Patents

Literature

49results about How to "High catalyst activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

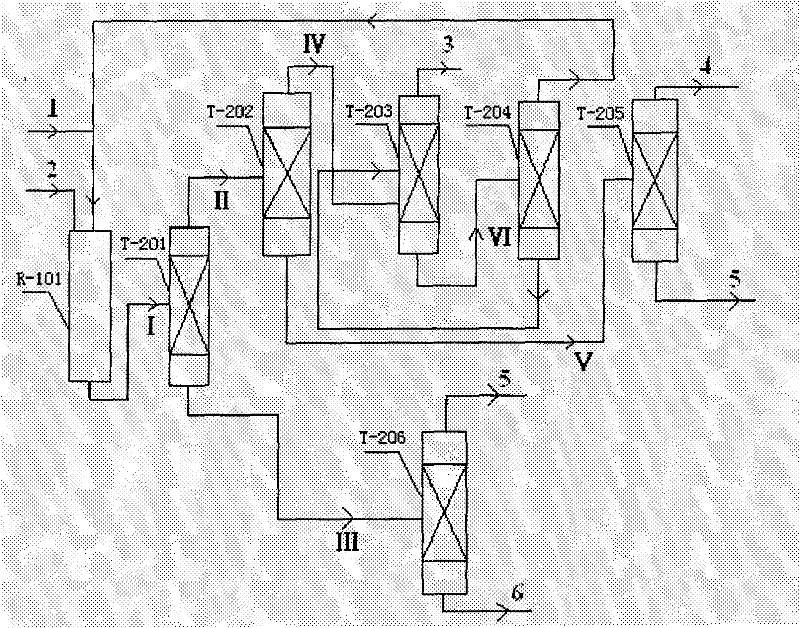

Method for producing 1,3-propanediol

ActiveCN101747150AMild reaction conditionsHigh catalyst activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsHydrogenolysis1,3-Propanediol

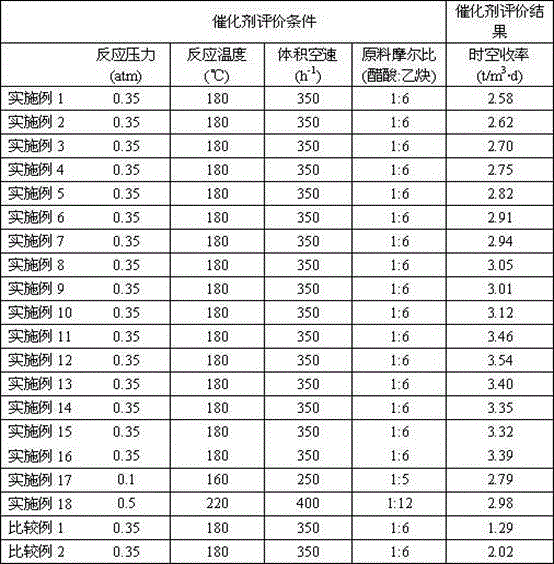

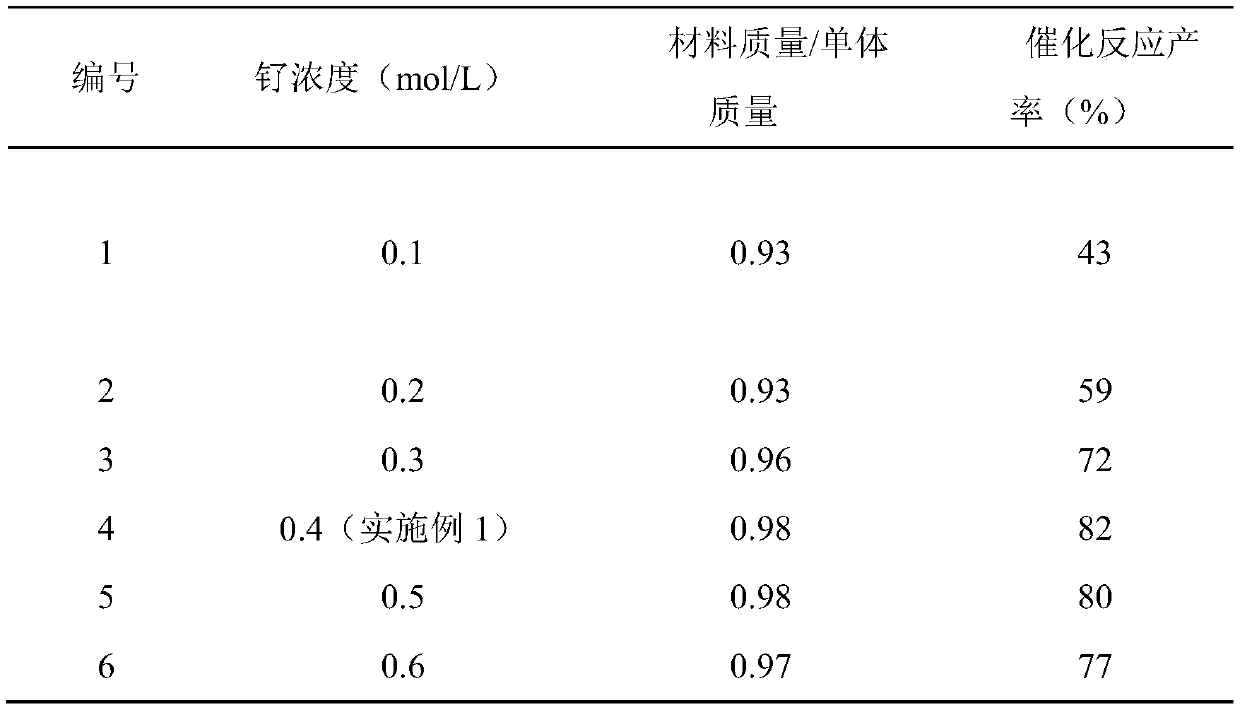

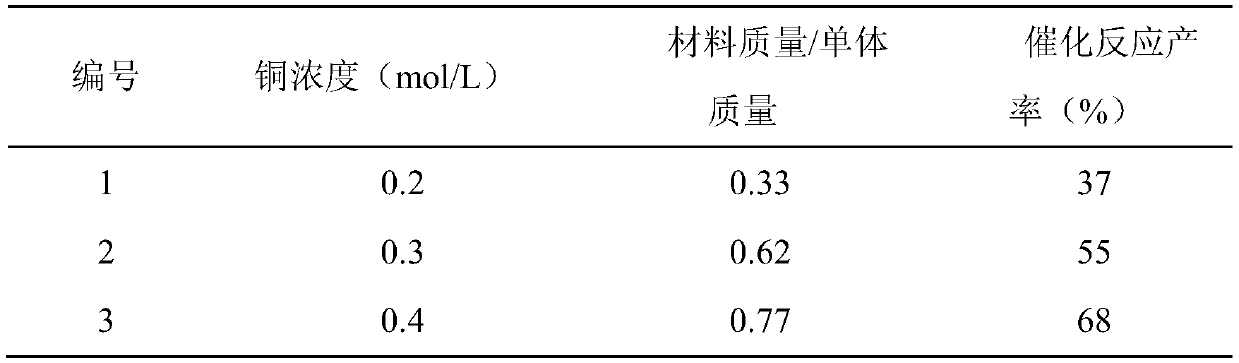

The invention relates to a method for producing 1,3-propanediol with glycerol as material by way of gas phase hydrogenolysis of glycerol, which includes the following step that: under the existence of metal-acid bifunctional catalyst, the glycerol receives gas phase hydrogenolysis, so that the 1,3-propanediol is prepared; and the invention also relates to the application of the metal-acid bifunctional catalyst in the reaction for preparing the 1,3-propanediol by way of gas phase hydrogenolysis of glycerol. The metal-acid bifunctional catalyst contains the following components loaded on carrier: (a) solid acidic active component, (b) metal component (one of copper, nickel or cobalt) with hydrogenation activity, and (c) optionally added metal addition agent component (one or more of iron, zinc, tin, manganese and chromium). The method can directly obtain the 1,3-propanediol by way of hydrogenolysis, as well as 1,2-propanediol. The method has the advantages of mild reaction conditions, simple technique and continuous operation.

Owner:SYNFUELS CHINA TECH CO LTD

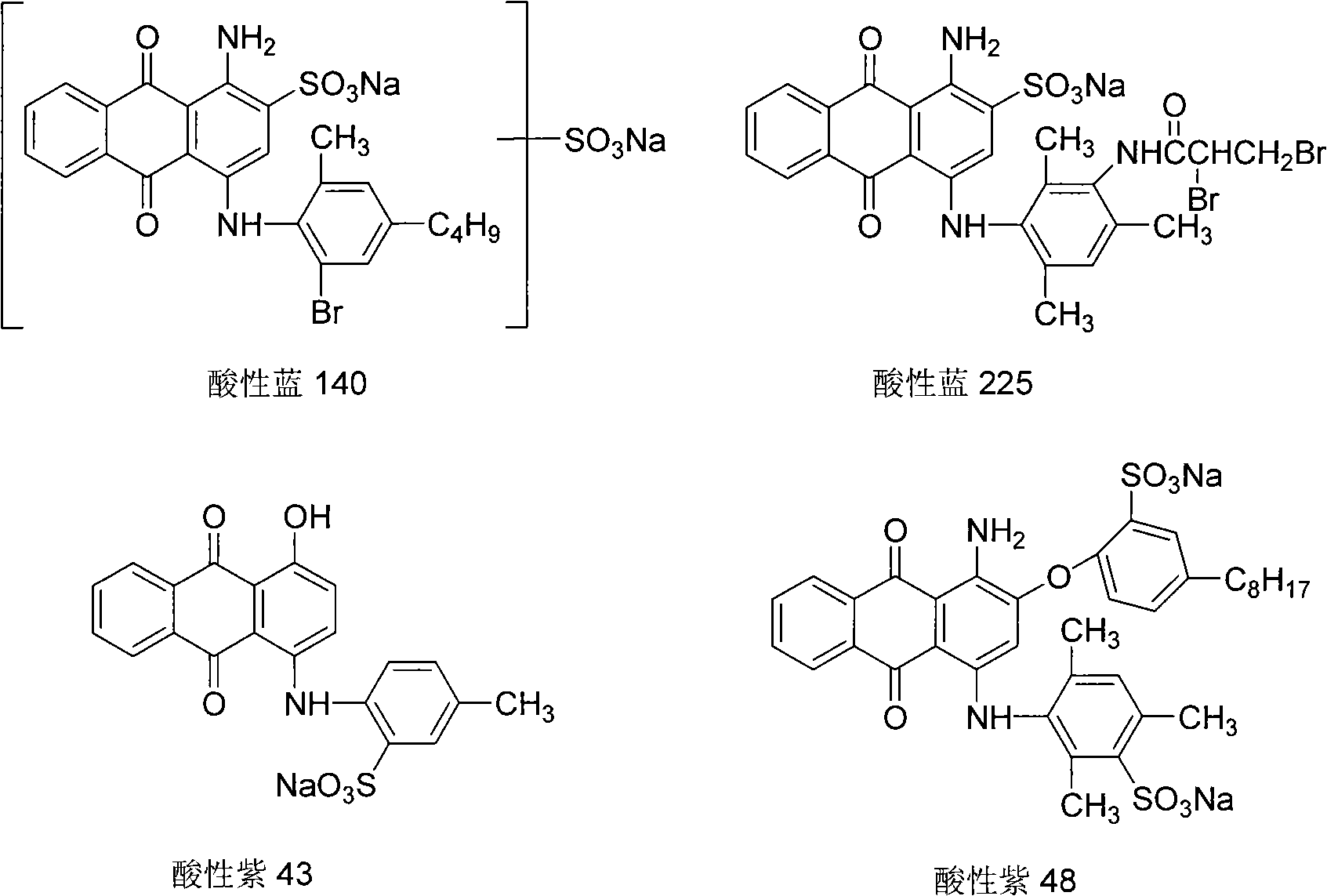

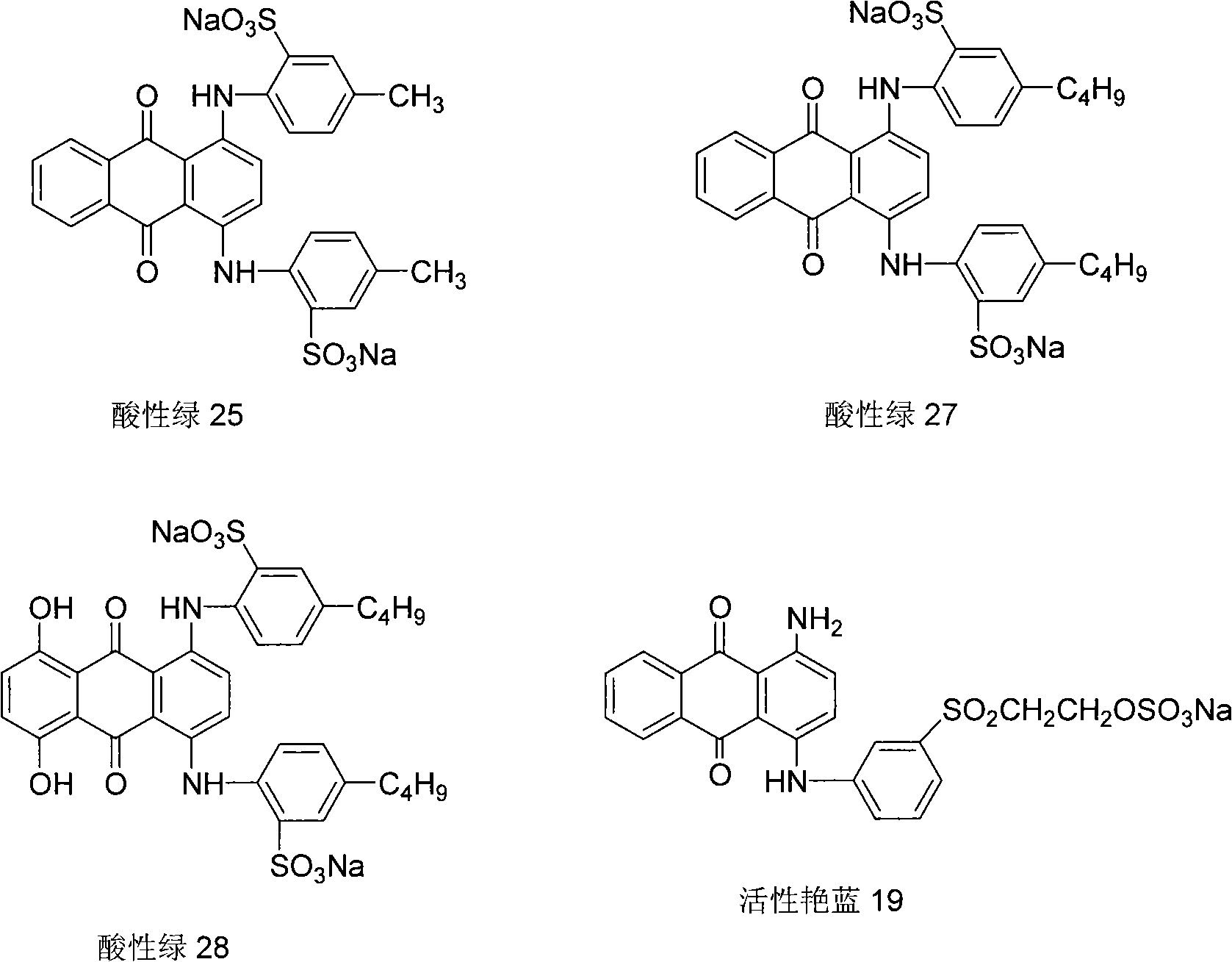

Photocatalysis oxidation method for treating waste water of anthraquinone dye

InactiveCN101318749AHigh catalyst activityMild reaction conditionsWater/sewage treatment by irradiationWater contaminantsChemistryAnthraquinone dye

