Liquid crystal/polymer composite electric control dimming film and preparation method thereof

A polymer, dimming film technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of single function, limited application, difficult production, etc., and achieve the effect of reducing the driving voltage and the difficulty of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

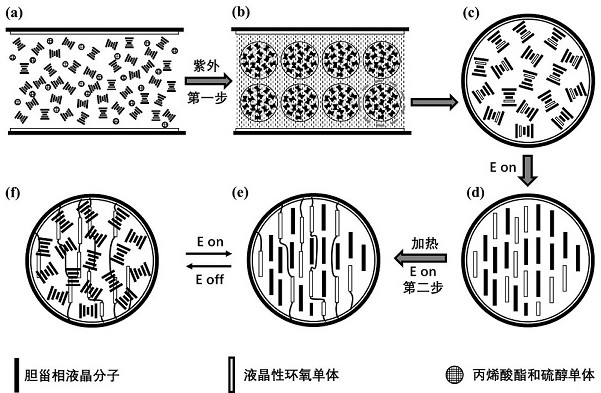

[0074] The present invention also provides a method for preparing a liquid crystal / polymer composite electronically controlled dimming film, the method comprising the following steps:

[0075] 1) Mix the liquid crystal material, the first polymerizable monomer, the second polymerizable monomer, the first initiator, the second initiator, and the spacer particles to obtain a uniform mixture;

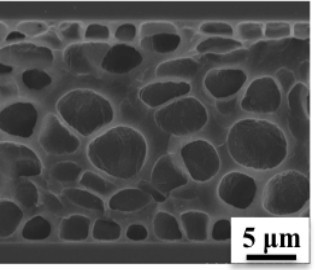

[0076] 2) The above mixture is filled between the two superimposed ITO conductive films to prepare a thin film, and under the condition of light irradiation or heating, the first polymerizable monomer is initiated by the first initiator to undergo photopolymerization or thermal polymerization to form a thin film. Porous microstructured polymer matrix, and the liquid crystal material is dispersed in the polymer matrix in the form of liquid crystal droplets;

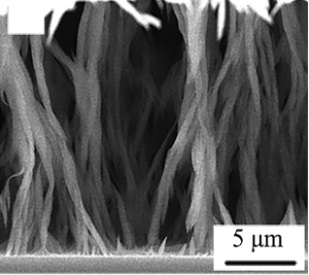

[0077] 3) Apply an electric field to the film to make the liquid crystal material molecules and the second polymerizable monomer mole...

Embodiment 1

[0095] The names and proportions of the selected liquid crystal material, the first polymerizable monomer, the second polymerizable monomer, the first initiator, the second initiator, and the spacer particles are listed in Table 1, and the total mass of the mixture is 15 g; 1. The materials are stirred at room temperature to form an isotropic liquid, mixed evenly, sandwiched between two ITO conductive plastic films plated with indium tin oxide, the size of the ITO conductive plastic film is 0.4*0.4 m², and the film is formed by rolling evenly; The film was irradiated with ultraviolet light with a wavelength of 365 nm at room temperature, and the ultraviolet light intensity was 5.0 mw / cm 2 , the irradiation time was 10 min, and the first polymerization (photopolymerization) was carried out. Subsequently, a voltage of 50 Hz and 100 V was applied to the film, and then the film was placed in a 70° C. oven for 5 hours for the second polymerization (thermal polymerization) to obtain...

Embodiment 2

[0100] The names and proportions of the selected liquid crystal material, the first polymerizable monomer, the second polymerizable monomer, the first initiator, the second initiator, and the spacer particles are listed in Table 2, and the total mass of the mixture is 15 g. The raw materials in Table 2 were stirred at room temperature (25 °C) to form an isotropic liquid, mixed evenly, and sandwiched between two ITO conductive plastic films plated with indium tin oxide. The size of the ITO conductive plastic film was 0.4*0.4 m². Roll evenly to form a film; at room temperature (25 °C), the film is irradiated with ultraviolet light with a wavelength of 365 nm, and the ultraviolet light intensity is 5.0 mw / cm 2 , the irradiation time was 3-5 min, and the first polymerization (photopolymerization) was carried out; then a voltage of 1000 Hz 100 V was applied to the film, and then at 25 °C, ultraviolet light with a wavelength of 254 nm was used for irradiation, UV light intensity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com