High-activity heavy distillate oil hydrotreatment catalyst preparation method

A heavy distillate oil, hydrotreating technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of lack of support structure for active components, low catalyst strength, and low metal loss rate and other problems, to achieve the effect of catalyst activity improvement, good hydrogenation activity, and large metal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

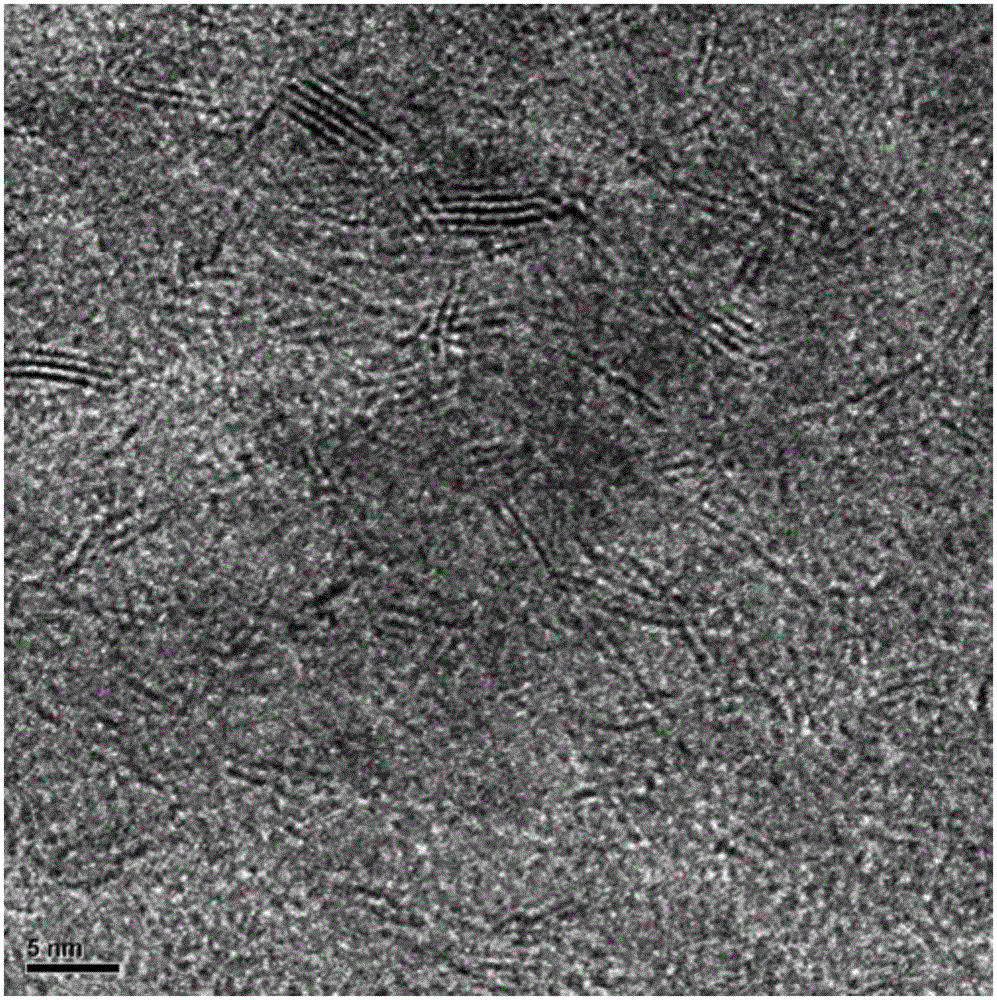

Image

Examples

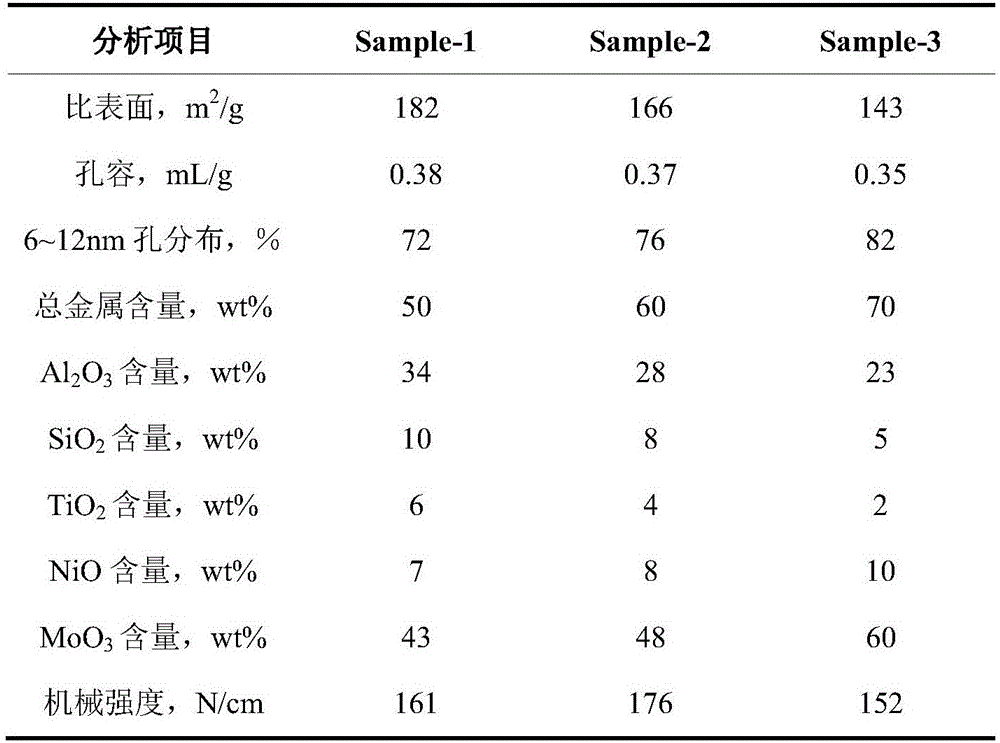

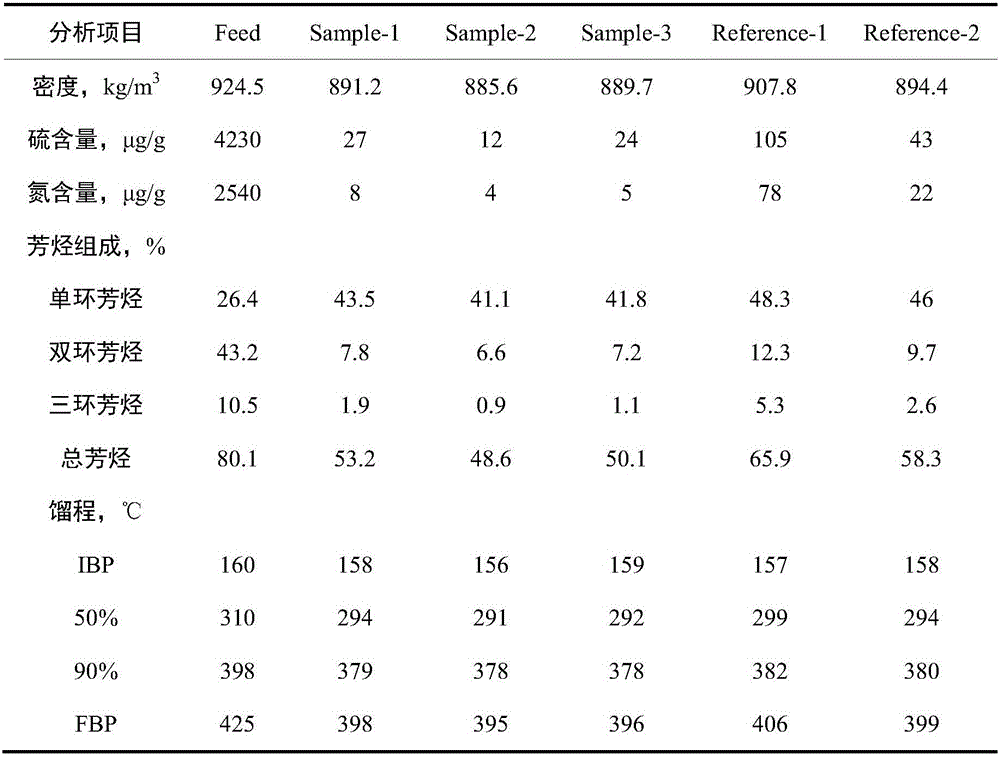

Embodiment 1

[0026] Take 40g of nickel acetate and 20g of oxalic acid, add them into deionized water and stir to dissolve, set the volume to 300mL for later use, and record it as A-1; take 84g of molybdenum oxide, add 198g of ammonia water, stir to dissolve, and make the volume to 300mL with deionized water for later use. It is B-1; take 108g of macroporous pseudoboehmite and 13g of nano-titanium dioxide powder, add it to 125mL of silica sol, adjust the speed of the stirring paddle to 300r / min, stir and beat for 30min, and obtain slurry C-1.

[0027] Heat the slurry C-1 to 60°C, keep the temperature constant, add the solution A-1 and the solution B-1 into the slurry C-1 at a constant speed under stirring, and seal the precipitation reaction for 1.5h. After the reaction, filter out the mother liquor. The filter cake was washed with deionized water.

[0028] Put the filter cake after washing and removing the impurity ions into a wheel-type mixer, add 6g of nitric acid, 5g of scallop powder, ...

Embodiment 2