The invention relates to the photocatalysis and oxidation treatment of anthraquinone dye wastewater, in particular to a photocatalysis and oxidation method for treating the anthraquinone dye wastewater. The method comprises the following steps that: firstly, acid or alkali is used to adjust the PH value of the anthraquinone dye wastewater to less than or equal to 12; the anthraquinone dye wastewater is added with a catalyst, passed through with air by one time and subject to the simulation of photodegradation in an illumination incubator under the sunlight; everyday, the solution is illuminated for 14 to 16 hours at a temperature of between 20 and 25 DEG C with an illumination intensity of between 5, 000 and 5, 800 Lux and then enters a dark state for 8 to 10 hours with a temperature kept between 16 and 20 DEG C; the catalyst consists of a composition A and a composition B; a weight ratio of the composition A to the composition B is 0.01 to 2; and a weight ratio of the catalyst to dye is 0.01 to 2. The method adopts natural light for carrying out the treatment on the anthraquinone dye wastewater and has good discoloring effect and a high removing rate of total organic carbon; and the method also has the advantages of high catalyst activation, low cost, low treatment cost, simple operation, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

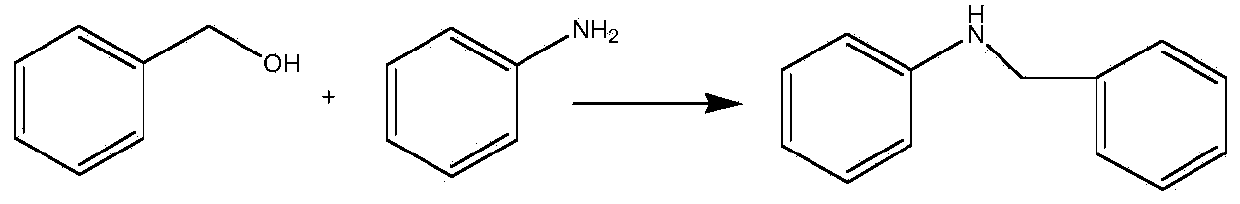

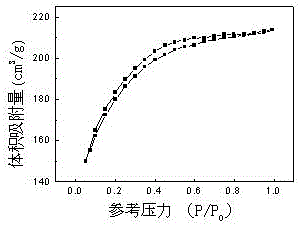

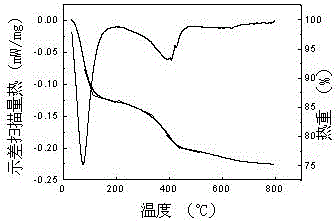

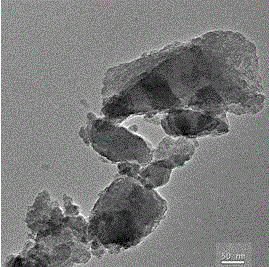

Preparation method of nanocrystalline metal catalyst loaded with carbon and nitrogen materials

InactiveCN104069882AHigh catalyst activityGood for recyclingPhysical/chemical process catalystsOrganic compound preparationOrganic compoundOrganic solvent

The invention relates to a preparation method of a nanocrystalline metal catalyst loaded with carbon and nitrogen materials. The preparation method is characterized by comprising the following steps: stirring metal compound and nitrogen-containing ligand in an organic solvent for carrying out coordinating reaction; adding a carrier, heating and stirring; removing the organic solvent; carrying out vacuum drying and finally carrying out calcination under inert gas to obtain the nanocrystalline metal catalyst loaded with the carbon and nitrogen materials. By coordinating metal salt and organic compound, the formation and dispersion of nano metal particles are facilitated; the multi-phase catalyst obtained through calcination has enhanced activity, and is convenient to recycle for repeated use. The preparation method of the catalyst is simple and convenient, raw materials are easily available, and therefore, the method is suitable for industrial production.

Owner:NANJING UNIV OF TECH

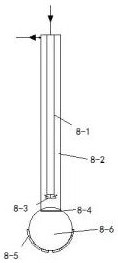

Method for preparing ethylene glycol mono-n-butyl ether by continuous pipe reaction

ActiveCN101337864AHigh catalyst activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesChemistryEther

The invention relates to a method for preparing glycol mono-n-butyl ether by continuous channel reaction, which comprises the following steps: mixing n-butyl alcohol, ethylene oxide and alkyl sulfonate serving as a catalyst, preheating, continuously feeding into a channel reactor, carrying out etherification reaction at a reaction temperature of 130 to 220 DEG C and under a pressure of 3.5 to 6.0 MPa, and rectifying the reaction result to recover the excessive n-butyl alcohol and obtain the glycol mono-n-butyl ether. According to the method, the conversion rate of the ethylene oxide is 100%, and the selectivity of the glycol mono-n-butyl ether is 85 to 94%. The continuous channel reaction process can improve the production efficiency of the glycol mono-n-butyl ether, and has excellent large-scale industrial application prospect.

Owner:江苏德纳化学股份有限公司

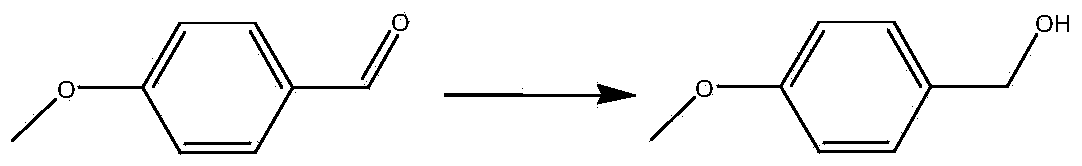

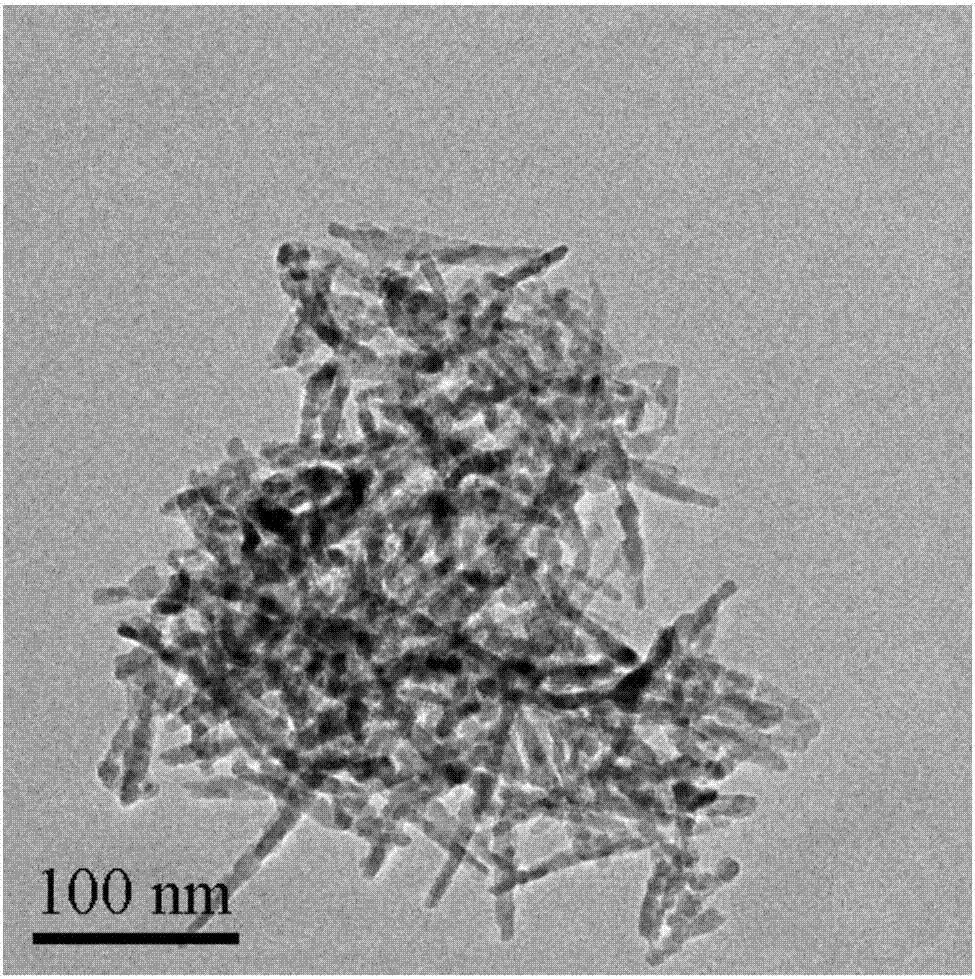

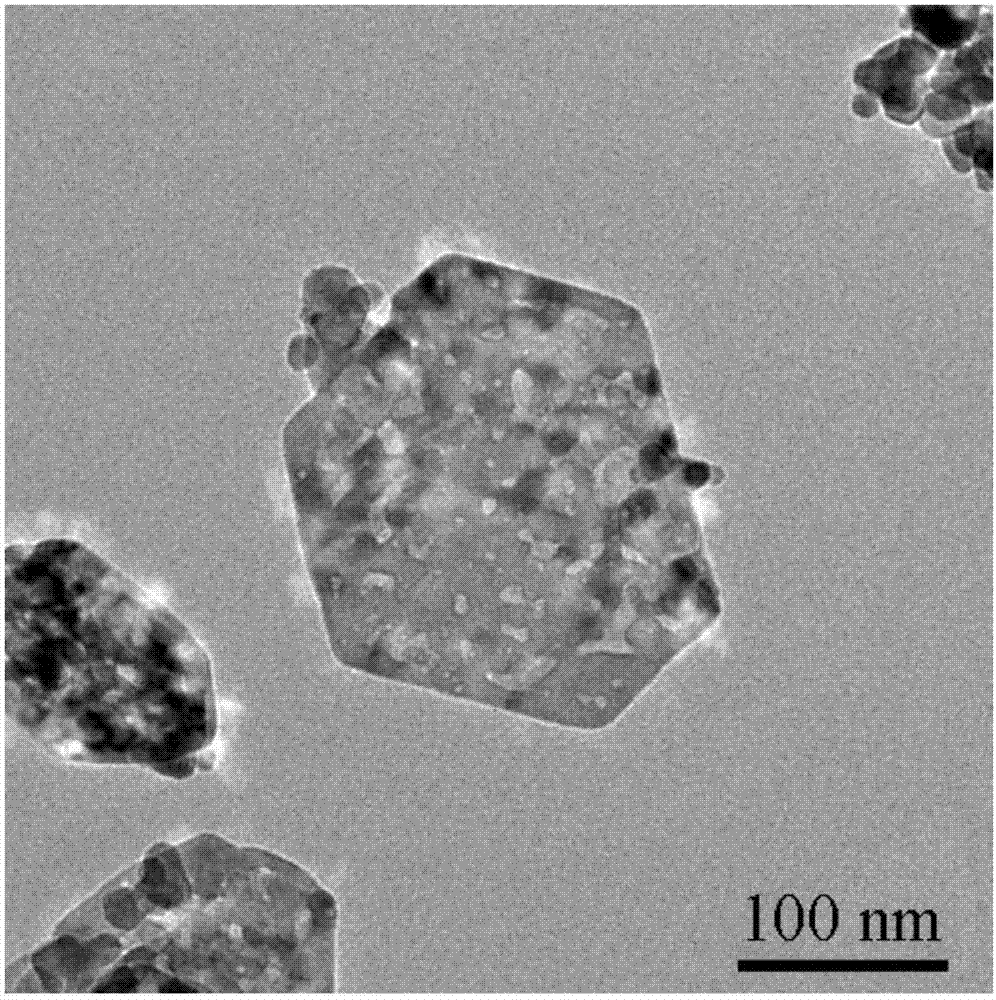

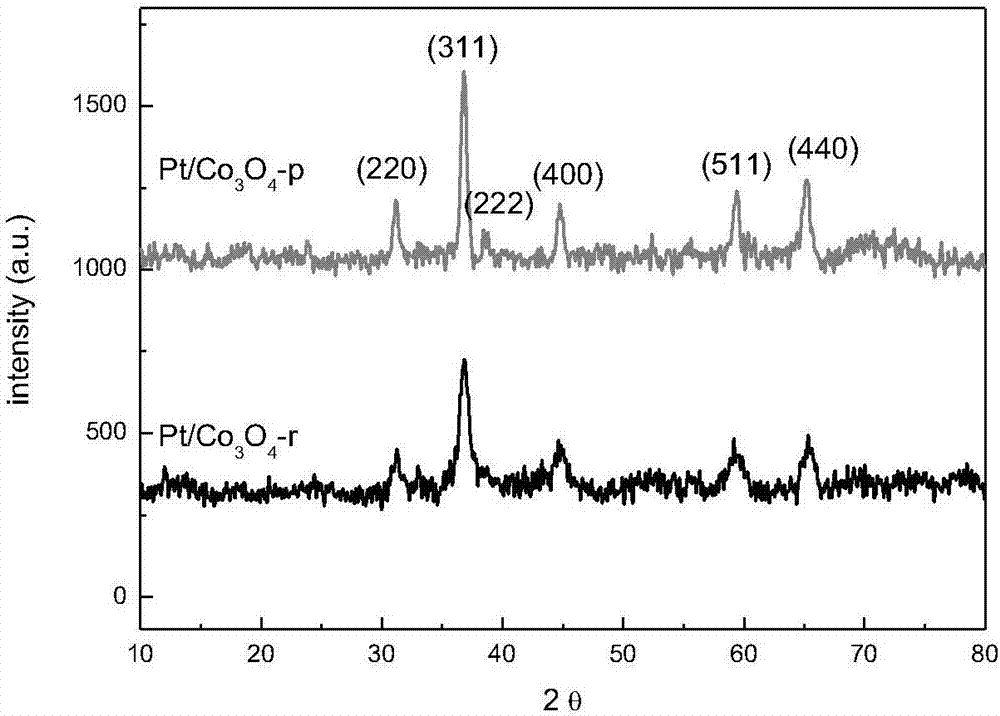

Specific-morphology Co3O4-loaded platinum catalyst and application thereof in low-carbon alcohol synthesis reaction through CO2 hydrogenation

ActiveCN106975487AHigh catalyst activityHigh selectivityOxygen compounds preparation by reductionMetal/metal-oxides/metal-hydroxide catalystsCOBALTOUS NITRATEPt element

The invention relates to the technical field of catalysts, in particular to a catalyst, a preparation method thereof and application thereof in low-carbon alcohol synthesis reaction through CO2 hydrogenation. The preparation method includes: using cobalt nitrate or cobalt acetate as a cobalt source; adopting a hydrothermal crystallization or co-precipitation method to prepare Co3O4 nanoparticles different in morphology; impregnating in dinitrodiammine platinum in an equivalent volume manner, and calcining in air to prepare a Pt / Co3O4 catalyst. The catalyst can be used for low-carbon alcohol synthesis reaction through CO2 hydrogenation, and high CO2 conversion rate and low-carbon alcohol selectivity can be realized in a mild condition. Product selectivity can be adjusted effectively by regulating and changing CO2 hydrogenation reaction. The preparation method is simple, and the catalyst has high activity and stability in the mild condition and has great industrial application prospect.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

High-activity heavy distillate oil hydrotreatment catalyst preparation method

ActiveCN106179376AHigh metal loadingHigh catalyst activityHeterogenous catalyst chemical elementsCatalyst activation/preparationFilter cakeHigh activity

