Metal nanocluster composite catalyst and preparation method and application thereof

A technology of metal nanoclusters and composite catalysts, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of high metal loading and small size of metal nanoclusters , high dispersion and other issues, to achieve the effect of high metal loading, small size and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Synthesis and catalytic performance of embodiment 1, Pt metal nanocluster composite catalyst (Pt content: 25wt%)

[0062] 1) Add 1g H 2 PtCl 6 ·6H 2 O was dissolved in 50 mL of ethylene glycol, and the resulting solution was mixed with 50 mL of NaOH in ethylene glycol (0.26 mol / L). at N 2 Stir the mixture under the atmosphere and heat the mixture to 160 °C with microwaves to react and then cool to room temperature to obtain a Pt metal nanocluster colloidal solution with a Pt concentration of 3.7 g / L;

[0063] 2) Dissolve 0.1385g of trimethylhexadecylammonium bromide (CTAB) in 10mL of n-propanol, add 59.4mg of conductive carbon black to the above mixture and ultrasonically treat it;

[0064] 3) Mix 10mL of the Pt metal nanocluster colloidal solution prepared in step 1) with the dispersion system prepared in step 2), stir and filter to obtain the solid in the reaction mixture;

[0065] 4) Wash the solid obtained in step 3) with hot water (90° C.), and dry it in a vac...

Embodiment 2

[0080] Synthesis and catalytic performance of embodiment 2, Pt metal nanocluster composite catalyst (Pt content: 37wt%)

[0081] Change the mass of conductive carbon black (EC-600) to 40.1 mg, and synthesize according to the steps and conditions described in Example 1 to obtain a Pt metal nanocluster catalyst.

