Patents

Literature

33results about How to "Improve conversion and selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

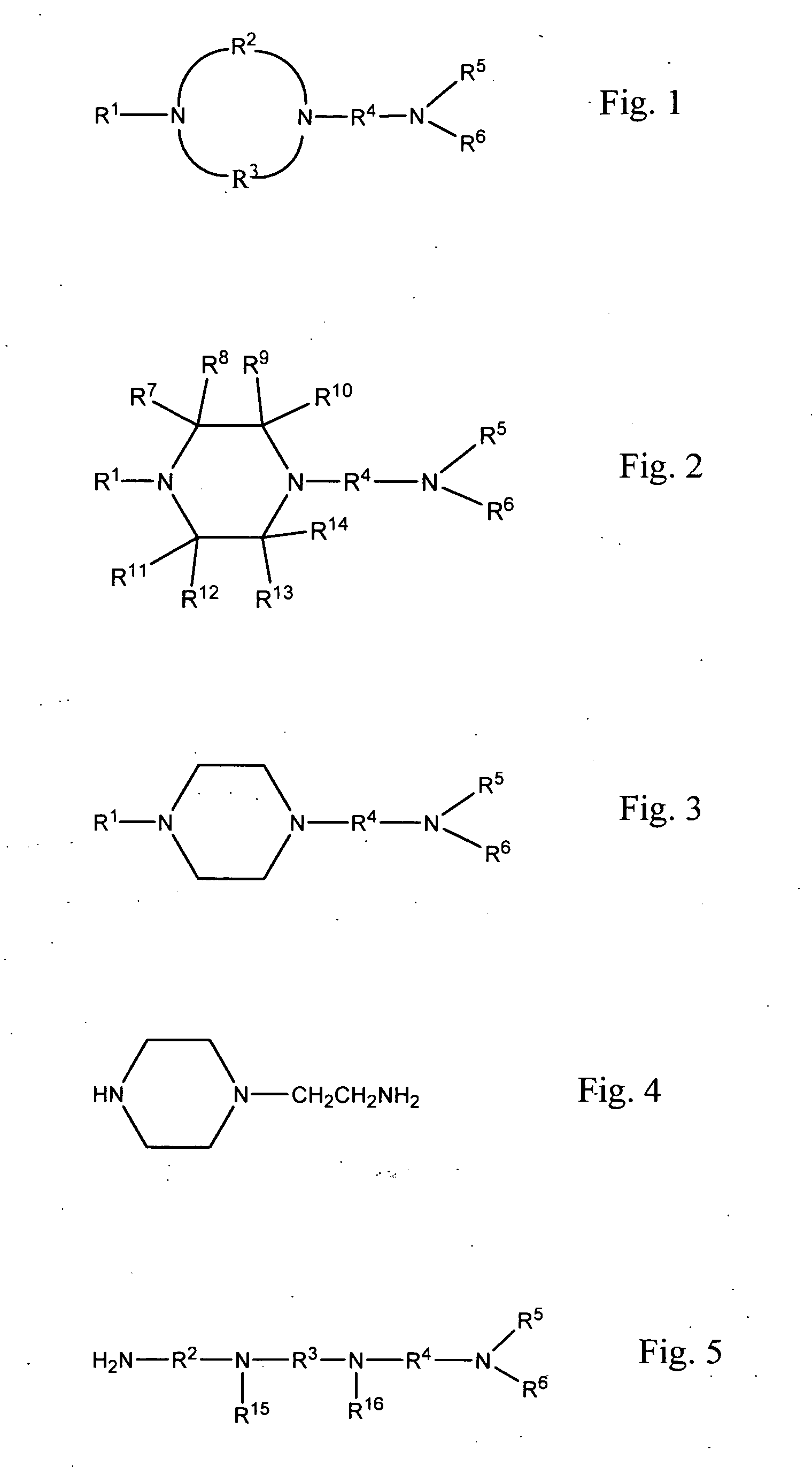

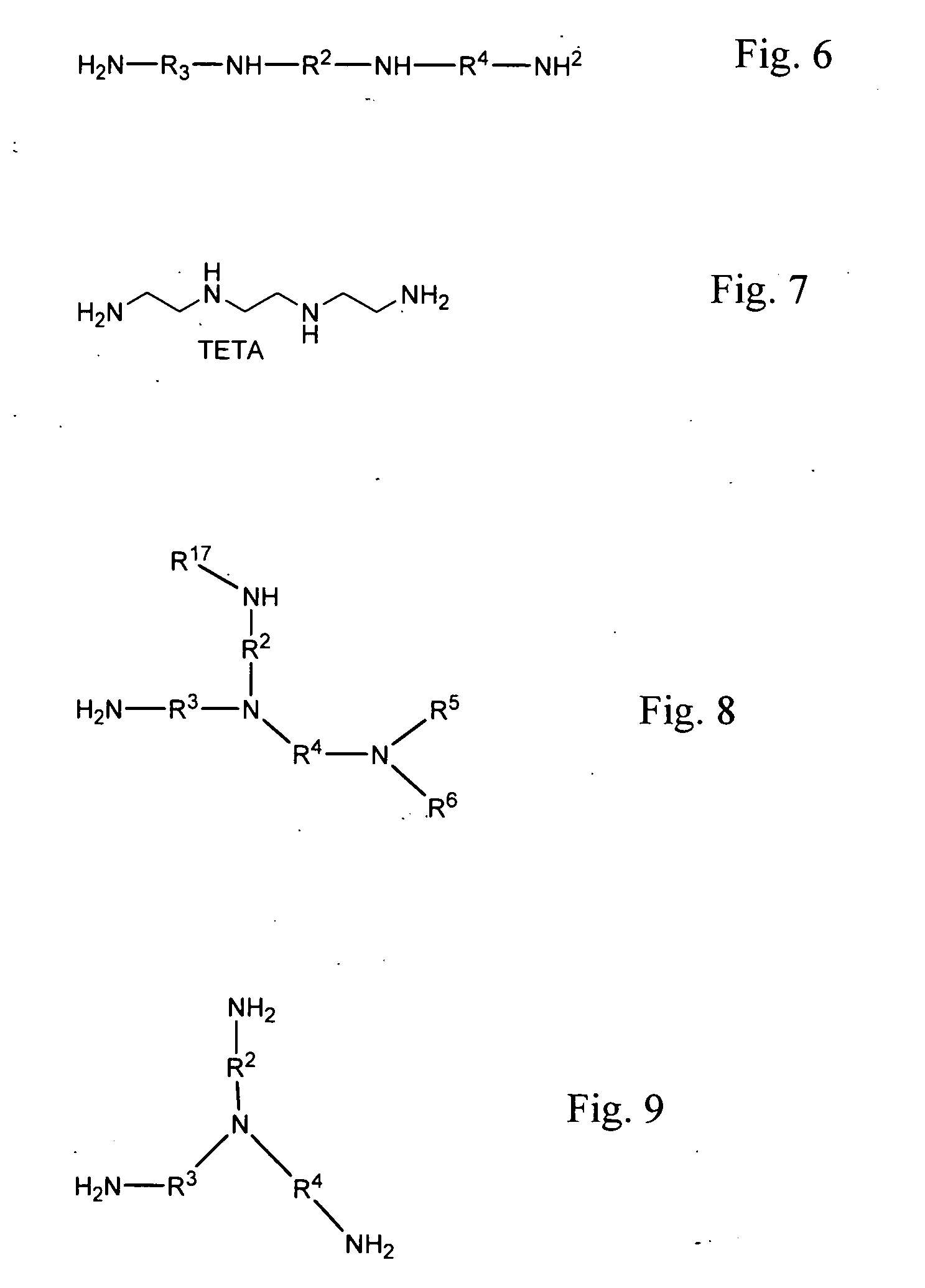

Methods of making cyclic, N-amino functional triamines

ActiveUS20100094007A1Improve conversion and selectivityNotable conversionOrganic active ingredientsOrganic chemistryBy-productReductive amination

The present invention provides strategies for making cyclic triamines. Reactant media including certain precursors and / or certain types of catalysts can be converted into cyclic triamines with improved conversion and selectivity. The strategies can be incorporated into reactions that involve transamination schemes and / or reductive amination schemes. In the case of transamination, for instance, using transamination to cause ring closure of higher amines in the presence of a suitable catalyst leads to desired cyclic triamines with notable conversion and yield. In the case of reductive amination, reacting suitable polyfunctional precursors in the presence of a suitable catalyst also yields cyclic triamines via ring closure with notable selectivity and conversion. Both transamination and reductive amination methodologies can be practiced under much milder temperatures than are used when solely acid catalysts are used. Preferred embodiments can produce reaction mixtures that are generally free of salt by-products.

Owner:UNION CARBIDE CORP

Catalysts Prepared from Nanostructures of MnO2 and WO3 for Oxidative Coupling of Methane

InactiveUS20180311658A1Improve conversion and selectivityReduce productionHeterogenous catalyst chemical elementsLiquid hydrocarbon mixtures productionManganese oxideOxidative coupling of methane

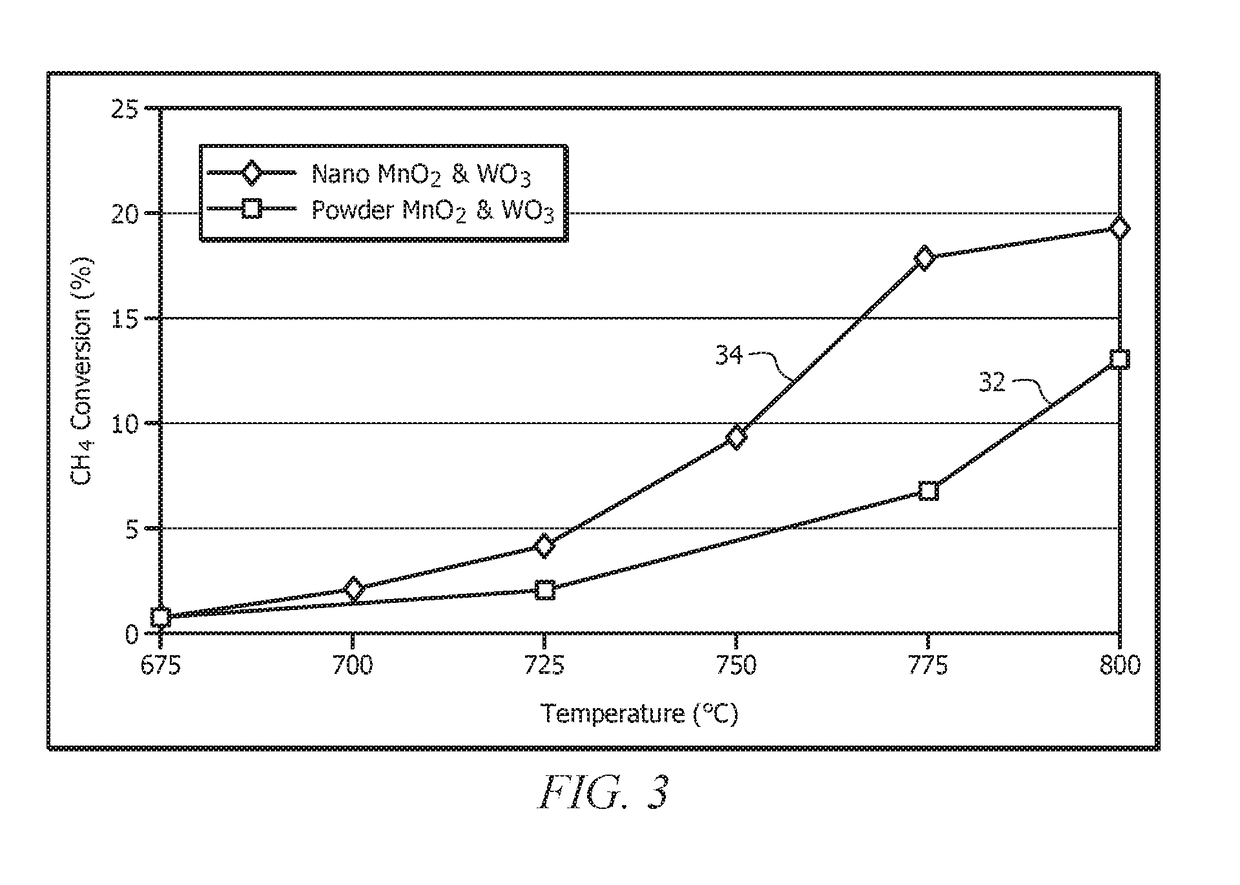

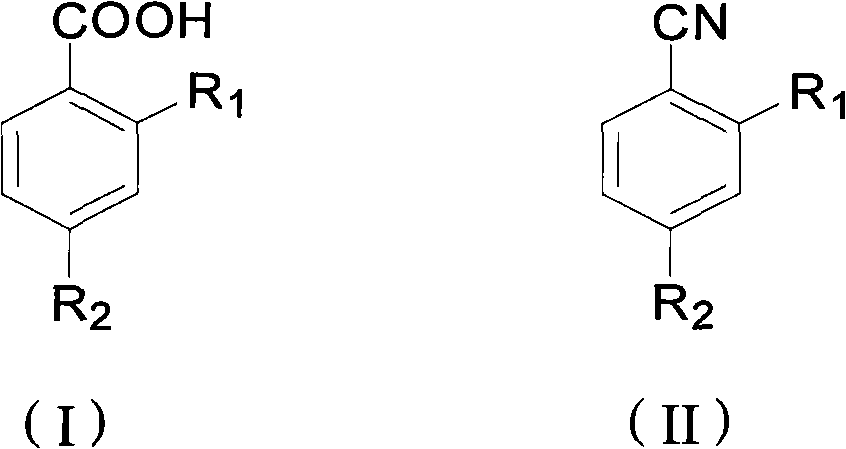

Disclosed is a process to prepare a [MnNaW]On / SiO2 catalyst using manganese oxide (MnO2) and tungsten oxide (WO3) nanostructures. Also disclosed are methods and systems using the aforementioned catalyst having higher methane conversion and C2 to C4 selectivity compared to similar catalysts not prepared with MnO2 and WO3 nanostructures.

Owner:SABIC GLOBAL TECH BV

Preparation method of ortho/para-substituted phenylformic acid compound

ActiveCN101575308AImprove conversion and selectivityHigh product yieldOrganic compound preparationSulfide preparationTemperature controlPhotochemistry

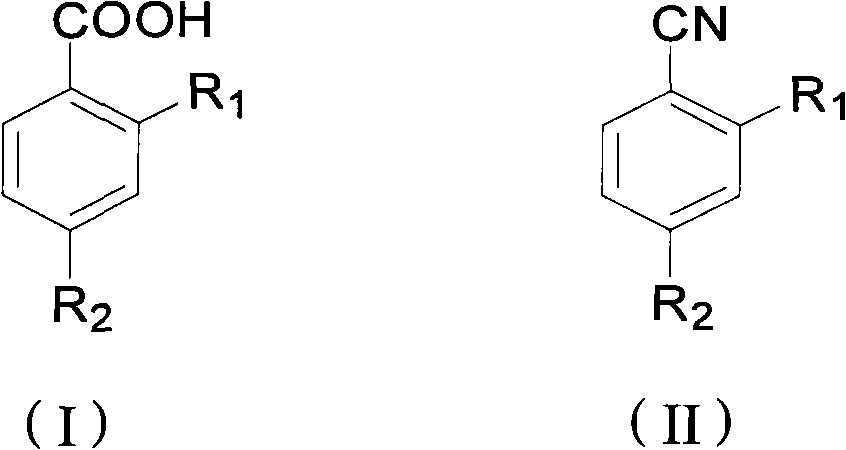

The invention relates to a preparation method of an ortho / para-substituted phenylformic acid compound with a general formula (I), wherein R1 and R2 are respectively or simultaneously C1-C3 sulfenyl, nitryl, CF3, C2F5 or C3F7 and other groups. The compound is obtained by conducting hydrolysis on a compound with a corresponding general formula (II) in an alkaline condition at the temperature controlled within a range of 80-180 DEG C for 1-6 h. The preparation method has the advantages of simple process, short reaction time, high reaction conversion rate and selectivity, high product purity and the like, and is suitable for large-scale industrial production.

