Thin-layer hollow FT synthetic catalyst and use thereof

A catalyst, hollow technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbon production from carbon oxides, etc. Effects of large porosity, improved mass transfer, high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

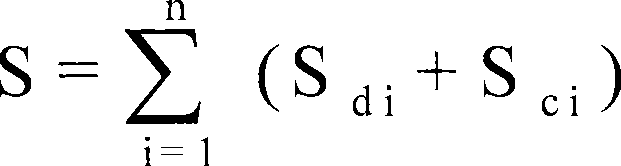

Method used

Image

Examples

preparation example Construction

[0016] When the catalyst also contains the auxiliary component, the preparation method of the catalyst further includes a step of introducing the auxiliary component into the catalyst. According to the usual method for preparing FT synthesis catalysts, the auxiliary component can be introduced during the preparation of the support, or can be introduced before, after or at the same time as the metal component is loaded. For example, the auxiliary component or the compound containing the auxiliary component is directly mixed with the carrier to be formed and / or the precursor during extrusion molding, and then the method of extrusion molding is introduced. Or it is introduced by the method of impregnating with the solution containing the auxiliary component compound before, after or simultaneously loading the metal component.

[0017] According to the catalyst provided by the present invention, it is necessary to reduce and activate the oxidized cobalt in the presence of hydrogen...

Embodiment 1~4

[0022] This example illustrates that the present invention provides a catalyst, its preparation method and performance.

[0023] Preparation of alumina carrier with hollow structure: Pseudo-boehmite is used as carrier precursor to prepare hollow carriers with different appearances by extrusion molding. The orifice plates are circular, three-lobed, and butterfly-shaped orifice plates with a circumscribed circular aperture of 2.1 mm, and the orifice pins are all circular pins with a diameter of 1 mm. The extruded product was dried at 120°C for 3 hours, and then calcined at 600°C for 3 hours with a heating rate of 3°C / min. The calcined carrier was cut into particles with a length of about 3 mm.

[0024] The following method is used to measure the pressure drop of different carrier packed beds: using air as the medium, the carrier particles are packed in a quartz tube with an inner diameter of 25 mm and a height of 250 mm to form a catalyst carrier bed. At both ends of the quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com