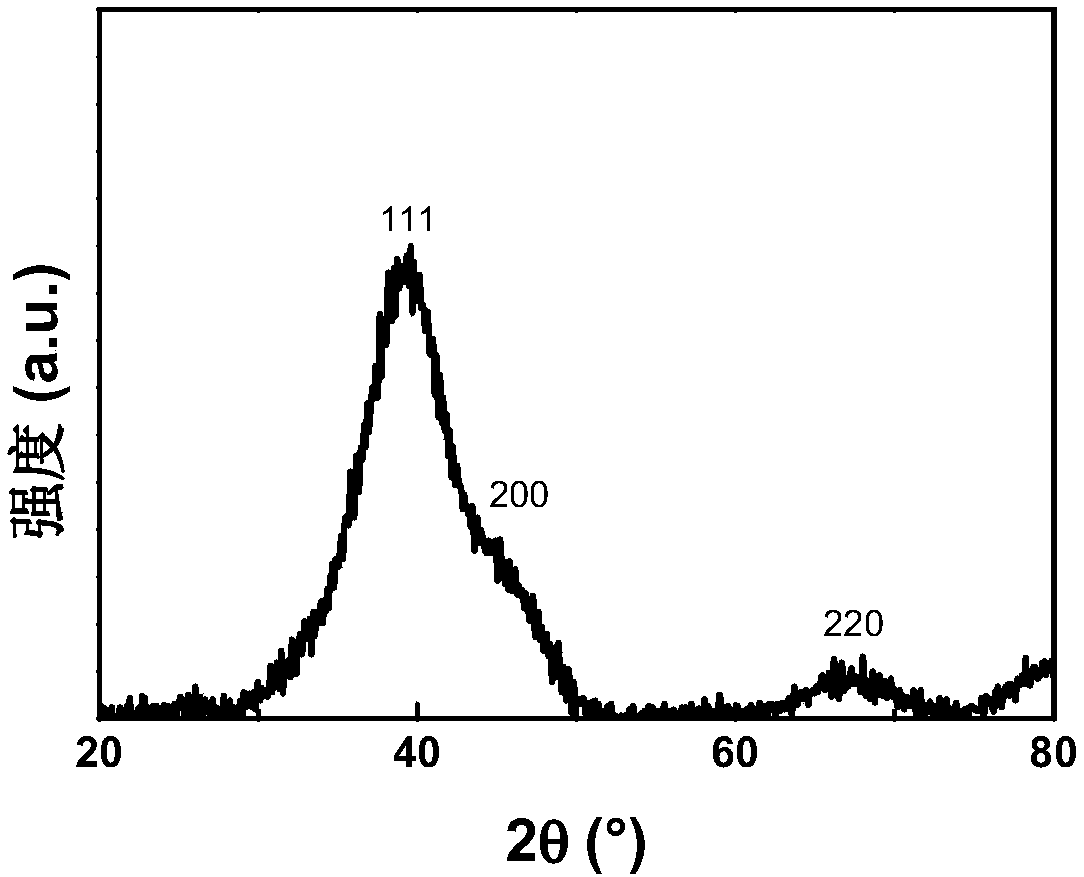

[0082] ICP-AES test shows that the mass percentage of Pt metal nanoclusters in the prepared nanocomposite catalyst is 37wt%. Elemental analysis showed that the mass percent content of nitrogen in the prepared nanocomposite catalyst was 0.75wt%. The mass percent content of the surfactant CTAB in the catalyst is 11%. X-ray diffraction spectrum obtains that the ratio of the diffraction peak area of Pt (200) crystal plane and (111) crystal plane diffraction peak area in the catalyst is 19.7% ( Figure 9 ), its ratio is less than the ratio of commercially available Pt / C-JM and commercially available Pt / C-TKK described in Example 1. The results of electrochemical cataly...

Embodiment 3

[0083] Synthesis and catalytic performance of embodiment 3, Pt metal nanocluster composite catalyst (Pt content: 41wt%)

[0084] Change the mass of conductive carbon black to 29.7 mg, and synthesize according to the steps and conditions described in Example 1 to obtain a Pt metal nanocluster catalyst.