Owner:NUTRICHEM LAB CO LTD

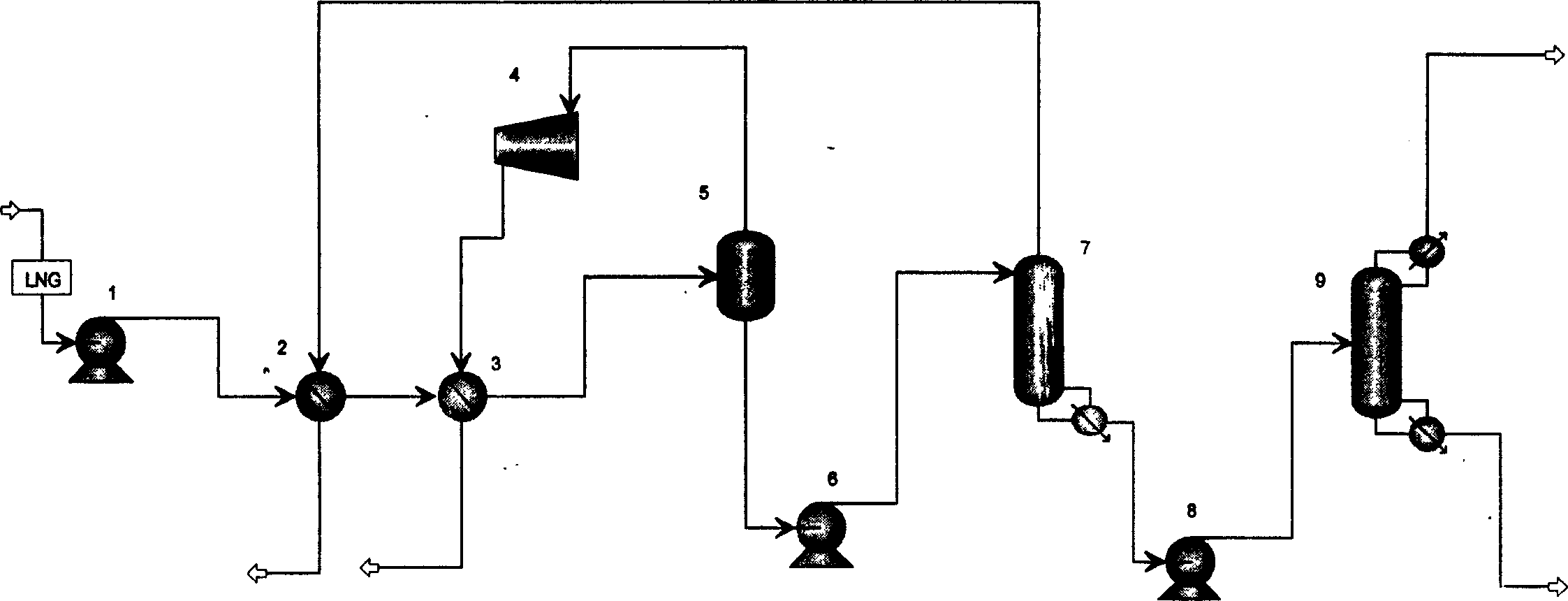

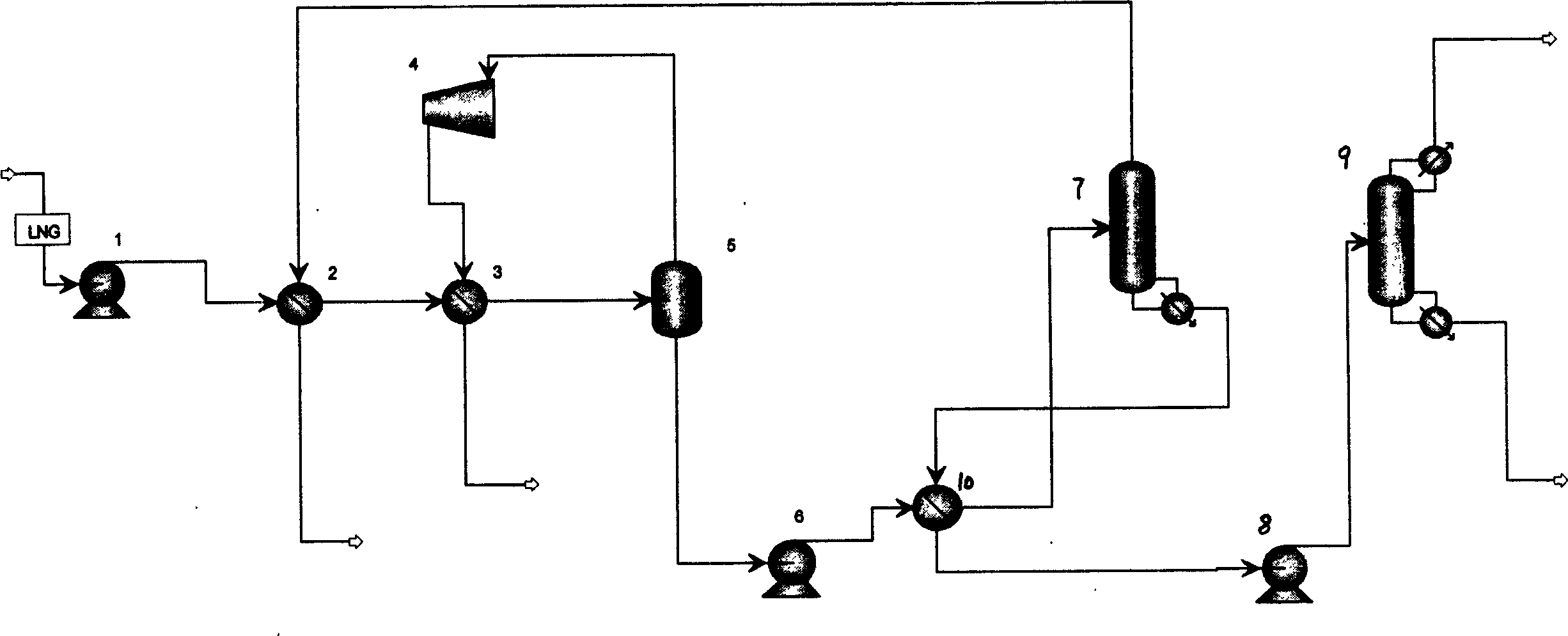

Method for separating light hydrocarbon from liquified natural gas

InactiveCN1737087AImprove conversion and selectivityReduce power consumptionLiquid hydrocarbon mixture recoveryChemistryLiquefied natural gas

The invention relates a process for the light ends separation of liquefied natural gas, comprising the following steps: preliminary heating the raw material of liquefied natural gas, separating methane and condensing it, demethanizing and making it liquefy, deethanizing and transferring the gas phase ethane to the ethylene cracking unit through pipe line, and finally getting the liquid phase discharging including weight constituent of dimethylmethane and butane. The invention utilizes part refrigerating of LNG, because it is conserved in low-temperature liquid methane after ethane and propane is reclaimed from LNG; only 60% methane gas is needed to be compressed, so the power consumption of compresser is reduced; it is convenient to store liquid methane because its pressure is low. The ethane from said invention is high output, separation flow process is simple, and equipment investment is only a little, running period is long, and operating cost is cheap.

Owner:SOUTH CHINA UNIV OF TECH

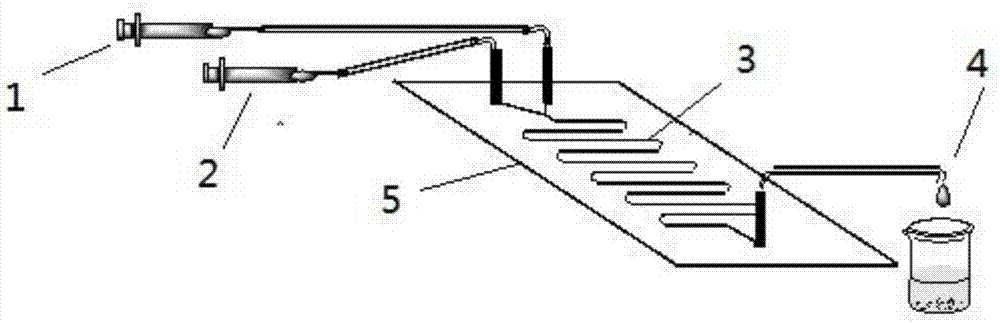

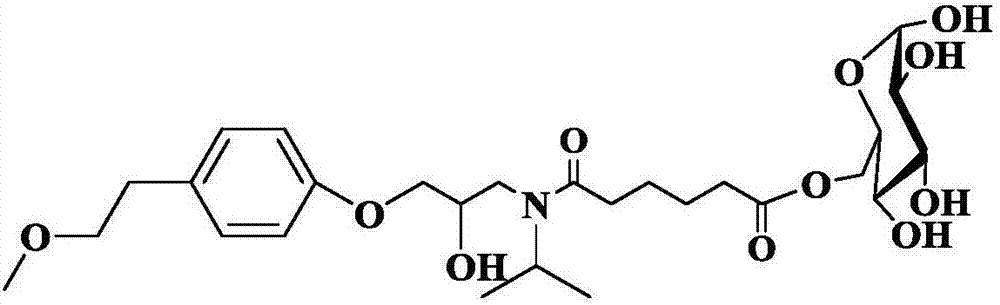

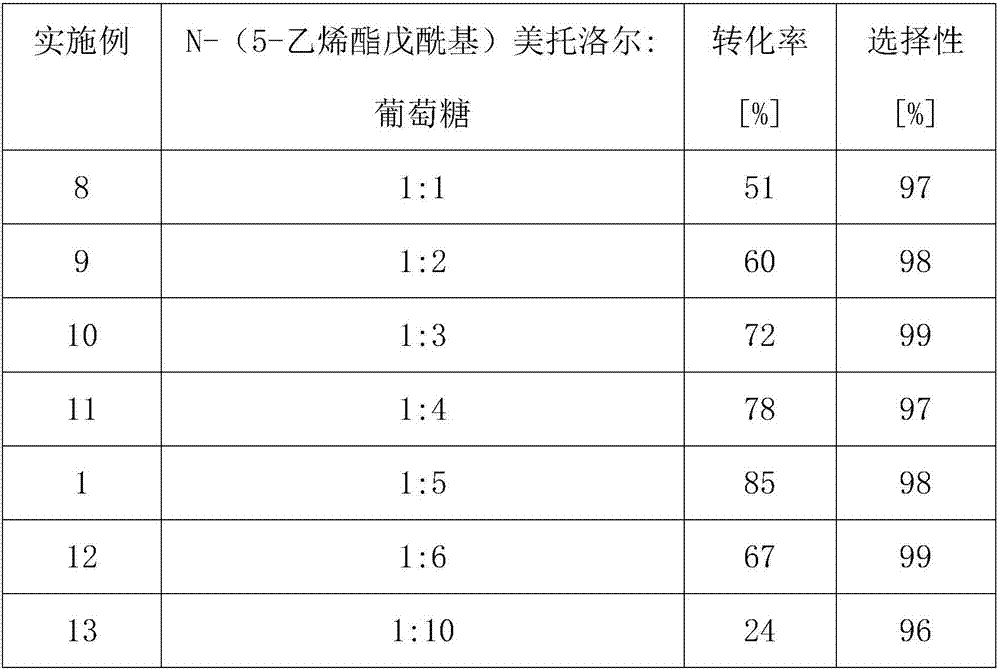

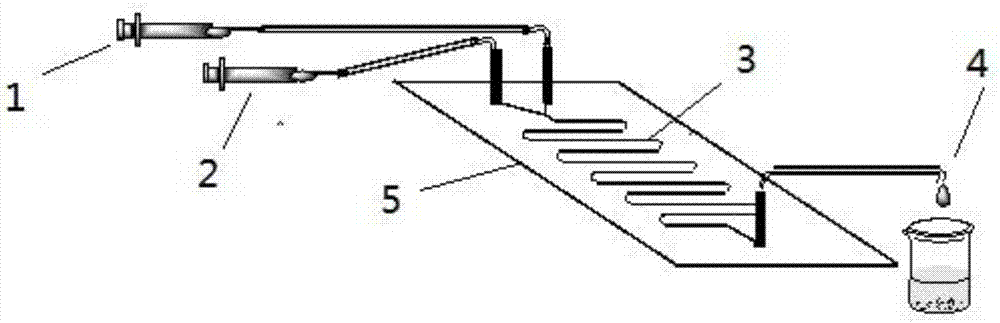

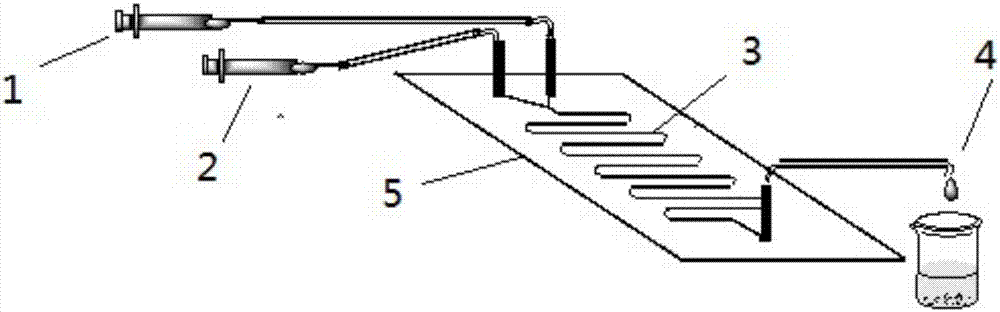

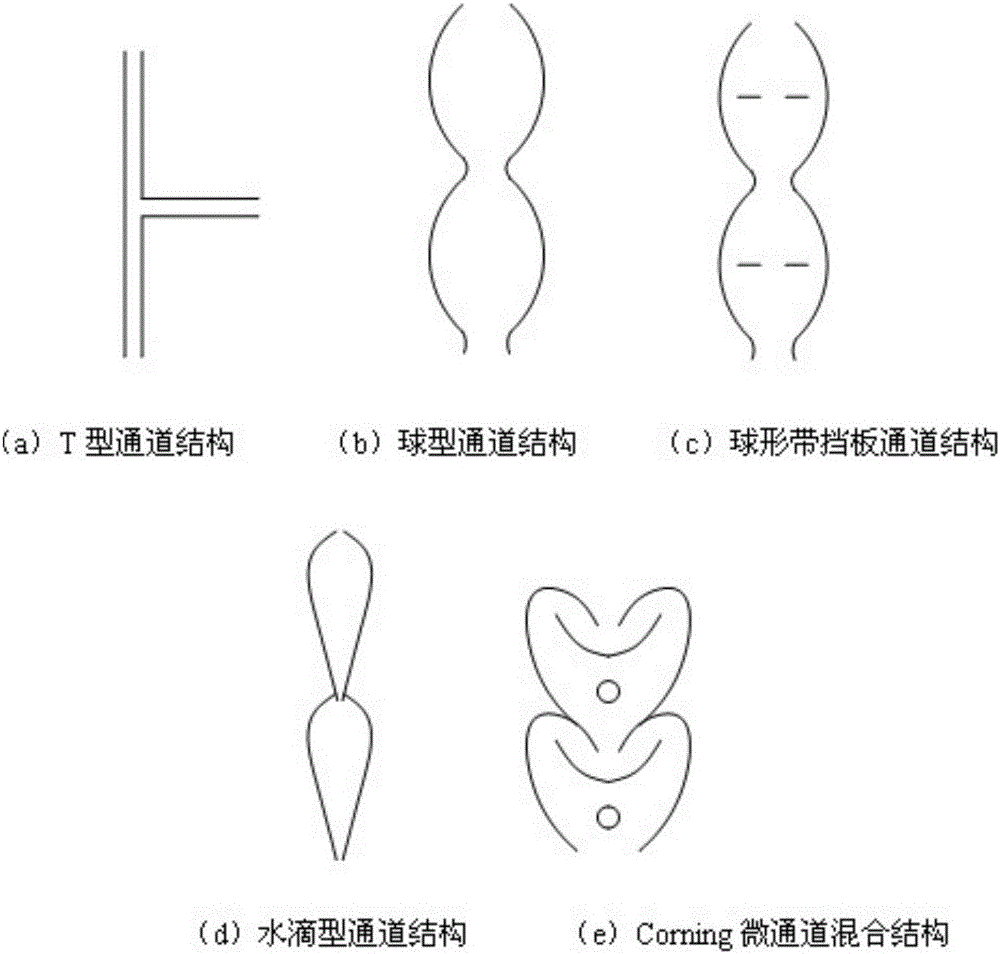

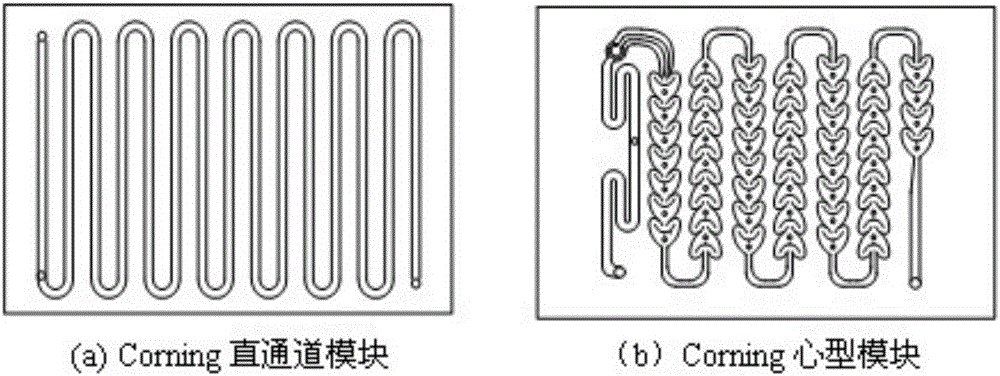

Method for synthesizing N-(5-glucose ester valeryl)metoprolol online by lipozyme catalysis

InactiveCN107475330AShort reaction timeImprove conversion and selectivityFermentationSubstance amountMicro fluidic

The invention discloses a method for synthesizing N-(5-glucose ester valeryl)metoprolol online by lipozyme catalysis. The method takes N-(5-vinyl ester valeryl)metoprolol and glucose as raw materials according to the amount of substance ratio of 1 to (1 to 10), dimethyl sulfoxide and tert-amyl alcohol as reaction solvents and lipozyme TL IM as a catalyst, and comprises the following steps: putting the raw materials and the reaction solvents into an injector; uniformly filling the lipozyme TL IM into a reaction channel of a micro-fluidic channel reactor; continuously introducing the raw materials and the reaction solvents into a reaction channel device under the pushing of the injector and carrying out ester exchange reaction, wherein the inner diameter of the reaction channel of the micro-fluidic channel reactor is 0.8mm to 2.4mm and the length of the reaction channel is 0.5m to 1.0m; controlling the esterification reaction temperature to 20 DEG C to 60 DEG C and the esterification reaction time to 20min to 40min; collecting a reaction solution online through a product collector and carrying out conventional post-treatment on the reaction solution to obtain the N-(5-glucose ester valeryl)metoprolol. The method disclosed by the invention has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