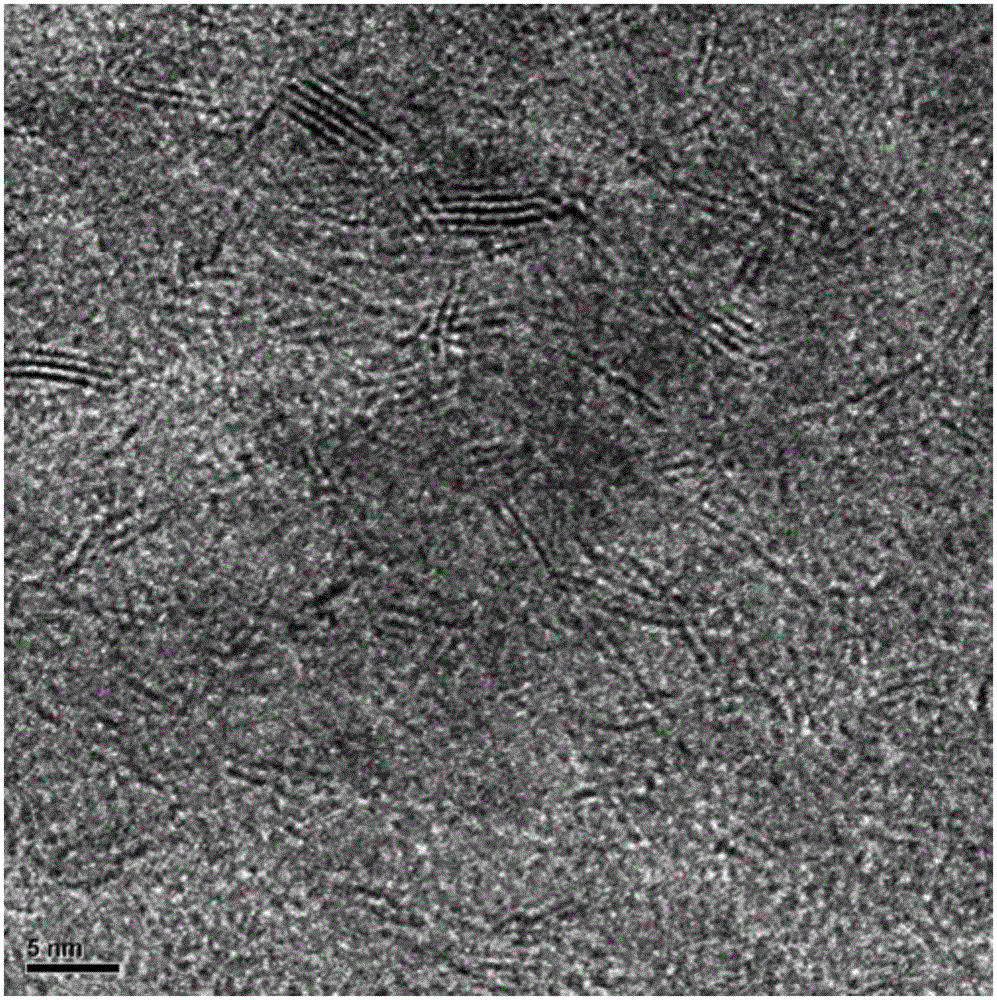

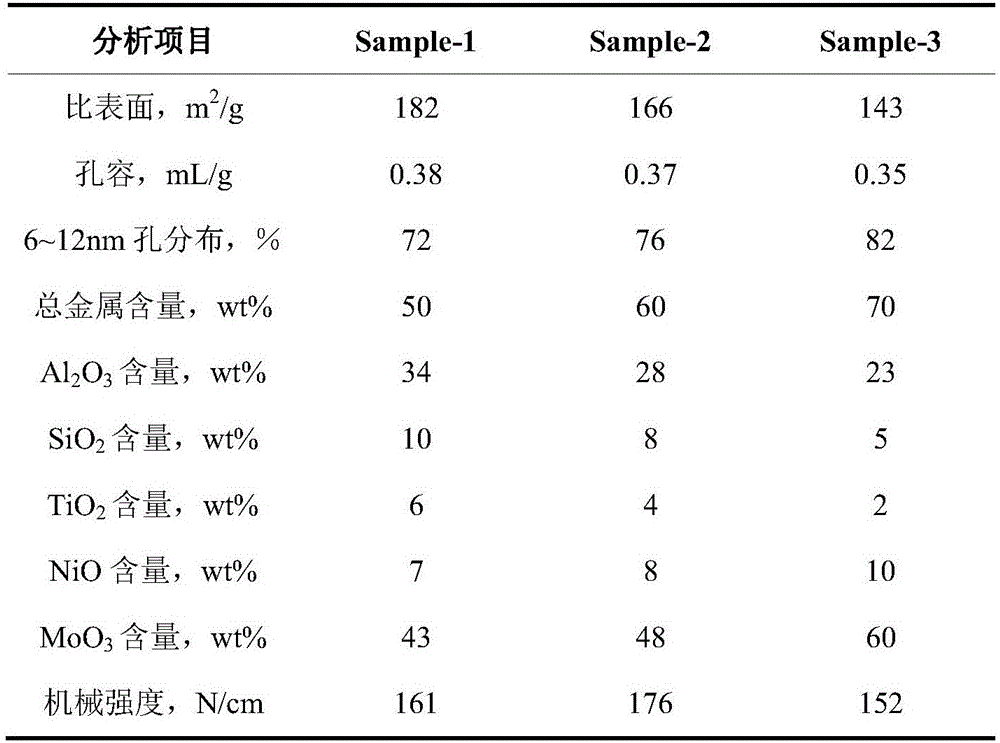

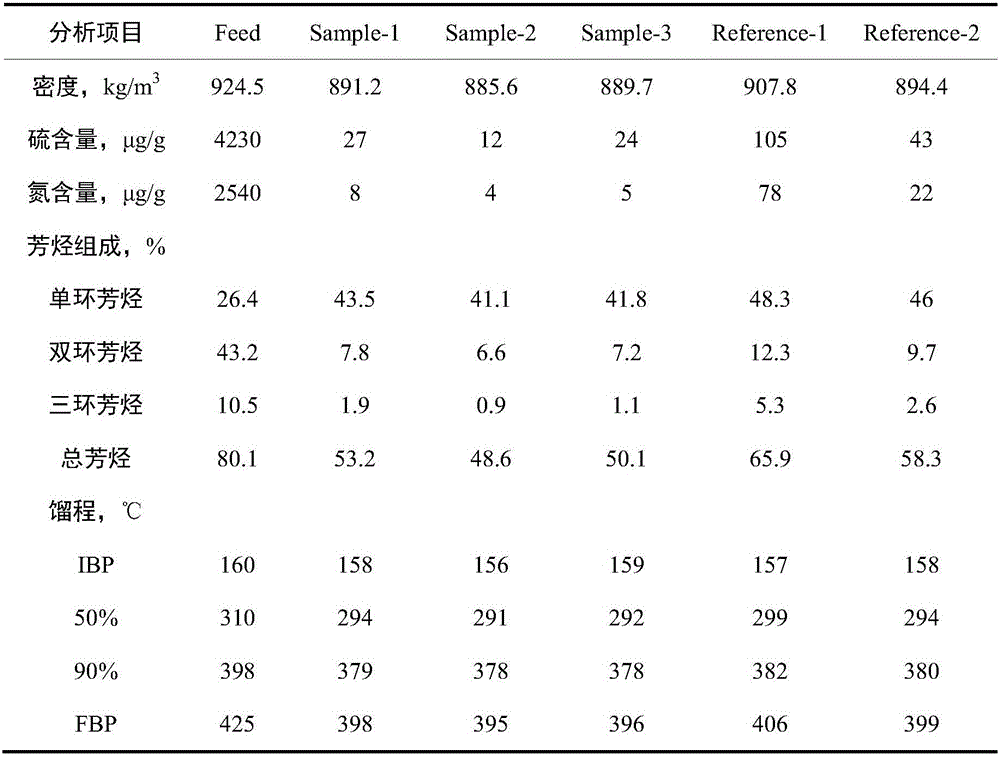

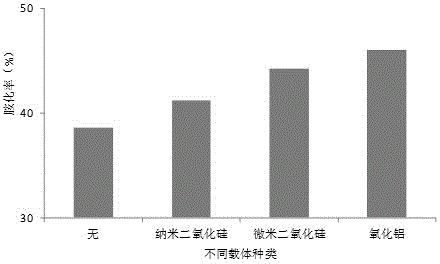

The invention relates to a high-activity heavy distillate oil hydrotreatment catalyst preparation method which includes the steps: selecting VIII-group metal nickel soluble salt and polyhydroxy acid complexing agents to prepare acid solution; selecting VIB-group metal molybdenum soluble salt and alkaline precipitants to prepare alkaline solution; mixing large pore volume pseudo boehmite, nanometer titania powder and silica sol to form suspension slurry serving as a substrate, merging flow, adding the acid solution and the alkaline solution, performing closed reaction, uniformly dispersing metal components in titanium-silicon-aluminum media, performing filtration and washing to obtain catalyst precursor filter cakes after reaction, and curing, forming, drying and roasting the catalyst precursor filter cakes to obtain finished catalysts. Compared with bulk phase hydrogenation catalysts prepared by an existing method, the catalysts prepared by the method have the advantages of high mechanical strength, low abrasion, large pore volume, high metal dispersity, good hydrogenation activity, long service life and the like, and are particularly suitable for hydrotreatment of inferior heavy distillate oil which is high in sulfur-nitrogen content, large in polycyclic aromatic hydrocarbon proportion and difficult to process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Supported Ni-Cu-Cr catalyst and application thereof

InactiveCN104475118AHigh catalyst activityGood choiceOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationSocial effects

Owner:NANJING FORESTRY UNIV

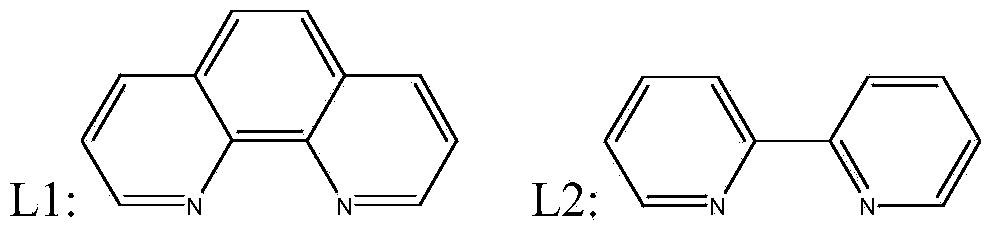

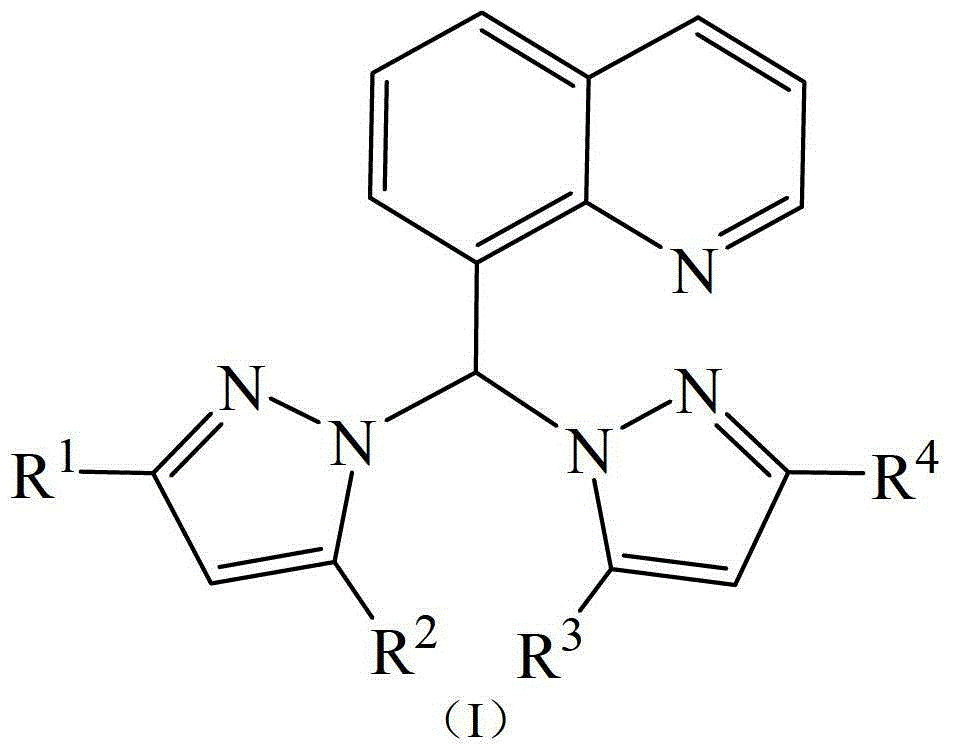

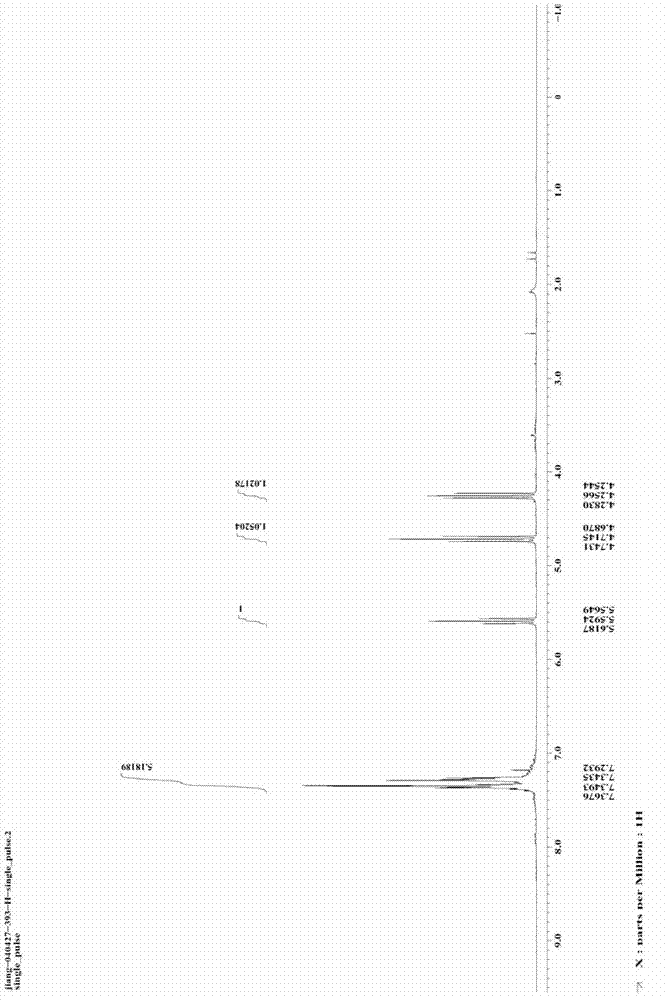

Olefin polymerization catalyst composition and application method thereof

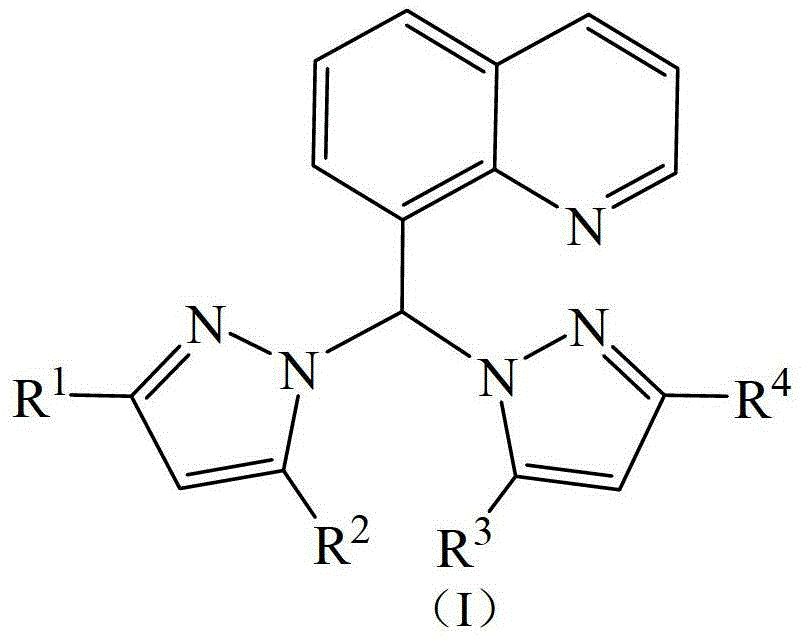

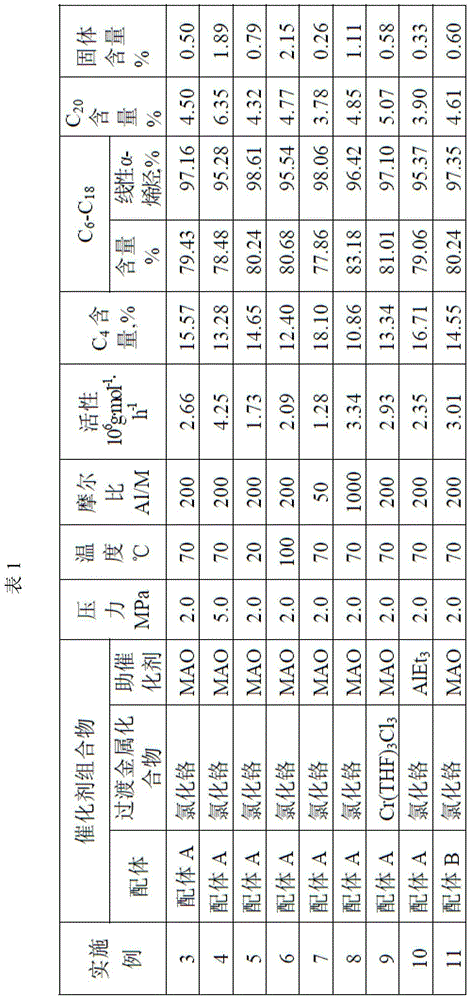

ActiveCN104415787AHigh catalyst activityThe catalytic system is simpleOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOlefin polymerizationNitrogen

