Shock absorber piston valve structure

A technology for piston valves and shock absorbers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as complex assembly relationships, cavitation, cavitation, etc., to improve stability and Reliability, reduction of cavitation phenomenon, effects of avoiding empty space phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

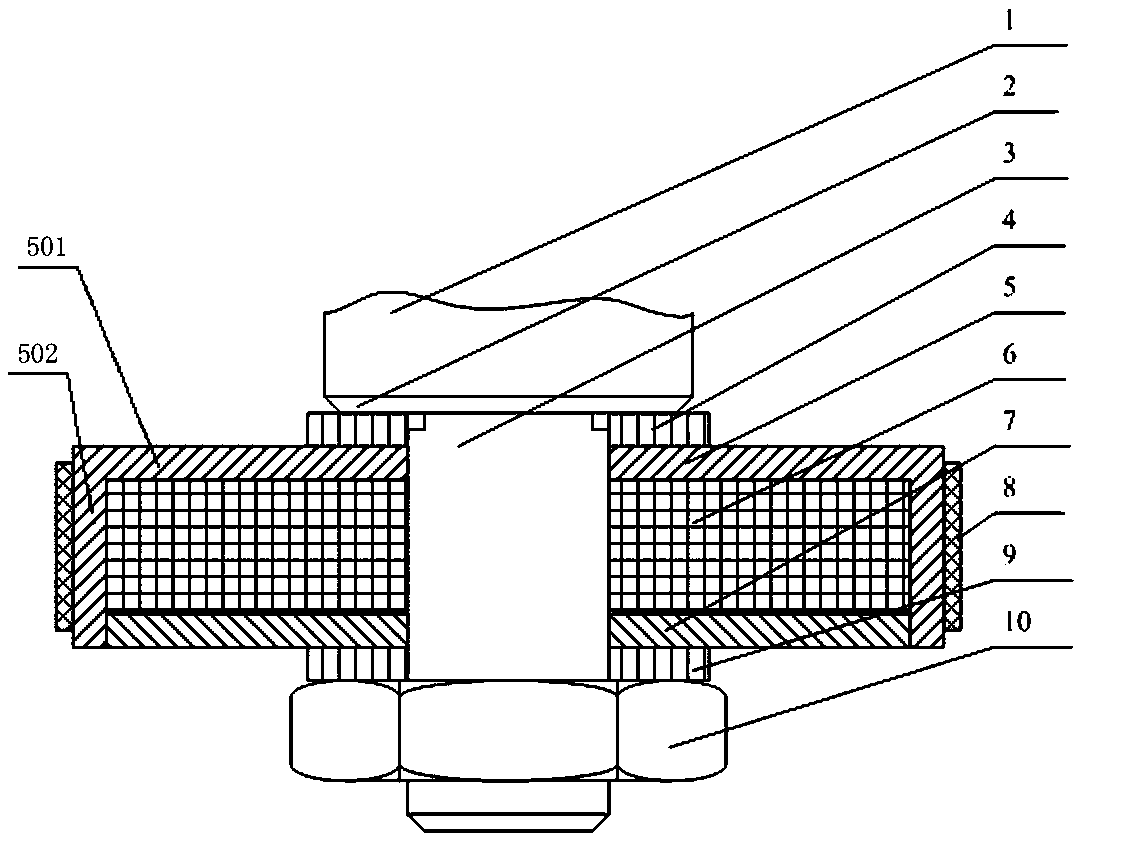

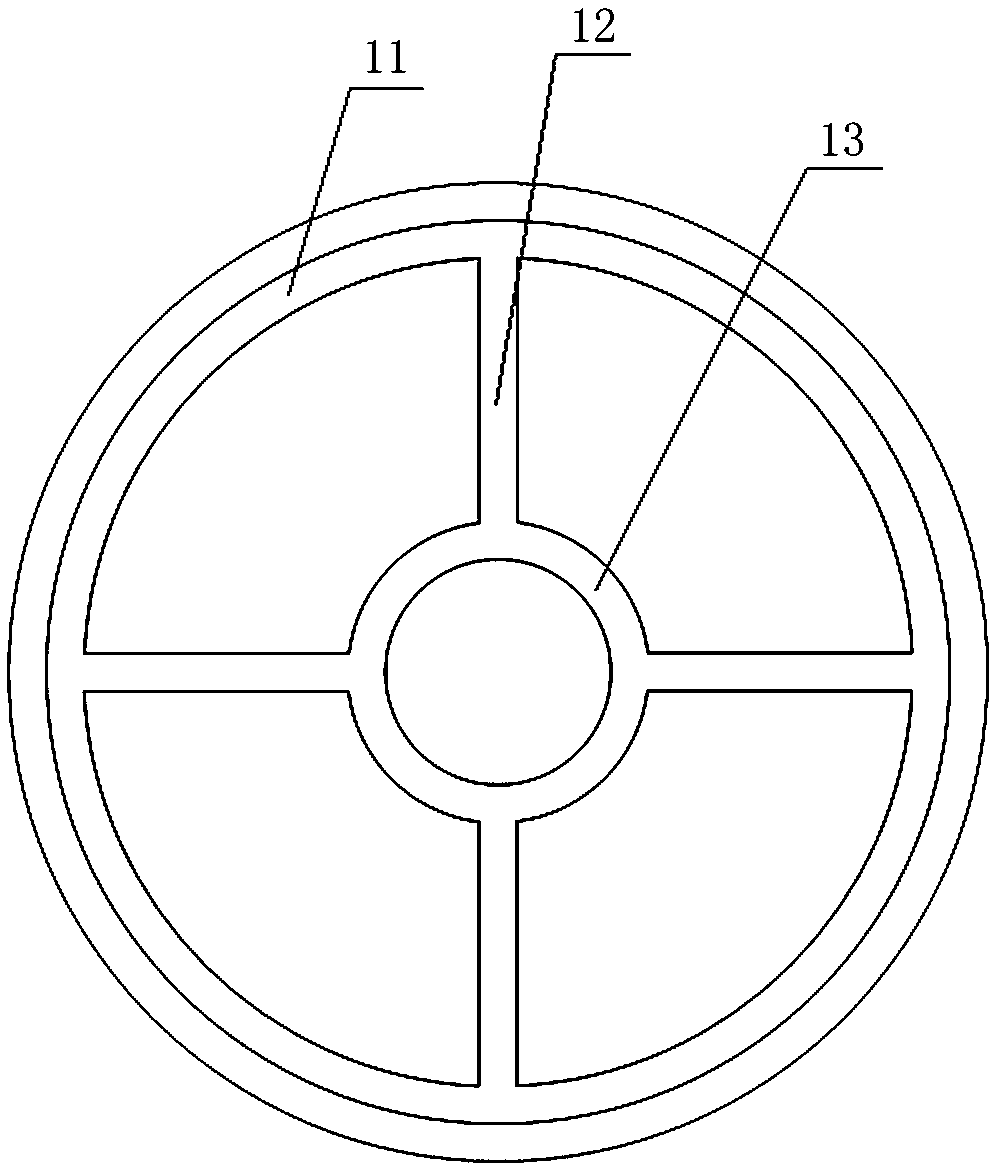

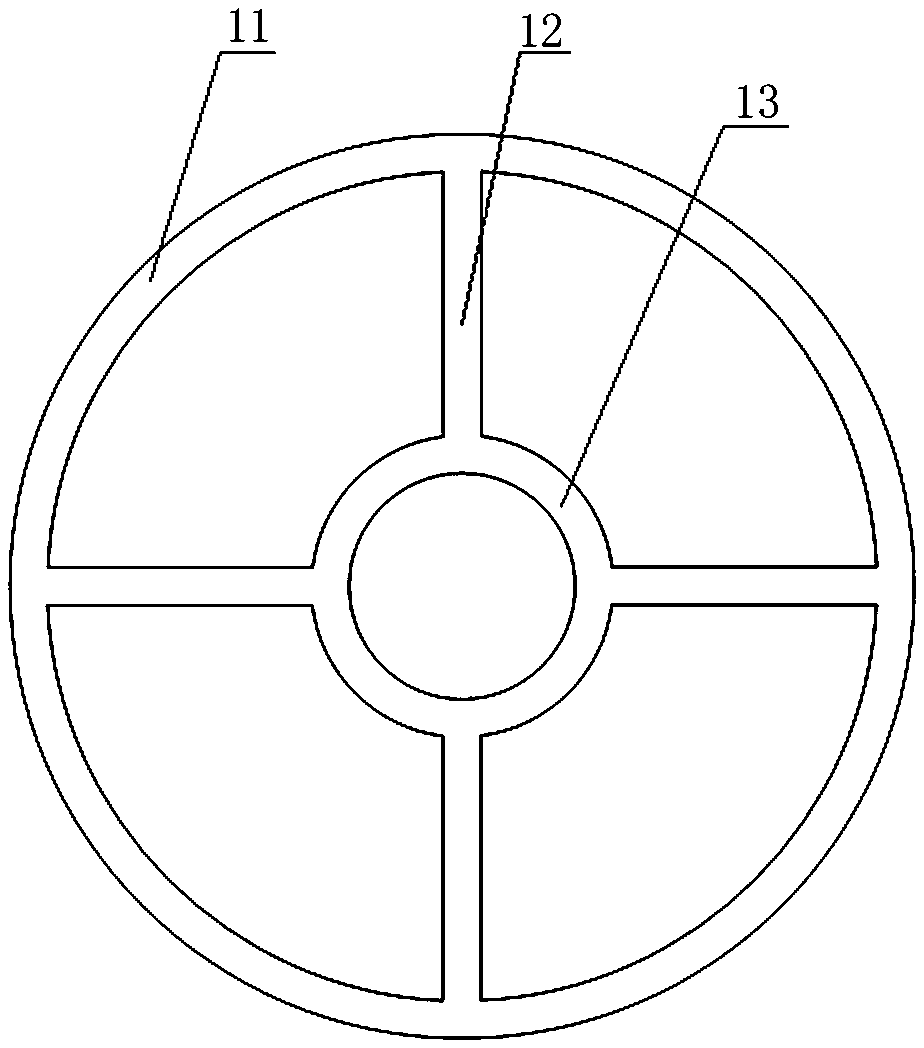

[0019] Such as Figure 1-3 As shown, it is a shock absorber piston valve structure, including a piston rod composed of a coaxial large-diameter section and a journal section. A piston valve is provided on the journal section 1 of the piston rod, and the piston valve includes a sleeve set on The spool 6 on the journal section 3 of the piston rod is made of porous material. The spool 6 is provided with a number of through-holes that communicate with each other, and the oil chambers located above and below the spool 6 can be connected through the through-holes. The valve core 6 is provided with a covering body 5 covering the valve core 6 , and the upper side and the lower side of the covering body 5 are provided with a plurality of through holes axially penetrating through the covering body 5 . The porous material is metal rubber, metal porous material, open foam aluminum or porous ceramic material. The valve core 6 is composited by one or more of the above-mentioned porous mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com