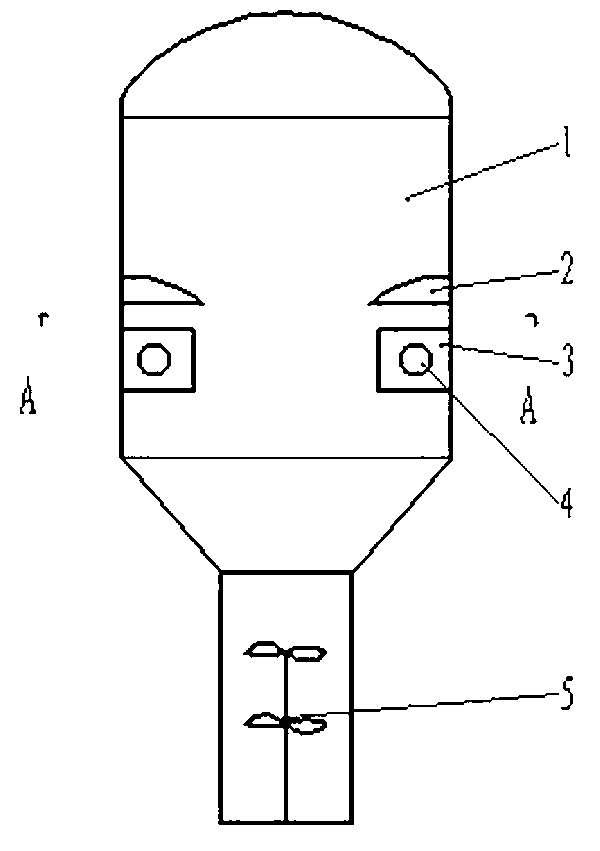

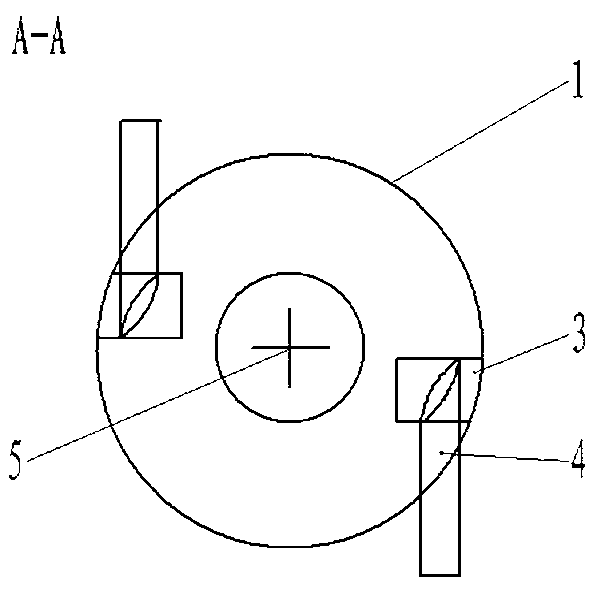

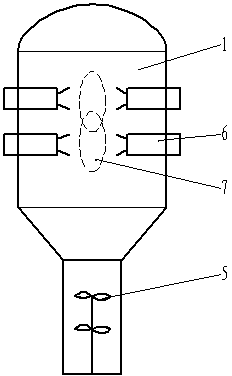

Nozzle impinging stream rearrangement reactor

ActiveCN103007870AImprove conversion and selectivityReduce the formation of side reaction productsLactams preparationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringKinetic energy

The present invention relates to a nozzle impinging stream rearrangement reactor, which mainly comprises a reaction kettle, wherein a stirring device and nozzles are arranged inside the reaction kettle, the nozzles are arranged horizontally and symmetrically, and are installed in a tangent line material feeding manner, the outlet position of the nozzle is provided with an immersion impinging chamber with an upward opening, a defogging cover is arranged above the immersion impinging chamber, and 1-5 layers of material feeding assemblies are arranged inside the reaction kettle, wherein each layer comprises 1-5 pairs of the material feeding assemblies, and every layer of the material feeding assemblies are axially arranged in a parallel manner. According to the present invention, turbulent flow kinetic energy in a multiphase fluid is adopted to strengthen micro mixing between fluid masses, increase conversion rate and selectivity of a caprolactam rearrangement reaction, and reduce reaction byproduct eight formation. The nozzle impinging stream rearrangement reactor is used for rearrangement processes of caprolactam production and chemical engineering production processes of multiphase liquid rapid reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

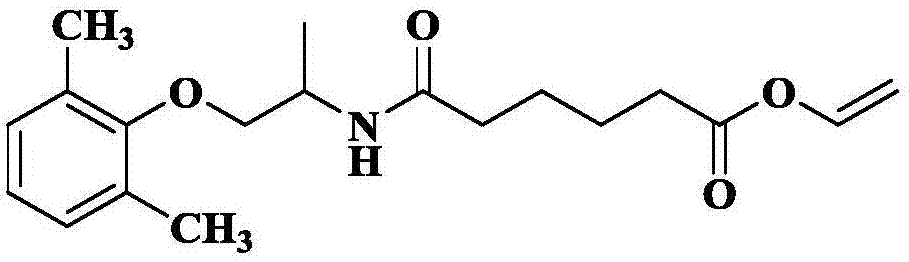

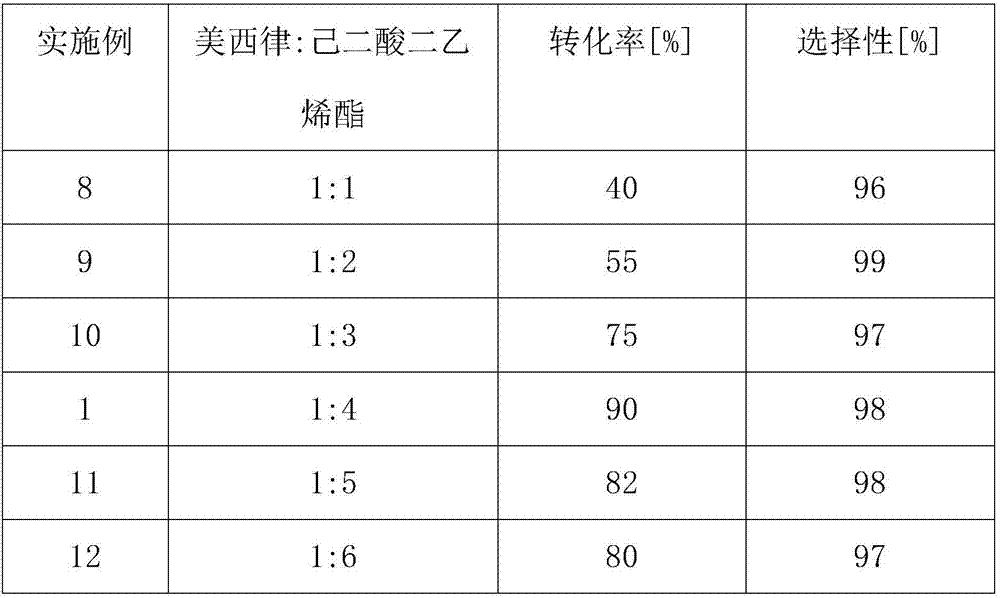

Method for lipase-catalyzed online synthesis of N-(5-vinyl ester valeryl)mexiletine

InactiveCN107488683AShort reaction timeImprove conversion and selectivityBioreactor/fermenter combinationsBiological substance pretreatmentsMicro fluidicSyringe

The invention discloses a method for lipase-catalyzed online synthesis of N-(5-vinyl ester valeryl)mexiletine. The method, adopting mexiletine and divinyl adipate with a molar ratio of 1:(1-6) as raw materials, dimethyl sulphoxide and tertiary amyl alcohol with a volume ratio of 1:(1-10) as a reaction solvent and lipase Lipozyme TL IM as a catalyst, comprises the following steps: placing the raw materials and the reaction solvent in a syringe, uniformly filling the reaction channel of a micro-fluidic channel reactor with the lipase Lipozyme TL IM, and continuously introducing the raw materials and the reaction solvent into the reaction channel reactor under the push of a syringe pump, wherein the internal diameter of the reaction channel of the micro-fluidic channel reactor is 0.8-2.4 mm, and the length of the reaction channel is 0.5-1.0 m; and carrying out an acylation reaction at a temperature of 30-70 DEG C for 20-40 min, online collecting the obtained reaction solution through a product collector, and routinely post-processing the reaction to obtain the N-(5-vinyl ester valeryl)mexiletine. The method has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

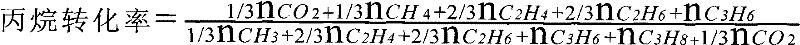

Method for preparing olefin by dehydrogenating low-carbon alkane

InactiveCN102531817AImprove conversion and selectivityImprove conversion rateHydrocarbonsHydrocarbon preparationAlkane synthesisAlkene

The invention discloses a method for preparing olefin by dehydrogenating low-carbon hydrocarbons. A hydrogen product is consumed by using reaction of hydrogen and carbon monoxide to break through the balance of the reaction, and the reaction tends to the dehydrogenation direction, so that the balance conversion rate of the low-carbon hydrocarbons and the selectivity of the corresponding olefin are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

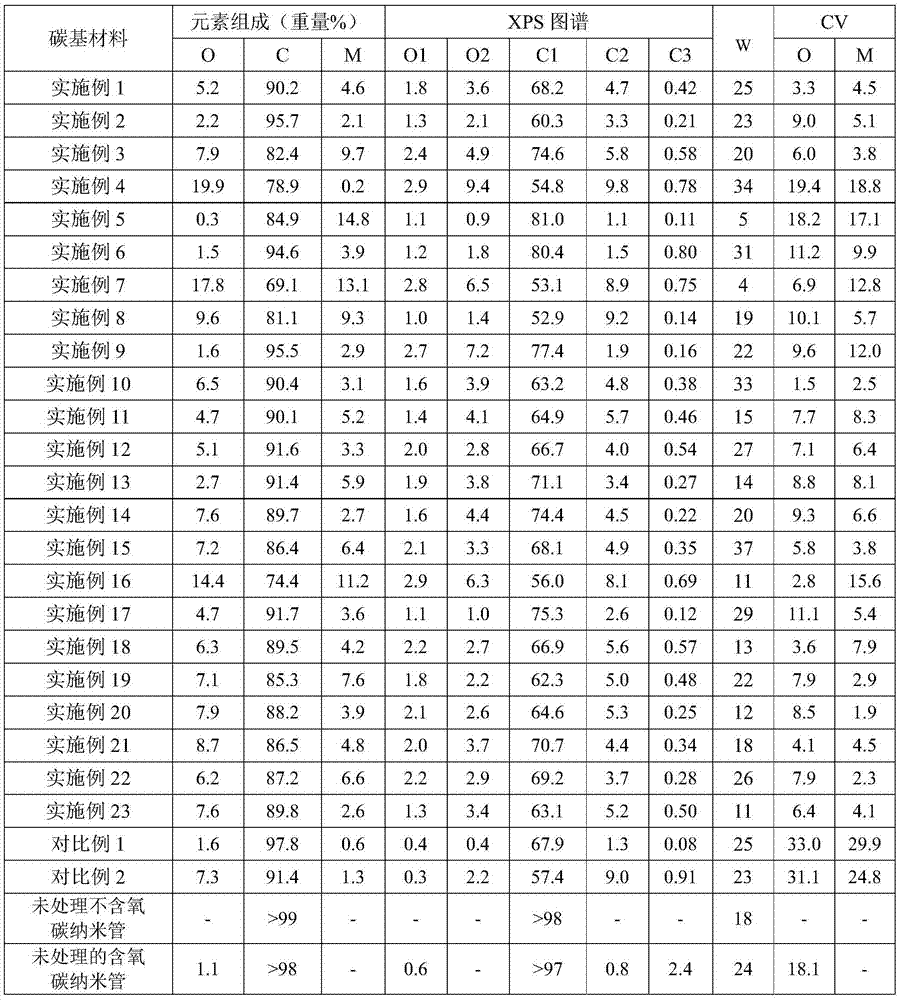

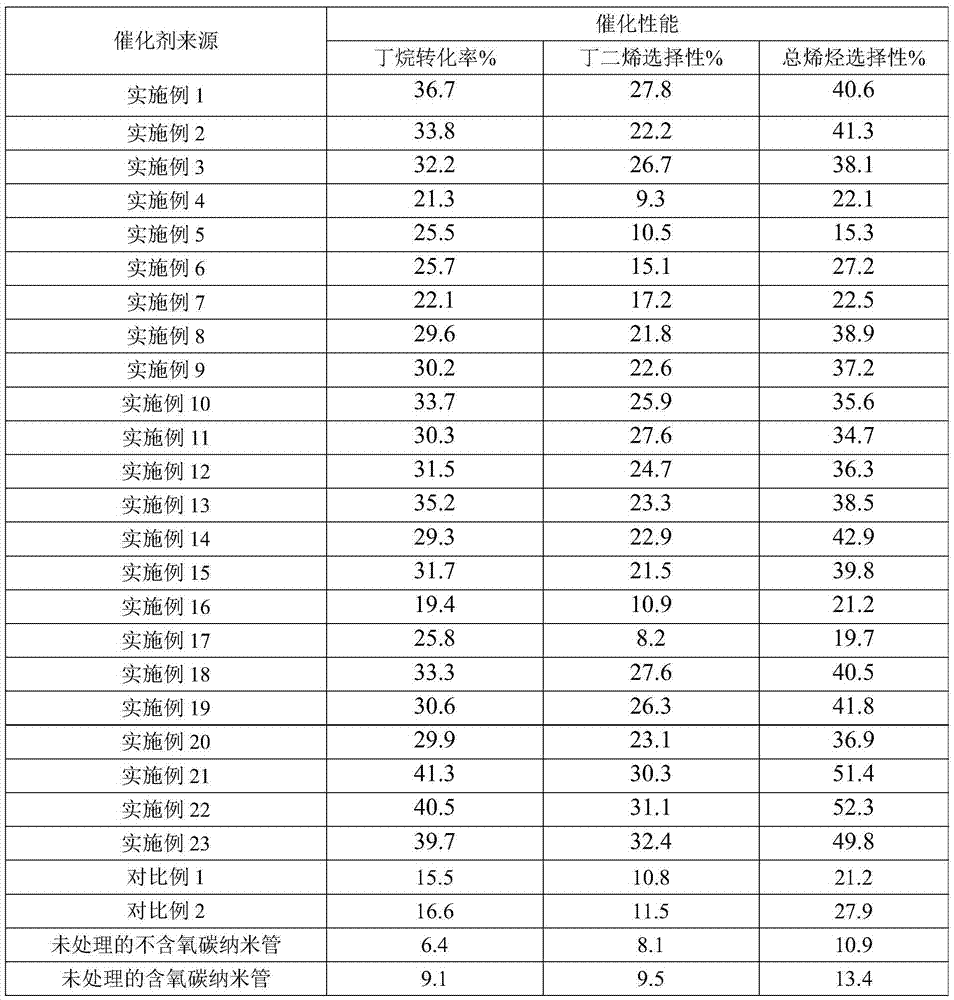

Carbon-metal composite material and synthesis method thereof

ActiveCN106925270AImprove conversion and selectivityHigh selectivityCatalystsHydrocarbon preparation catalystsHydrocarbonSolid carbon

The invention discloses a carbon-metal composite material and a synthesis method thereof. By the total weight of a carbon-based material, the carbon-based material comprises 70-99% by weight of a carbon element, 0.2-20% by weight of an oxygen element and 0.1-15% by weight of a metal element. The invention further provides a method for preparing the carbon-metal composite material. The method comprises the following steps: (1) mixing a solid carbon source, a precursor and water so as to obtain mixed materials, wherein the precursor comprises metal sources; (2) performing hydrothermal treatment on the mixed materials obtained in the step (1) so as to obtain a material after hydrothermal treatment, and performing solid separation and drying on the material after hydrothermal treatment so as to obtain a dried material; (3) roasting the dried material obtained in the step (2). The invention further provides application of the carbon-metal composite material to catalyzing hydrocarbonoxidizing. By adopting the carbon-metal composite material, the selectivity and the conversion rate of hydrocarbonoxidizing in preparation of olefin can be simultaneously increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

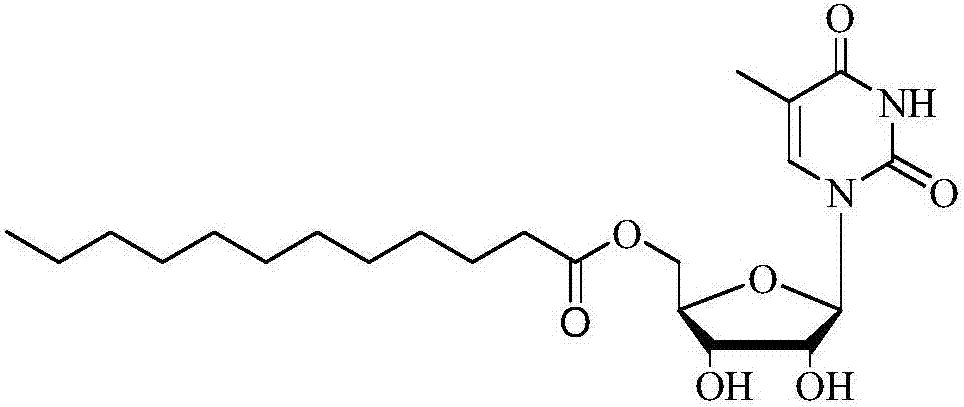

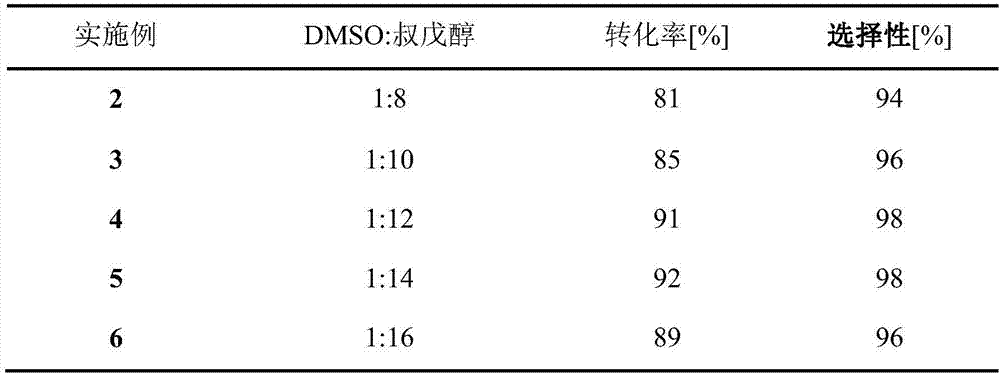

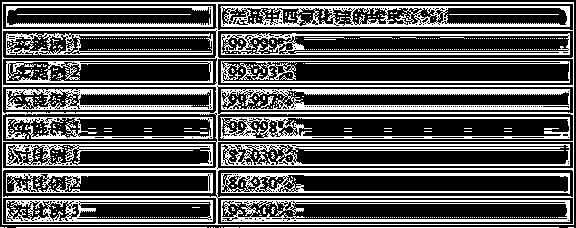

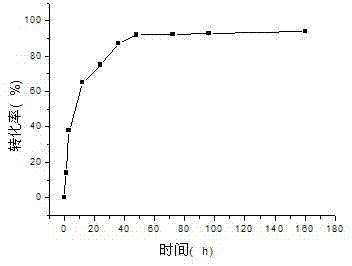

Method for synthesizing 5'-O-lauroyl-5-methyluridine on line through catalyzing of lipase

InactiveCN107384992AShort reaction timeImprove conversion and selectivityEnzyme production/based bioreactorsFermentationSolventInjector

