Preparation method of nickel-based methane carbon dioxide reforming catalyst

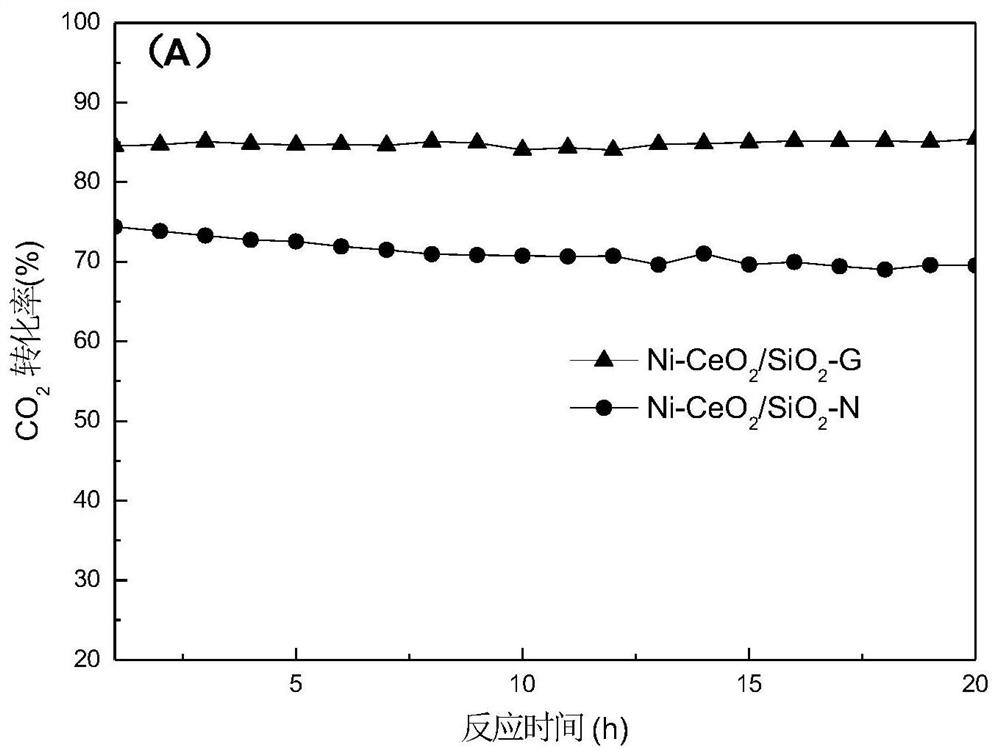

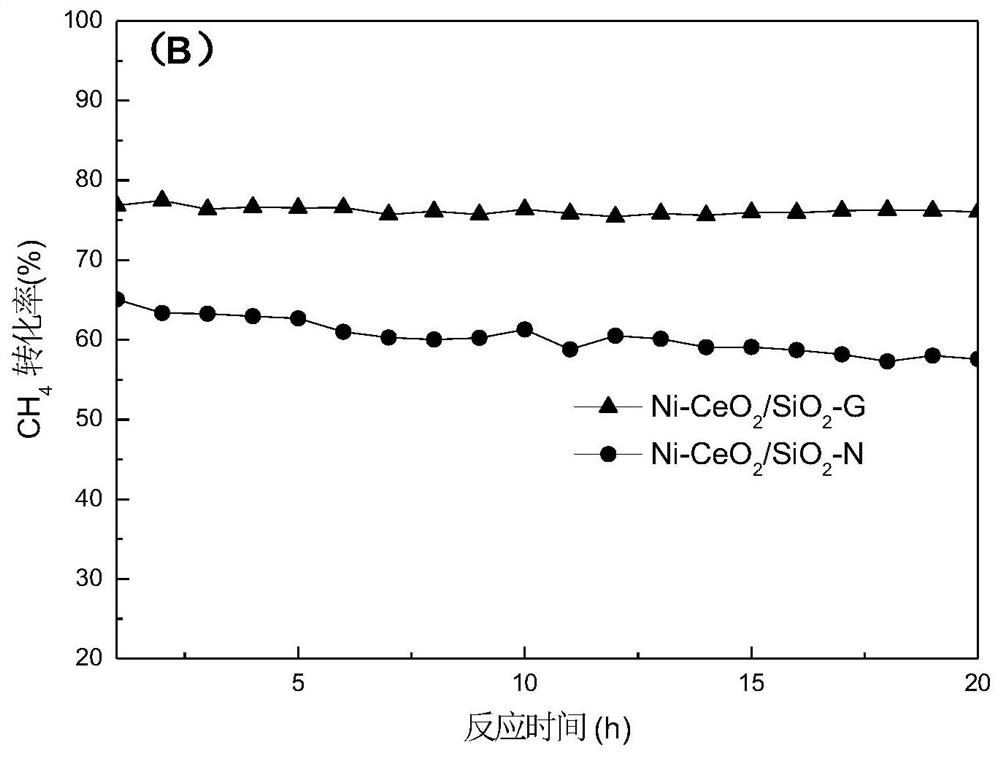

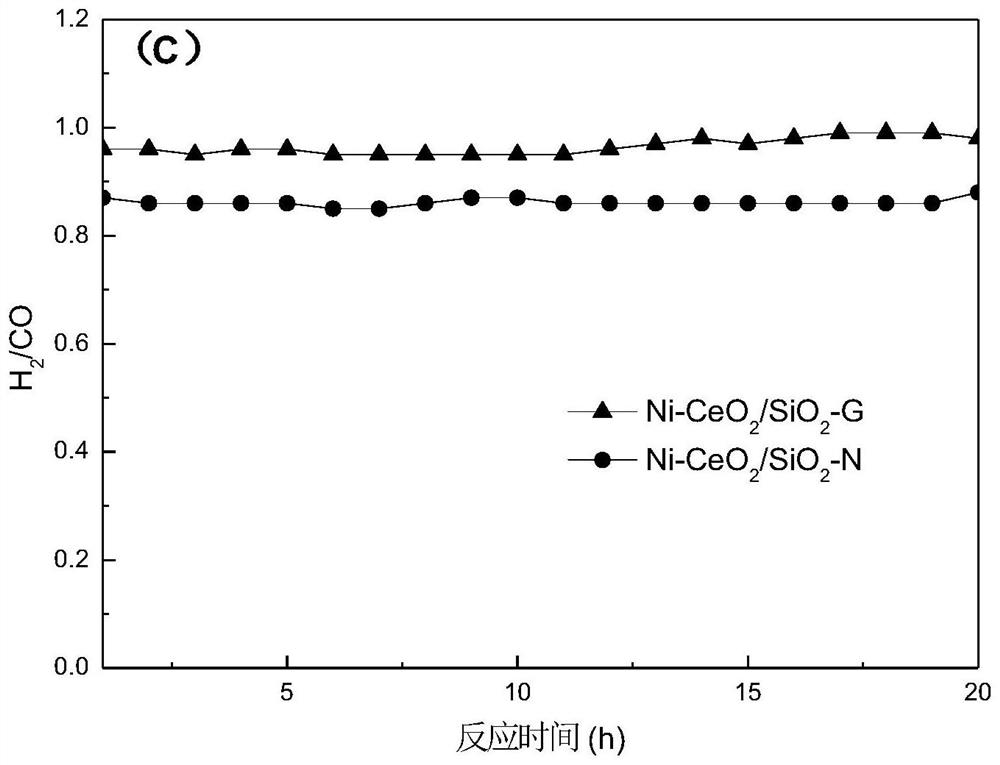

A reforming catalyst, carbon dioxide technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of catalyst sintering deactivation, low conversion rate of methane and carbon dioxide and other problems, to achieve high conversion rate, improve catalyst activity, and avoid sintering deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 2.36g Ce(NO 3 ) 3 ·6H 2 O, 0.32g Ni(NO 3 ) 2 ·6H 2 O and 0.6g glycine are mixed, and add 6.3mL deionized water, obtain nitrate solution after stirring;

[0031] (2) Add 1.26mL silica sol in the nitrate solution;

[0032] (3) Heat the mother liquor on a 230°C electric heating plate and evaporate to dryness until the sample undergoes a combustion reaction;

[0033] (4) Put the product obtained after combustion into a muffle furnace for calcination at 600° C. for 4 hours to obtain the nickel-based methane carbon dioxide reforming catalyst.

Embodiment 2