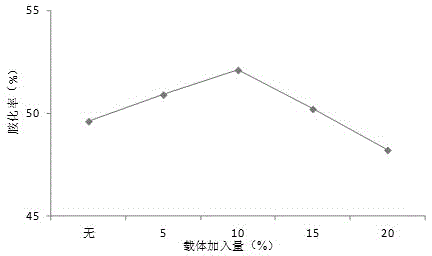

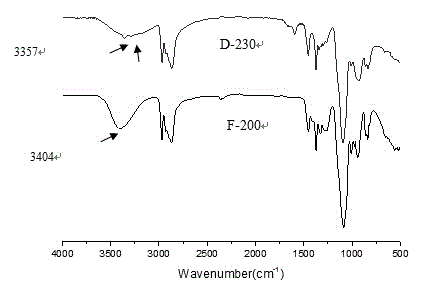

The invention provides an olefin polymerization catalyst composition comprising a nitrogen-containing heterocyclic ligand compound as shown in formula I, a transition metal compound and a cocatalyst; and R1, R2, R3 and R4 can be independently selected from hydrogen, alkyl, or alkoxy. The invention also provides an application method of the catalyst composition, including olefin polymerization of olefins in the presence of the catalyst composition and an organic solvent in a reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

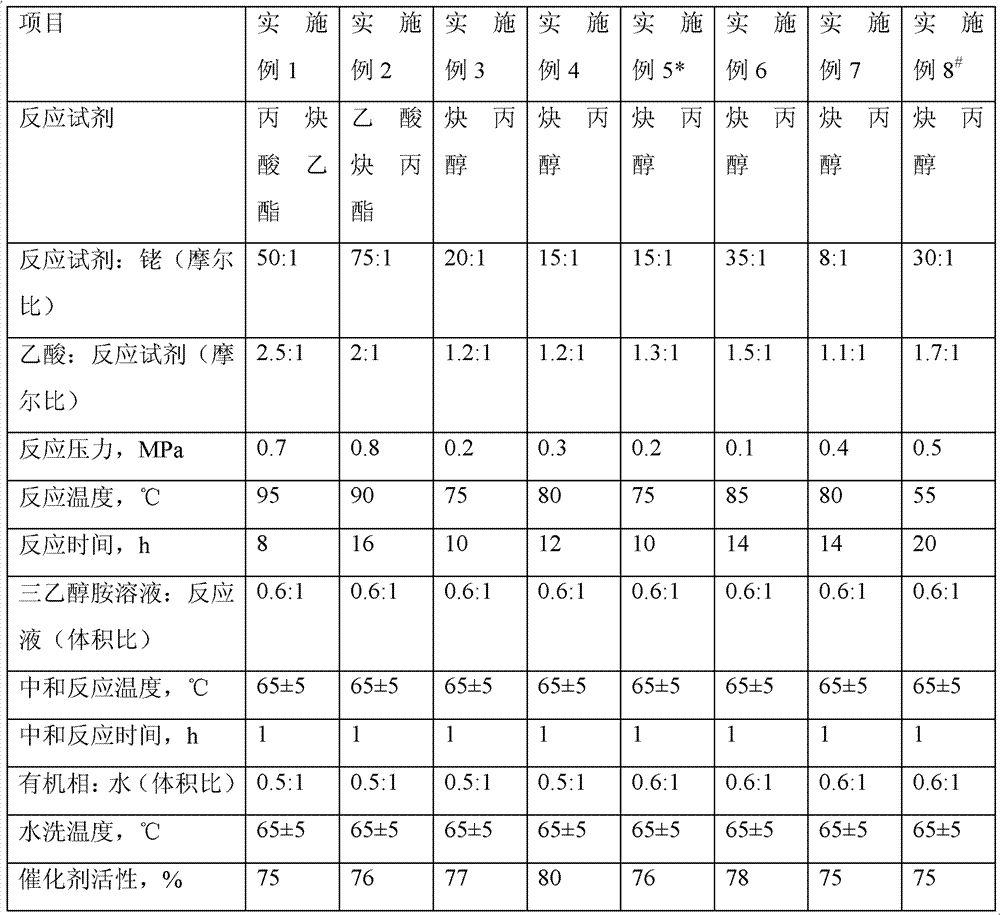

Regeneration method of inactivated rhodium complex catalyst used for carbonyl reaction

ActiveCN102950027AHigh catalyst activitySimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationL&D processWater soluble

The invention belongs to the technical field of the catalyst regeneration, and particularly relates to a regeneration method of an inactivated rhodium complex catalyst used for a carbonyl reaction. The regeneration method of the inactivated rhodium complex catalyst comprises the steps of: firstly mixing a reaction liquid containing an inactivated rhodium complex catalyst with alkynol or ester containing 3-6 carbon atoms, and carboxylic acid, and carrying out the regeneration reaction in the existence of hydrogen or nitrogen at the reaction pressure of 0.1-1.0MPa; then adding an aqueous tertiary alkanol amine solution into the obtained reaction liquid, neutralizing unreacted carboxylic acid or halide to generate water soluble salt; then carrying out the settlement separation to obtain an organic phase containing a rhodium complex catalyst; and washing the organic phase with water to obtain a solution containing the rhodium complex catalyst, the catalytic activity of which is higher than the catalytic activity of the existing inactivated rhodium catalyst. The regeneration method of the inactivated rhodium complex catalyst solves the polymerization problem in the regeneration process of the alkynol or the ester containing 3-6 carbon atoms. The regeneration method of the inactivated rhodium complex catalyst has the advantages of low reagent dosage, mild reaction conditions, easiness in technological process, and high generated catalyst activity, and also has the advantage that the regeneration method of the inactivated rhodium complex can carry out online regeneration of the catalyst under the condition that the carbonyl reaction can be continuously carried out without any pauses.

Owner:CHINA PETROLEUM & CHEM CORP

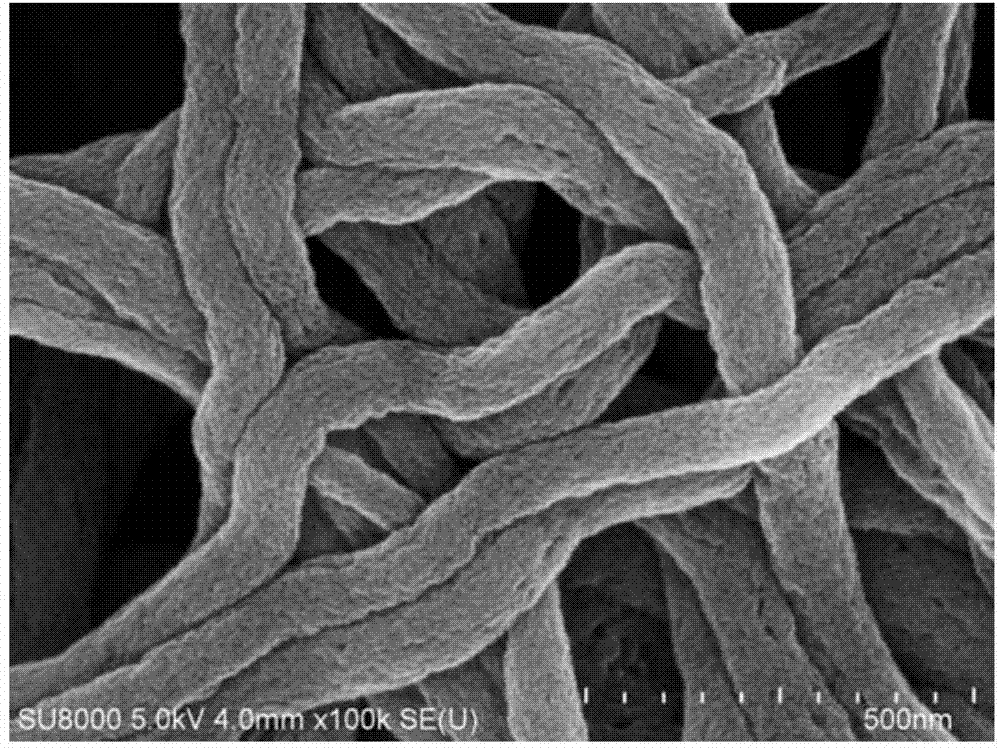

Platinum-based catalyst having high catalytic activity and high durability and adopting porous carbon nano fiber as carrier and preparation method of platinum-based catalyst

ActiveCN104752736AImprove catalytic activity and durabilityHigh catalyst activityCell electrodesSolid electrolyte fuel cellsPlatinum based catalystsNanometre

The invention relates to a platinum-based catalyst having high catalytic activity and high durability and adopting porous carbon nano fibers as a carrier and a preparation method of the platinum-based catalyst, and particularly relates to a method of improving the catalytic activity and durability of a catalyst adopting a loose three-dimensional netted through structure composed of the porous carbon nano fibers as a carrier to load nano platinum particles and an application of the catalyst in a proton exchanging membrane fuel cell. According to the platinum-based catalyst adopting the porous carbon nano fibers as the carrier, the porous carbon nano fibers which are used as the carrier form a loose three-dimensional netted through structure, and metal platinum is loaded on the porous carbon nano fibers; the catalytic activity of the platinum-based catalyst adopting the porous carbon nano fibers as the carrier is as follows: the peak potential is 100mA ahead of that of a platinum-carbon catalyst, and the utilization rate of platinum reaches 80 percent; the durability of the platinum-based catalyst adopting the porous carbon nano fibers as the carrier is as follows: the ECSA retention rate after the fuel cell is circulated for 1000 times can reach 50 percent.

Owner:DONGHUA UNIV

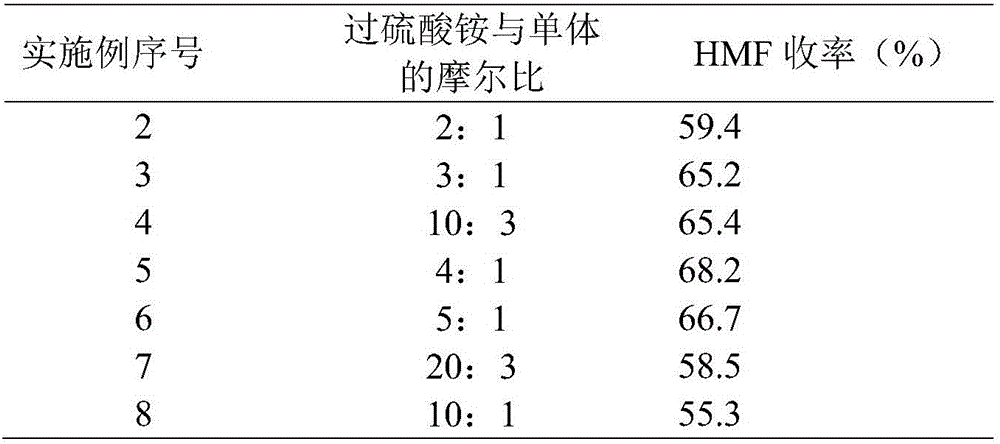

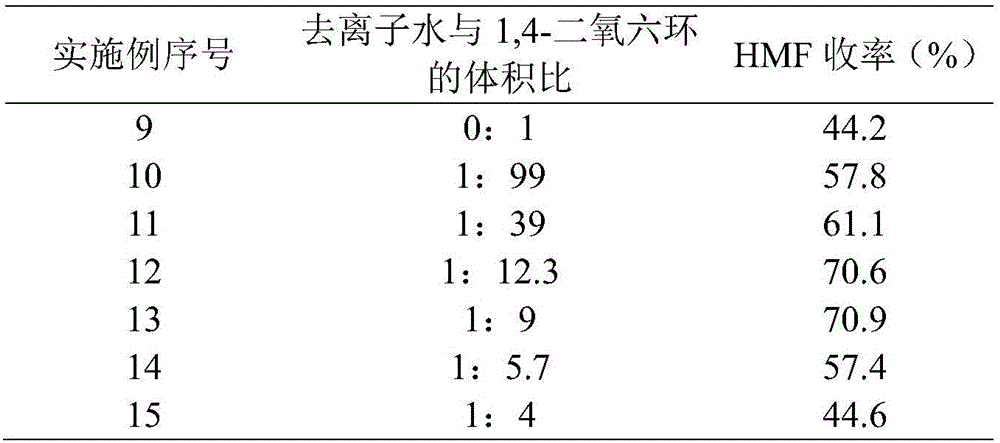

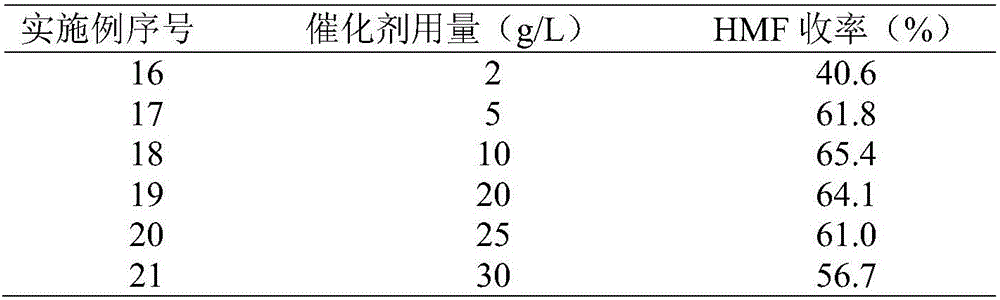

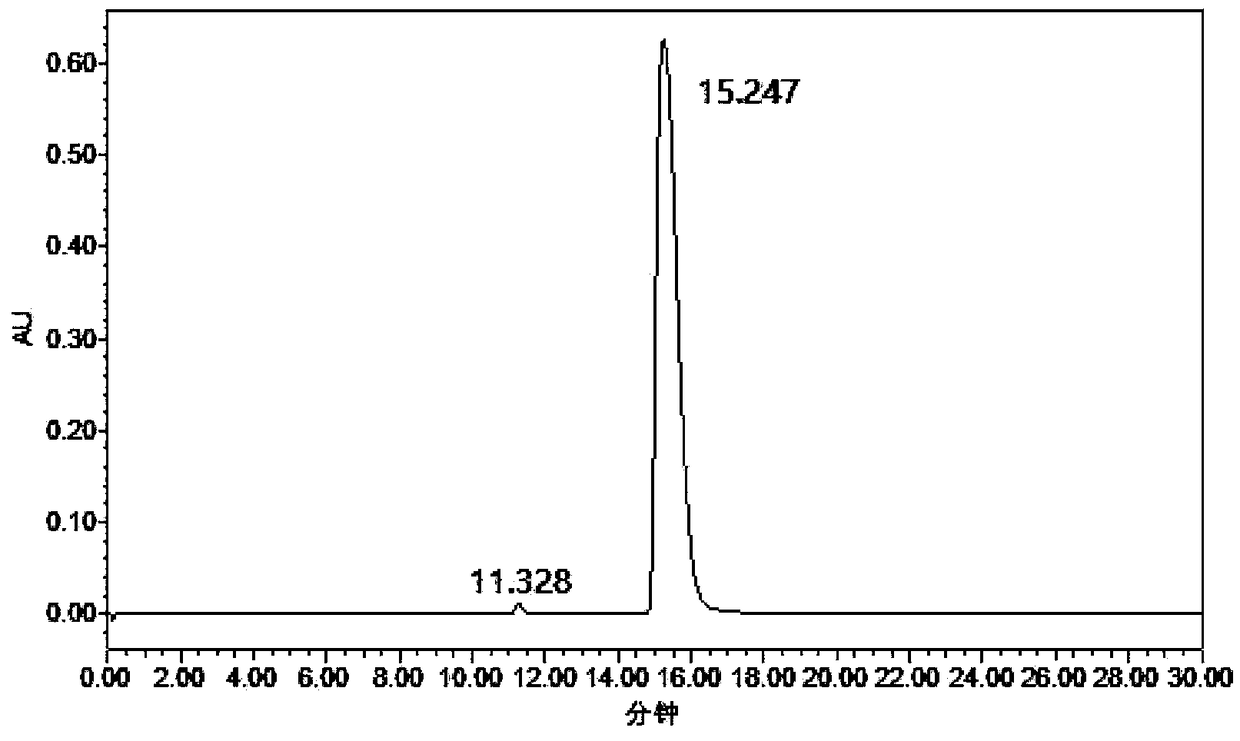

Method for sulfonated polyaniline catalytic synthesis of 5-hydroxymethylfurfural from carbohydrates

ActiveCN106432145AHigh catalyst activityNot easy to dissolveOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIonAmmonium sulfate

The invention provides a method for the sulfonated polyaniline catalytic synthesis of 5-hydroxymethylfurfural from carbohydrates. According to the invention, metanilic acid and freshly distilled aniline are adopted as monomers, and ammonium persulfate is adopted as an oxidant. The monomers and the oxidant are subjected to reaction to synthesize a sulfonated polyaniline catalyst in a deionized water solution. Carbohydrates are subjected to dehydration reaction in a low-boiling-point organic solvent containing the deionized water to form the HMF. The sulfonated polyaniline catalyst is high in catalytic activity, and no by-product levulinic acid is generated. Meanwhile, the sulfonated polyaniline catalyst is stable in activity and can be repeatedly used. The above reaction is carried out in a low-boiling solvent, and the obtained HMF is easy in separation and purification. Meanwhile, the production energy consumption and the cost are low. Therefore, the method has a good industrial application prospect.