The invention discloses a method for synthesizing 5'-O-lauroyl-5-methyluridine on line through catalyzing of lipase. The method comprises the steps that dimethylsulfoxide and tert-amyl alcohol are used as reactive solvents, wherein the volume ratio of the dimethylsulfoxide to the tert-amyl alcohol is 1:(8-16); 5-methyluridine and vinyl laurate are used as raw materials, wherein the mole ratio of the 5-methyluridine to the vinyl laurate is 1:(5-13); 0.5-1.0 g of the lipase Lipozyme TLIM is used as a catalyst; the raw materials and the reactive solvents are put into an injector, a reaction channel of a microfluidic channel reactor is uniformly filled with the lipase Lipozyme TLIM, and under pushing of an injection pump, the raw materials and the reaction solvents are continuously injected into the reaction channel to conduct an acylation reaction, wherein the inner diameter of the reaction channel of the microfluidic channel reactor is 0.8-2.4 mm, and the length of the reaction channel is 0.5-1.0 m; the temperature of the acylation reaction is controlled to be 15-50 DEG C, and the time of the acylation reaction is 20-35 min; and reaction liquid is collected on line through a product collector and conventionally post-processed, and thus the 5'-O-lauroyl-5-methyluridine is obtained. The method has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

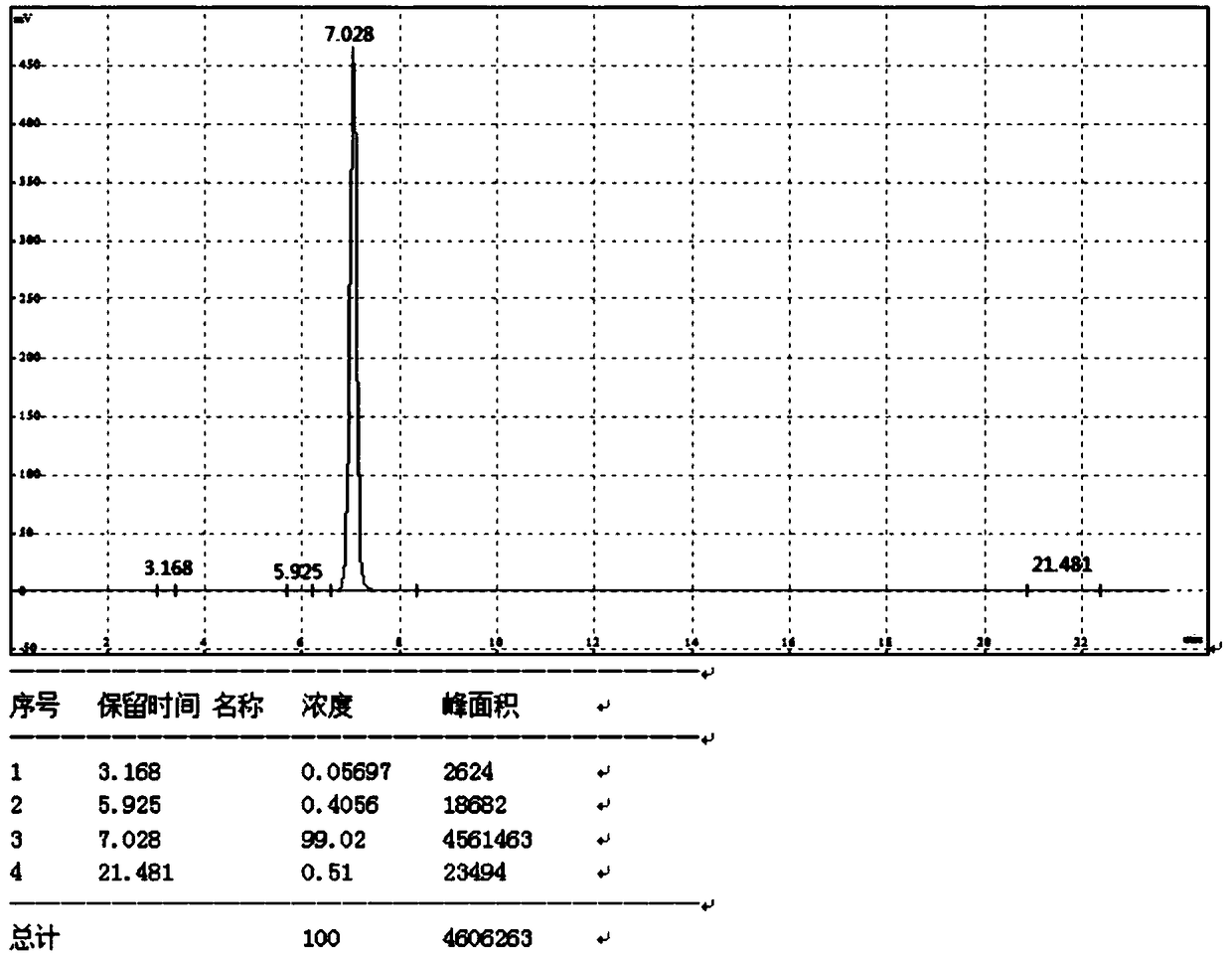

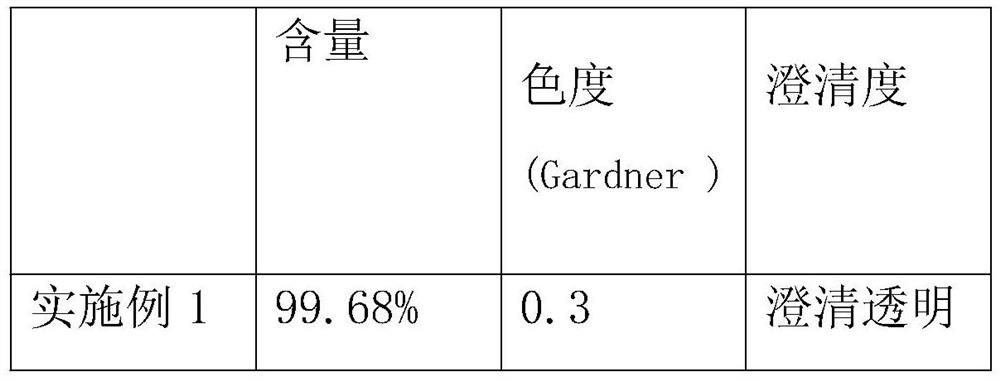

Synthesis and purification method of high-purity silicon tetrafluoride

ActiveCN110606490AImprove conversion and selectivityAdd complex distillation process systemChemical industryHalogenated silanesUnit operationChemistry

The invention provides a synthesis and purification method of high-purity silicon tetrafluoride. The method for synthesizing and purifying high-purity silicon tetrafluoride comprises the following steps: pretreatment fluosilicate; carrying out cracking reaction on fluosilicate to prepare a silicon tetrafluoride coarse material; trace moisture and acid gas are removed in the first adsorption section; carrying out removal and polymerization inhibition control on fluorosilicone ether in a second adsorption section; separating the light components from the heavy components in the rectification section; and separating azeotrope impurities through a complex rectification section. According to the synthesis and purification method of high-purity silicon tetrafluoride provided by the invention, heating cracking, adsorption unit operation, rectification and complex rectification are scientifically combined, fluorosilicone ether is removed by adopting an adsorption unit, and a complex rectification process is added after conventional rectification unit operation to remove azeotrope.

Owner:绿菱电子材料(天津)有限公司 +1

Method for preparation of methyl alkyl carbonate

InactiveCN103044260AEnvironmentally friendlyImprove conversion and selectivityPreparation from organic carbonatesIonSolvent

The invention belongs to the field of biochemical industry and provides a method for preparation of methyl alkyl carbonate. The method comprises the following steps of: using ion liquid as a reactant medium or adding dimethyl carbonate instead of a solvent, adding alkyl alcohol of which the mol ratio of alcohol to ester is 1:1-1:20, adding 1%-25% of candida antarctica lipase by mass percentage in the reactant, performing transesterification reaction after stirring, and then obtaining a product of methyl alkyl carbonate by means of treatment after the reaction. The method disclosed by the invention has the advantages of high transformation rate, high selectivity, high universality, simple technique, environmental friendliness and the like.

Owner:WUHAN UNIV

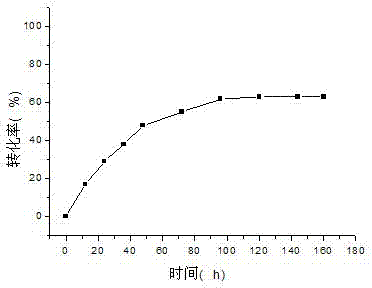

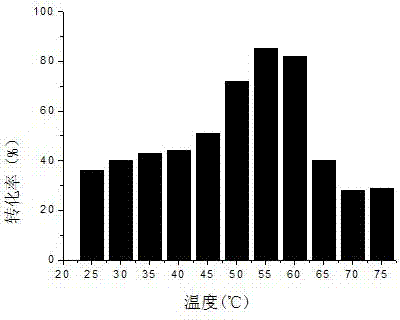

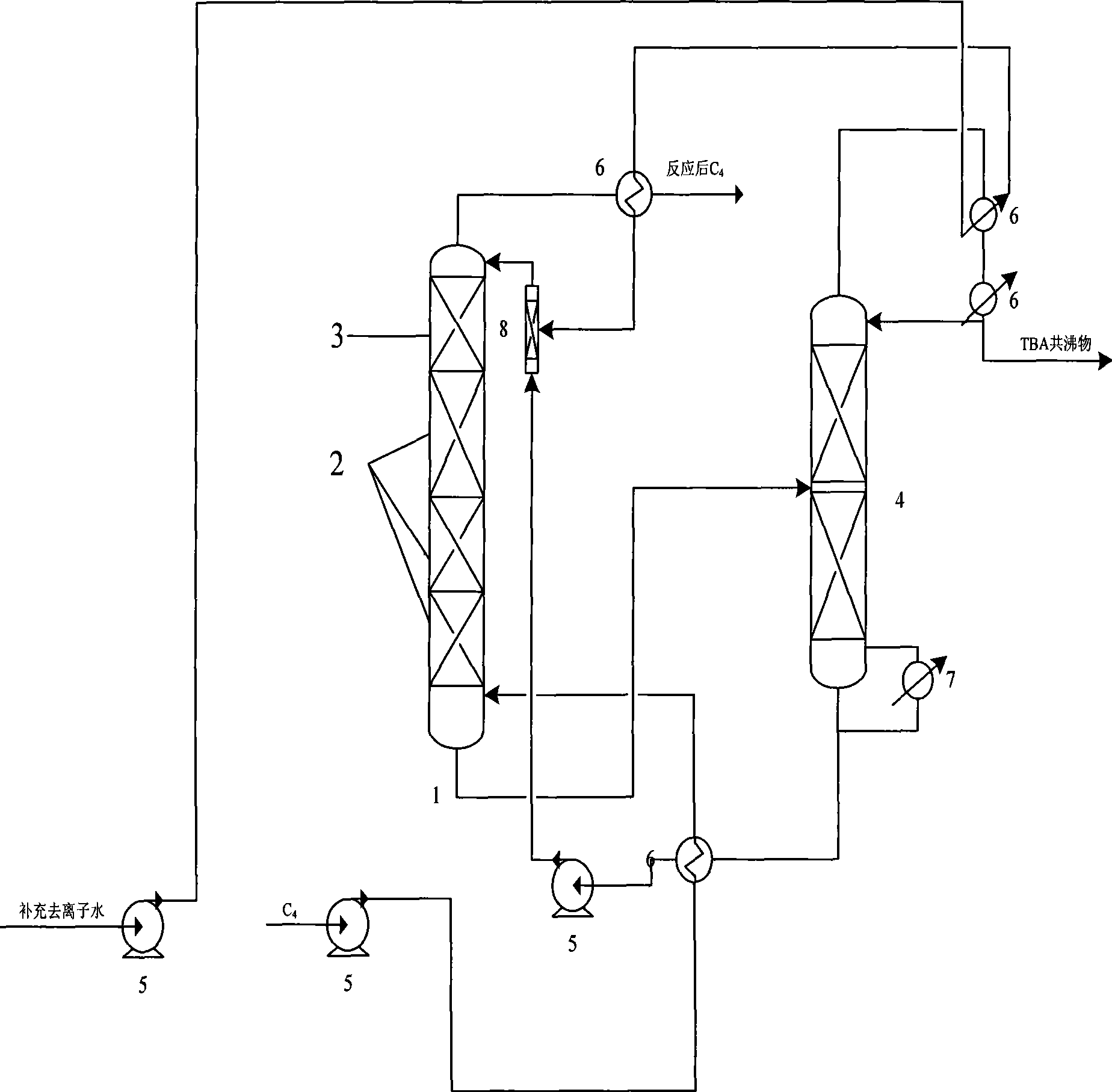

Method for preparing tert-butanol by extraction of carbon 4 hydrocarbon containing isobutene

ActiveCN101423454AImprove conversion and selectivitySimple processOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionChemistryCationic exchange

The invention provides a method for continuously producing tertiary butyl alcohol by C4 hydrocarbon containing isobutene through a hydration reaction and extraction action in the presence of a cation exchange resin catalyst. The method is characterized in that a reactor and an extracting tower are combined in a device, the functions of the hydration reaction and the extraction separation are synchronously realized in the device, and the tertiary butyl alcohol generated by the reaction is extracted by water in time, thereby breaking through the limit of chemical equilibrium, improving the conversion rate and the selectivity of the isobutene, simplifying the flow, saving the investment cost for the device, also realizing heat integration, and greatly reducing the energy consumption in the production.

