Preparation method of PET with light scattering porous micro-foaming structure and diffusion film

A micro-foaming and light-scattering technology, applied in optics, optical components, diffusing components, etc., can solve problems such as unfavorable scattering, complicated manufacturing, friction and warping, etc., and achieve the effect of improving uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

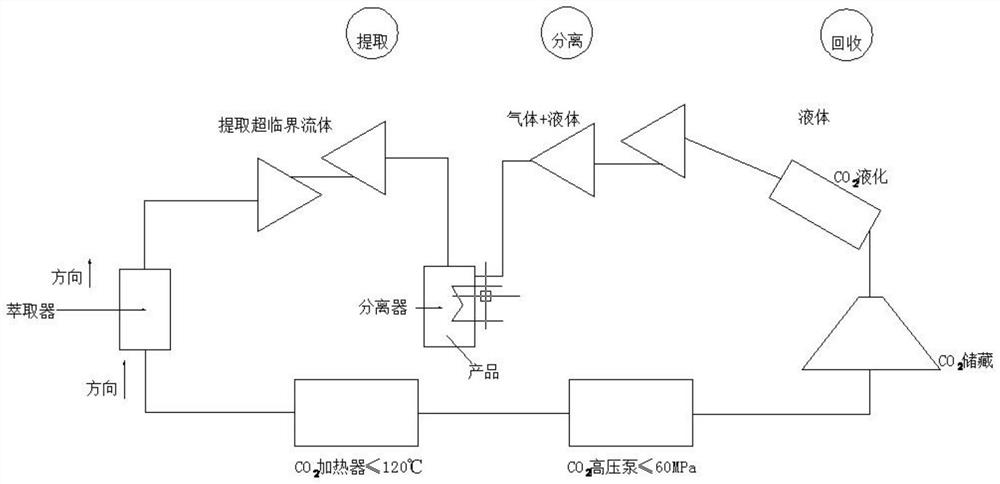

[0049] The preparation method of the light-scattering porous micro-foam structure PET is realized by a pressure transition method.

[0050] Using CO 2 The supercritical gas dissolves into the PET material, and after a period of saturation, the CO 2Mix evenly with PET to become a homogeneous system, through phase separation technology, realize CO 2 nucleation, followed by decompression to prevent bubble growth

[0051] Specifically, the production of porous and micro-foamed PET is realized by adjusting the foaming pressure, foaming temperature, saturation time and pressure relief.

[0052] The foaming pressure is: 40MPa-50MPa, the foaming temperature is: 60°C-100°C, the saturation time is 0.5min-2min, and the pressure relief method is rapid pressure relief, which is divided into two stages:

[0053] First stage rapid depressurization from initial pressure down to CO 2 Critical pressure, the critical pressure is: 7.38MPa, CO 2 The density of supercritical gas is: 0.448g / cm ...