Owner:SICHUAN UNIV

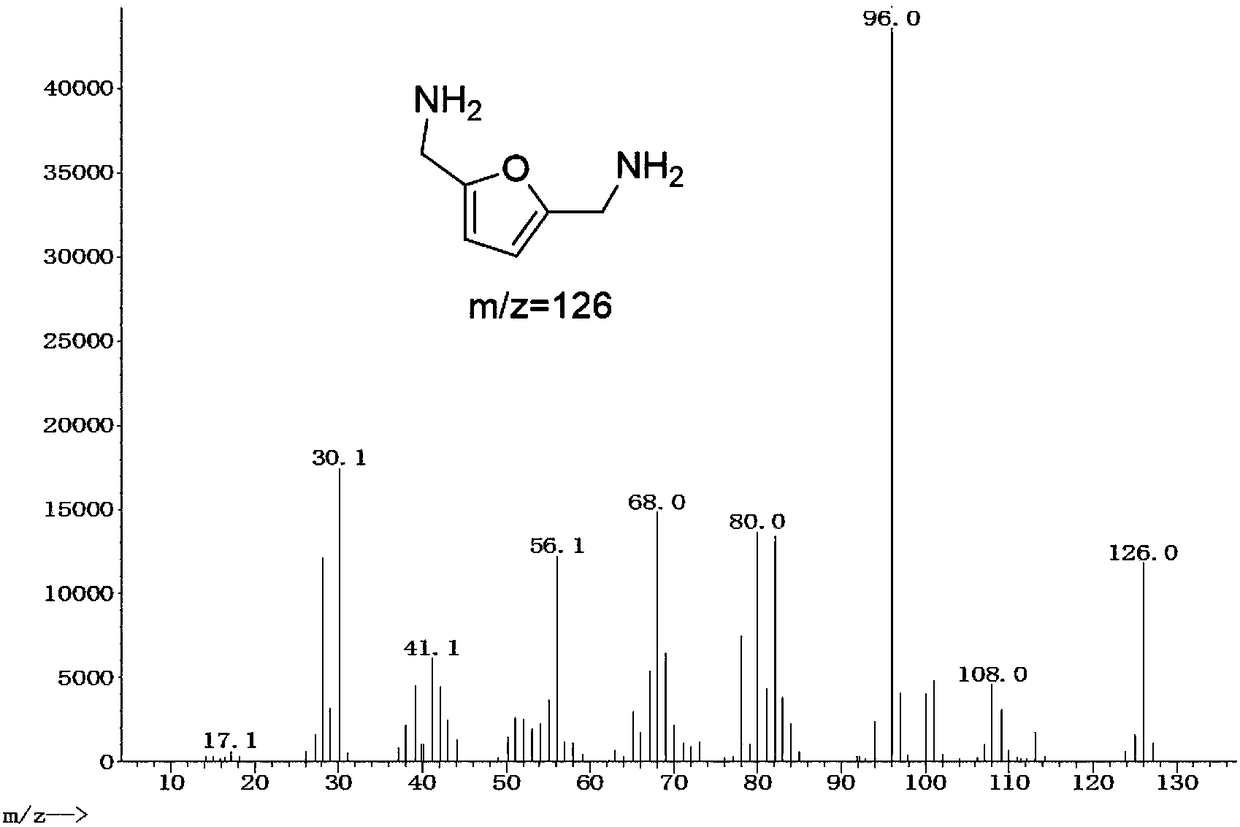

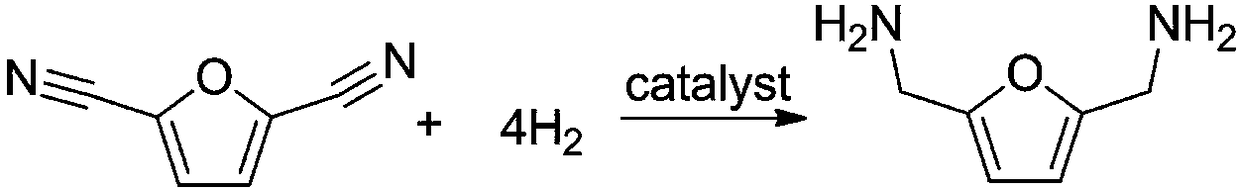

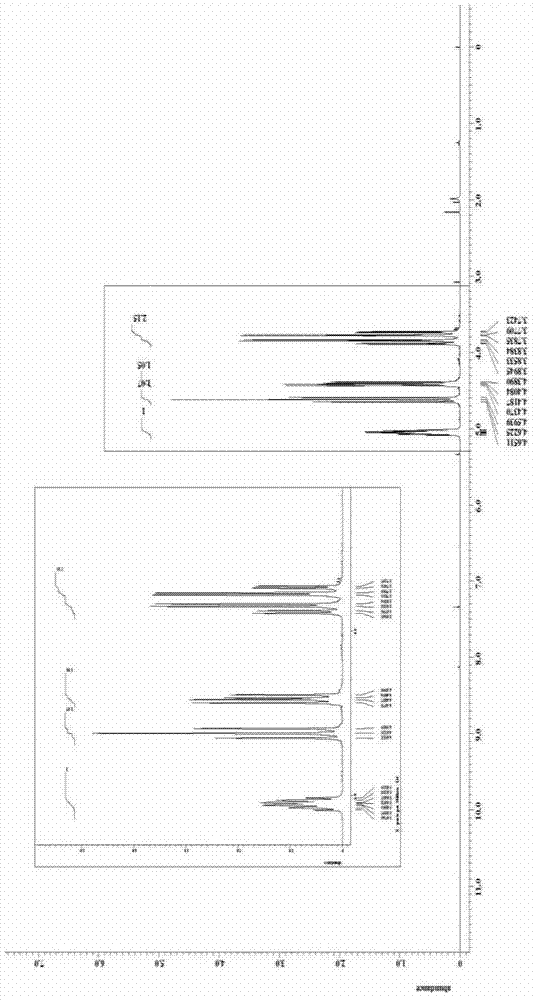

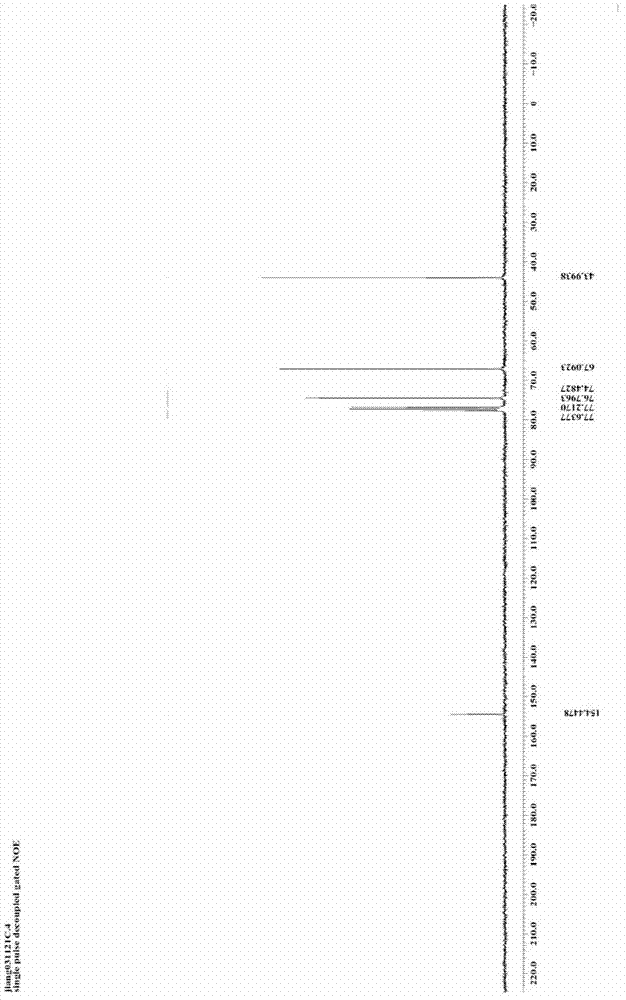

Method for synthesizing 2,5-dimethylamino furan through catalytic hydrogenation of 2,5-dicyanofuran

ActiveCN108129426AHigh catalyst activityGood product selectivityOrganic chemistryFuranMolecular sieve

The invention discloses a method for synthesizing 2,5-dimethylamino furan through catalytic hydrogenation of 2,5-dicyanofuran. According to the method, mesoporous and microporous molecular sieve supported active metal components are taken as a catalyst, and 2,5-dicyanofuran is hydrogenated and converted into 2,5-dimethylamino furan in a high-selectivity manner. The catalysis system uses mild reaction conditions and is simple to operate; the prepared product 2,5-dimethylamino furan has high purity; the used multi-phase catalyst is simple to prepare, high in activity and selectivity and easy toseparate from the system and can still keep higher activity after being repeatedly used.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

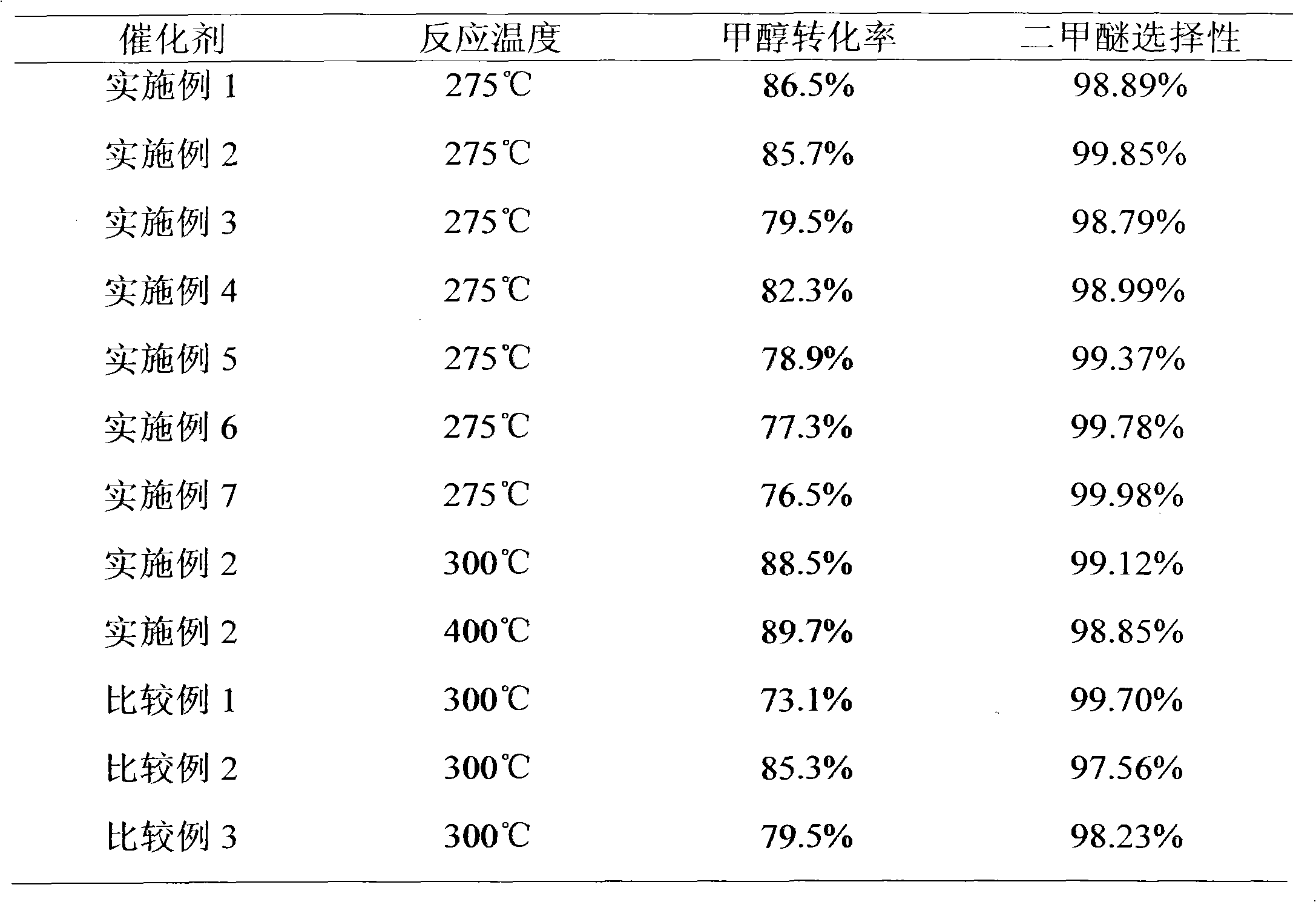

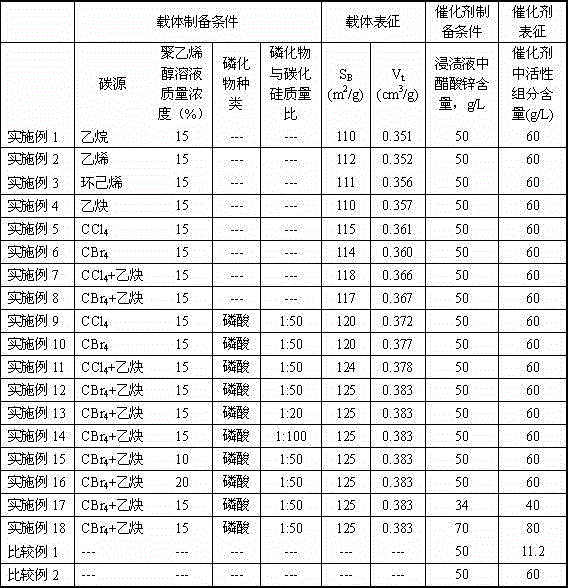

Catalyst for dimethyl ether preparation through methanol dehydration, its preparation method and application