[0030] Take 48g of nickel acetate and 39g of tartaric acid, add them into deionized water and stir to dissolve, set the volume to 300mL for later use, and record it as A-2; take 122g of ammonium paramolybdate and 33g of sodium carbonate, add them into deionized water, stir to dissolve, and set the volume to 300mL For later use, record it as B-2; take 86g of macroporous pseudo-boehmite and 10g of nano-titanium dioxide powder, add it to 100mL of silica sol, adjust the rotation speed of the stirring paddle to 300r / min, stir and beat for 30min, and obtain slurry C-2.

[0031] Heat the slurry C-2 to 60°C, keep the temperature constant, add the solution A-2 and the solution B-2 into the slurry C-2 at a constant speed under stirring, seal the precipitation reaction for 1 hour, filter the mother liquor after the reaction, and use The filter cake was washed with deionized water.

[0032] The filter cake after washing to remove miscellaneous ions was placed in a wheel-type mixer, and 6 g ...

Embodiment 3

[0034] Take 56g of nickel acetate and 45g of malic acid, add them into deionized water and stir to dissolve, set the volume to 300mL for later use, and record it as A-3; take 142g of ammonium paramolybdate and 39g of sodium hydroxide, add them into deionized water, stir to dissolve, and set the volume to To 300mL for later use, record it as B-3; take 65g of macroporous pseudo-boehmite and 8g of nano-titanium dioxide powder, add it to 75mL of silica sol, adjust the speed of the stirring paddle to 300r / min, stir and beat for 30min, and obtain slurry C-3 .

[0035] Heat the slurry C-3 to 60°C, keep the temperature constant, add the solution A-3 and the solution B-3 into the slurry C-3 at a constant speed while stirring, seal the solution for precipitation reaction for 0.5h, filter the mother liquor after the reaction, The filter cake was washed with deionized water.

[0036] The filter cake after washing to remove the impurity ions was placed in a wheel-type mixer, and 6 g of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com