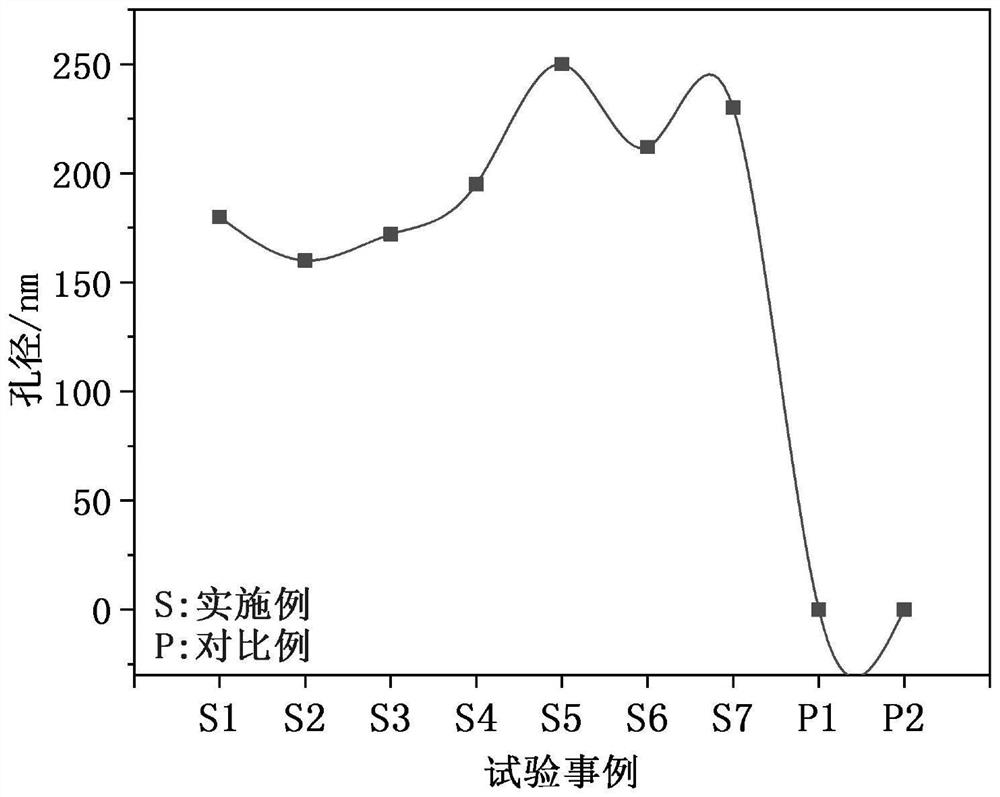

Embodiment 1

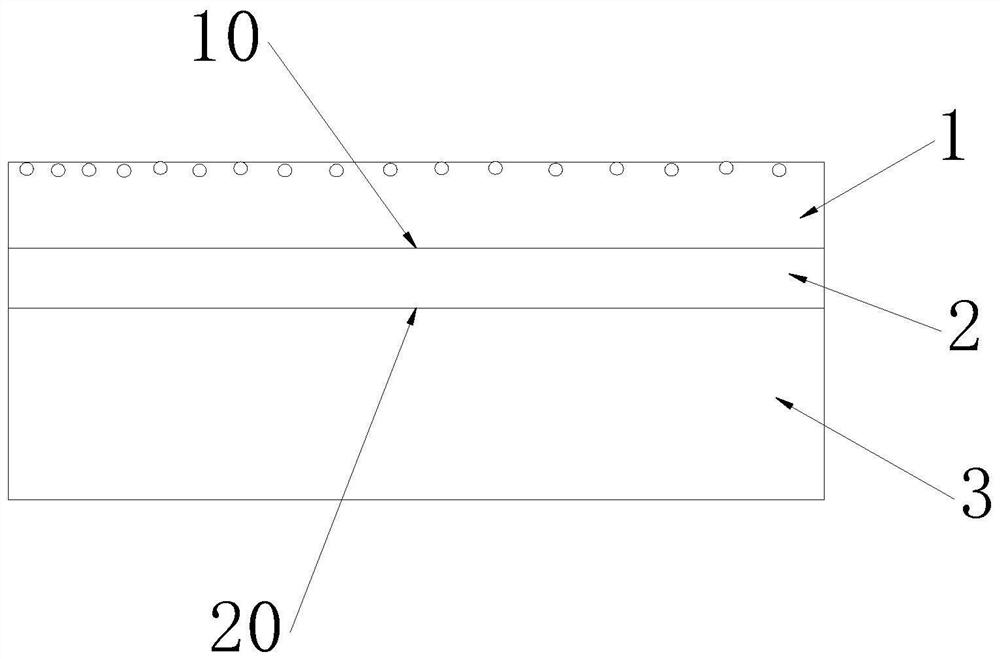

[0057] A method for preparing a warp-controllable and non-scattering particle diffusion film, the preparation method comprising the following steps:

[0058] S1: Light-scattering porous micro-foamed PET is prepared by the following steps: 2 Foaming device preparation, foaming pressure 40MPa, foaming temperature 60°C, foaming time 0.5min, the first stage of pressure relief takes 1s, the second stage of pressure relief takes 5s to obtain a diffusion layer 1, the thickness of which accounts for the total membrane material 10% of the thickness, that is, the foamed microstructure PET diffusion layer 1 .

[0059] S2: Unwind 10 parts of the diffusion layer 1 onto 55 parts of the film core layer 2, the intermediate substrate PET includes the first optical surface and the second optical surface, and after drying, it is rolled to obtain a semi-finished product containing a front coating .

[0060] S3: the back coating of the diffusion film is to unwind the front coating semi-finished ...

Embodiment 2

[0063] A method for preparing a warp-controllable and non-scattering particle diffusion film, the preparation method comprising the following steps:

[0064] S1: Light-scattering porous micro-foamed PET is prepared by the following steps: 2 Foaming device preparation, foaming pressure 50MPa, foaming temperature 80°C, foaming time 1min, the first stage of pressure relief takes 2s, and the second stage of pressure relief takes 10s to obtain a diffusion layer 1, the thickness of which accounts for the total membrane thickness 10%, that is, the foamed microstructure PET diffusion layer 1.

[0065] S2: Unwind 10 parts of the diffusion layer 1 onto 55 parts of the film core layer 2, the intermediate substrate PET includes the first optical surface and the second optical surface, and after drying, it is rolled to obtain a semi-finished product containing a front coating .

[0066] S3: the back coating of the diffusion film is to unwind the front coating semi-finished product prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com