Method for separating light hydrocarbon from liquified natural gas

A technology for liquefied natural gas and a separation method, which is applied in the field of liquefied natural gas separation and recovery of light hydrocarbons, can solve the problems of methane pressure, high temperature, large compressor power consumption, unfavorable storage, etc., so as to save operating costs, reduce energy consumption and production costs , the effect of reducing power consumption

Inactive Publication Date: 2006-02-22

SOUTH CHINA UNIV OF TECH

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] 2. In the above patents, all the separated methane needs to be compressed by a compressor, which consumes a lot of power

[0013] 3. The pressure and temperature of methane separated by the above patents are relatively high, which is not conducive to storage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0046] The liquefied natural gas in the first step is raised to 800Pa by the feed pump; the pressure of the demethanizer is 1800Pa;

Embodiment 3

[0048] The liquefied natural gas in the first step is raised to 1200Pa by the feed pump; the pressure of the demethanizer is 2500Pa;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

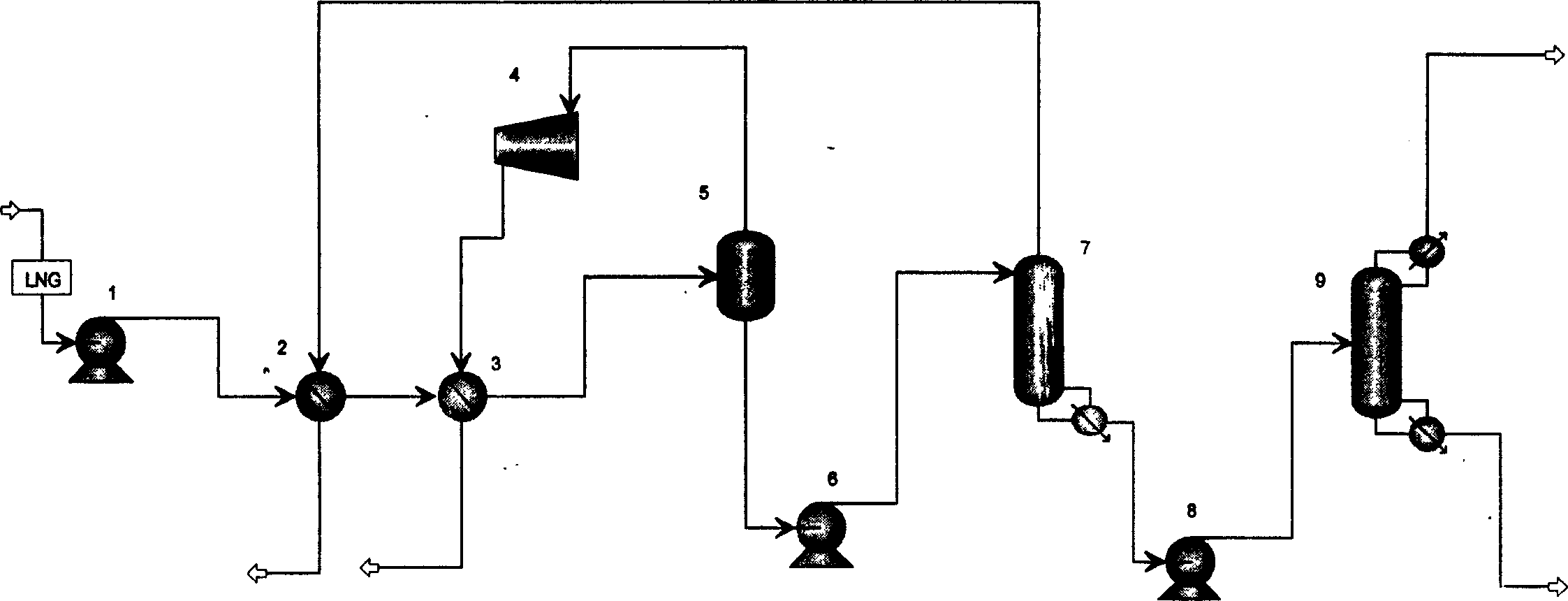

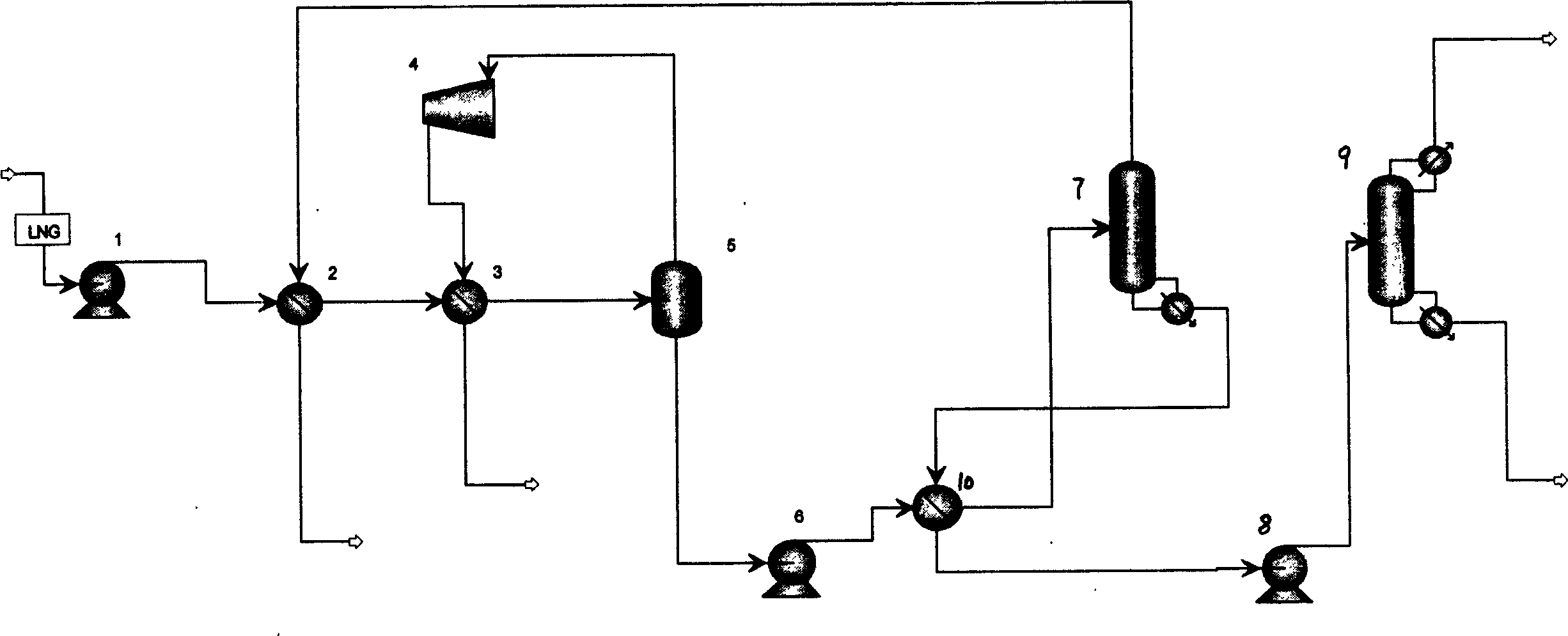

The invention relates a process for the light ends separation of liquefied natural gas, comprising the following steps: preliminary heating the raw material of liquefied natural gas, separating methane and condensing it, demethanizing and making it liquefy, deethanizing and transferring the gas phase ethane to the ethylene cracking unit through pipe line, and finally getting