Owner:PETROCHINA CO LTD

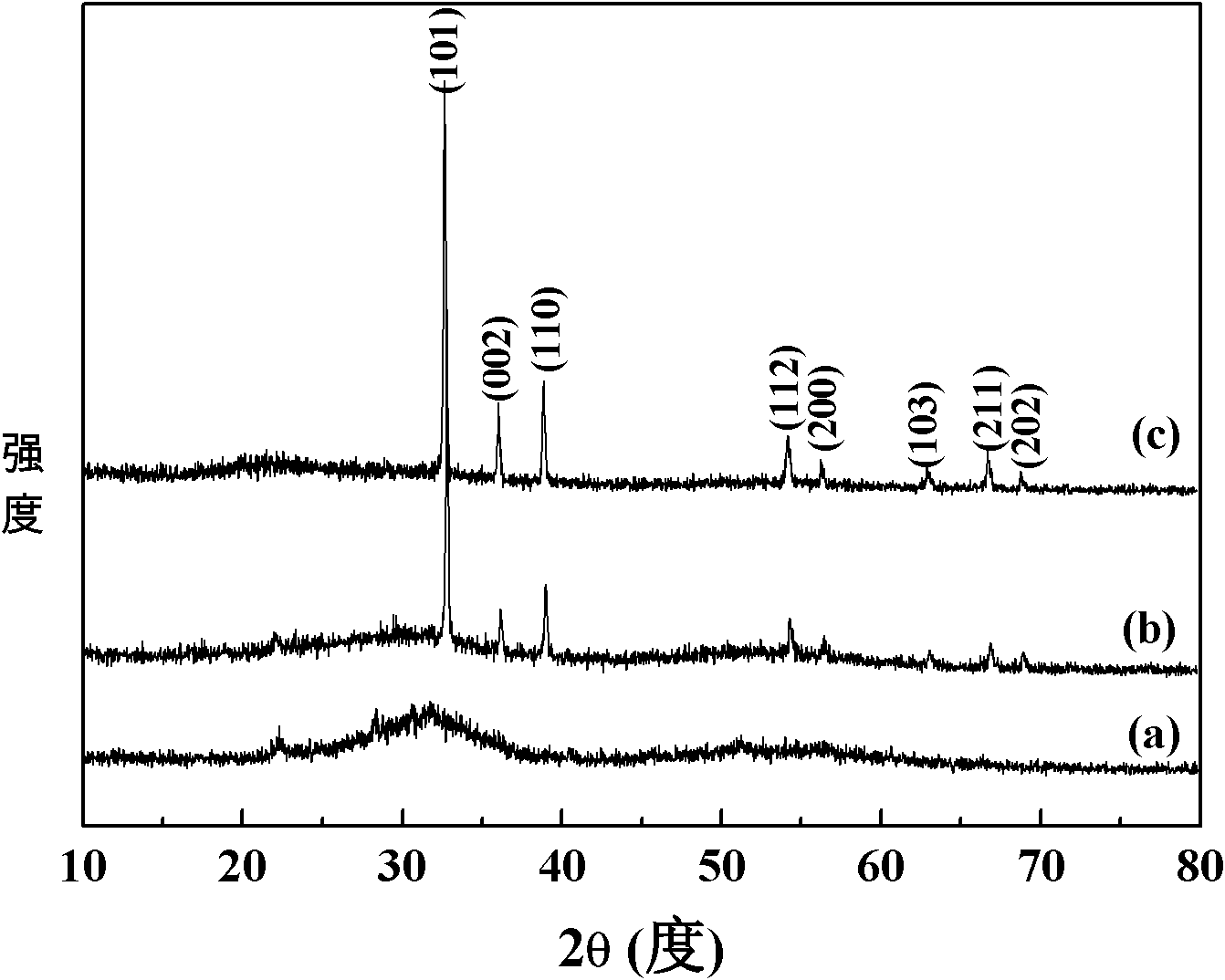

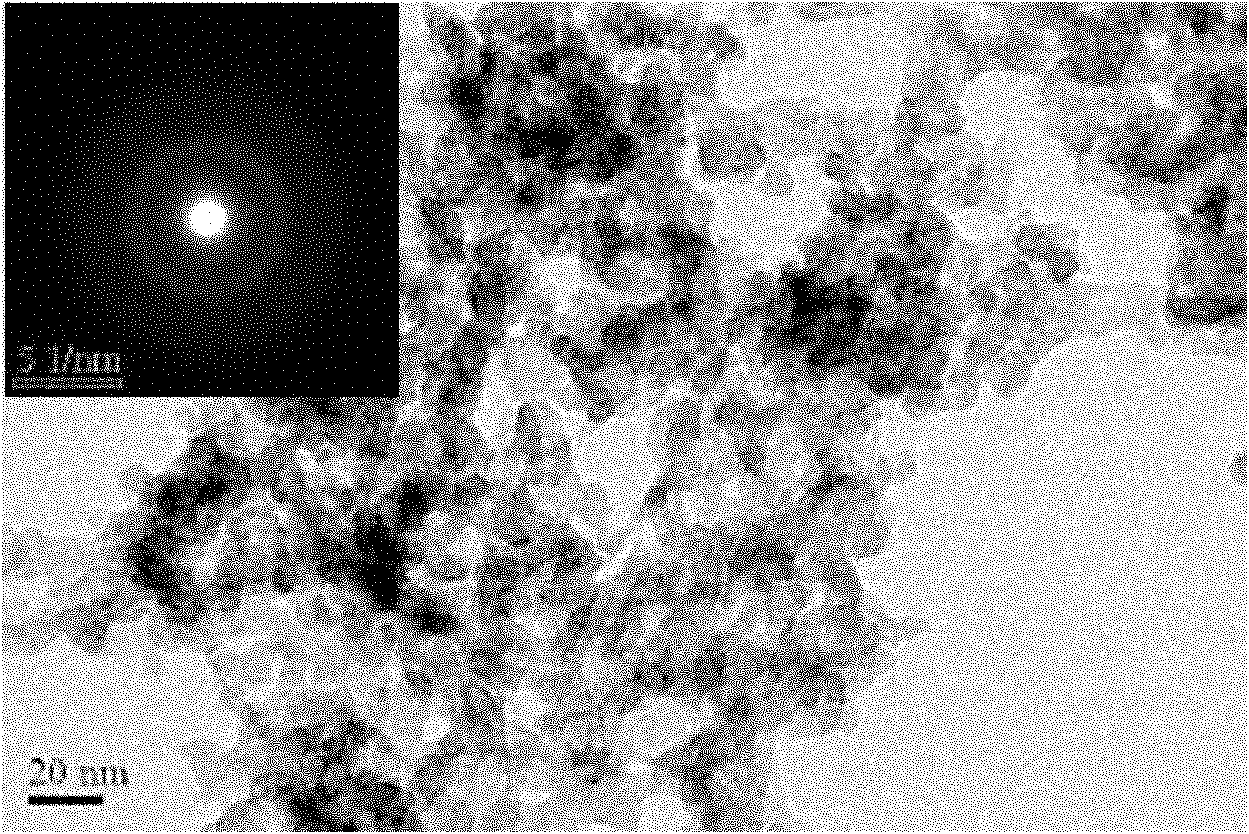

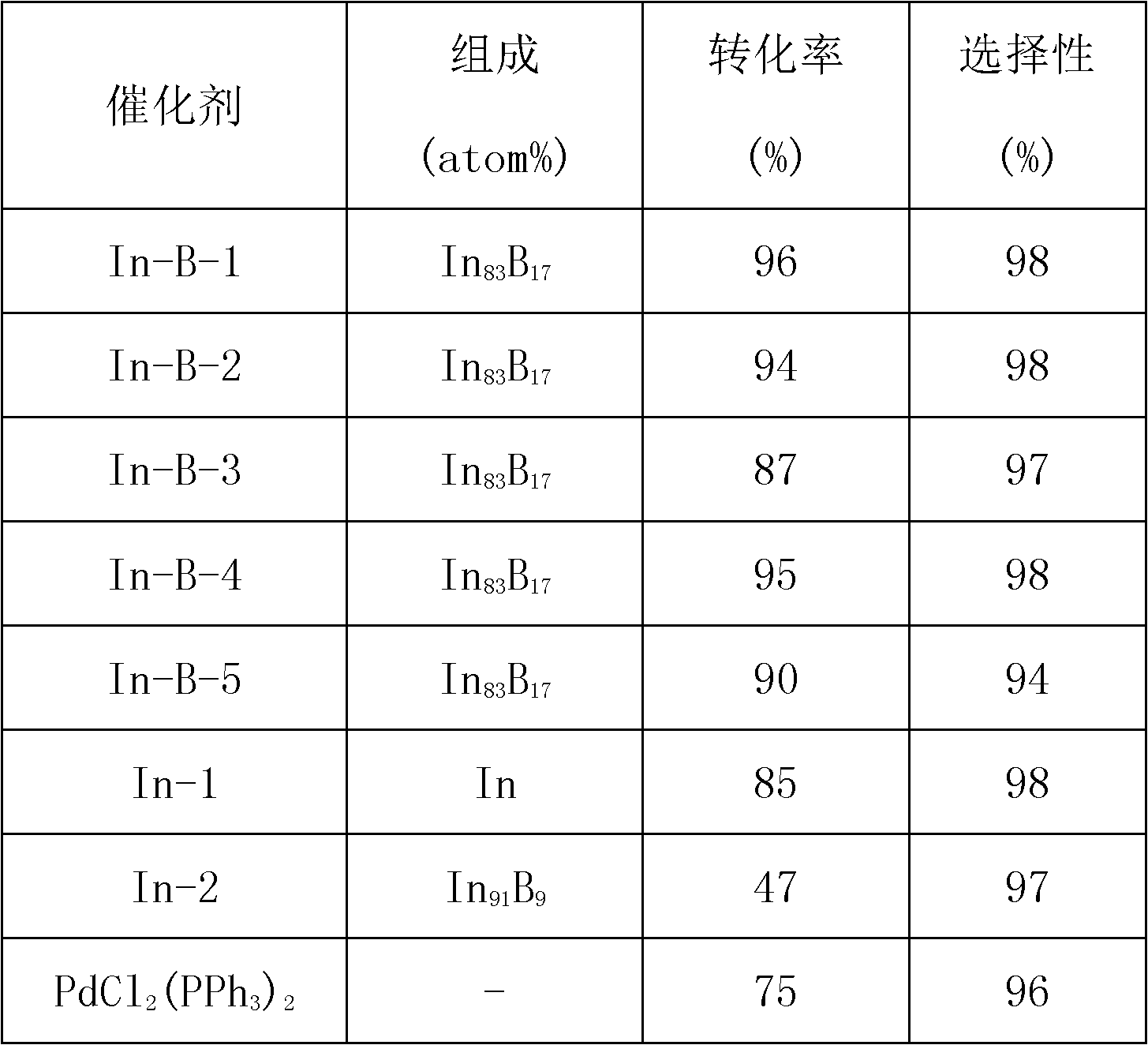

Binary amorphous alloy catalyst and preparation method and use thereof

InactiveCN102179240AImprove conversion and selectivityExcellent catalytic performanceOrganic compound preparationHydroxy compound preparationHydrogen compoundsIon

The invention discloses a novel binary indium-boron amorphous alloy catalyst for allylation. The general formula of the catalyst can be represented by InxBy, wherein the sum of x and y is 100, x ranges from 75 to 95 and y ranges from 5 to 25; and the catalyst are spherical particles with a particle size ranging from 5 to 50 nanometers. The preparation method comprises: performing a chemical reduction reaction by regulating the concentration of inorganic salt of indium, keeping temperature between 0 and 20 DEG C and a stirring speed between 600 and 1,000 rpm and adding solution of a hydride ofmetal boron into solution of inorganic salt of indium; and performing centrifugal separation and washing an obtained black solid precipitate in deionized water till the precipitate is neutral. The amorphous alloy provided in the invention can be used as a catalyst for the allylation of compounds such as benzaldehyde and acetophenone in a water phase for preparing enol, has high conversion rate and selectivity in reaction, and has higher catalytic performance than a homogeneous catalyst.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for fluorinating pyrimidine derivative by using micro-channel reactor

InactiveCN106432099AImprove conversion and selectivitySimple purification processOrganic chemistryPyrimidineFluorouracil

The invention discloses a method for directly fluorinating a pyrimidine derivative by using a micro-channel reactor. A uracil and / or cytosine and fluorine-containing acid and / or fluorine-containing alcohol mixture used as a raw material reacts with fluorine to prepare corresponding fluorouracil and / or fluorocytosine. The prepared fluorouracil and fluorocytosine have the advantages of high purity, low cost advantage, and safe and easily controlled fluorination process.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

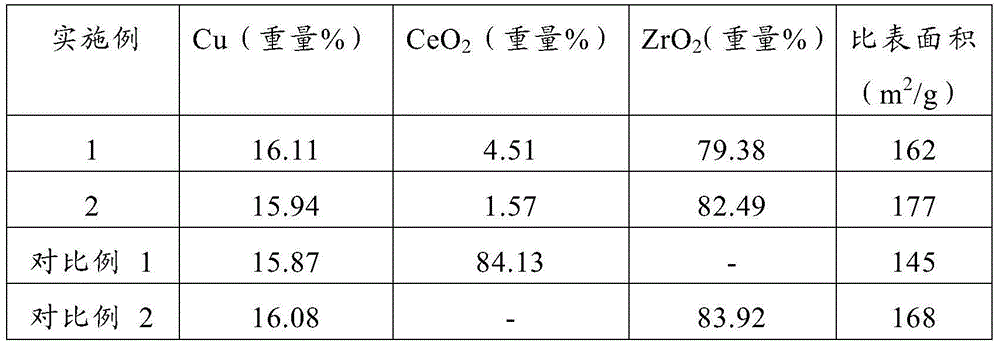

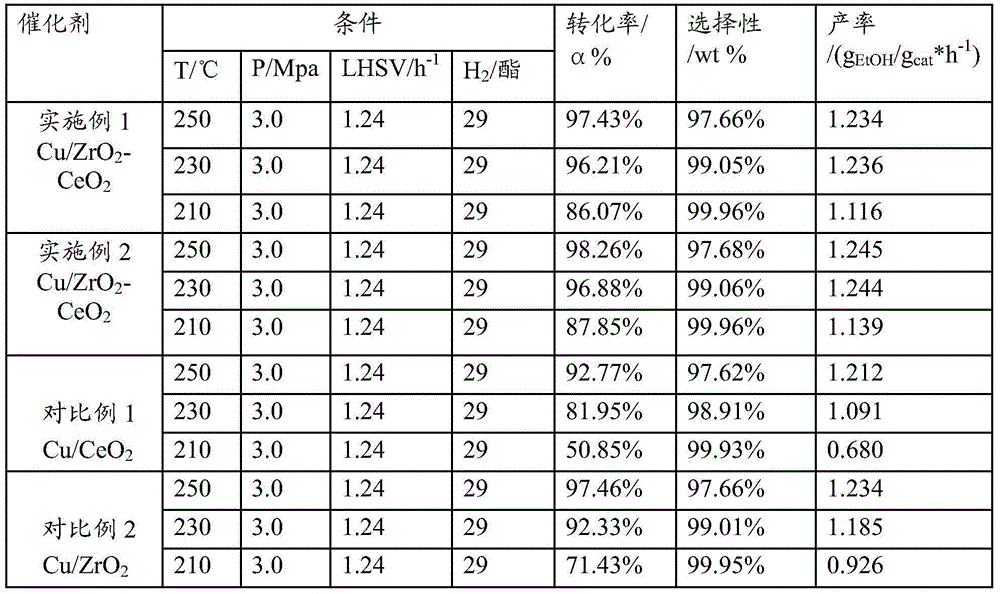

Catalyst for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester, preparation method thereof, application thereof, and method for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester

InactiveCN105797735AImprove conversion and selectivityImprove conversion rateOrganic compound preparationHydroxy compound preparationUreaPrecipitation

The invention relates to a catalyst for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester, a preparation method thereof, an application thereof, and a method for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester. The catalyst comprises an active component Cu and a composite carrier CeO2-ZrO2; the weight of the active component Cu is 5-80% of the total weight of the catalyst, the weight of the composite carrier CeO2-ZrO2 is 95-20% of the total weight of the catalyst, and the weight ratio between ZrO2 and CeO2 is 0.01:1-1:0.01. The catalyst can be prepared by a homogenous precipitation-ammonia distillation method and a homogenous precipitation-urea hydrolysis method. The catalyst for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester has the advantages of high conversion rate of short chain fatty acid ester and low selectivity of low carbon alcohol.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

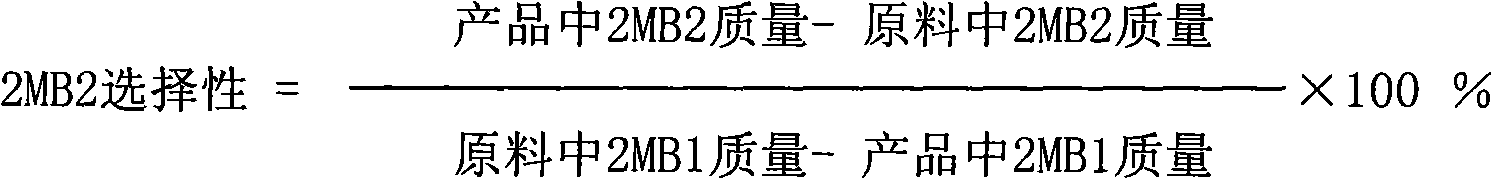

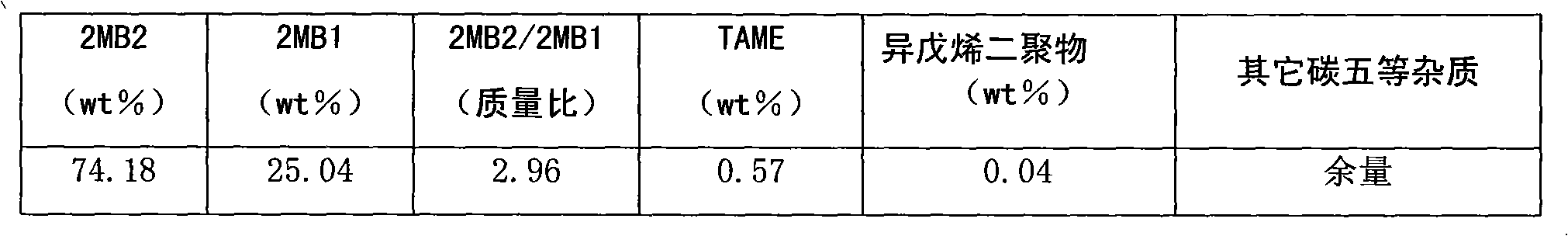

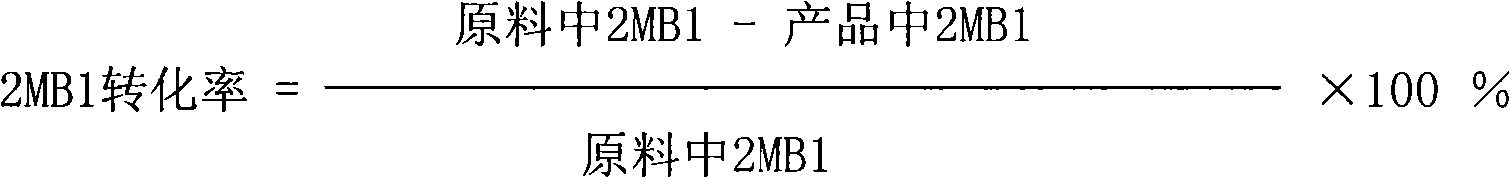

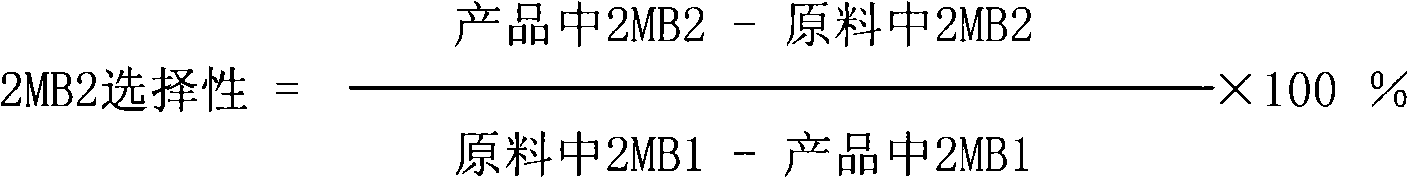

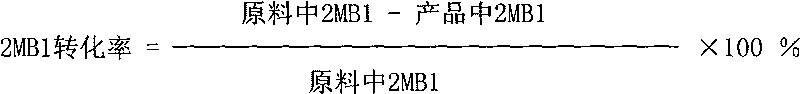

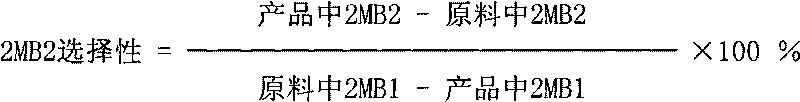

Isomerization method of 2-methyl-1-butylene

InactiveCN102040451AReduce the content of dimersImprove conversion and selectivityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveChemistry

The invention provides an isomerization method of 2-methyl-1-butylene, which is used for improving the content of the 2-methyl-2-butylene in coarse isoamylene. The method comprises the steps: 1) performing an isomerization reaction on the coarse isoamylene by a catalyst bed layer of a fixed bed to convert the 2-methyl-1-butylene to the 2-methyl-2-butylene, wherein the catalyst is HZSM-5 molecular sieve, the ratio of silicon to aluminum of the catalyst is 20-50, the specific surface of the catalyst is 200-500m<2> / g, and the average pore size of the catalyst is 2-8nm; and 2) modifying the molecular sieve before the molecular sieve is in use, wherein the step of modifying comprises the procedures of soaking the molecular sieve into an alkaline water solution which is prepared from calcium hydroxide or magnesium hydroxide under the normal temperature, the concentration of the alkaline water solution is 0.5-1.5wt%, the volume ratio of the alkaline water solution to the molecular sieve is 1.1-2:1, and the soaking time is 10-36 hours; and washing after the molecular sieve is soaked, dewatering and drying. The method effectively restrains the dimerization reaction when the isomerization reaction is performed, can not put extra burden on the purifying or the refining of a product since other materials can not be led into a reaction system, and effectively overcomes the defects in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving content of 2-methyl-2-butylene in coarse isoamylene

ActiveCN101597198AReduce the content of dimersImprove conversion and selectivityHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsCationic exchangeFixed bed

