Azacarbon/nano metal wire composite material and preparation method for electromagnetic shielding

A nano metal wire and composite material technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of low reflectivity, cumbersome operation, complicated process, etc., and achieve enhanced aromatization, simple process, and simplified post-processing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a nitrogen heterocarbon material nano-metal wire composite material and its preparation, and the technical scheme is as follows:

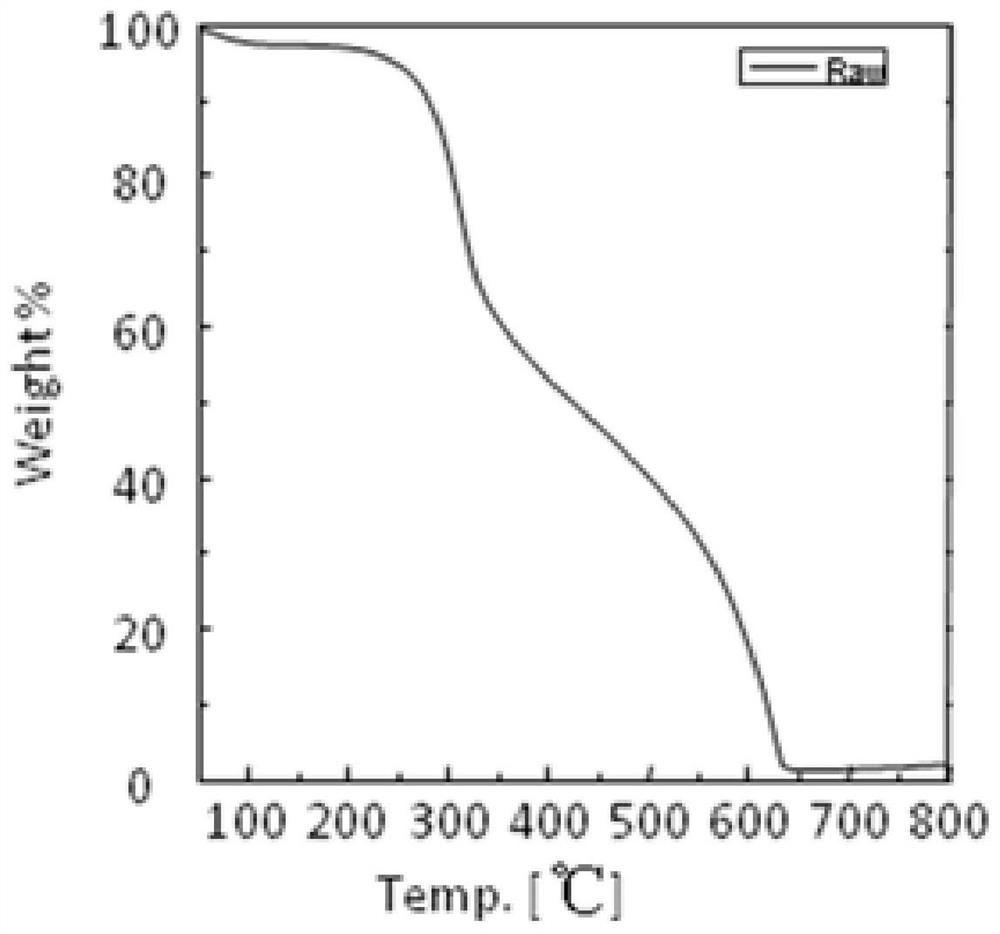

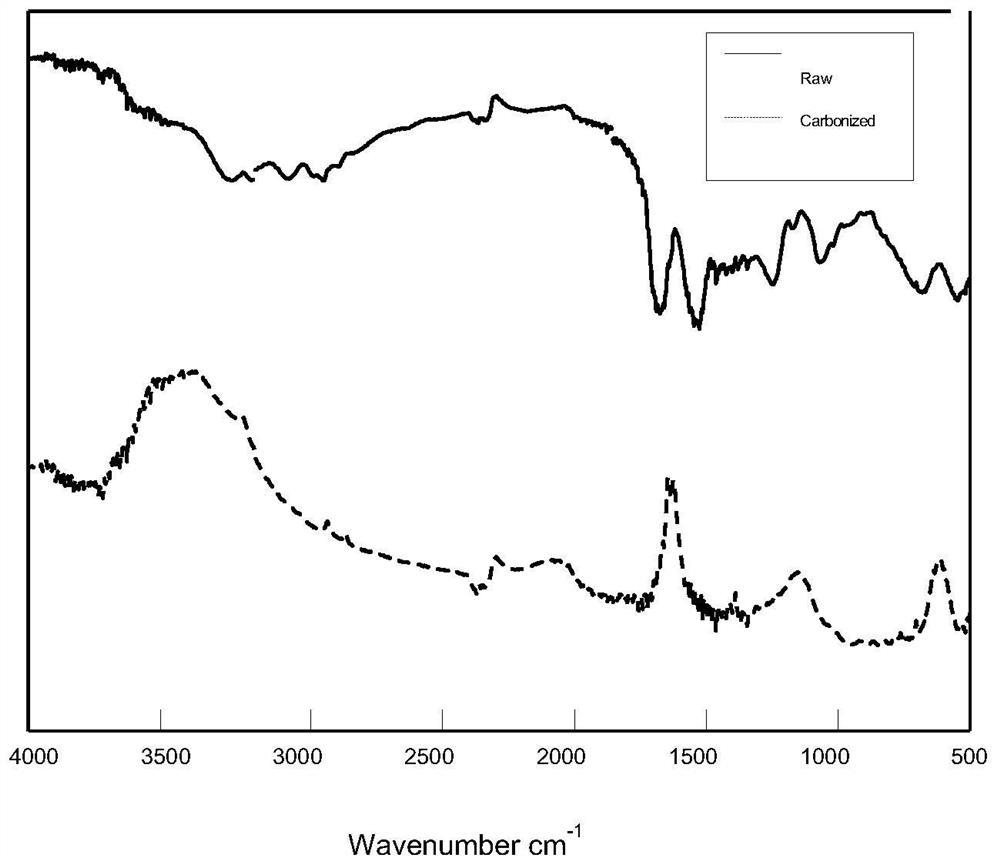

[0045] (1) Select white silkworm silk as the biomass material, which is often washed with warm ultrasonic water and dried in an incubator. The biomass material silkworm cocoon is preferably Lepidoptera (Lepidoptera) Bombycidae (Bombycidae), and there is a certain amount of metal potassium, Calcium, magnesium, iron, manganese, zinc, nickel, among which the biomass material silkworm cocoon contains a large amount of crystallized and non-crystallized proteins (the sum accounts for 96% of the total mass), and the presence of metals is beneficial to the activation of materials during pyrolysis , azacarbons can be formed after protein pyrolysis;

[0046] (2) The reaction boat is placed in the furnace, and then the furnace is purged with inert gas for 5 minutes at an inert gas flow rate of 500ml / min, and purged three times;...

Embodiment 2

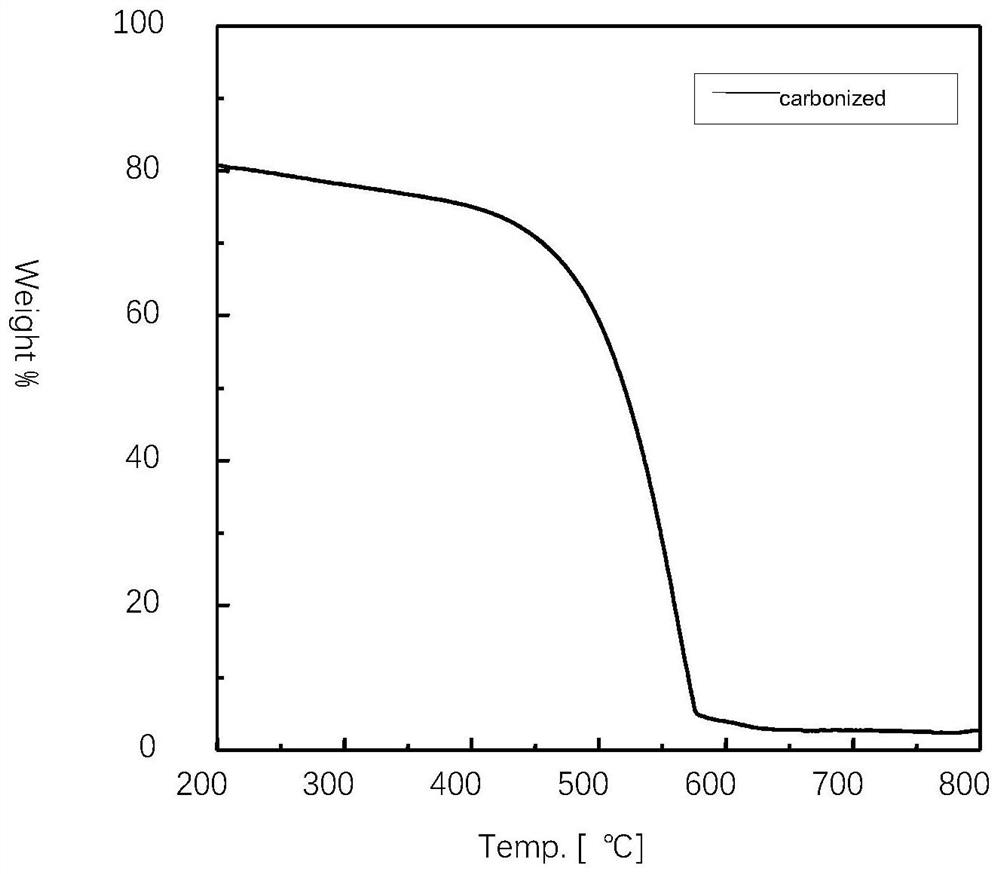

[0061] The method of this example is basically the same as that of Example 1, except that in step (3) the tube furnace is used to control the temperature at 1000°C, and azacarbon materials can also be successfully prepared, and according to the requirements of the following steps, A biomass-based carbon-nitrogen-phosphorus composite fiber material was obtained. The composite fiber material was a grooved layered azacarbon fiber, and the introduced silver seed was an isopropanol dispersion containing silver wires of uniform size with a length of 8 μm and a diameter of 70 nm. After the secondary growth, the silver wire has a diameter of 70nm and a length of millimeter order, and is wound to the carbon material base fiber.

Embodiment 3

[0063] The method of this embodiment is basically the same as that of Example 1, except that in step (3), the tube furnace is used to control the temperature at 650° C., and the reaction system is glycerol. The azacarbon material can also be successfully prepared, and according to the requirements of the following steps, a biomass-based carbon nitrogen phosphorus composite fiber material is obtained. The composite fiber material is a grooved layered azacarbon fiber. 8μm, 75nm diameter uniform size silver wire dispersion in isopropanol. After the secondary growth, the silver wire has a diameter of 75nm and a length of millimeter order, and is wound to the carbon material base fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com