Immobilized ionic-liquid catalyst and application thereof to synthesizing ester lubricating oil

The technology of ionic liquid and catalyst is applied in the field of immobilized ionic liquid catalyst and in the field of synthetic ester lubricating oil, which can solve the problems of high energy consumption, high cost, large amount of consumption, etc., and achieves high catalyst activity and simple synthesis method. , the effect of speeding up the process of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1-Butanesulfonic acid-3-methylimidazolium bisulfate ([BHSO 3 MIm]HSO 4 )Synthesis

[0027] Step 1. Mix 1 mol of methylimidazole, equimolar 4-butane sultone and 100 mL of acetone in a three-necked flask, 25 o C with mechanical stirring for 3 days. When a white solid is separated out, the reaction temperature is raised to 50 o C, continue to react for 3 days, a large amount of white solid is precipitated, and the white solid obtained by filtering is BMImSO 3 , BMImSO can be crystallized again after distillation 3 , the product was purified by washing with acetone.

[0028] Step 2. Slowly add 1 mol of the above product dropwise to 1.02 mol of concentrated sulfuric acid (98%) under ice-bath stirring conditions to form a liquid product, and evaporate the water in the product to obtain a colorless viscous liquid [BHSO 3 MIm] + [HSO 4 ] - .

Embodiment 2

[0030] Synthesis of 1-butylsulfonic acid-3-methylimidazolium dihydrogen phosphate

[0031] Under the condition of stirring in an ice bath, 1 mol of the product in Step 1 of Example 1 was slowly added dropwise to 1.18 mol of concentrated phosphoric acid (85%) to generate a liquid product, and the water in the product was evaporated to dryness to obtain a colorless viscous liquid [BHSO 3 MIm] + [H 2 PO 4 ] - .

Embodiment 3

[0033] Synthesis of 1-butylsulfonic acid-3-methylimidazole trifluoroacetate

[0034] Under the condition of stirring in an ice bath, 1 mol of the product in Step 1 of Example 1 was slowly added dropwise to an equimolar amount of trifluoroacetic acid to form a solid product, and the water in the product was evaporated to dryness to obtain a white solid [BHSO 3 MIm] + [CF 3 CO 2 ] - .

PUM

| Property | Measurement | Unit |

|---|---|---|

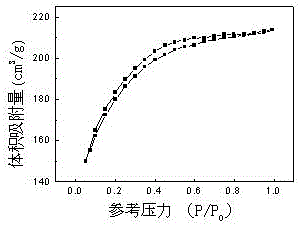

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com