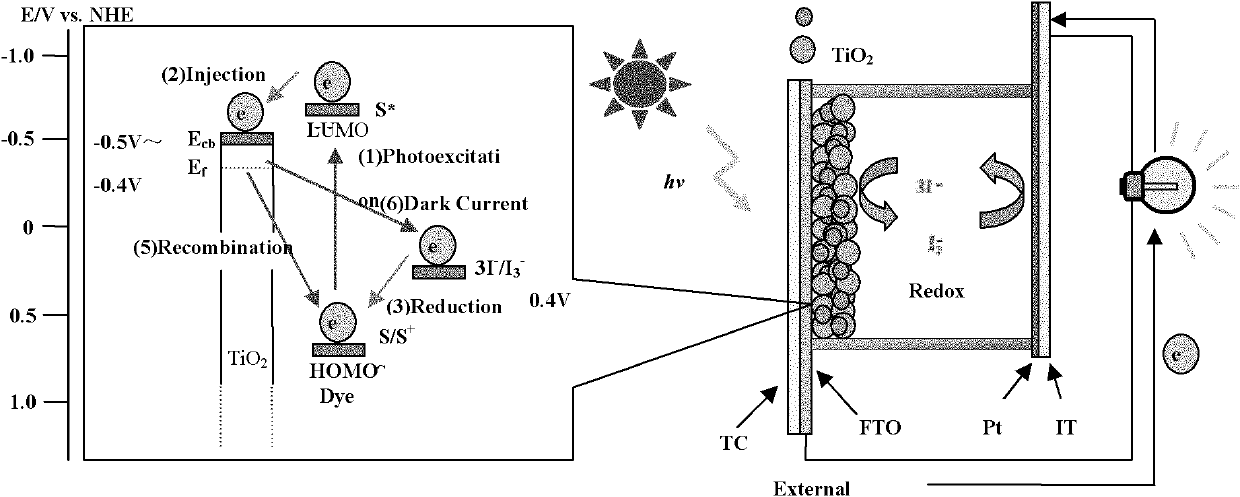

Dye-sensitized externally loaded TiO2/(PPA-Pt) surf. film electrode and preparation process thereof

A thin-film electrode and dye sensitization technology, which is applied in photosensitive equipment, capacitor electrodes, sustainable manufacturing/processing, etc., can solve the problems of high cost of monocrystalline silicon solar cells, difficulties in large-scale production and application, and low conversion efficiency of polycrystalline silicon solar cells. problem, to achieve the effect of solving long-term effects and light utilization, easy industrial production, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

