PANI/Go/PAN nanofiber membrane composite potassium air battery negative electrode and preparation method thereof

A nanofiber membrane and air battery technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve negative electrode corrosion failure, easy chemical reaction, discharge termination of potassium-air battery And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

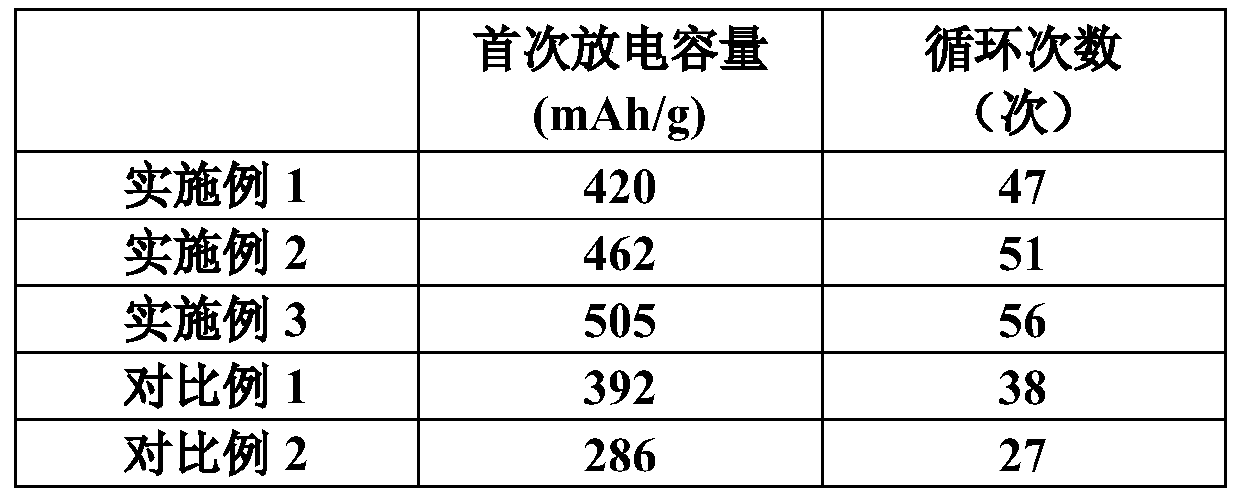

Examples

Embodiment 1

[0026] (1) Preparation of spinning solution

[0027] Add 0.6g polyacrylonitrile (PAN) to the mixed solvent of 1g chloroform and 6.5g N,N-dimethylformamide (DMF), stir at room temperature for 2h to obtain a uniform colloidal liquid, mix 0.1800g aniline and 0.216g After camphorsulfonic acid was added to the colloidal liquid and stirred at room temperature for 2 hours, 0.45 g of ammonium persulfate was added and stirred at room temperature for 30 minutes. into the above solution, and stirred at room temperature for 12 hours to obtain a spinning solution;

[0028] (2) Preparation of PGP film

[0029] A 1mL plastic spray gun head cover is used in a 5mL syringe, and 3mL of spinning solution is injected into the syringe. The receiving device is a wire mesh placed horizontally for electrospinning. The electrospinning parameters are: the spinning voltage is 6kV, and the plastic spray gun The distance between the needle tip and the wire mesh is 12cm, the ambient temperature is 20°C-28...

Embodiment 2

[0035] (1) Preparation of spinning solution

[0036] Add 0.6g polyacrylonitrile (PAN) to the mixed solvent of 1g chloroform and 6.5g N,N-dimethylformamide (DMF), stir at room temperature for 3h to obtain a uniform colloidal liquid, mix 0.1800g aniline and 0.216g After camphorsulfonic acid was added to the colloidal liquid and stirred at room temperature for 3 hours, 0.45 g of ammonium persulfate was added and stirred at room temperature for 60 minutes. into the above solution, and stirred at room temperature for 18 hours to obtain a spinning solution;

[0037] (2) Preparation of PGP film

[0038] A 1mL plastic spray gun head cover is used in a 5mL syringe, and 3mL of spinning solution is injected into the syringe. The receiving device is a wire mesh placed horizontally for electrospinning. The electrospinning parameters are: the spinning voltage is 8kV, and the plastic spray gun The distance between the needle tip and the wire mesh is 10cm, the ambient temperature is 20°C-28...

Embodiment 3

[0044] (1) Preparation of spinning solution

[0045]Add 0.6g polyacrylonitrile (PAN) to the mixed solvent of 1g chloroform and 6.5g N,N-dimethylformamide (DMF), stir at room temperature for 4h to obtain a uniform colloidal liquid, mix 0.1800g aniline and 0.216g After camphorsulfonic acid was added to the colloidal liquid and stirred at room temperature for 4 hours, 0.45 g of ammonium persulfate was added and stirred at room temperature for 60 minutes. into the above solution, and stirred at room temperature for 24 hours to obtain a spinning solution;

[0046] (2) Preparation of PGP film

[0047] A 1mL plastic spray gun head cover is used in a 5mL syringe, and 3mL of spinning solution is injected into the syringe. The receiving device is a wire mesh placed horizontally for electrospinning. The electrospinning parameters are: the spinning voltage is 10kV, and the plastic spray gun The distance between the needle tip and the wire mesh is 18cm, the ambient temperature is 20°C-28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com