The invention relates to a method for improving the content of 2-methyl-2-butylene in coarse isoamylene, which comprises the following steps: tert butyl alcohol is added to the coarse isoamylene; and then the coarse isoamylene with the tert butyl alcohol is subjected to an isomerization reaction through a fixed bed catalyst bed layer consisting of sulfonic acid group cation exchange resin so as to ensure that 2-methyl-1-butylene in the coarse isoamylene is converted into the 2-methyl-2-butylene, wherein the addition of the tert butyl alcohol takes the coarse isoamylene as a reference and is 0.2-2.2 percent by weight; the mass exchange capacity of the sulfonic acid group cation exchange resin is 3-5.5 mmol / g, and the mass space velocity is 1-35 hr; the reaction temperature is 18-45 DEG C; and the reaction pressure is 0.3-1.0 MPa. The method effectively restrains respective or mutual dipolymer reactions of the 2-methyl-2-butylene and the 2-methyl-1-butylene in the process of the isomerization reaction.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Ethyl tert-butyl ether etherification preparation process method

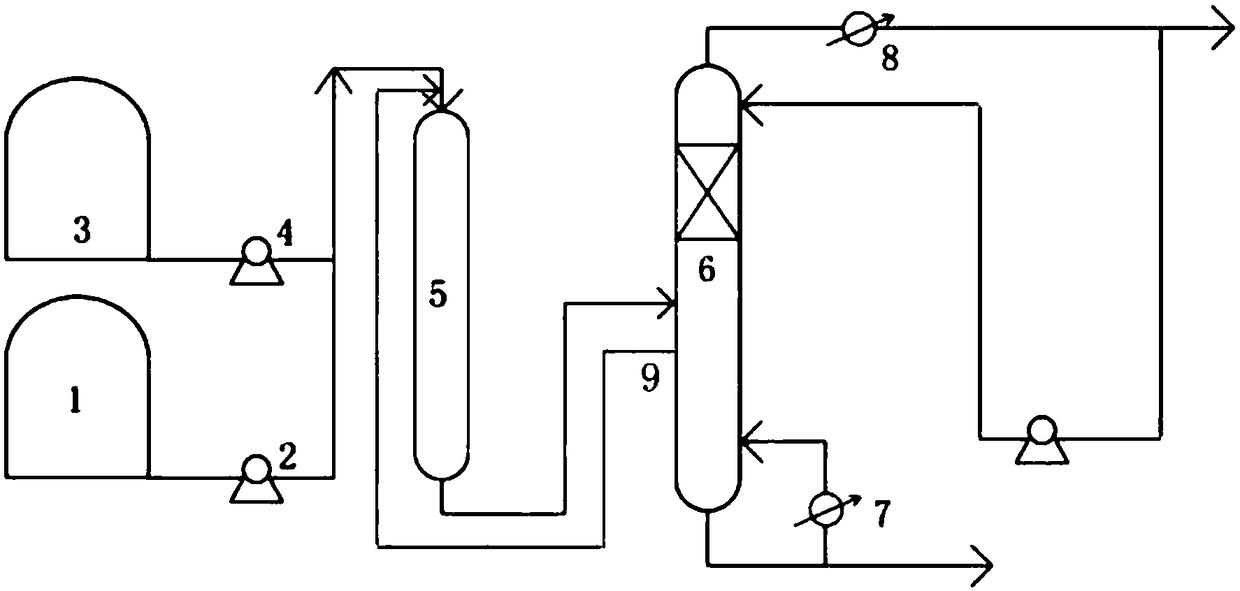

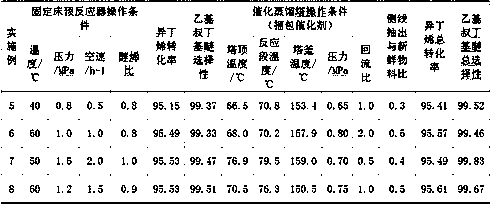

ActiveCN108218675ADecrease the molar ratio of alcohol to eneneImprove conversion and selectivityEther separation/purificationOrganic-compounds/hydrides/coordination-complexes catalystsMaterial consumptionChemistry

The application provides an ethyl tert-butyl ether etherification preparation process method. The ethyl tert-butyl ether etherification preparation process method comprises a pre-reaction stage of a fixed bed reactor and a catalytic distillation column reaction stage thereafter. Mixed carbon four containing isobutylene and a fresh material of ethanol is pumped into the fixed bed reactor at a ratioof alcohol to olefin of (0.8 to 1.0), pre-reaction is conducted at a temperature of 40 to 60 DEG C, a material space velocity of 0.5 to 2. 0h<-1>, and the reaction pressure of 0.8 to 1.5 MPa, and a liquid phase product is sent to the catalytic distillation column reaction stage through a pipeline. The technical scheme effectively reduces the molar ratio of alcohol to olefin of the raw material, improves the conversion rate and selectivity of the etherification reaction, and greatly reduces the material consumption, energy consumption and purity of an ethyl tert-butyl ether product.

Owner:丹东明珠特种树脂有限公司

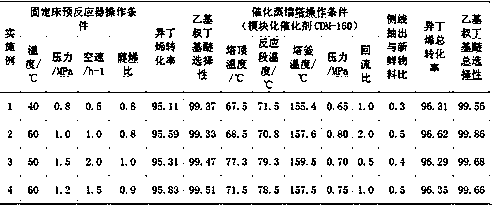

Catalytic epoxidation of styrene with molecular oxygen using metal ion exchanged zeolites

InactiveUS20070149791A1Improve conversion and selectivityIncrease styrene oxide selectivityOrganic chemistryMolecular sieve catalystsIonIon exchange

This invention provides a catalytic epoxidation of styrene to styrene oxide with molecular oxygen using cobalt containing zeolite. Catalytic epoxidation of styrene-to-styrene epoxide was carried out using molecular oxygen in presence of Co2+ exchanged zeolites. Molecular oxygen from air is also useful for the epoxidation reaction at atmospheric pressure. The presence of adsorbed water molecules in the catalyst also increases the styrene conversion without affecting the styrene oxide selectivity. Various alkali and alkaline earth cationic promoters were introduced into the zeolite catalyst to increase the styrene oxide selectivity. The present invention explore the effect of adsorbed water molecules and alkali and alkaline earth metal cationic promoters in the cobalt exchanged zeolite catalyst, on the styrene conversion and styrene oxide selectivity for the catalytic epoxidation of styrene to styrene oxide with molecular oxygen.

Owner:CENT SALT & MARINE CHEM RES INST

Method for preparing isoamylene by taking tertiary amyl methyl ether as raw material

ActiveCN101723777AReduce contentImprove conversion and selectivityHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsDecomposition2-Methyl-2-butene

The invention relates to a method for preparing isoamylene by taking tertiary amyl methyl ether as raw material, comprising the following steps: making methyl tert-amyl ether to be subjected to decomposition reaction at 130-300 DEG C with the gas phase through a catalyst bed layer; removing methanol in the products of decomposition reaction to obtain rough isoamylene; and adding water to the rough isoamylene to enable the rough isoamylene to be subjected to the isomerization reaction through a fixed bed catalyst bed layer which is formed by sulfonic cation exchange resin and enable 2-methyl-1-butene in the rough isoamylene to be converted into 2-methyl-2- butane, wherein the addition amount of the water is 0.03-0.10 percent by weight of the rough isoamylene, and the mass exchange capacity of the sulfonic cation exchange resin is 3-5.5 mmol / g, the mass space velocity is 1-35hr-1, the reaction temperature is 18-45 DEG C and the reaction pressure is 0.3-1.0 MPa. The invention effectively controls the occurence of the dimerization reaction in the isomerization reaction process.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

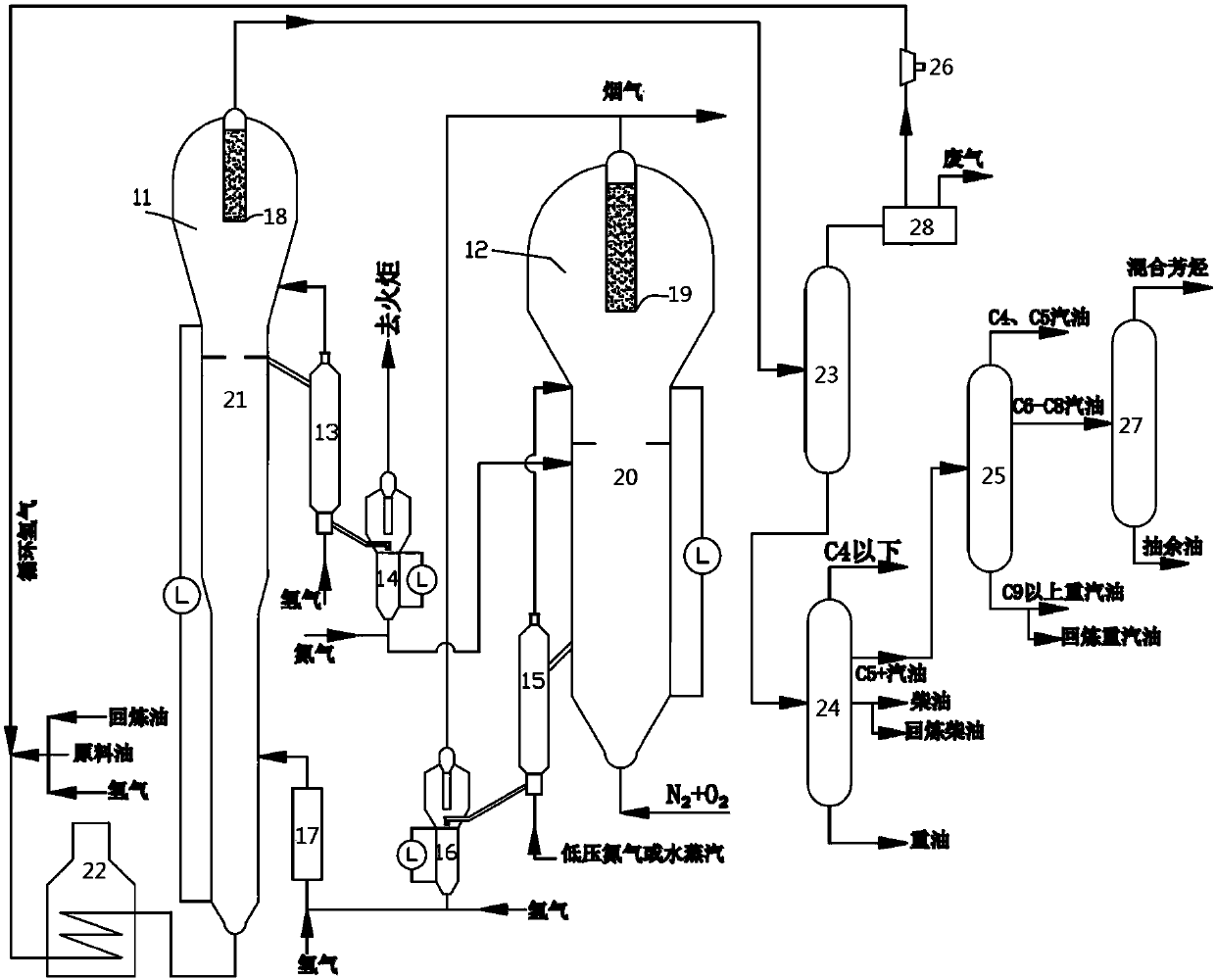

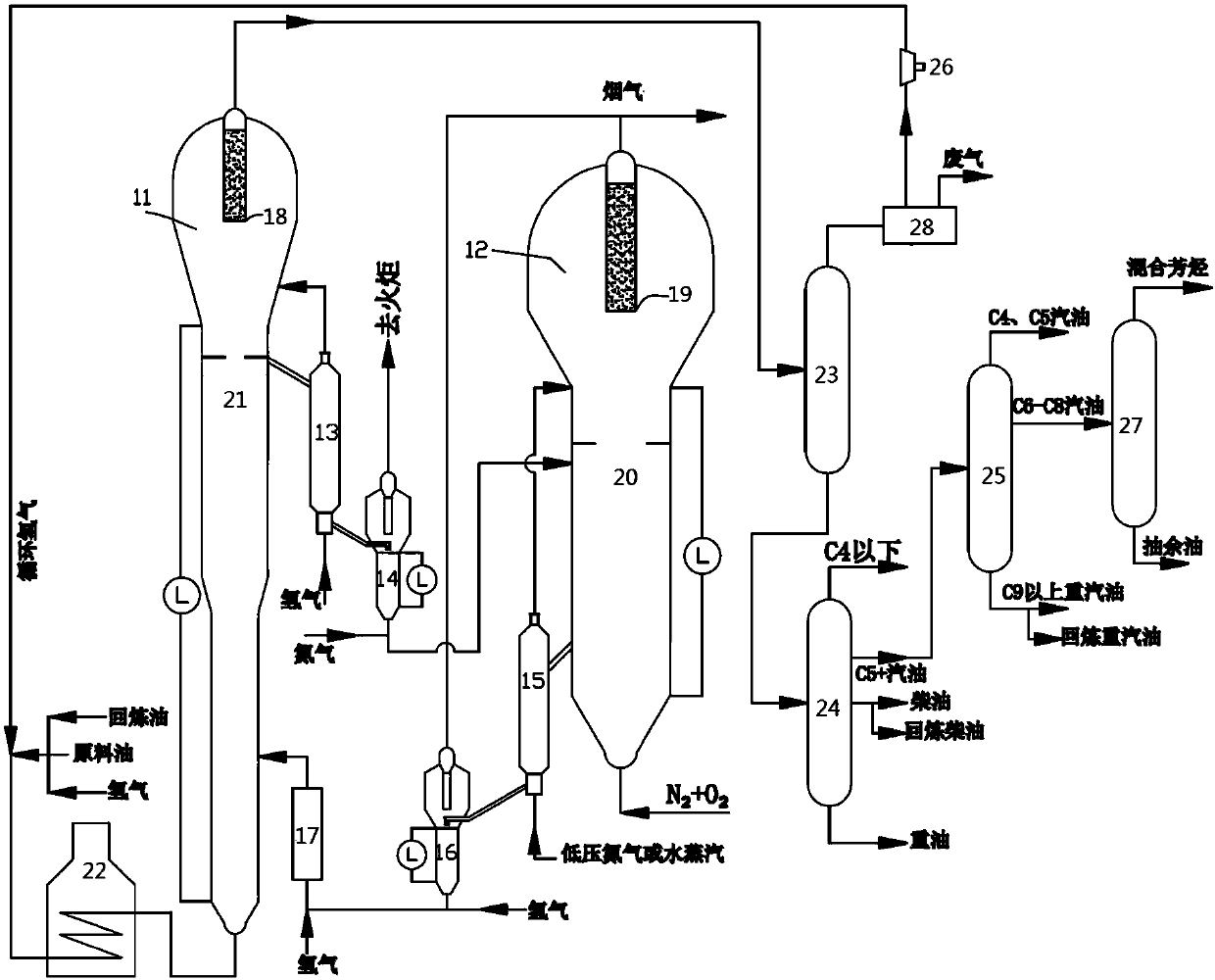

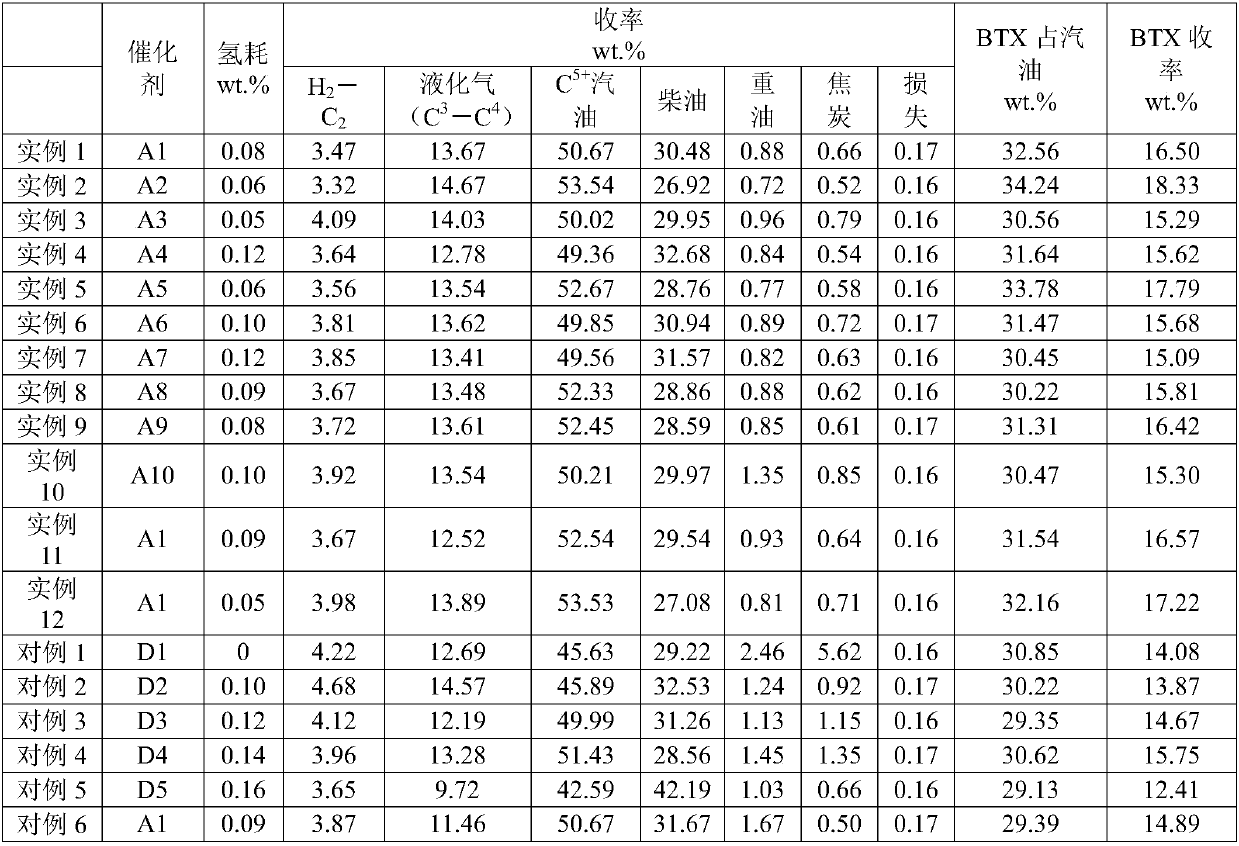

Heavy raw oil hydrocracking method and system

ActiveCN109705910AReduce hydrogen consumptionImprove conversion and selectivityMolecular sieve catalystsTreatment with hydrotreatment processesChemistryCatalyst regeneration