ActiveCN102463134AHigh catalyst activityHigh selectivityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sieveDimethyl ether

The invention discloses a catalyst for dimethyl ether preparation through methanol dehydration, its preparation method and application. The catalyst is composed of 30%-80% (dry basis weight) of a molecular sieve and 70%-20% (dry basis weight) of a binder, wherein, the molecular sieve is a Y-beta composite molecular sieve, and the binder is silica. The preparation method consists of: subjecting the hydrogen type Y-beta composite molecular sieve, the binder, a lubricating agent, and water to kneading and molding, then conducting drying and roasting so as to obtain the catalyst with high activity, high selectivity and good stability. The production process of the catalyst in the invention is simple, thus being in favor of industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for synthesis of vinyl acetate by acetylene method and synthetic method of vinyl acetate

ActiveCN103934025AHigh catalyst activityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsZinc Acetate DihydrateCarbide silicon

The invention relates to a catalyst for synthesis of vinyl acetate by an acetylene method and a preparation method thereof, and mainly solves the problem of low catalyst activity in the prior art. The catalyst is a catalyst used for synthesis of the vinyl acetate by use of the acetylene method, and comprises a carrier and an active component, the carrier is carbon deposited silicon carbide, and the active component is zinc acetate; and by use of the technical scheme, the problem of the low catalyst activity in the prior art can be solved. The catalyst can be used for industrial production of synthesis of the vinyl acetate by use of the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-metal crosslinked matched catalyst for degrading unsymmetrical dimethylhydrazine as well as preparation method and application of multi-metal crosslinked matched catalyst

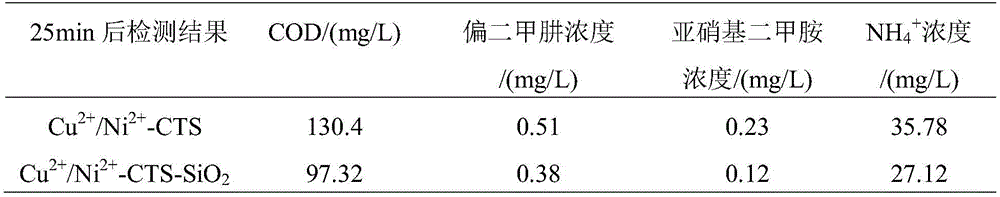

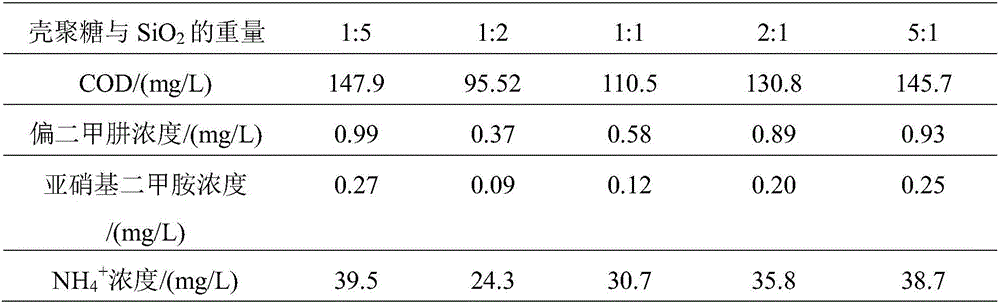

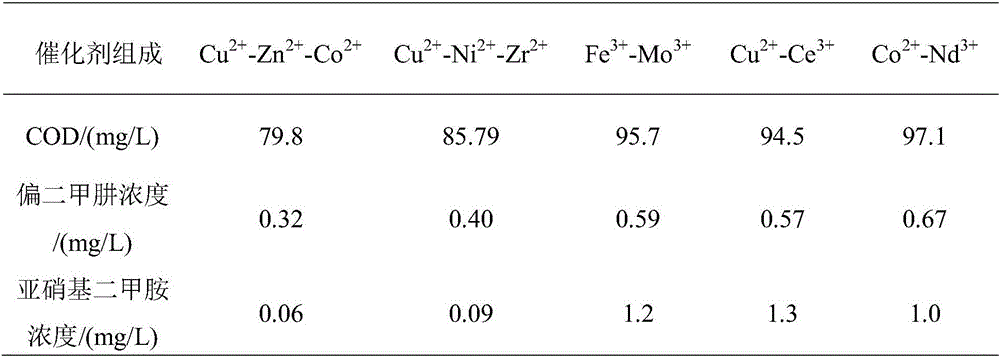

ActiveCN106111200AHigh catalyst activityGood prospects for industrial applicationOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHigh concentrationUnsymmetrical dimethylhydrazine

The invention discloses a multi-metal crosslinked matched catalyst for degrading unsymmetrical dimethylhydrazine as well as a preparation method and an application of the multi-metal crosslinked matched catalyst. The multi-metal crosslinked matched catalyst is represented as a formula M-N, wherein, M is at least two metals from transition metals and / or rare earth metals, N is a modified chitosan carrier, and the ratio of the total mole number of M to the weight of N is (0.5-5):100. The preparation method comprises steps as follows: at least two metals from the transition metals and / or rare earth metals in the ratio are taken as active ingredients and are loaded to the modified chitosan carrier after the temperature is adjusted, washing, drying, grinding and sieving are performed, and the multi-metal crosslinked matched catalyst is obtained. The multi-metal crosslinked matched catalyst has the mimic enzyme catalysis activity similar to the bio-enzyme function, can degrade unsymmetrical dimethylhydrazine wastewater at the room temperature, has high catalytic activity, can be recycled, and can be particularly used for treating the unsymmetrical dimethylhydrazine wastewater with high concentration without dilution and initial pH adjustment.

Owner:SOUTHEAST UNIV

Immobilized ionic-liquid catalyst and application thereof to synthesizing ester lubricating oil

ActiveCN105879907AThe synthesis method is simpleHigh catalyst activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetraethyl orthosilicateEthyl ester

The invention discloses an immobilized ionic-liquid catalyst. A preparing method of the immobilized ionic-liquid catalyst includes the following steps that 1, ionic liquid, absolute ethyl alcohol and tetraethyl orthosilicate are stirred at the constant temperature of 40 DEG C to 70 DEG C till the ionic liquid is dissolved, and the solution is clarified; then a hydrochloric acid solution is added, the mixture is continuously stirred for 1 h to 3 h to be stood and aged for 12 h to 24 h, and a primary product of the mesoporous-silica immobilized ionic-liquid catalyst is obtained; 2, the primary product of the mesoporous-silica immobilized ionic-liquid catalyst is subjected to vacuum drying for 3 h to 6 h at the temperature of 80 DEG C to 100 DEG C, and the mesoporous-silica immobilized ionic-liquid catalyst is obtained. The invention further discloses an application of the catalyst to synthesizing ester lubricating oil. According to the immobilized ionic-liquid catalyst and the application thereof to synthesizing the ester lubricating oil, the catalyst is simple in the synthesizing method and high in catalyst activity, and the process of industrial applications of the catalyst is greatly quickened.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for co-producing 1,2-epoxycyclohexane, α,α-dimethylbenzyl alcohol and cyclohexane

ActiveCN102295624AHigh catalyst activityGood product selectivityDistillation purification/separationPreparation by oxygen reductionChemistryCogeneration

The invention relates to a method for producing 1,2-epoxy cyclohexane, alpha, alpha-dimethyl benzyl alcohol and cyclohexane. The method mainly solves the problems of serious production process pollution, poor product quality and high production cost when the 1,2-epoxy cyclohexane and the alpha, alpha-dimethyl benzyl alcohol are separately produced in the prior art and the problems that the accumulated cyclohexane in the raw material affects the reaction efficiency and affects normal reaction. Isopropyl benzene hydroperoxide and cyclohexene undergo oxidation-reduction reaction on a titanium-containing porous silicon dioxide catalyst under the mild reaction condition, wherein the isopropyl benzene hydroperoxide is reduced into the alpha, alpha-dimethyl benzyl alcohol, and the cyclohexene isoxidized into the 1,2-epoxy cyclohexane; and meanwhile, the cyclohexane and the cyclohexene are efficiently separated by adopting an extractive rectification technology. According to the technical scheme, the problems are well solved, and the method can be used for industrial production of producing the 1,2-epoxy cyclohexane, the alpha, alpha-dimethyl benzyl alcohol and the cyclohexane.

Owner:CHINA PETROLEUM & CHEM CORP +1

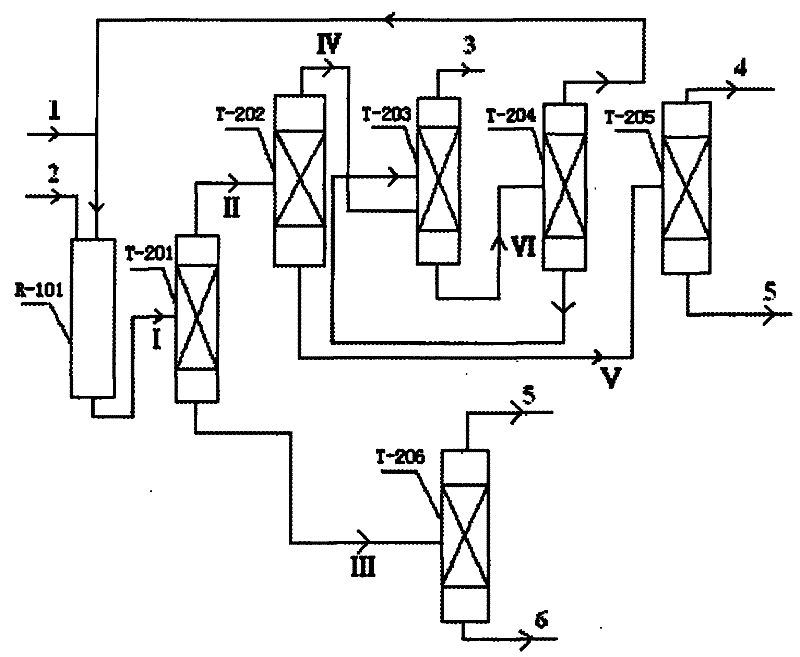

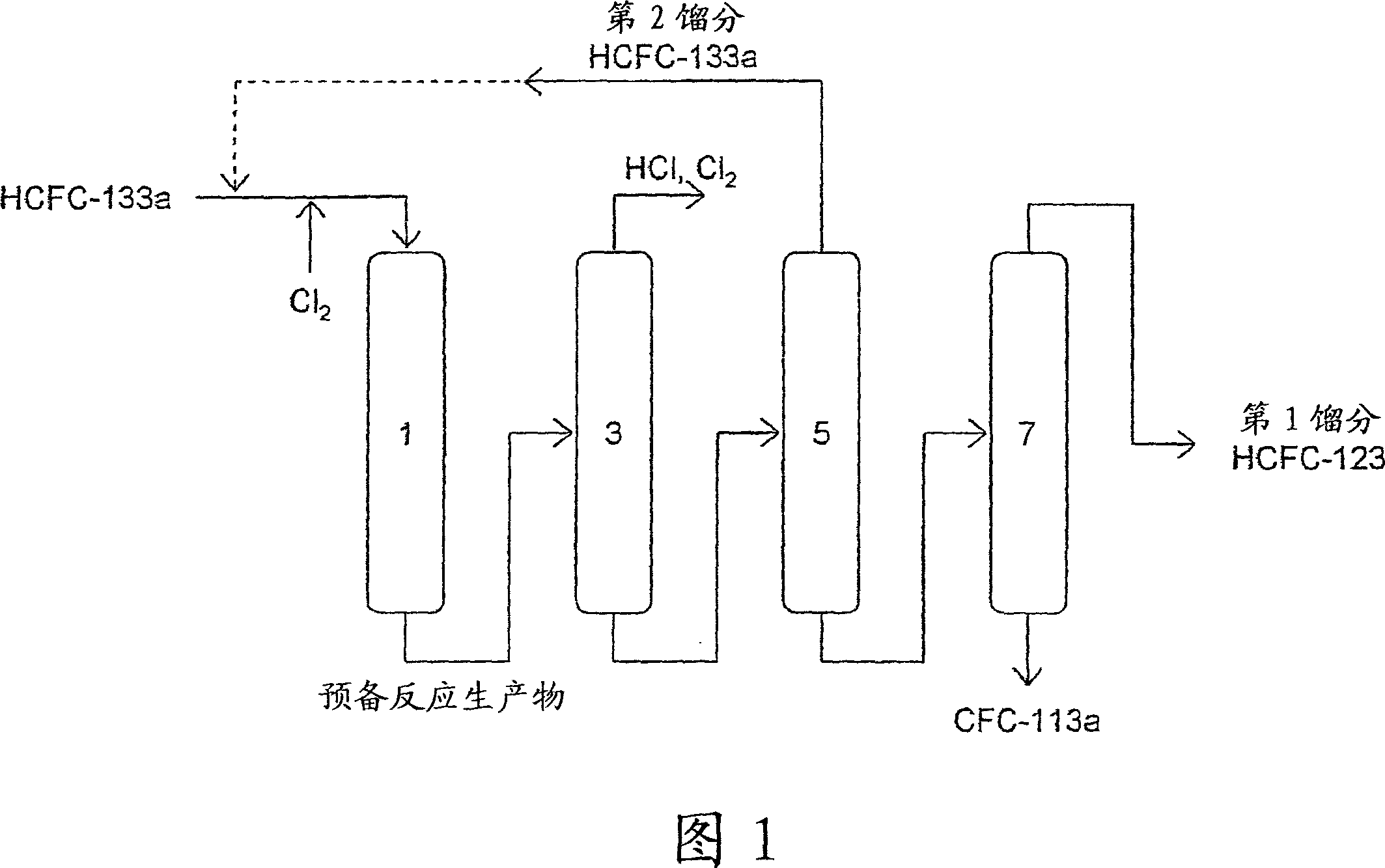

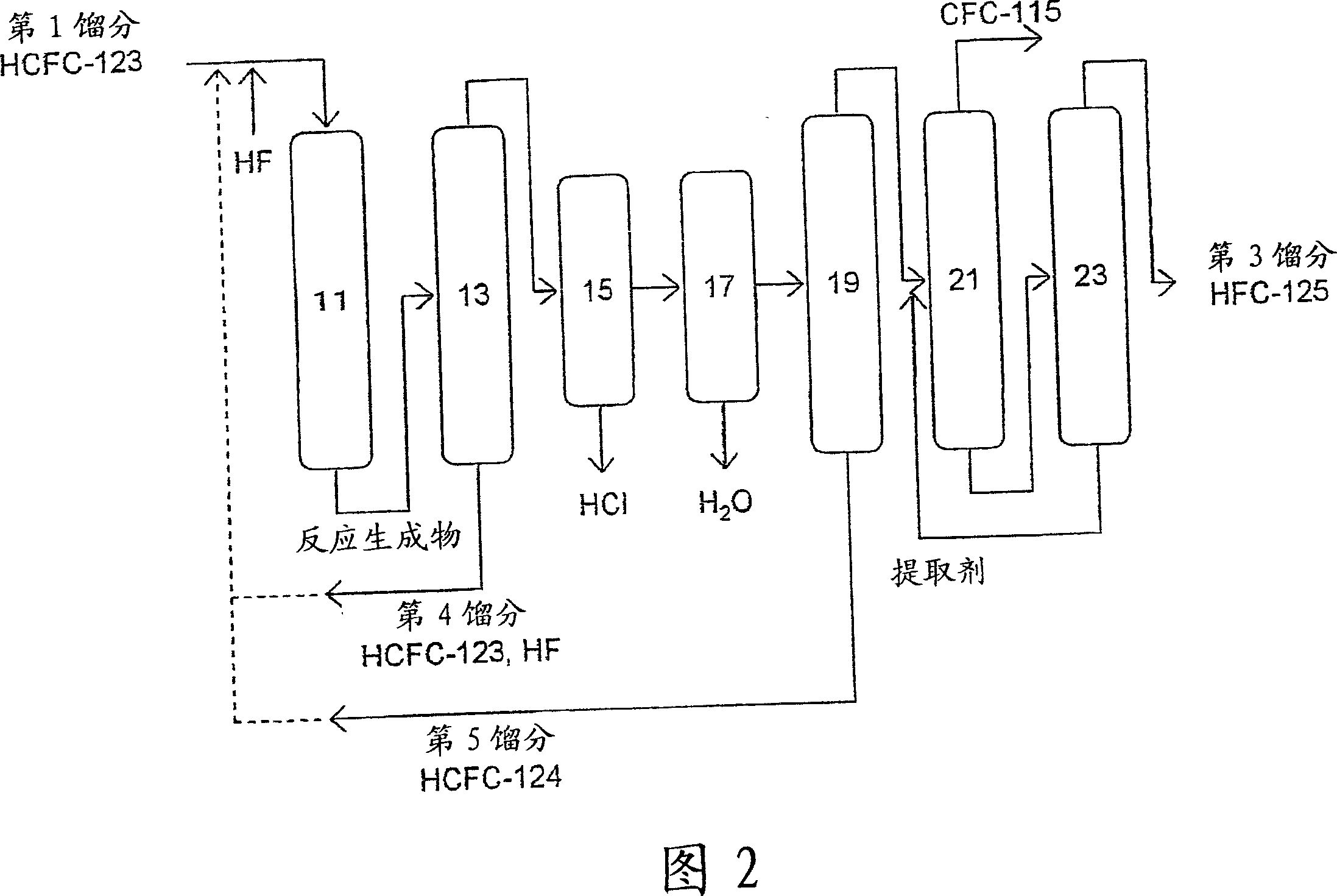

Method of preparing pentafluoroethane

InactiveCN1935757AReduce catalyst poisoningHigh catalyst activityPreparation by halogen replacementChemistryDichloroethane

The present invention provides a novel method of preparing pentafluoroethane. The manufacturing method in accordance with the present invention comprises such reaction procedure where reaction materials containing 1,1,1-trifluoro-2,2-dichloroethane (HCFC-123) essentially exclusively 1,1,1,4,4,4-hexafluoro-2-chloro-2-butylene and 1,1,1,4,4,4-hexafluoro-2-fluoro-2-butylene are adopted. In the presence of a catalyst, a reaction between 1,1,1-trifluoro-2,2-dichloroethane and HF occurs in a gas phase and produces pentafluoroethane (HFC-125) final product.

