Method for separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals

A technology of rare earth elements and rare earth metals, which is applied to the field of separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals, which can solve the problems of high recovery rate of rare earths, generation of waste liquid containing acid or alkali, complex process, etc., to achieve The effect of avoiding pollution, good environmental benefits, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

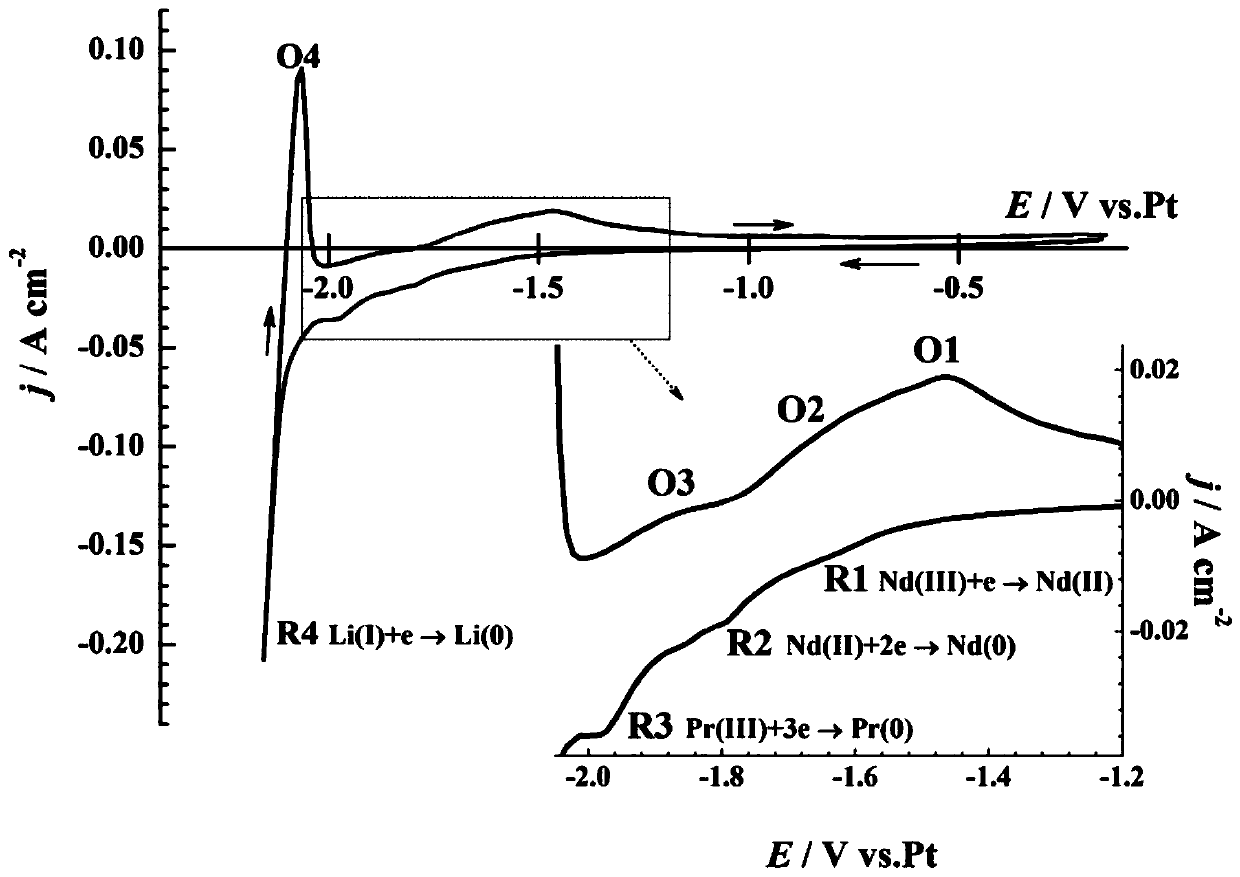

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals, including steps:

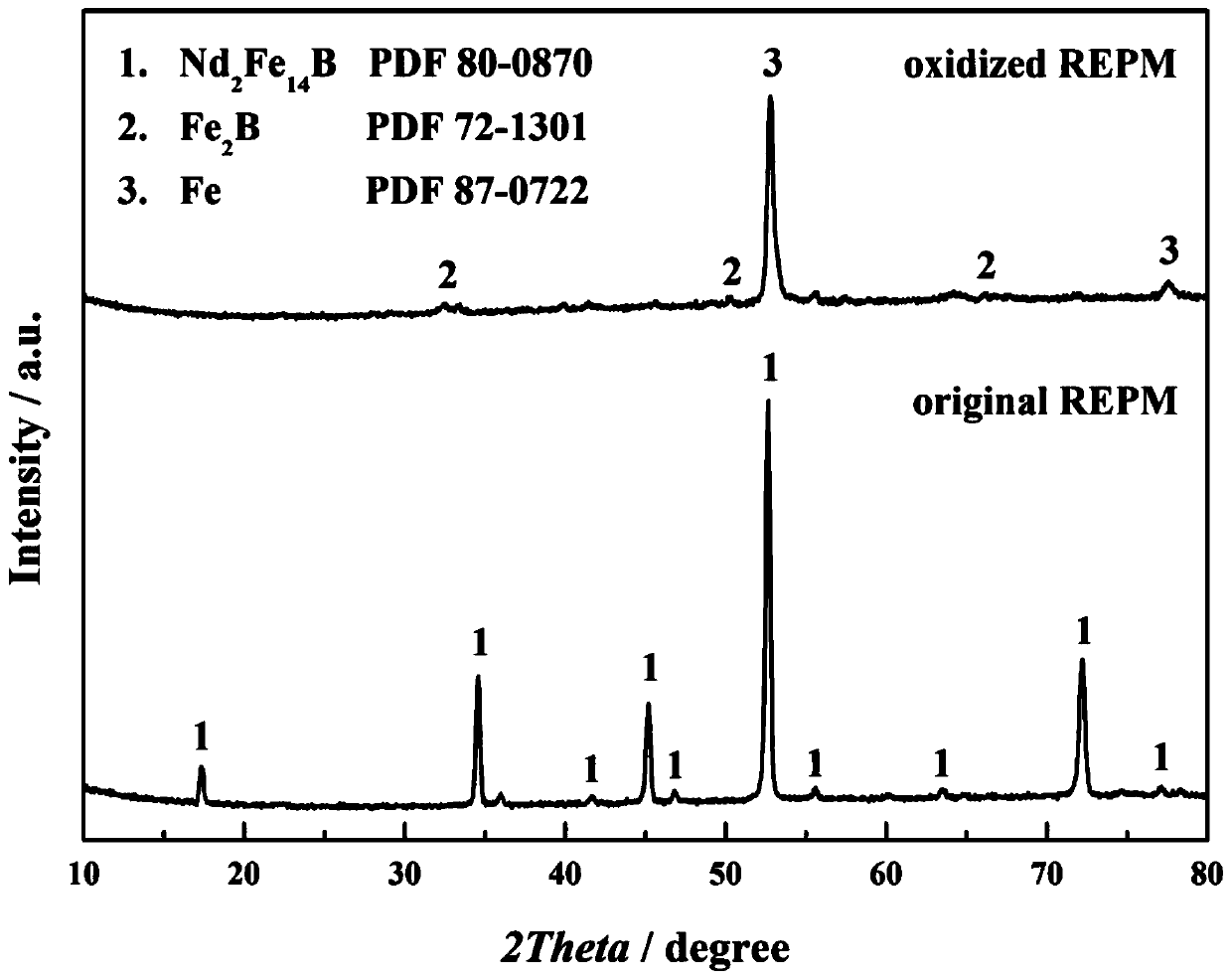

[0033] Cut the NdFeB alloy waste into 10mm×10mm×10mm blocks, place them in the anode basket made of molybdenum wire, and connect the anode basket with the anode of the DC power supply with molybdenum wire; wherein, the inductively coupled plasma spectrometer ( ICP-AES) analyzes the mass fraction of each component in the NdFeB alloy waste to be Nd27.1%, Pr8.1%, Fe63.7% and B1.1%;

[0034] The tungsten wire is used as the cathode, which is connected to the cathode of the DC power supply, and the platinum wire is used as the reference electrode;

[0035] Put LiF in a boron nitride crucible after vacuum drying at 400°C for 24 hours, and then place it in a vacuum electrolysis furnace; control the temperature at 850°C, and after the material in the crucible is melted, conduct electrolysis with direct current; among them, cont...

Embodiment 2

[0041] This embodiment provides a method for separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals, including steps:

[0042] Cut the NdFeB alloy waste into 10mm×10mm×10mm blocks, place them in the anode basket made of molybdenum wire, and connect the anode basket with the anode of the DC power supply with molybdenum wire; wherein, the inductively coupled plasma generation spectrometer ( ICP-AES) analyzes the mass fraction of each component in the NdFeB alloy waste to be Nd27.1%, Pr8.1%, Fe63.7% and B1.1%;

[0043] The tungsten wire is used as the cathode, which is connected to the cathode of the DC power supply, and the platinum wire is used as the reference electrode;

[0044]Put LiF in a boron nitride crucible after vacuum drying at 400°C for 24 hours, and then place it in a vacuum electrolysis furnace; control the temperature at 1100°C, and after the material in the crucible is melted, conduct electrolysis with direct current; among...

Embodiment 3

[0051] This embodiment provides a method for separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals, including steps:

[0052] Cut the NdFeB alloy waste into 10mm×10mm×10mm blocks, place them in the anode basket made of molybdenum wire, and connect the anode basket with the anode of the DC power supply with molybdenum wire; wherein, the inductively coupled plasma generation spectrometer ( ICP-AES) analyzes the mass fraction of each component in the NdFeB alloy waste to be Nd27.1%, Pr8.1%, Fe63.7% and B1.1%;

[0053] The tungsten wire is used as the cathode, which is connected to the cathode of the DC power supply, and the platinum wire is used as the reference electrode;

[0054] Combine LiF and NdF 3 Mix well after vacuum drying at 400°C for 24 hours, where NdF 3 The mass fraction is 80%; the uniformly mixed fluoride (LiF and NdF 3 ) in a boron nitride crucible, and then placed in a vacuum electrolytic furnace; the temperature is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com