The invention relates to the field of hydrocracking, in particular to a heavy raw oil hydrocracking method and system. The method comprises the following steps: raw oil and hydrogen are heated to obtain a mixture; then the mixture is sent to a pressurized fluidized bed reactor to be in contact with a catalyst for reaction; a product is fed to a high-pressure separator for high-pressure separationto obtain a light component and a heavy component; separation treatment is performed on the light component to obtain a circulating hydrogen material flow as a part of hydrogen source; the heavy component is sent to a rectifying tower for rectification so as to separate to obtain gasoline; the gasoline is sent to a second rectifying tower for rectification so as to separate to obtain light gasoline; the light gasoline is sent to an aromatic hydrocarbon extraction unit for extraction to obtain light aromatics and raffinate oil; part of diesel and part of heavy gasoline are used as part of heavyraw oil; and a to-be-generated catalyst is sent to a catalyst regeneration unit for regeneration so as to obtain a regenerated catalyst, and the regenerated catalyst is circulated to the pressurizedfluidized bed reactor. The heavy raw oil hydrocracking method can be used for high conversion rate and high selectivity preparation of BTX by catalysis of diesel at relatively low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

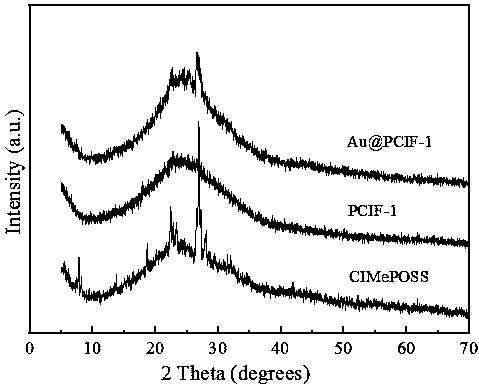

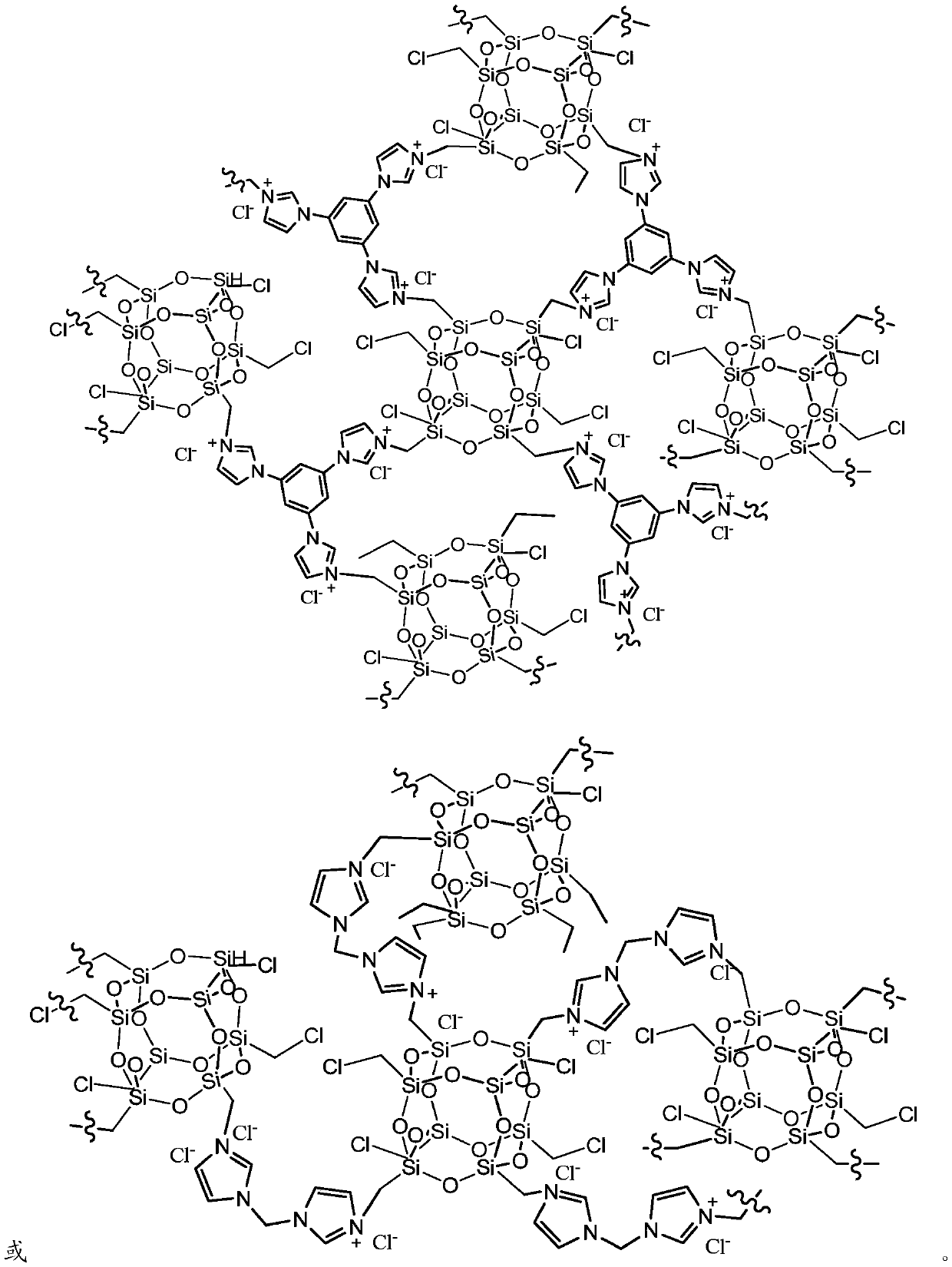

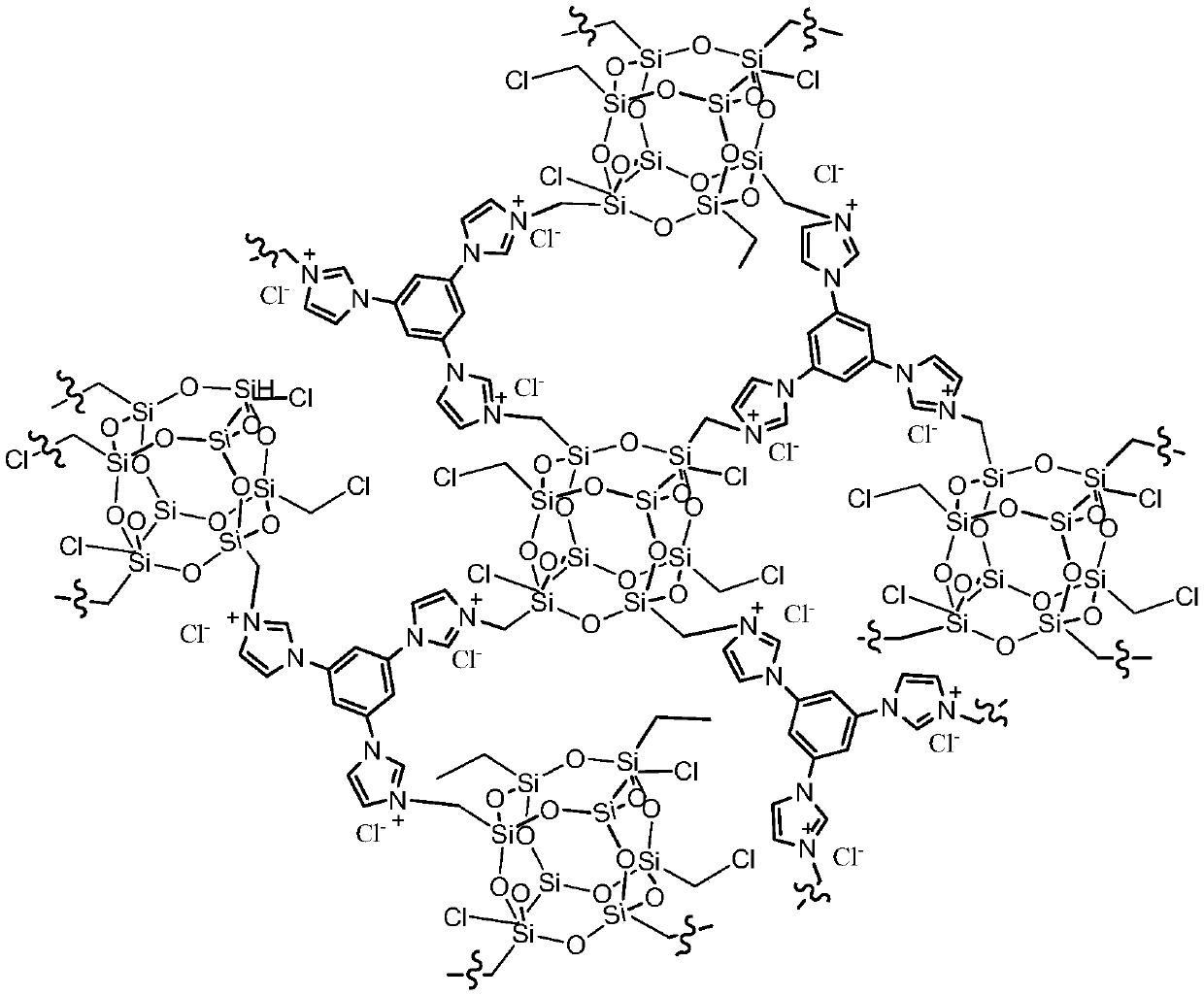

Catalyst for biphenyl preparation as well as preparation method and application thereof

ActiveCN111068780AImprove conversion and selectivityIonic site richOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsChemistryBenzene

The invention discloses a catalyst for biphenyl preparation and a preparation method and application thereof, and belongs to the technical field of chemical catalysis. The catalyst comprises nanogoldAu and an imidazolyl porous ion frame PCIF loaded with nanogold. The method comprises the following steps: putting benzene, a catalyst, a solvent and an additive into a closed reaction kettle, uniformly mixing, introducing oxygen into the reaction kettle, keeping the pressure of the reaction system in the kettle within the range of 8-20 atm, keeping the temperature of the reaction kettle within the range of 100-180 DEG C, and carrying out an oxidative coupling reaction to obtain biphenyl. The catalyst that is Au@PCIF has the advantages of rich ion sites, high nano-gold dispersity, high catalytic efficiency, a simple preparation process, stability, difficulty in decomposition, easiness in separation from a liquid phase, high precious metal utilization rate and the like, has high selectivityand conversion rate in biphenyl preparation, and has high industrial application value.

Owner:YANCHENG INST OF TECH

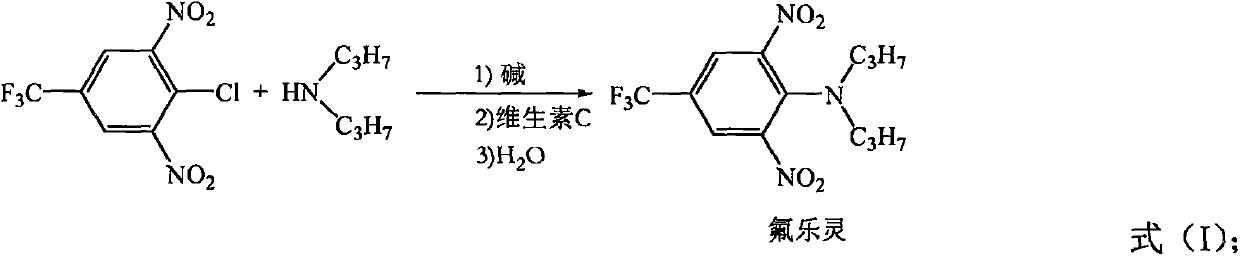

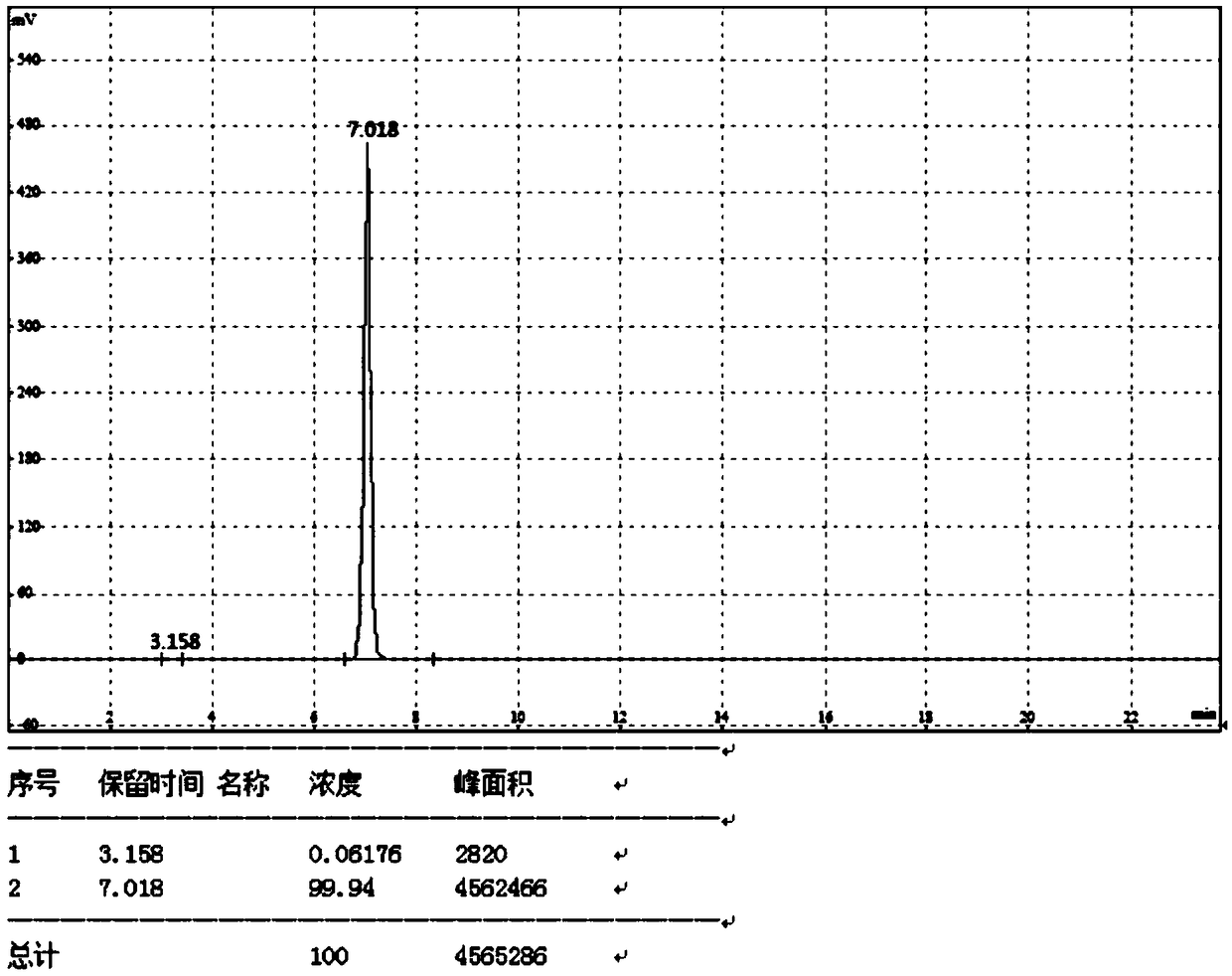

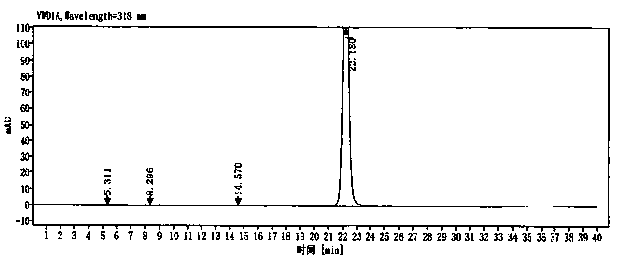

Synthesis method of trifluralin

ActiveCN110759830AImprove conversion and selectivityWide variety of sourcesOrganic compound preparationAmino compound preparationTolueneNitroso

The invention discloses a synthesis method of trifluralin. The method uses 4-chloro-3,5-dinitrotrifluorotoluene and di-n-propylamine as raw materials, a base as an acid binding agent, and vitamin C asan auxiliary agent, and the target compound is prepared under heating. The advantages of the method are as follows: (1) the used raw materials and auxiliary materials are wide in source, and convenient in preparation; (2) the catalytic effect is good, a raw material conversion rate is high, and the product selectivity is good; and (3) the content of N-nitroso-di-n-propylamine in the product is low, the post-treatment is simple and convenient, the method is a new preparation process of trifluralin, and the large-scale industrial development is facilitated.