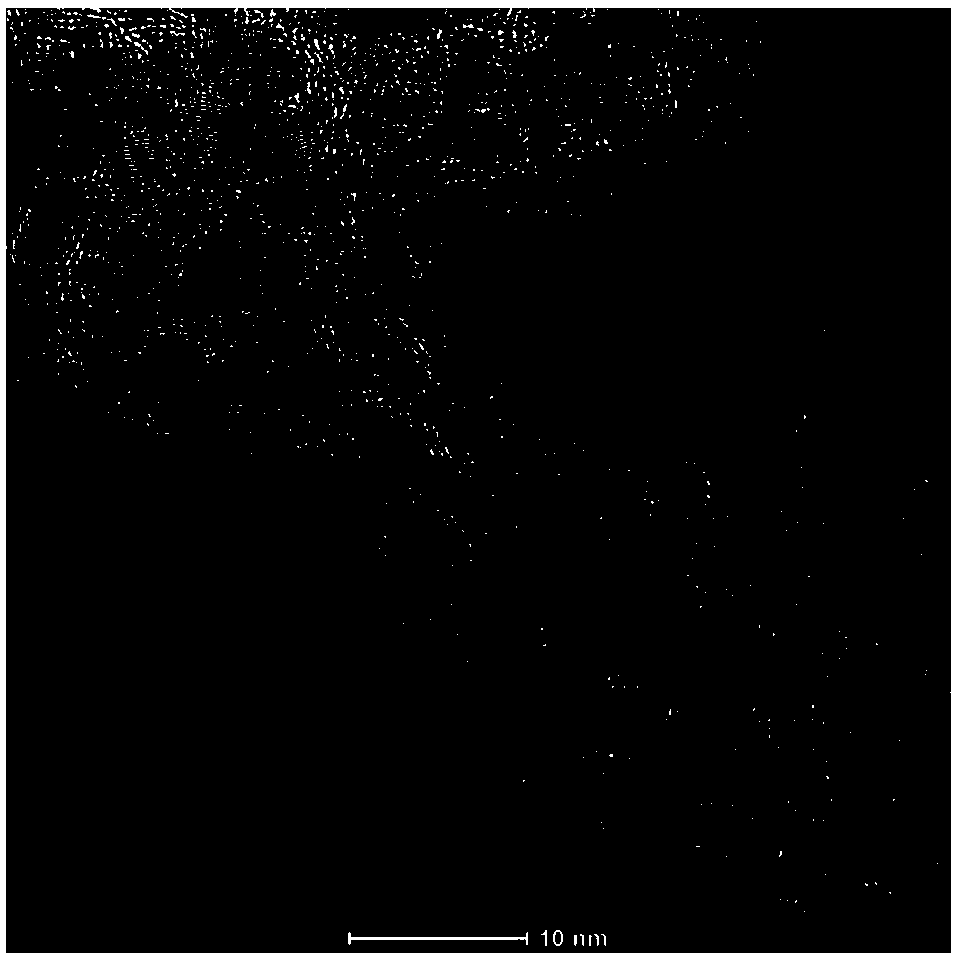

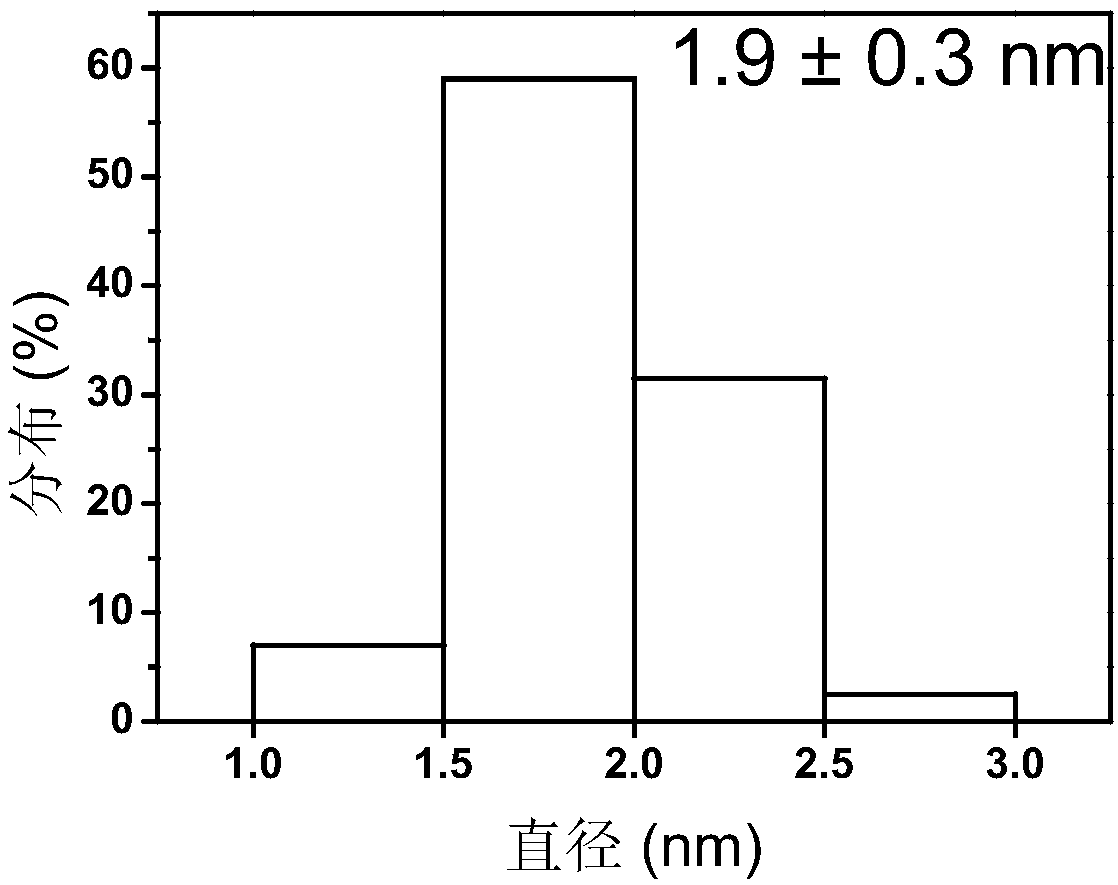

[0085] ICP-AES test shows that the mass percentage of Pt metal nanoclusters in the prepared nanocomposite catalyst is 41wt%. TEM analysis ( Figure 12 , Figure 13 ) shows that the number-average particle size of the Pt metal nanoclusters in the catalyst is 2.5nm, and the standard deviation of particle size distribution is 0.5nm. In the transmission electron microscope image, it can be seen that the morphology is projected as a hexagonal Pt nanocluster. The statistical results show that the Pt nanoparticles whose morphology is projected as hexagon account for 6% of the total number of nanoparticles. The longest diagonal of the hexagon is 2.0 nm to 3.2 nm. Elemental analysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com