[0035] (1) 2.36g Ce(NO 3 ) 3 ·6H 2 O, 0.12g Ni(NO 3 ) 2 ·6H 2 O and 0.6g glycine are mixed, and add 10mL deionized water, obtain nitrate solution after stirring;

[0036] (2) Add 1 mL of silica sol to the nitrate solution, and stir to obtain the mother liquor;

[0037] (3) Heat the mother liquor on a 220°C electric heating plate and evaporate to dryness until the sample undergoes a combustion reaction;

[0038] (4) Put the product obtained after combustion into a muffle furnace for calcination at 550° C. for 5 hours to obtain the nickel-based methane carbon dioxide reforming catalyst.

Embodiment 3

[0040] (1) 2.45g Ce(NO 3 ) 3 ·6H 2 O, 0.40g Ni(NO 3 ) 2 ·6H 2 O and 0.7g glycine are mixed, and add 8mL deionized water, obtain nitrate solution after stirring;

[0041] (2) Add 2.0mL silica sol to the nitrate solution, and stir to obtain the mother liquor;

[0042](3) Heat the mother liquor on a 240°C electric heating plate and evaporate to dryness until the sample undergoes a combustion reaction;

[0043] (4) Put the product obtained after combustion into a muffle furnace for calcination at 650° C. for 3 hours to obtain the nickel-based methane carbon dioxide reforming catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com