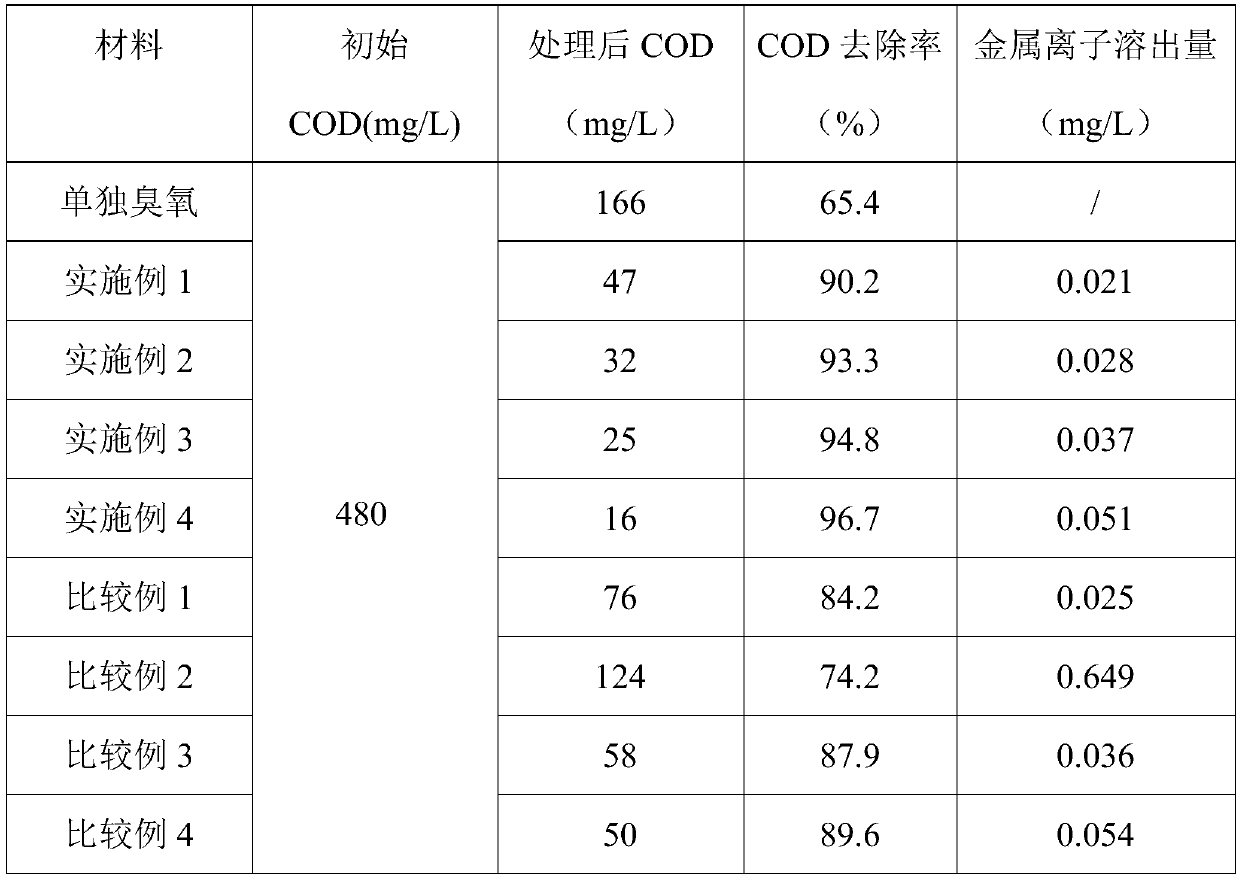

Examples

Embodiment 1

[0032] A kind of preparation method of the efficient catalyst of ozone degradation water body COD, comprises the following steps:

[0033] (1) The activated alumina ball carrier is roasted in a gas-fired mesh belt kiln at 350°C for 4 hours, and then stored in a silo for later use after cooling down to room temperature;

[0034] (2) Take by weight 15 parts of ferric chloride hexahydrate, 1 part of cerium chloride heptahydrate, and 1 part of citric acid, add in the mixing tank and mix and stir, and add 40 parts of water to make it dissolve completely, weigh 90 parts of activated alumina balls are transported to the mixing tank and mixed with the above mixed solution for 10 minutes;

[0035] (3) Pump 40 parts of 0.1mol / L sodium hydroxide solution into the mixing tank of step (2), and stir for 20 minutes;

[0036] (4) Open the bottom valve of the mixing tank, and centrifuge the solid-liquid mixture after the reaction in step (3) in a flat bag centrifuge to remove the remaining li...

Embodiment 2

[0040] A kind of preparation method of the efficient catalyst of ozone degradation water body COD, comprises the following steps:

[0041] (1) The activated alumina ball carrier is roasted in a gas-fired mesh belt kiln at 350°C for 4 hours, and then stored in a silo for later use after cooling down to room temperature;

[0042] (2) Take by weight 25 parts of ferric chloride hexahydrate, 3 parts of cerium chloride heptahydrate, and 3 parts of citric acid, add in mixing tank and mix and stir, and add 50 parts of water to make it dissolve completely, weigh 90 parts of activated alumina balls are transported to the mixing tank and mixed with the above mixed solution for 20 minutes;

[0043] (3) Pump 50 parts of 0.5mol / L sodium carbonate solution into the mixing tank of step (2), and stir for 20 minutes;

[0044] (4) Open the bottom valve of the mixing tank, and centrifuge the solid-liquid mixture after the reaction in step (3) in a flat bag centrifuge to remove the remaining liquid...

Embodiment 3

[0048] A kind of preparation method of the efficient catalyst of ozone degradation water body COD comprises the following steps:

[0049] (1) The activated alumina ball carrier is roasted in a gas-fired mesh belt kiln at 450°C for 2 hours, and then stored in a silo for later use after cooling down to room temperature;

[0050] (2) Weigh 45 parts of ferrous sulfate heptahydrate, 6 parts of cerium sulfate tetrahydrate, and 5 parts of polyvinylpyrrolidone by weight, add 50 parts of water to dissolve it completely, and weigh 85 parts of activated alumina balls are transported to the mixing tank and mixed with the above mixed solution for 20 minutes;

[0051] (3) Pump 40 parts of 0.5mol / L sodium carbonate solution into the mixing tank of step (2), and stir for 20 minutes;

[0052] (4) Open the bottom valve of the mixing tank, and centrifuge the solid-liquid mixture after the reaction in step (3) in a flat bag centrifuge to remove the remaining liquid. After the remaining liquid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com