Method for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as solvent

A technology of dimethylaminobenzoic acid and p-nitrobenzoic acid, which can be used in the preparation of cyanide reaction, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as toxicity, achieve simple process, less use of species, and lightening The effects of dealing with stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

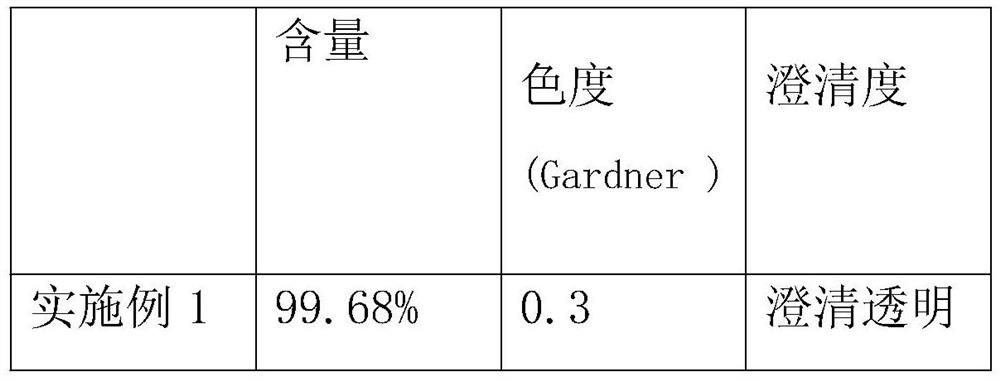

Embodiment 1

[0031] Use water as solvent hydrogenation to prepare the method for isooctyl p-dimethylaminobenzoate, comprising the steps:

[0032] (1) water, isooctyl p-nitrobenzoate and active nickel catalyst are added in proportion to the reactor;

[0033] (2) Heating until hydrogen gas is introduced, heat preservation and pressure keeping and reaction until no hydrogen is absorbed (heating temperature is 85°C, and hydrogen pressure control is 0.5-0.7MPa);

[0034] (3) cooling, adding paraformaldehyde to the reactor, and then adding the catalyst of active nickel in proportion;

[0035] (4) Heating until hydrogen gas is introduced, heat preservation and pressure keeping, until no hydrogen is absorbed (the heating temperature is 85°C, and the hydrogen pressure control is 0.5-0.7MPa);

[0036] (5) Continue heat preservation and pressure holding for 4 hours, terminate the reaction, and take samples for analysis;

[0037] (6) After the catalyst is filtered, the catalyst is recycled, activate...

Embodiment 2-5

[0042] Embodiment 2-5 (following embodiment is used for researching the impact of catalyst usage times on product)

[0043] With the nickel catalyst of Example 1, through reactivation, the specific method of activation is: after adding a certain amount of recovered catalyst into the catalyst washing tank, add an appropriate amount of methanol, stir for 10 minutes at 50-55 ° C, keep the temperature for 20 minutes, put The supernatant is hydraulically fed into the washing liquid temporary storage tank. After washing with methanol for 5 times according to the above method, add an appropriate amount of deionized water, stir at 60-65°C for 10 minutes, let it stand for 20 minutes, pour the supernatant into the washing liquid temporary storage tank, and wash it with water three times according to the above method. After washing, operate according to the catalyst activation procedure. The following table shows the specific practical times and results:

[0044] Table 1 The impact of c...

Embodiment 6

[0046] Embodiment 6 (for researching the impact of one-time hydrogenation on product)

[0047] The preparation method of the nickel catalyst is the same as that of Comparative Document 1.

[0048] Use water as solvent hydrogenation to prepare the method for isooctyl p-dimethylaminobenzoate, comprising the steps:

[0049] (1) Water, isooctyl p-nitrobenzoate, paraformaldehyde and active nickel catalyst are added in proportion to the reactor;

[0050] (2) Heating until hydrogen gas is introduced, heat preservation and pressure keeping and reaction until no hydrogen is absorbed (heating temperature is 80-90°C, hydrogen pressure control is 0.5-0.7MPa);

[0051] (3) Continue to keep warm and pressurized for 4 hours, terminate the reaction, and take samples for analysis;

[0052] (4) After the catalyst is filtered, the catalyst is reclaimed, activated and reused, the stratification is allowed to stand, the water layer is discharged into the sewage system, and the oil layer enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com