Owner:DAIKIN IND LTD

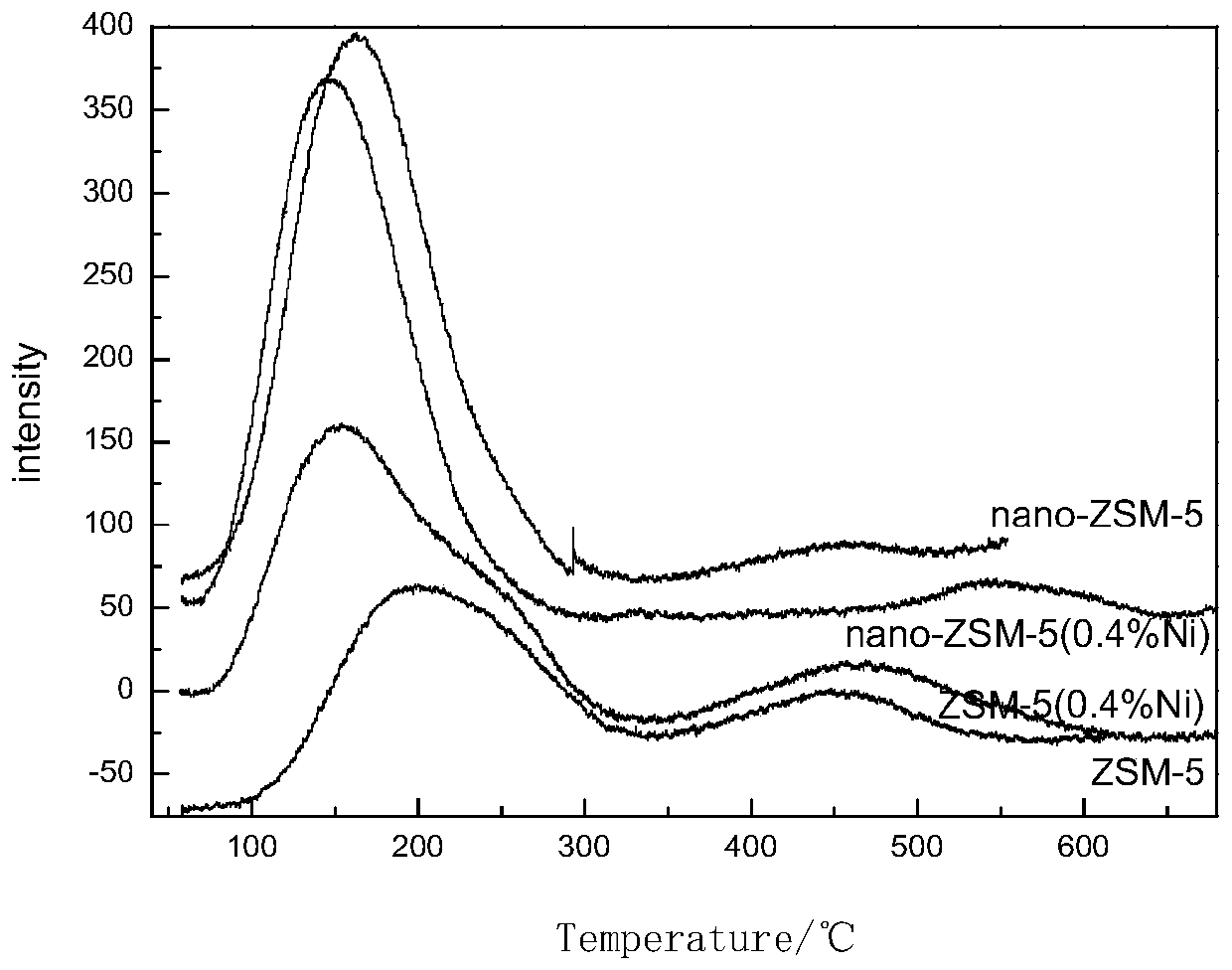

Nano ZSM-5 catalyst for alkylation of benzene and methanol and preparation method thereof

ActiveCN110605140AHigh catalyst activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystAluminium isopropoxideOxide

The invention discloses a modified molecular sieve catalyst for alkylation of benzene and methanol. According to the method, tetraethoxysilane (TEOS) and aluminum isopropoxide (AIP) are used as a silicon source and an aluminum source; tetrapropylammonium hydroxide (TPAOH) is used as a template agent; gamma-aminopropyltriethoxysilane (APTES) is used as a silane coupling agent, so that the nano molecular sieve catalyst is prepared, wherein the silica-alumina ratio (nSiO2 / Al2O3) of the prepared catalyst is 50 to 200; oxides of nickel and phosphorus are respectively supported as active component modifiers, and the catalyst is preapred through impregnation, drying and roasting treatments; by using the catalyst, in the reaction of preparing methylbenzene and p-xylene through benzene and methanolalkylation, the one-way conversion rate of benzene can reach 59% or above, the selectivity of methylbenzene and xylene can reach 95% or above, by-products of propylbenzene are eliminated, the contentof by-products of ethylbenzene, methyl ethylbenzene and the like is greatly reduced, and the catalyst has the characteristics of good activity, high shape selectivity and the like.

Owner:BEIJING UNIV OF CHEM TECH

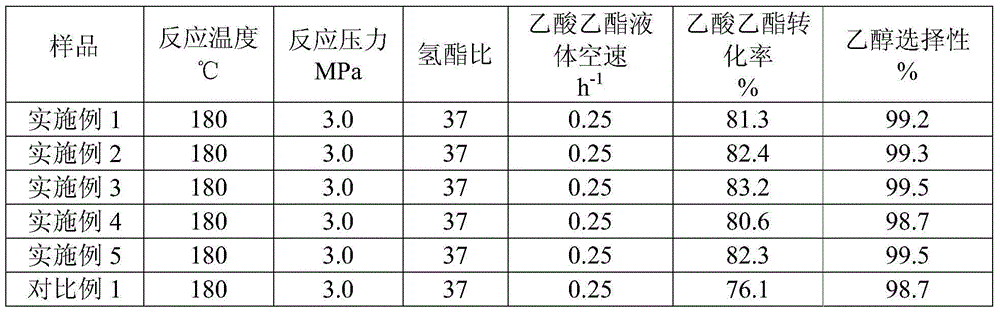

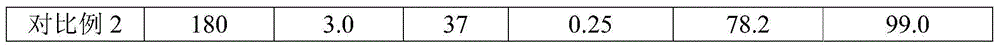

Method for preparing ethanol through hydrogenation of acetate

ActiveCN105481648AIncrease profitHigh catalyst activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAluminiumFixed bed

The present invention discloses a method for preparing ethanol through hydrogenation of acetate. According to the present invention, in the presence of hydrogen, acetate contacts an activated composite catalyst in a fixed bed reactor to prepare ethanol at a reaction temperature of 100-200 DEG C under a reaction pressure of 1.0-5.0 MPa at an acetate liquid space velocity of 0.1-2 h<-1>, wherein the loaded catalyst comprises an organic polymer material carrier and Rainey alloy particles loaded on the organic polymer material carrier surface, and the Rainey alloy comprises Rainey metal copper and an element aluminum capable of being leached. According to the present invention, the loaded catalyst can load more active metals, the loaded active metals are exposed to the surface of the plastic carrier, such that the utilization rate of the active metal in the loaded catalyst is high; and during the preparation process, no high-temperature treatment process exists, such that the catalyst activity reducing caused by the copper grain aggregation during the activation process is effectively reduced, and high reaction activity and high stability are provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ruthenium-copper bimetallic catalyst, preparation method and application thereof

ActiveCN110961151AHigh catalyst activityReaction Condition TemperatureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAqueous solutionMethyl palmoxirate

The invention discloses a ruthenium-copper bimetallic catalyst, a preparation method and application thereof. The preparation method includes the steps of: mixing a ruthenium-copper mixed aqueous solution of equal volume with a hydrochloric acid solution of substituted aniline, adjusting the pH value of the solution to neutral, then blowing air for 12-36h at a speed of 0.5-1mL / s, and drying the obtained precipitate to obtain the ruthenium-copper bimetallic catalyst. Benefited from the synergistic catalysis effect of ruthenium and copper, the catalyst has extremely high activity, available o-methyl diphenyl diselenide can be catalyzed for air oxidation, thus synthesizing a useful selenium-oxygen heterocyclic compound. The technology has a clean and simple preparation process, and is suitable for large-scale production.

Owner:YANGZHOU UNIV

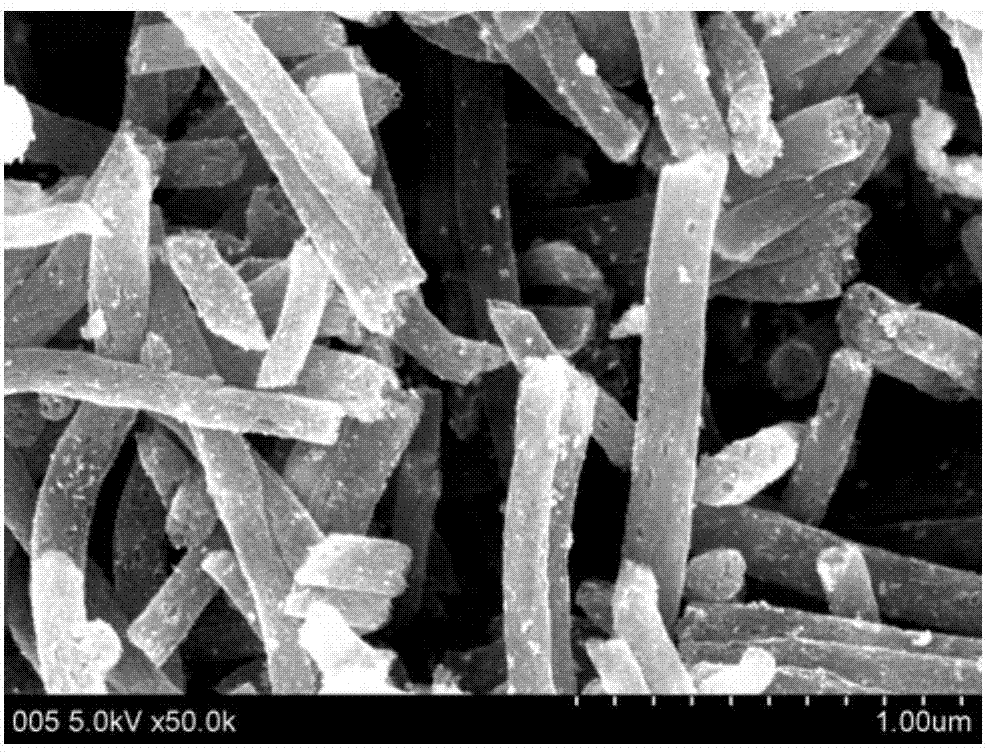

Thin-layer hollow FT synthetic catalyst and use thereof

InactiveCN101462055AHigh catalyst activityHigh porosityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsThin layerFixed bed

The invention discloses a thin-layer hollow FT synthesis catalyst and application thereof. The catalyst contains a carrier and an effective amount of active metal component supported on the carrier. The catalyst is characterized in that the carrier has a thin-layer hollow structure, and the bulk density of the carrier is between 0.5 and 0.95. Compared with the prior granular catalyst, the catalyst with the hollow structure has larger outer surface and lower bulk density, and is particularly suitable for an FT synthesis reaction which adopts a fixed bed reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy metal sewage treatment equipment and process using ozone for complex breaking

ActiveCN112678941AHigh catalyst activityEasy to separate and recycleWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processMagnetic separatorCalcium hydroxide

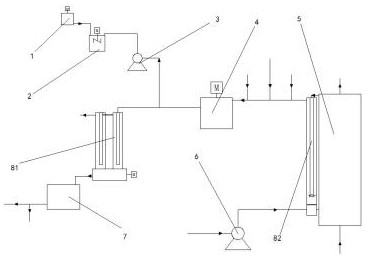

The invention discloses heavy metal sewage treatment equipment and a process using ozone for complex breaking. According to the heavy metal sewage treatment equipment, sewage is introduced into a water inlet of a sewage pump, a drainage pipe of the sewage pump is connected with a fluidized bed reactor through a sludge pipe of a second magnetic separator, and a tail gas outlet is formed in the upper portion of the fluidized bed reactor; a sewage outlet on the upper portion of the fluidized bed reactor is connected with the top of the second magnetic separator, the bottom of the fluidized bed reactor is connected with ozone, a second magnetic separator water discharging pipe is connected with a ferrite reactor, and a calcium hydroxide inlet, a magnetic sludge inlet and a ferrite inlet are formed in corresponding pipelines, the ferrite reactor is connected with the top of a first magnetic separator and a metering water pump through pipelines, The potassium permanganate preparation box is connected with the catalyst reaction kettle through a pipeline, a water outlet of the metering pump is connected with the catalyst reaction kettle, and a sewage up-to-standard discharge outlet is formed in the top of the magnetic separator I; the equipment is obvious in complex breaking effect, simple in magnetic separator structure, high in surface load and high in drained water quality.

Owner:NANJING ZHONGWEI NANO FUNCTIONAL MATERIALS RESEARCH INSTITUTE CO LTD

Method for synthesizing cyclic carbonate

ActiveCN102775379AReduce manufacturing costHigh catalyst activityOrganic chemistryChemical recyclingSolventIon

The invention discloses a method for synthesizing cyclic carbonate. The method comprises the following steps of: under the condition of using terpyridyl as a catalyst, carrying out cyclization reaction on an epoxy compound expressed by a formula II in a carbon dioxide atmosphere so as to obtain a compound expressed by a structural general formula I after reaction. The method uses the non-metallic organic molecule terpyridyl as a catalyst system, thereby efficiently preventing the pollution of metallic ions to a product (cyclic carbonate) caused by the use of the metallic catalyst and ensuring the requirement on the product as an electric product; the catalyst used for the invention is a stable non-metallic organic molecule and can be recycled for use, and the catalyst system is environment-friendly; and the reaction can be carried out in a solvent-free system, so that the reaction cost is reduced.