the liquid phase discharging including weight constituent of dimethylmethane and butane. The invention utilizes part refrigerating of LNG, because it is conserved in low-temperature liquid methane after ethane and propane is reclaimed from LNG; only 60% methane gas is needed to be compressed, so the power consumption of compresser is reduced; it is convenient to store liquid methane because its pressure is low. The ethane from said invention is high output, separation flow process is simple, and equipment investment is only a little, running period is long, and operating cost is cheap.

Description

technical field [0001] The invention relates to the technical field of separation and recovery of light hydrocarbons from liquefied natural gas (LNG), in particular to a method for separating light hydrocarbons from liquefied natural gas (LNG). Background technique [0002] In 2004, the Chinese government formulated a new energy strategy with the core of "optimizing structure, improving efficiency, emphasizing environmental protection, ensuring supply, and developing the west", requiring an increase in the proportion of natural gas in energy composition. In the next 15 years, my country's natural gas consumption is expected to increase from 30 billion m 3 / a grows to 220 billion m 3 / a. [0003] Natural gas deposits are mostly associated with oil and condensate, which are separated during extraction. Condensate and liquefied petroleum gas (LPG) are mainly composed of C 3 ~C 6 Hydrocarbons, natural gas is mainly methane, containing about 10% (mol) ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G5/06

Inventor 华贲李亚军杨晓梅熊永强

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com