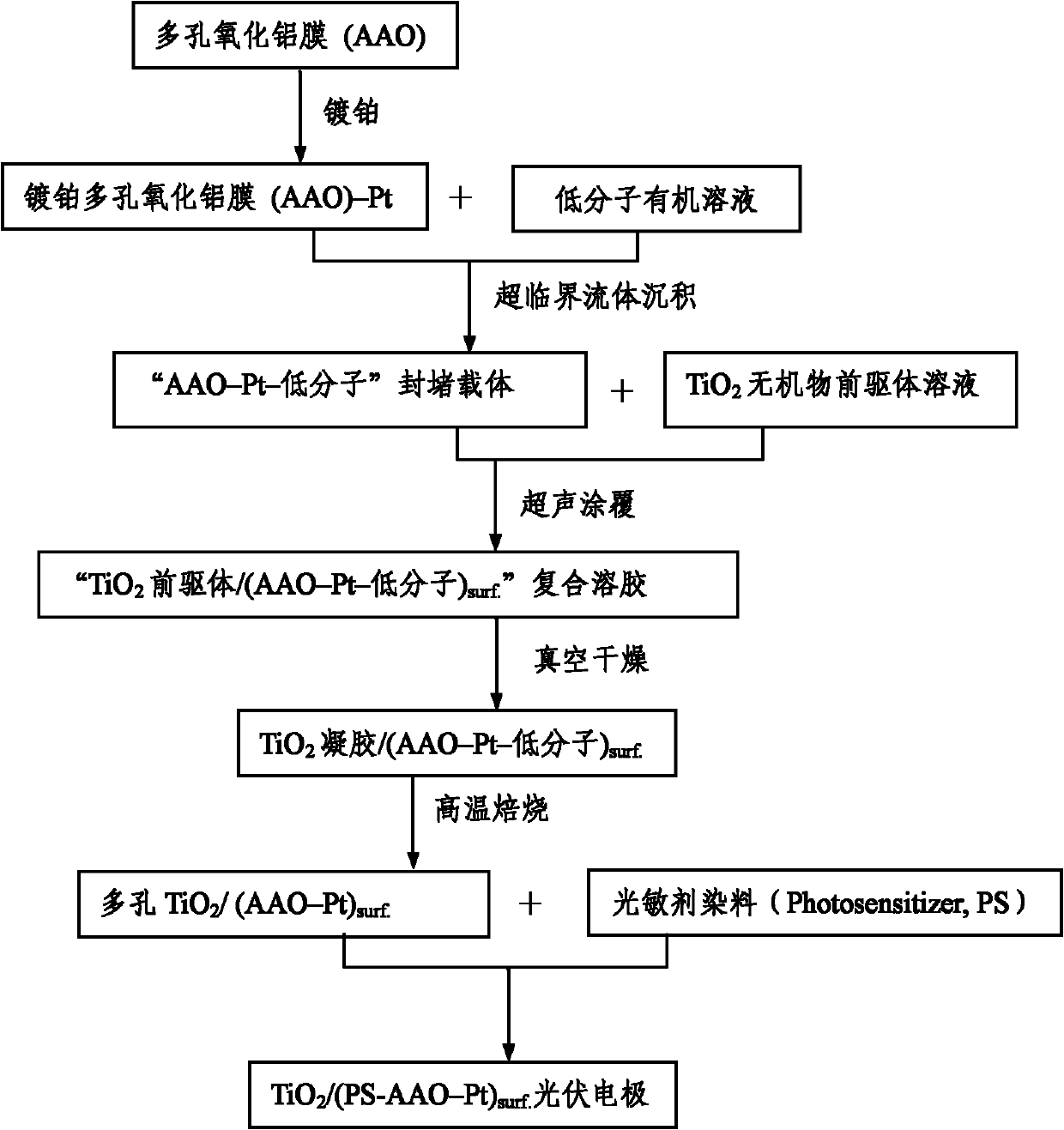

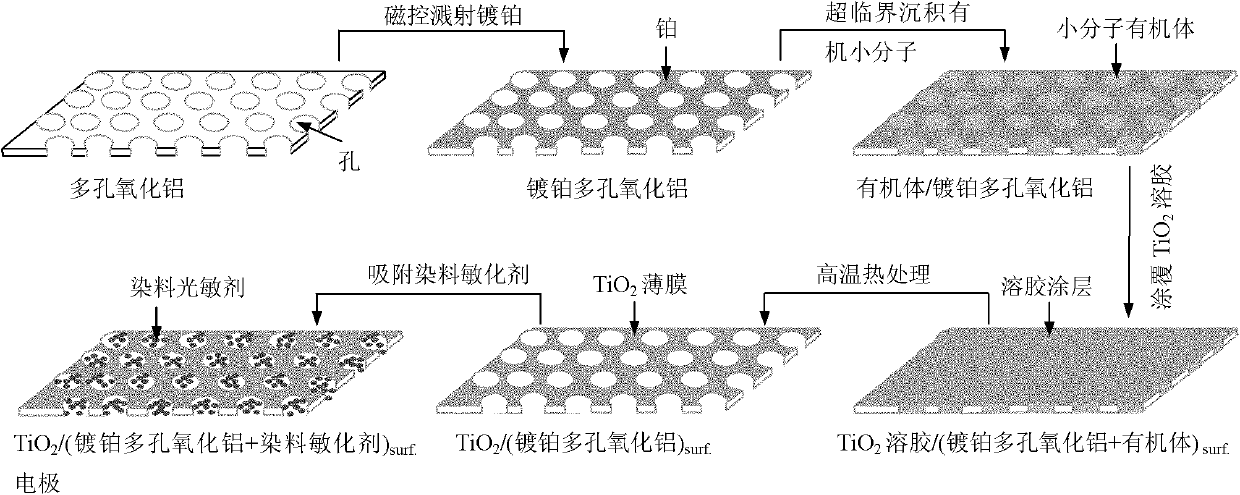

Embodiment 1

[0044] Embodiment 1: at first 0.5g platinum-plated porous alumina (PPA-Pt) is put into the shelf in the supercritical still, and isobutanol 20ml is arranged in the autoclave, is warming up to 100 ℃ according to heating rate 2 ℃ / min, and pressure is After 9MPa, keep it for 2h; then cool the supercritical tank to room temperature to obtain the low molecular weight-PPA-Pt plugged carrier. In addition, using the sol-gel method, mix 60g of butyl titanate with a purity of 99.0%, 3g of diethanolamine and 10g of absolute ethanol, add them into a three-necked flask, and use a GS122 electronic constant speed stirrer to stir evenly. Mix 20 g of absolute ethanol with 4 g of distilled water, and then slowly drop them into the three-necked flask through a separatory funnel. Butyl titanate forms TiO through hydrolysis and condensation reactions 2 Sol. Second, put the obtained low-molecular-PPA-Pt plugging support into TiO 2 In the body of the sol, it is coated on the surface of the pluggi...

Embodiment 2

[0045] Example 2: Using the sol-gel method, after mixing 60g of butyl titanate with a purity of 99.0%, 3g of diethanolamine, 10g of absolute ethanol and 2g of ferric nitrate, they were added to a three-necked flask, and a GS122 electronic constant velocity was used to Blend with a mixer. Mix 20 g of absolute ethanol with 4 g of distilled water, and then slowly drop them into the three-necked flask through a separatory funnel. Butyl titanate forms TiO through hydrolysis and condensation reactions 2 Sol, and secondly, put the obtained low-molecular-PPA-Pt plugging support into TiO 2 In the body of the sol, it is coated on the surface of the plugging carrier during the ultrasonic vibration process, the coating frequency is 1 time, and the ultrasonic time is 10 minutes. Finally TiO 2 Precursor / (low molecular weight-PPA-Pt) surf. Carry out heat treatment at a temperature of 100° C. for 3 hours, and a heating rate of 0.5° C. / min; then perform roasting under nitrogen protection a...

Embodiment 3

[0046] Example 3: Using the sol-gel method, 60 g of butyl titanate with a purity of 99.0%, 3 g of diethanolamine and 10 g of absolute ethanol were mixed, then added to a three-necked flask, and stirred evenly with a GS122 electronic constant speed stirrer. Mix 20 g of absolute ethanol with 10 g of distilled water, and then slowly drop them into a three-necked flask through a separatory funnel. Butyl titanate forms TiO through hydrolysis and condensation reactions 2 Sol, and secondly, put the obtained low-molecular-PPA-Pt plugging support into TiO 2 In the body of the sol, it is coated on the surface of the plugging carrier during the ultrasonic vibration process, the coating frequency is 1 time, and the ultrasonic time is 10 minutes. Finally TiO 2 X Precursor / (Low Molecular-PPA-Pt) surf. Carry out heat treatment at a temperature of 150° C. for 2 hours and a heating rate of 1° C. / min; then roast under nitrogen protection at a temperature of 300° C. for 3 hours. Its crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com