Method for continuously synthesizing PPS-OH

A technology for synthesizing hydroxypropanesulfonic acid pyridinium salt and pyridine, which is applied in organic chemistry and other fields, can solve problems such as difficulty in satisfying high-end electroplating customers, cumbersome separation process, and low production efficiency, so as to achieve suitable industrial production, reduce side reactions, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

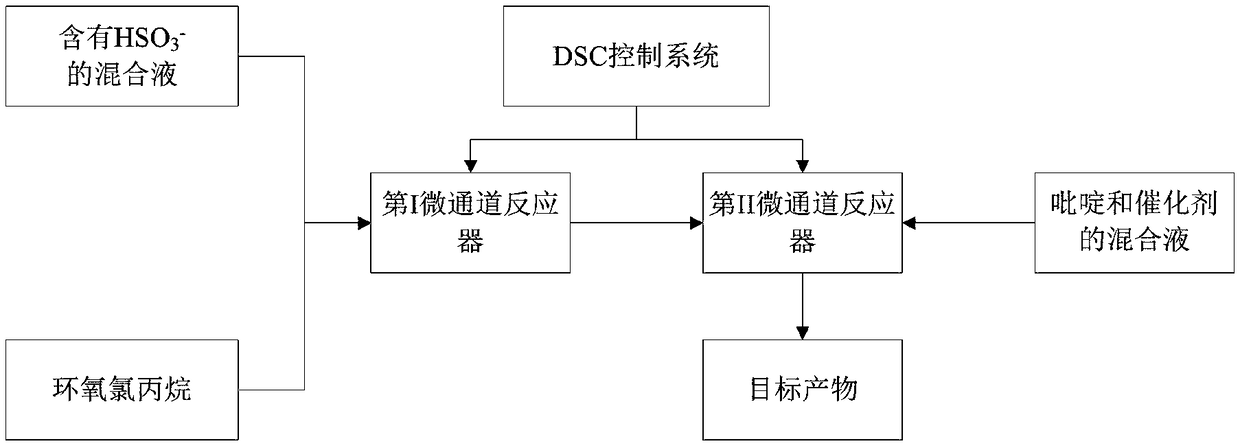

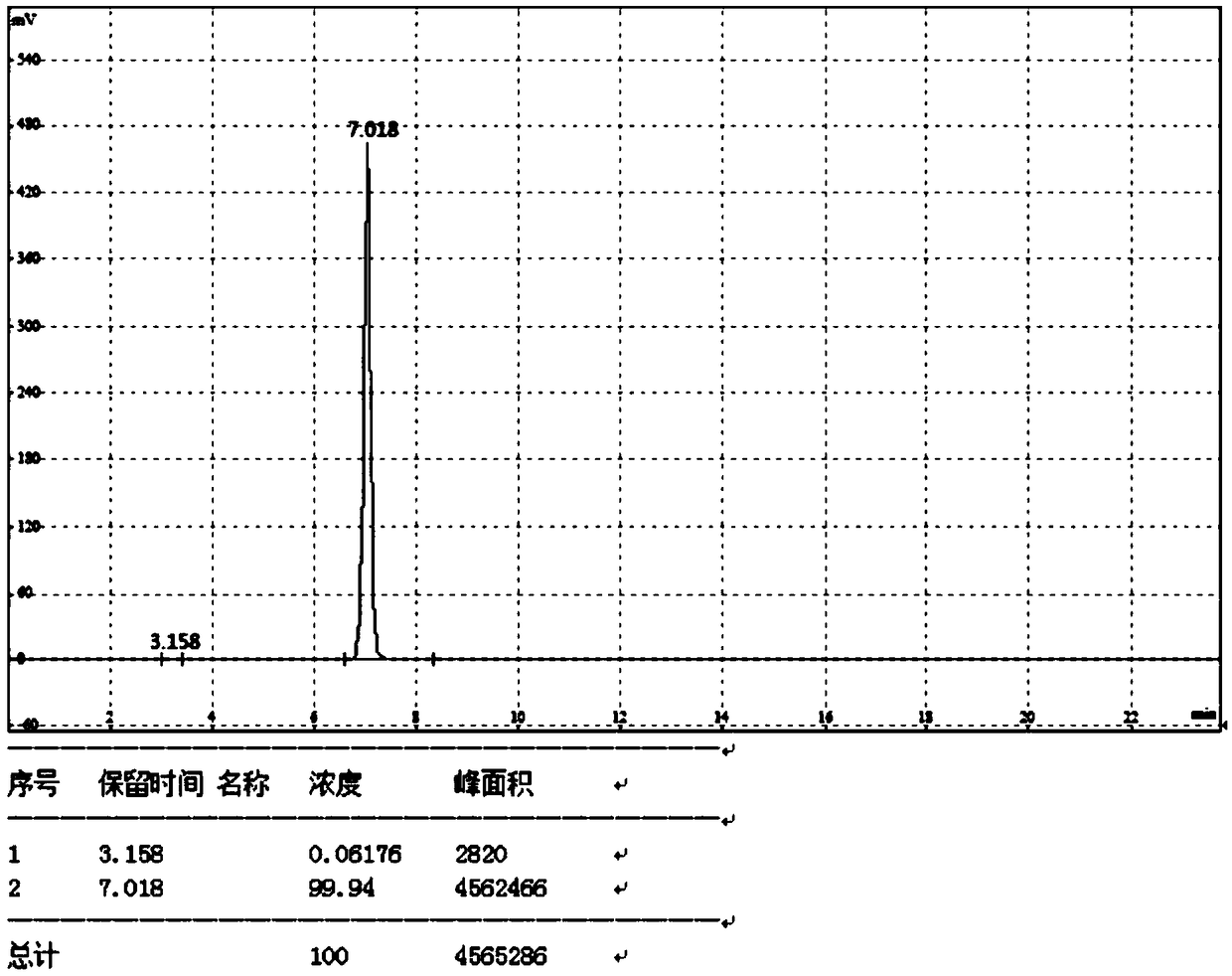

[0030] Dissolve 2000g of sodium metabisulfite in 5450g of deionized water. After it is completely dissolved, add 2g of sodium metabisulfite and 0.2g of tetrabutylammonium bromide to the sodium metabisulfite solution. - The mixed solution enters the metering pump after being filtered through the membrane, and then the mixed solution containing HSO3 - The mixed solution is passed in the 1st microchannel reactor simultaneously with the speed of 100g / min, 1910g epichlorohydrin with the speed of 25.63g / min, the reaction temperature in the 1st microchannel reactor is adjusted to 50 ℃, adjusts After the back pressure valve makes the pressure of the 1st microchannel reactor stabilized at 2MPa, the reaction product in the 1st reaction unit of the microchannel reactor is entered into the 2nd microchannel reactor, simultaneously with the feed rate of 21.76g / min to the 2nd Pass into the mixed solution of 1620g pyridine and 1.62g 1,4,7,13-tetraoxa-10-aza-2,3-benzocyclopentacene-2-ene in II...