Owner:YANCHENG TEACHERS UNIV

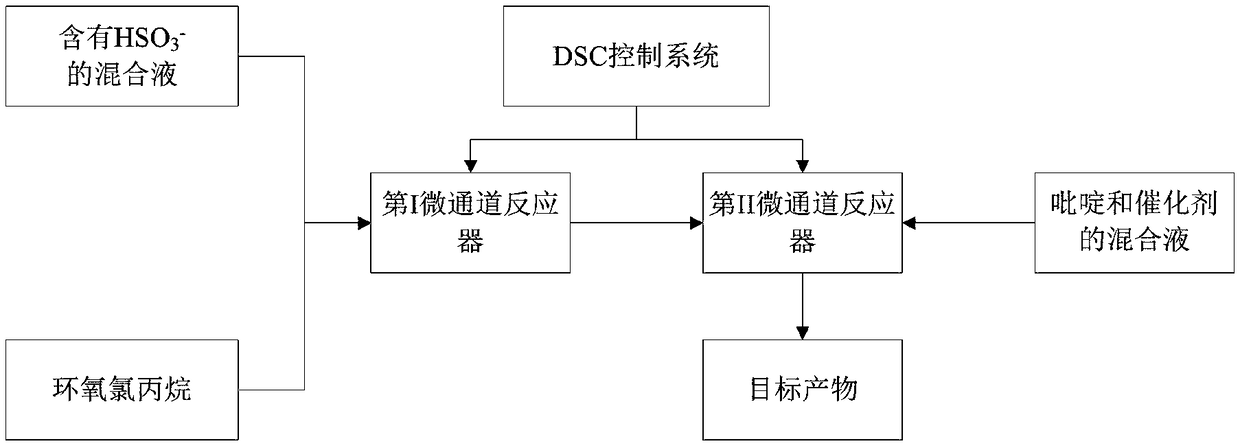

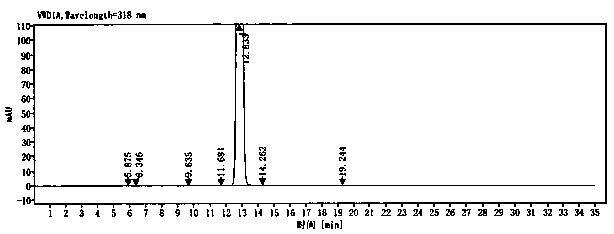

Method for continuously synthesizing PPS-OH

ActiveCN109265392ALess side effectsImprove conversion and selectivityOrganic chemistrySodium sulfitePhase-transfer catalyst

The invention discloses a method for continuously synthesizing PPS-OH. The method comprises the following steps of adding a phase transfer catalyst and sodium sulfite into a hydrosulfite solution or pyrosulfite solution of alkali metal, so as to obtain a mixed solution containing HSO3<->; simultaneously adding the mixed solution and epichlorohydrin into a first reactor, and generating ring-openingreaction; simultaneously adding a mixed solution of pyridine and a catalyst and a ring-opening reaction product into a second reactor, and reacting to obtain a target product. The method has the advantages that the mixing order and adding order of the raw materials are changed, and the raw materials participating in reaction are simultaneously sent into the corresponding reactor to participate inthe corresponding reaction, so that the generation of side effect is effectively reduced, the selectivity and the conversion rate of reaction are improved, the yield rate and purity of the product are improved, and the requirement of high-end customers in the electroplating industry are met; compared with the intermittent operation of the traditional technology, the reaction time is shortened, the production efficiency is improved, and the method is suitable for industrialized production.

Owner:湖北吉和昌化工科技有限公司

Method for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as solvent

ActiveCN111606817AImprove conversion and selectivityEasy to filterOrganic compound preparationAmino-carboxyl compound preparationSolventProcess engineering

The invention relates to the field of fine chemical engineering, in particular to a method for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as a solvent. Themethod for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as a solvent is characterized by comprising the following steps: (1) adding water, 4-nitro-benzoic acid 2-ethyl-hexyl ester and an active nickel catalyst into a reactor in proportion; (2) performing heating, introducing hydrogen, and carrying out heat preservation and pressure maintaining reaction until no hydrogen is absorbed; (3) cooling, namely adding paraformaldehyde into the reactor, and supplementing the active nickel catalyst in proportion; (4) heating, introducing hydrogen, and carrying out heat preservation and pressure maintaining reaction until hydrogen is not absorbed; (5) continuing to preserve heat and pressure for several hours, terminating the reaction, and sampling and analyzing; (6) after the catalyst is filtered, recycling, activating and reusing the catalyst, standing for layering, discharging a water layer into a sewage system, and feeding an oil layer into a distillation tower; and (7) heating, rectifying and purifying by the distillation tower until the product specification is met, and barreling and packaging.

Owner:浙江优创材料科技股份有限公司

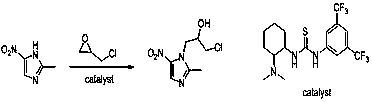

Process for preparing 5-nitroimidazole medicine through catalysis of small organic molecules

ActiveCN111471017AImprove conversion and selectivityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTrifluoromethylOrganic molecules

The invention provides a process for preparing a 5-nitroimidazole medicine through catalysis of small organic molecules. The preparation method comprises the following steps: 1) uniformly stirring andmixing 2-methyl-5-nitroimidazole, a solvent and a catalyst which is selected from 1-(3, 5-ditrifluoromethyl phenyl)-3-(2-dimethylamino-cyclohexyl)-thiourea, and 2) adding epoxy chloropropane or epoxypropane into a reaction system in the step 1), and reacting to obtain the 5-nitroimidazole medicine. According to the present invention, the 5-nitroimidazole medicine prepared by using the synthesisprocess has characteristics of low catalyst consumption, high catalytic activity, high reaction selectivity, high yield, easy catalyst recycling, and environmental protection.

Owner:湖南九典宏阳制药有限公司 +1

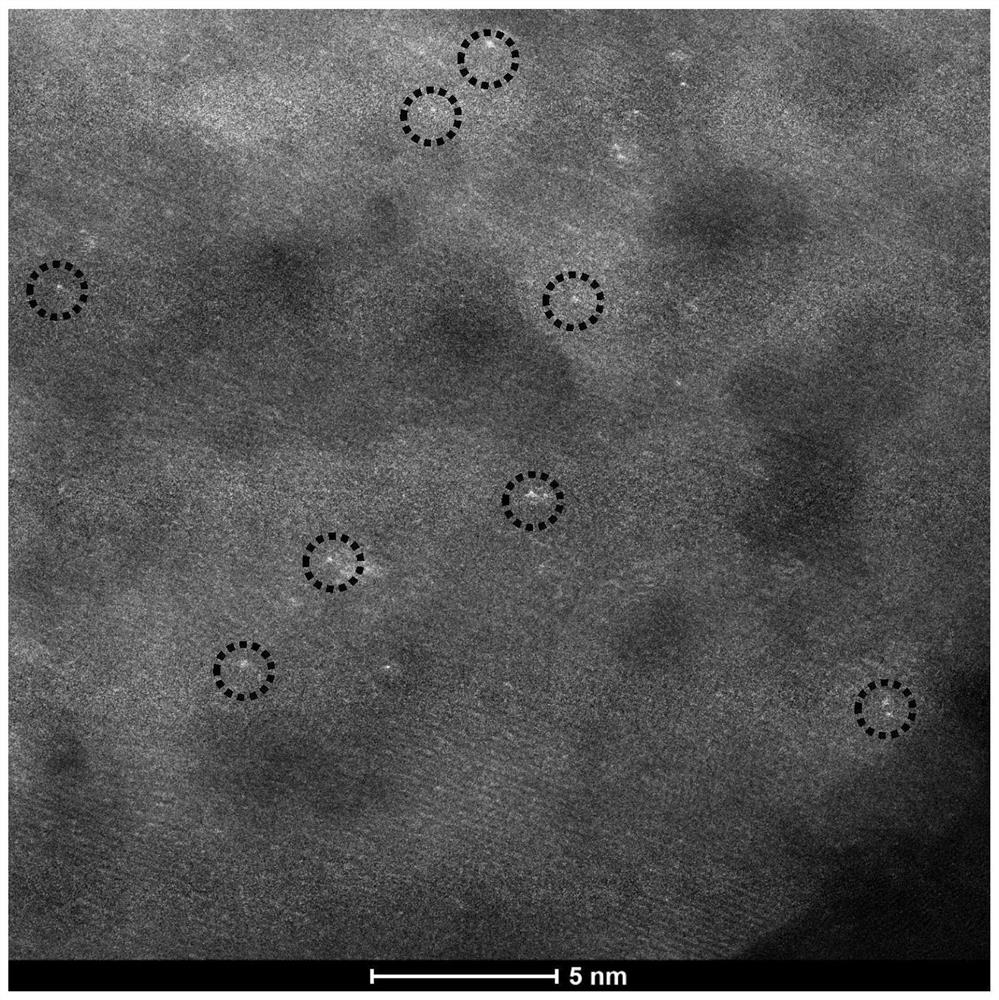

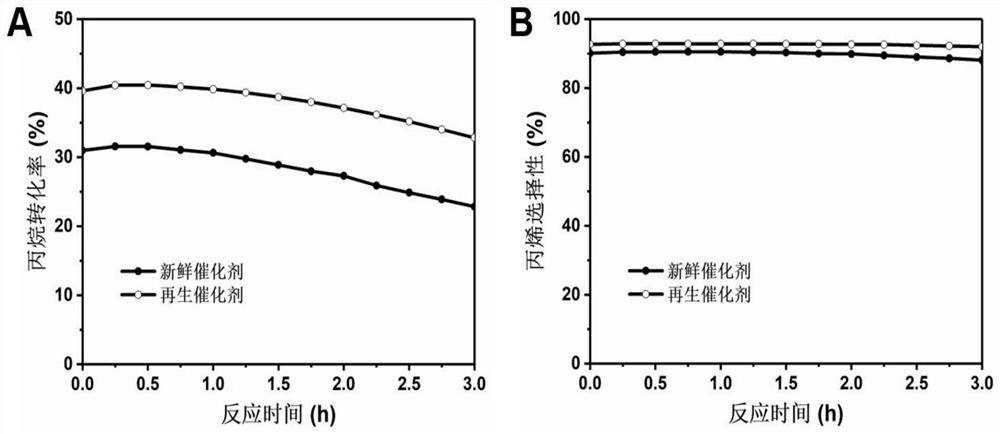

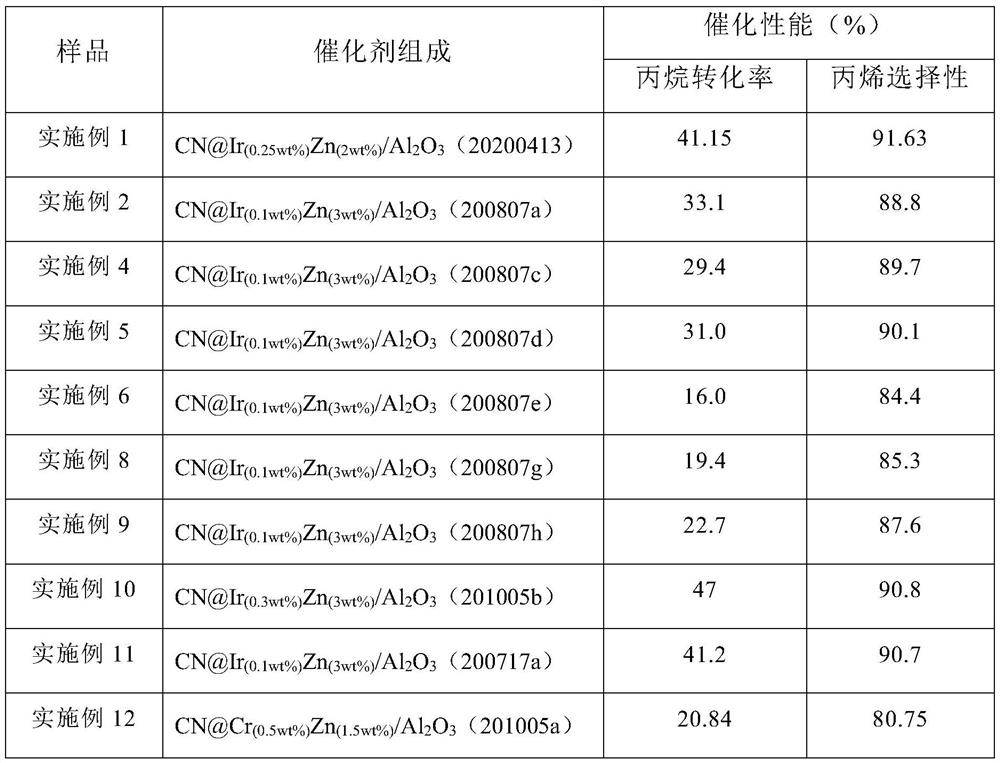

Preparation method and application of CN (at) Ma-Mb supported monatomic catalyst

PendingCN114682282AImprove conversion and selectivityImprove conversion ratePhysical/chemical process catalystsCatalystsAlkanePyrolysis

The invention discloses a preparation method of a CN (at) Ma-Mb metal supported monatomic catalyst, which comprises the following steps: supporting active metals Ma and Mb on a carrier to form a catalyst precursor; adding a ligand to form a complex; and performing pyrolysis to form the CN (at) Ma-Mb metal supported monatomic catalyst. The preparation method of the monatomic catalyst is simple in process and easy to regenerate, the catalytic activity is still kept after regeneration, the conversion rate and selectivity of the catalyst for catalyzing direct dehydrogenation of low-carbon alkane are high, and the monatomic catalyst is suitable for large-scale industrial application.

Owner:BEIJING SINGLE ATOM SITE CATALYSIS TECH CO LTD

Preparation method of hydrazine hydrate

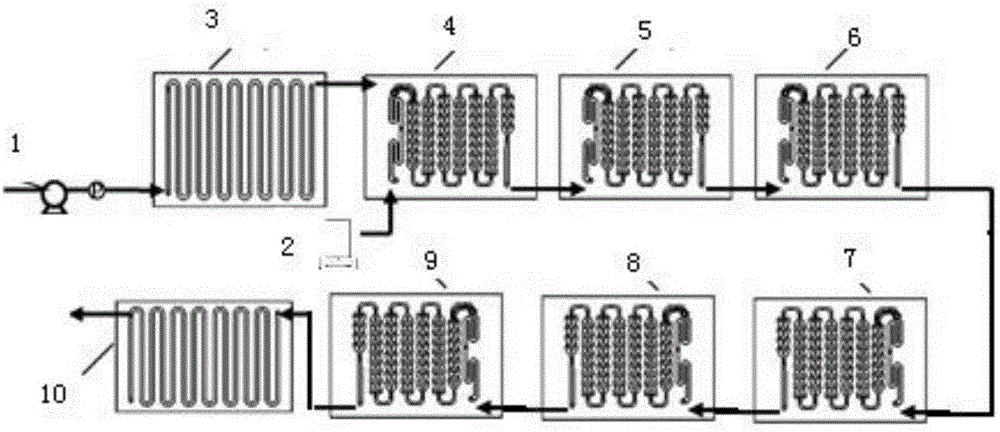

The invention provides a preparation method of hydrazine hydrate. The preparation method is used for significantly improving the production technology of Raschig process. The preparation method is characterized in that a sodium hypochlorite solution and liquid ammonia or ammonia gas are used as the raw materials, and a tubular reaction device is used for preparing the hydrazine hydrate; the tubular reaction device comprises a first tubular reactor and a second tubular reactor in series, the two steps of reaction are performed by sections according to different reaction temperatures, the side effect is effectively avoided, and the yield rate of the hydrazine hydrate reaches 90% or above; the mass concentration of the generated hydrazine hydrate is greater than 10%, and is greater than the mass concentration of Raschig process and urea process, the energy consumption in the hydrazine hydrate concentrating and recycling process is greatly decreased, the production efficiency is improved,and the production cost is reduced; compared with the ketazine method, the ketazine hydrolysis procedure with high energy consumption is not needed, the equipment investment is reduced, the high-salinity organic wastewater which has high COD (chemical oxygen demand) content and is difficult to treat is not produced, and the production is more energy-saving and environment-friendly.

Owner:重庆晶萃化工科技有限公司

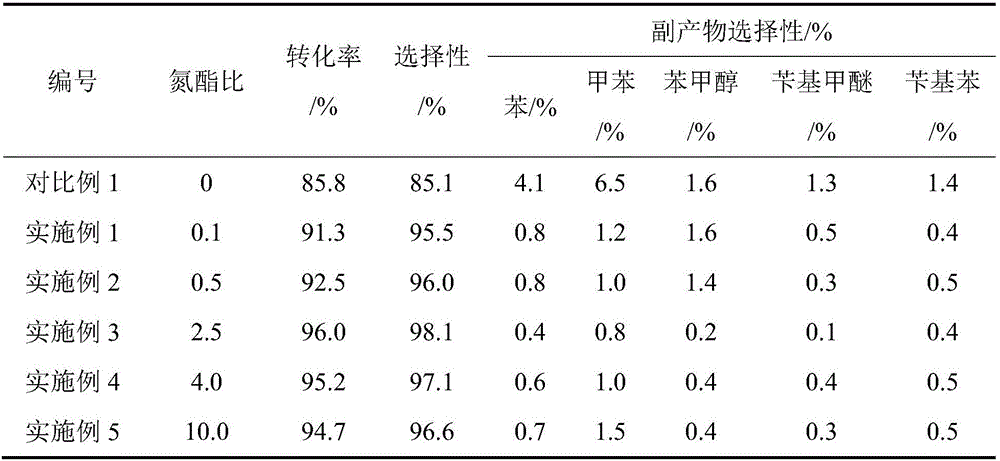

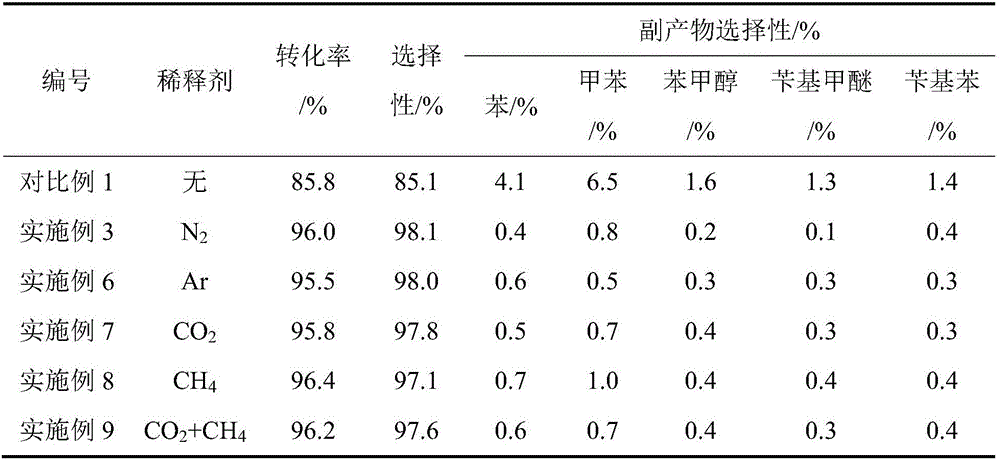

Technological method for preparing benzaldehyde through methyl benzoate hydrogenation

ActiveCN106588607AImprove conversion and selectivityInhibit side effectsPreparation by hydrogenolysisBenzaldehydeChemistry

The invention relates to a technological method for preparing benzaldehyde through methyl benzoate hydrogenation. Methyl benzoate and a catalyst are in contact to carry out hydrogenation reaction to generate benzaldehyde, and a dilutent is introduced during the reaction; and the diluent is selected from one or more of N2, Ar, He, CO2 and CH4. According to the technological method, the conversion rate and the selectivity of the methyl benzoate are improved, side reaction is obviously inhibited, and generation of byproducts is reduced; and therefore, the reaction can be retained in a high-conversion-rate and high-selectivity reaction process for a long time.

Owner:湖南中岭化工有限责任公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com