Supported Ni-Cu-Cr catalyst and application thereof

A ni-cu-cr, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problems of low polyether amination rate, etc. High ether amination rate, low polyether amination rate and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

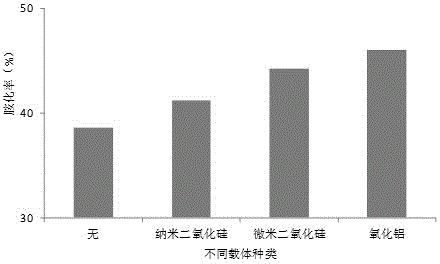

[0038] Example 1

[0039] Weigh the nitrate corresponding to the metal salt (Ni(NO 3 ) 2 , Cu(NO 3 ) 2 , Cr(NO 3 ) 2 ), prepare a 1mol / L mixed solution with deionized water, where n(Ni):n(Cu):n(Cr)=20:5:1; in the same way, configure a 1mol / L alkaline solution as a precipitation agent. Under strong stirring at 60℃, add the metal salt solution dropwise to Na 2 CO 3 In the solution, the catalyst precursor was obtained by aging, washing, suction filtration, and drying in an oven at 105°C for 10 hours. The obtained precursor is uniformly mixed with the carrier M, and the carrier content is controlled to 20%, and then transferred to the muffle furnace through milling and granulation, and calcined with a programmed temperature (10℃ / min) to 330℃ for 2h, and then the calcined catalyst Press the tablet, and finally transfer to the reduction activation device, in the H 2 Under the environment (180℃ reduction 2h, 400℃ reduction 8h, H 2 The flow rate is 80mL / min) for the reduction and activat...

Example Embodiment

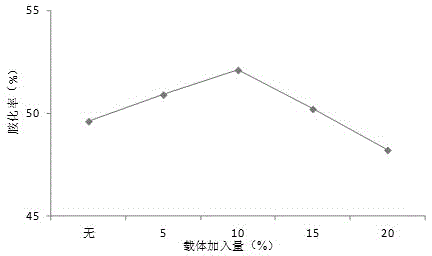

[0048] Example 2

[0049] Preparation of Ni-Cu-Cr catalyst: Weigh the nitrate corresponding to the metal salt (Ni(NO 3 ) 2 , Cu(NO 3 ) 2 , Cr(NO 3 ) 2 ), prepare a 1mol / L mixed solution with deionized water, where n(Ni):n(Cu):n(Cr)=20:5:1; in the same way, configure a 1mol / L alkaline solution as a precipitation agent. Under strong stirring at 60℃, add the metal salt solution dropwise to Na 2 CO 3 In the solution, the catalyst precursor was obtained by aging, washing, suction filtration, and drying in an oven at 105°C for 10 hours. Prepare precursor and carrier γ-Al 2 O 3 Mix uniformly, control the amount of added carrier to be 5%, 10%, 15%, 20% respectively, then transfer to the muffle furnace through milling and granulation, and use the programmed temperature (10°C / min) to roast at 350°C for 2h, and then The calcined catalyst is pressed into tablets, and finally transferred to the reduction activation device. 2 Under the environment (180℃ reduction 2h, 400℃ reduction 8h, H 2 The...

Example Embodiment

[0052] Example 3

[0053] The preparation of the Ni-Cu-Cr catalyst is the same as in Example 2. The Ni-Cu-Cr catalyst has no support added, and Ni-Cu-Cr / Al 2 O 3 When blended γ-Al 2 O 3 The amount of carrier is 10%.

[0054] The performance evaluation of the hydroamination reaction is the same as in Example 1.

[0055] Recycling of the catalyst: the catalyst filtered out in the subsequent treatment of the hydroamination reaction is washed three times with 100 mL ethanol, dried in an oven at 105°C for 10 hours, and then used in the next hydroamination reaction.

[0056] The recycling effect of the catalyst is shown in Table 2. In multiple uses, the catalyst performance after adding the support is better than the sample without adding the support.

[0057] Table 2 Comparative experiments and recycling of catalysts

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com