Owner:TSINGHUA UNIV

Preparation method of 3-ethyl-4-7-aminocephalosporanic acid

ActiveCN105131015AHigh catalyst activityExtended service lifeOrganic chemistryChemical recyclingSolventBenzene

The invention discloses a preparation method of 3-ethyl-4-7-aminocephalosporanic acid. The method comprises the following steps: taking 7-(phenylacetyl) amino-3-vinyl-4-cephalosporanic acid p-methoxybenzyl ester as a raw material, taking solid superacid as a catalyst, reacting for 1 to 10 hours in mixed solvent of haloalkane, acetate and acetonitrile at the temperature of 0 to 50 DEG C, cooling a reaction solution to the room temperature, then processing to obtain faint-yellow solid and to obtain a target product, wherein solid superacid is a tin-series solid superacid modified by transitional metal; haloalkane is alkyl chloride with a carbon atomic number of 1 to 10; the acetate is CH3COOR, wherein R is alkane with a carbon atomic number of 1 to 10. By adopting a heterogeneous catalytic one-pot reaction technology and solid acid catalyst with high activity to prepare 7-(phenylacetyl) amino-3-vinyl-4-cephalosporanic acid p-methoxybenzyl ester, the technology is easy to operate, does not corrode equipment, has less waste water, waste gas and waste solid, is convenient in post-treatment and capable of reutilizing solid acid, and is an economical and practical environment-friendly technology.

Owner:山东昌邑四方医药化工有限公司

Preparation method of carboxylic ester compounds

PendingCN111116363ASimple processHigh catalyst activityOrganic compound preparationCarboxylic acid esters preparationCarboxylic esterMedicinal chemistry

The invention belongs to the technical field of compound synthesis, and particularly relates to a preparation method of carboxylic ester compounds. A compound having a structure represented by formula(A) reacts with a compound having a structure represented by formula (B) under the action of a catalyst to obtain the carboxylic ester compounds having a structure represented by formula (C); in theformulas (A)-(C), R1 is selected from C1-C2 alkyl groups; R2 to R5 are independently selected from hydrogen, halogen, C1-3 alkyl groups or C1-3 halogenated alkyl groups; and the catalyst comprises azodiisobutyronitrile and / or a peroxide catalyst. The compound of formula (A) and the compound of formula (B) are used as reaction raw materials and directly react under the action of the specific catalyst to obtain the carboxylic ester compounds. The method has the advantages of high catalytic activity, simple process flow, low post-treatment difficulty and high production efficiency, can avoid thegeneration of three wastes, and conforms to the environmental protection requirements.

Owner:SHANDONG WEIFANG RAINBOW CHEM

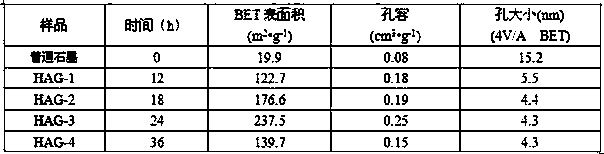

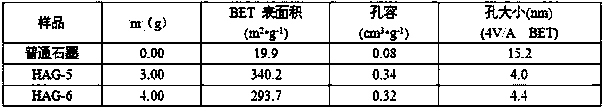

Ruthenium ammonia synthesis catalyst with high-specific-surface-area graphite as carrier and preparation of ruthenium ammonia synthesis catalyst

ActiveCN104014336ASimple equipment structureHigh catalyst activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMaterials sciencePtru catalyst

The invention discloses a ruthenium ammonia synthesis catalyst with high-specific-surface-area graphite as a carrier and a preparation of the ruthenium ammonia synthesis catalyst. The ruthenium ammonia synthesis catalyst comprises Ru-Ba / HAG, wherein Ru refers to an active ingredient ruthenium accounting for 1-8% of the mass of the carrier; Ba refers to assistant barium accounting for 1-10% of the mass of the carrier; HAG refers to the graphite with a high specific surface area. With the high-specific-surface-area graphite as the carrier, the ammonia synthesis catalyst is prepared by preparing potassium ruthenate, supporting the catalyst, pressing and forming. The high-specific-surface-area graphite has relatively large specific surface area and porous volume and can provide enough space for metal dispersion; the surface energy is singular to provide the precondition for obtaining uniform metallic particles; the activity of the catalyst taking the high-specific-surface-area graphite as the carrier is higher than that of the catalyst taking ordinary graphite as the carrier; the surface functional groups of the graphite can be adjusted through different atmospheres, so as to obtain high-specific-surface-area graphite with different kinds and different quantity of surface functional groups; the high-specific-surface-area graphite has different characteristics when being used as the carrier of the ruthenium ammonia synthesis catalyst.

Owner:FUZHOU UNIVERSITY

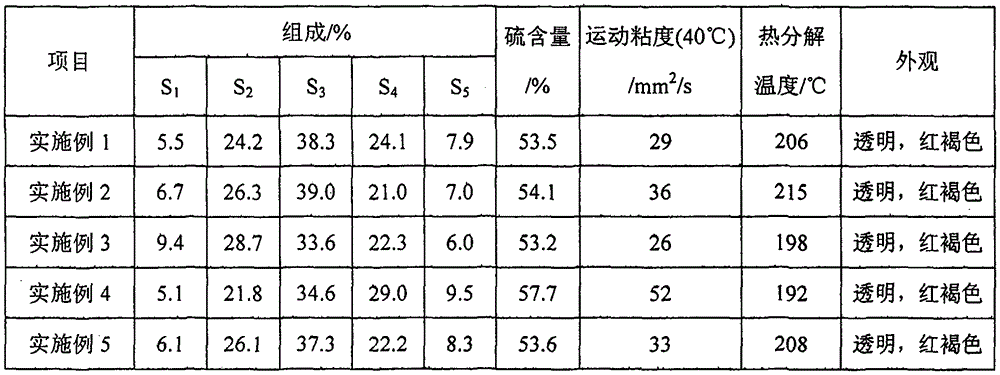

Preparation method of organic vulcanizing agent for hydrogenation catalyst pre-vulcanizing

InactiveCN105037225AHigh catalyst activityHigh activityCatalyst activation/preparationHydropoly/poly sulfide preparationChemistryIsobutylene

The present invention discloses a preparation method of an organic vulcanizing agent for hydrogenation catalyst pre-vulcanizing. According to the present invention, in the presence of a catalyst, isobutylene, 1-butene or 2-butene, or a mixture comprising two or three selected from isobutylene, 1-butene and 2-butene reacts with sulphur to produce the required additive product; the consumption of the catalyst used in the method is low, the catalyst can be dissolved in the product, the performance of the product during the subsequent use process is not affected, and the catalyst is not required to be separated from the product; and the preparation method has characteristics of simple process, high yield, low production cost and no production of dust, wastewater and waste residue, belongs to the environmentally friendly green process technology, and is easily subjected to industrialization promotion.

Owner:ERDOS FLOURISHING FINE CHEM

Method for preparing catalyst for slurry-process ethylene polymerization process

ActiveCN105777952AHigh catalyst activityGood hydrogen sensitivityBulk chemical productionWaxMelt flow index

The invention relates to a method for preparing a catalyst for a slurry-process ethylene polymerization process. According to the method, an electron donor is added during the preparation of the catalyst, so that a catalyst support is restored, and the active center is optimized. Thus, the prepared catalyst is high in activity, sensitive in hydrogen regulation, good in copolymerization performance and uniform in particle size distribution and can be applied to the production of products with high melt index and double-peak polyethylene products. The products with high melt index and the double-peak polyethylene products produced by using the catalyst are high in bulk density, good in grain morphology and low in wax content.

Owner:PETROCHINA CO LTD

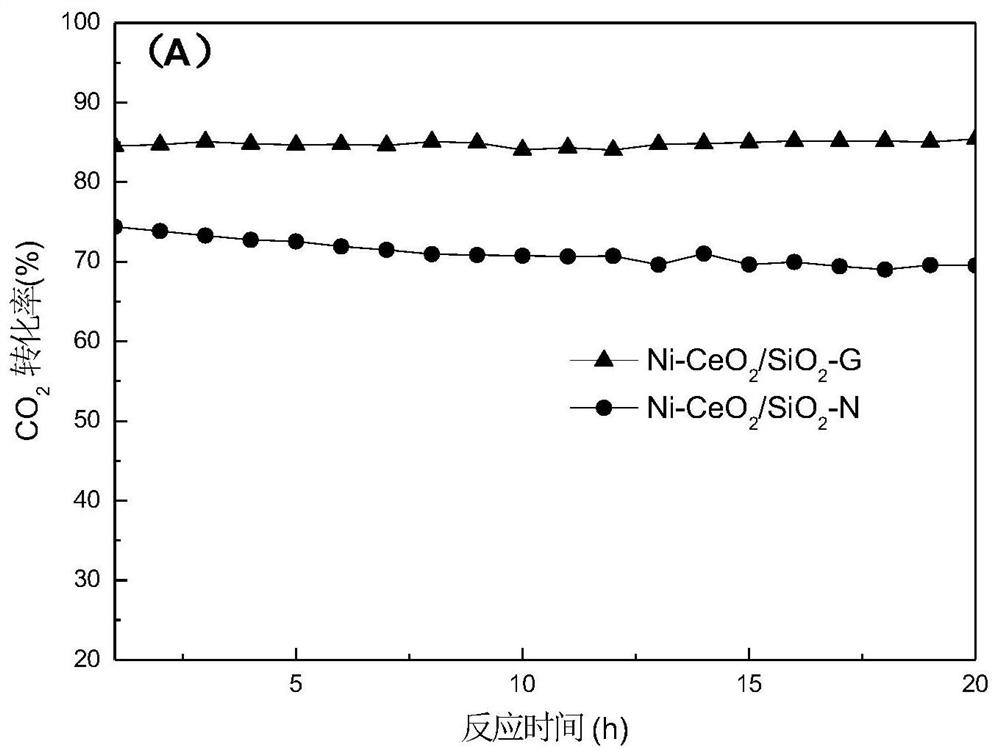

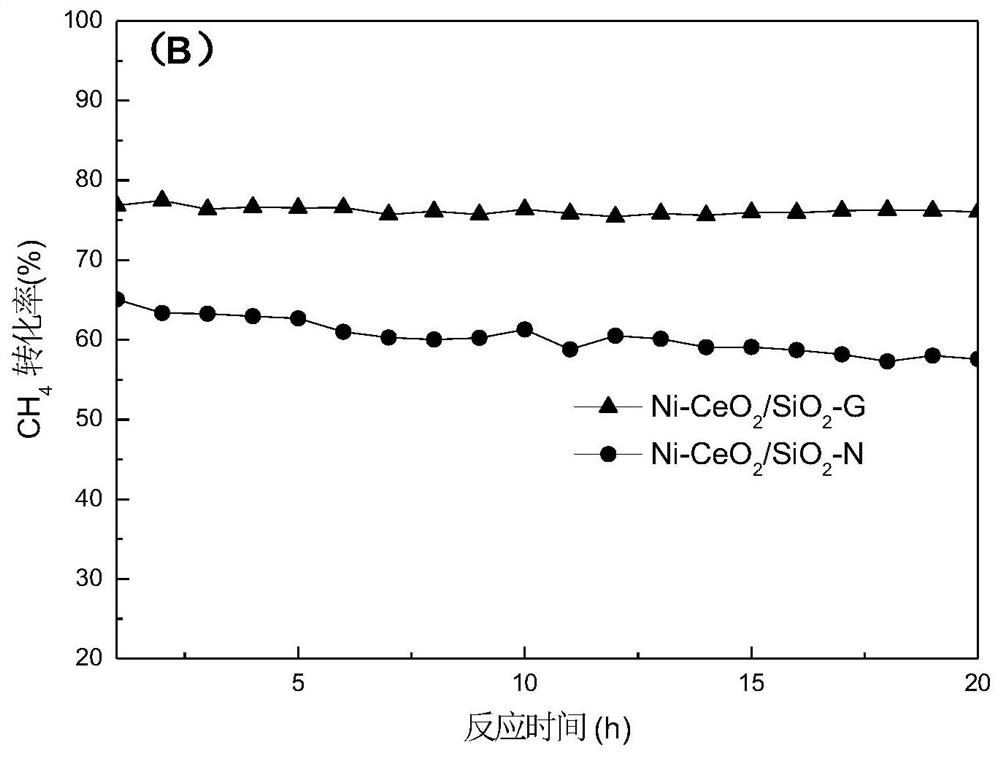

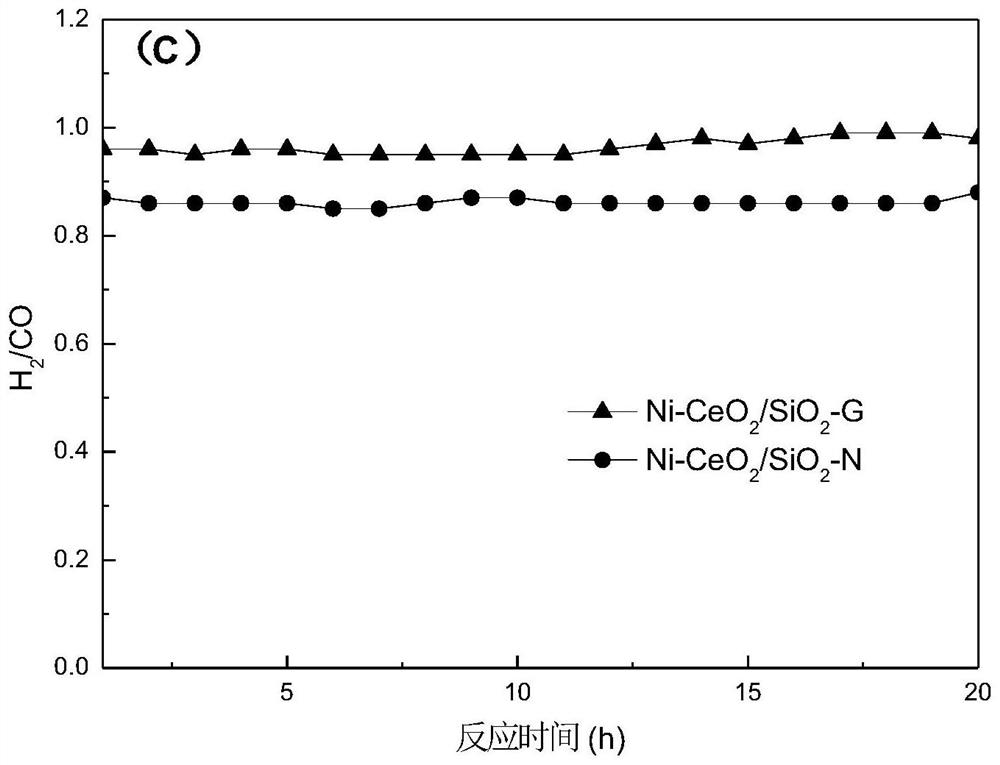

Preparation method of nickel-based methane carbon dioxide reforming catalyst

PendingCN112387285AHigh catalyst activityHigh activityCatalyst carriersHydrogenMother liquorSolution combustion

The invention discloses a preparation method of a nickel-based methane carbon dioxide reforming catalyst, which comprises the following steps: (1) mixing Ce (NO3) 3.6 H2O, Ni (NO3) 2.6 H2O and glycine, adding deionized water, and uniformly stirring to obtain a nitrate solution; (2) adding silica sol into the nitrate solution, and uniformly stirring to obtain mother liquor; (3) heating and evaporating the mother liquor to dryness until the sample is subjected to combustion reaction; and (4) calcining a product obtained after combustion to obtain the nickel-based methane carbon dioxide reformingcatalyst. According to the invention, NiO and CeO2 are loaded on the SiO2 carrier through a solution combustion method to prepare the high-dispersion Ni-CeO2 / SiO2 catalyst, and meanwhile, the high-dispersion Ni-CeO2 / SiO2 catalyst has good methane and carbon dioxide reforming activity, stability and carbon deposition resistance.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com