Method for fluorinating pyrimidine derivative by using micro-channel reactor

A technology of microchannel reactor and pyrimidine derivatives, which is applied in the field of fluorination of pyrimidine derivatives, can solve the problems of difficult production process, long route, low yield, etc., achieve high conversion rate and selectivity, simplify the purification process, and produce The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

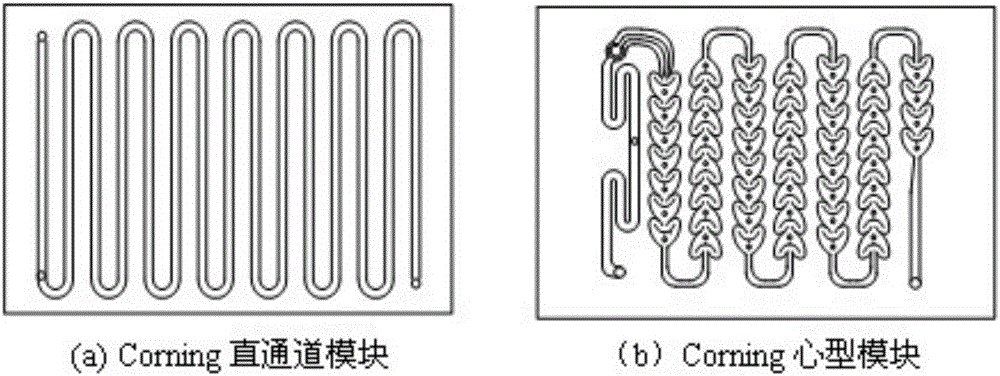

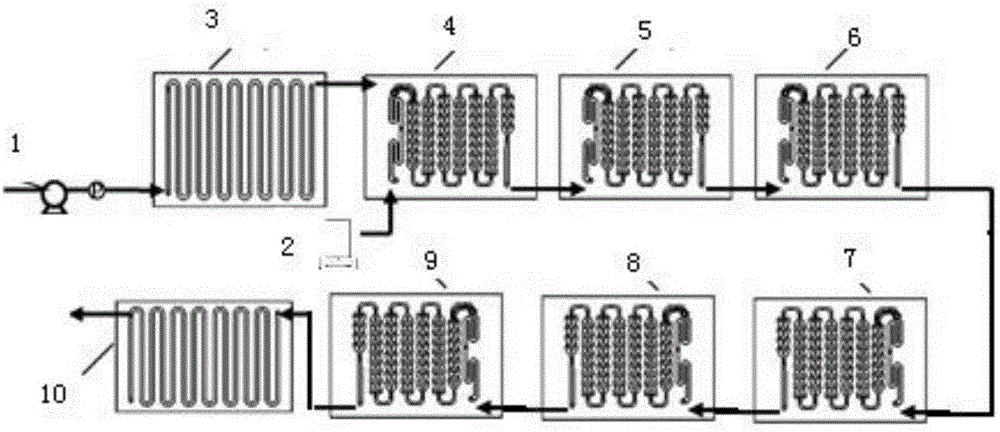

[0029] optional attachment figure 2 1 medium corning straight channel module (as a pre-mixing preheating module), 6 corning "heart-shaped" microchannel reaction modules, 1 corning straight channel module (as a quenching module) and 8 heat transfer modules, according to the attached image 3 The reaction process shown constitutes a continuous flow microchannel reaction system. Heat transfer oil is used as the reaction heat exchange medium. According to the forced heat transfer principle of the microchannel reactor, only two temperature measuring points are set at the reactor inlet and outlet. Before the reaction, the microchannel reaction system and connecting pipelines were dewatered and degreased respectively, and the system and connecting pipelines were passivated with fluorine gas with 5mol% fluorine-nitrogen mixed gas, and the air tightness inspection was carried out at 1.0MPa. by attaching image 3 A liquid-phase pump (such as a diaphragm metering pump) in the microchan...

Embodiment 2

[0033] Use the same Corning microchannel reactor as in Example 1, and follow the same connection and control methods. In this example, the reaction conditions were changed.

[0034] Set the temperature of the heat exchanger to -5°C, which is the reaction temperature. Set the reaction pressure to 0.1MPa. The reaction raw material 2 is a uracil solution, that is, a mixture of uracil and trifluoroacetic acid, the mass concentration of uracil is 7%, and the feed rate is 100 g / min. Raw material 1 is 30mol% fluorine-nitrogen mixed gas, and the feed rate is 4.67L / min. The molar ratio of fluorine gas to uracil is 1:1.

[0035]The reaction raw material 2 uracil solution enters the "heart-shaped" micro-channel reaction module 4 after passing through the micro-channel premixing and preheating module 3, and the fluorine-nitrogen mixed gas directly enters the micro-channel reaction module 4 through the gas mass flow meter, and enters the "heart-shaped" micro-channel reaction module 4 di...

Embodiment 3

[0038] Use the same Corning microchannel reactor as in Example 1, and follow the same connection and control methods. In this example, the reaction conditions were changed.

[0039] Set the heat exchanger temperature to 50°C, which is the reaction temperature. Set the reaction pressure to 0.3MPa. The reaction raw material 2 is a uracil solution, i.e. a mixture of uracil, trifluoroacetic acid and anhydrous hydrofluoric acid, with a mass concentration of uracil of 15%, wherein the mass ratio of trifluoroacetic acid to anhydrous hydrofluoric acid is 3:1, The feed rate of reaction raw material 2 was 30 g / min. Raw material 1 is 20mol% fluorine-nitrogen mixed gas, and the feed rate is 5.4L / min. The molar ratio of fluorine gas to uracil is 1.2:1.

[0040] The reaction raw material 2 uracil solution enters the "heart-shaped" micro-channel reaction module 4 after passing through the micro-channel premixing and preheating module 3, and the fluorine-nitrogen mixed gas directly enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com