Embodiment 2

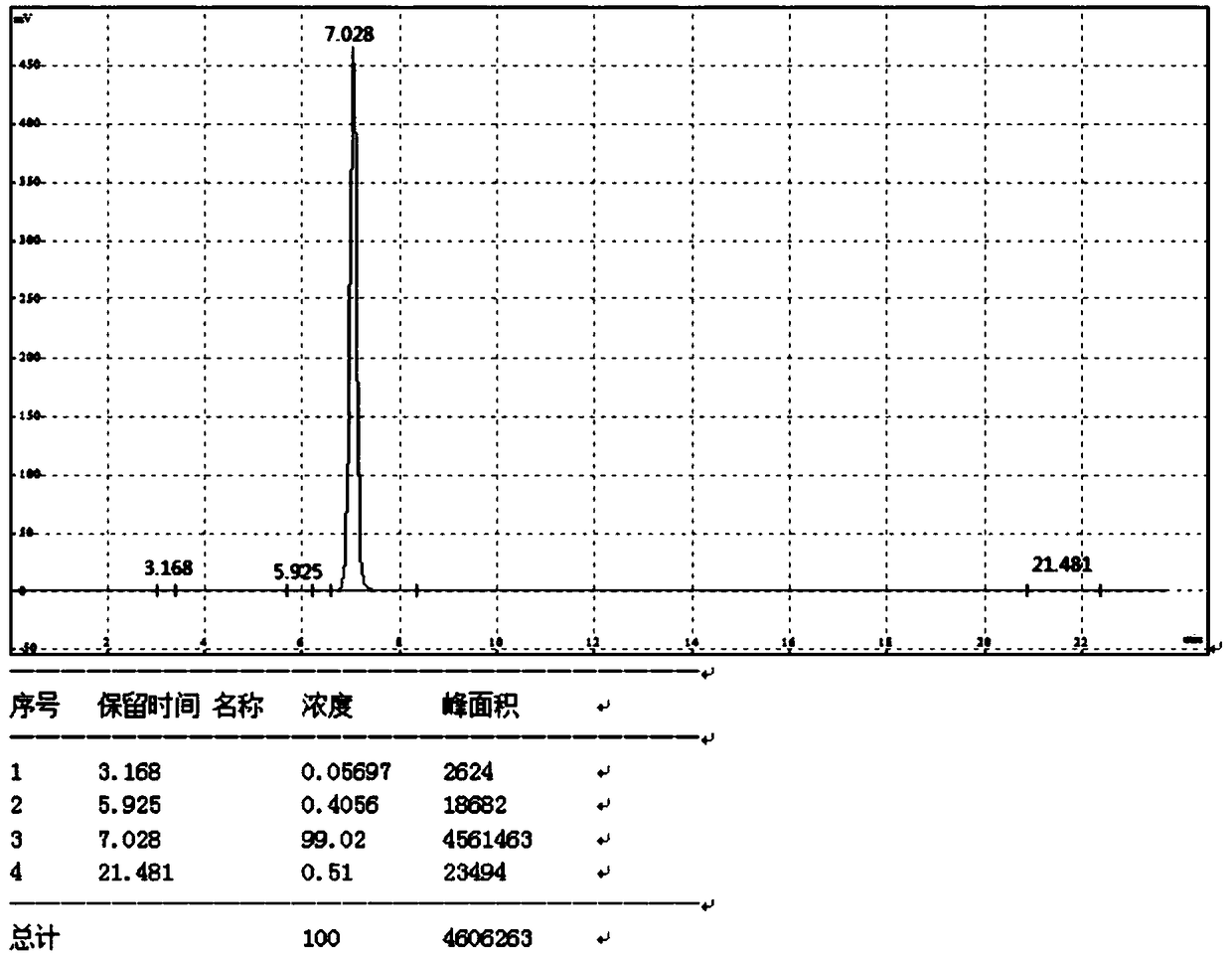

[0033] Dissolve 2000g of sodium metabisulfite in 5450g of deionized water. After it is completely dissolved, add 5g of sodium metabisulfite and 0.4g of tetrabutylammonium bromide to the sodium metabisulfite solution. - The mixed solution enters the metering pump after being filtered through the membrane, and then the mixed solution containing HSO3 -The mixed solution is passed in the 1st microchannel reactor simultaneously with 100g / min speed, 1910g epichlorohydrin with 25.62g / min speed, the reaction temperature in the 1st microchannel reactor is adjusted to 30 ℃, regulates back pressure Valve makes the pressure of the 1st microchannel reactor stabilized at 2.5MPa, makes the reaction product in the 1st microchannel reactor enter the 2nd microchannel reactor, simultaneously with the feeding speed of 21.77g / min to the 2nd microchannel The mixed solution of 1620g pyridine and 3g1,4,7,13-tetraoxa-10-aza-2,3-benzocyclopenta-2-ene is passed into the reactor, and the microchannel rea...

Embodiment 3

[0036] Dissolve 2000g of sodium metabisulfite in 5450g of deionized water. After it is completely dissolved, add 3g of sodium metabisulfite and 0.4g of tetrabutylammonium bromide to the sodium metabisulfite solution. - The mixed solution enters the metering pump after being filtered through the membrane, and then the mixed solution containing HSO3 - The mixed solution is passed in the 1st microchannel reactor with 90g / min speed, 1948g epichlorohydrin simultaneously with 23g / min speed, the reaction temperature in the 1st microchannel reactor is adjusted to 30 ℃, adjusts the back pressure valve After the pressure of the 1st microchannel reactor is stabilized at 2.5MPa, the reaction product in the 1st microchannel reactor is entered into the 2nd microchannel reactor, and simultaneously with the feed rate of 22g / min to the 2nd microchannel reactor Into the mixed solution of 1665g pyridine and 3g 1,4,7,13-tetraoxa-10-aza-2,3-benzocyclopenta-2-ene, the II microchannel reactor The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com