Preparation method of organic vulcanizing agent for hydrogenation catalyst pre-vulcanizing

A technology of hydrogenation catalyst and vulcanizing agent, which is applied in the field of oil refining aids and sulfides with acyclic unsaturated carbon framework, can solve the problems of low conversion rate of raw materials, corrosiveness, low product yield, etc., and achieve high catalyst activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

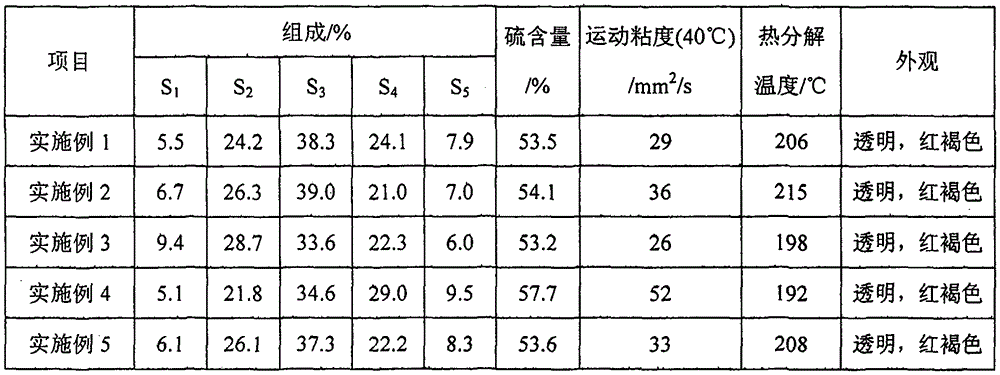

Examples

Embodiment 1

[0014] Add 1200g of sulfur and 5g of catalyst into the autoclave, heat up to 160°C, stir at constant temperature for 1 hour, then pump 1,000g of isobutene into the autoclave with a metering pump, and the pressure of the autoclave rises rapidly after the isobutene is introduced, and the temperature rises to 160°C When it reaches above 3MPa, control the feed rate of isobutylene to ensure that the reaction pressure is between 3-6MPa, stir and react at 160-170°C for 2 hours, then lower the temperature, release the pressure, and filter to obtain 2200g of the additive product.

Embodiment 2

[0016] Add 1200g of sulfur and 5g of catalyst into the autoclave, heat up to 160°C, stir at constant temperature for 1 hour, then, as in Example 1, inject 1000g of 1-butene into the autoclave with a metering pump, and control the reaction pressure to 3 ~6MPa, 160~170°C stirring and reacting for 2 hours, then cooling down, depressurizing and filtering to obtain 2200g of the additive product.

Embodiment 3

[0018] Add 1200g of sulfur and 5g of catalyst into the autoclave, heat up to 160°C, stir at constant temperature for 1 hour, then, as in Example 1, inject 1000g of 2-butene into the autoclave with a metering pump, and control the reaction pressure to 3 ~6MPa, 160~170°C stirring and reacting for 2 hours, then cooling down, depressurizing and filtering to obtain 2200g of the additive product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com