Preparation method of graphene/polyethylenedioxythiophene composite fiber assembly body

A technology of ethylenedioxythiophene and composite fibers, applied in the field of materials, can solve the problems that conventional materials cannot meet people's needs, and achieve the effects of short production cycle, convenient operation and improved diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

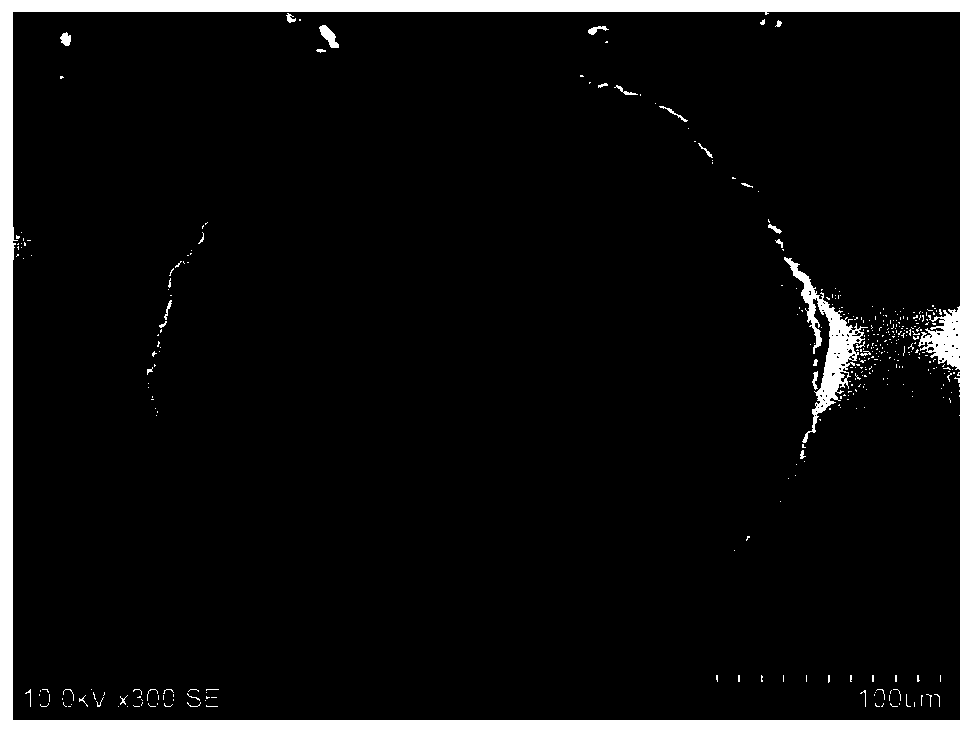

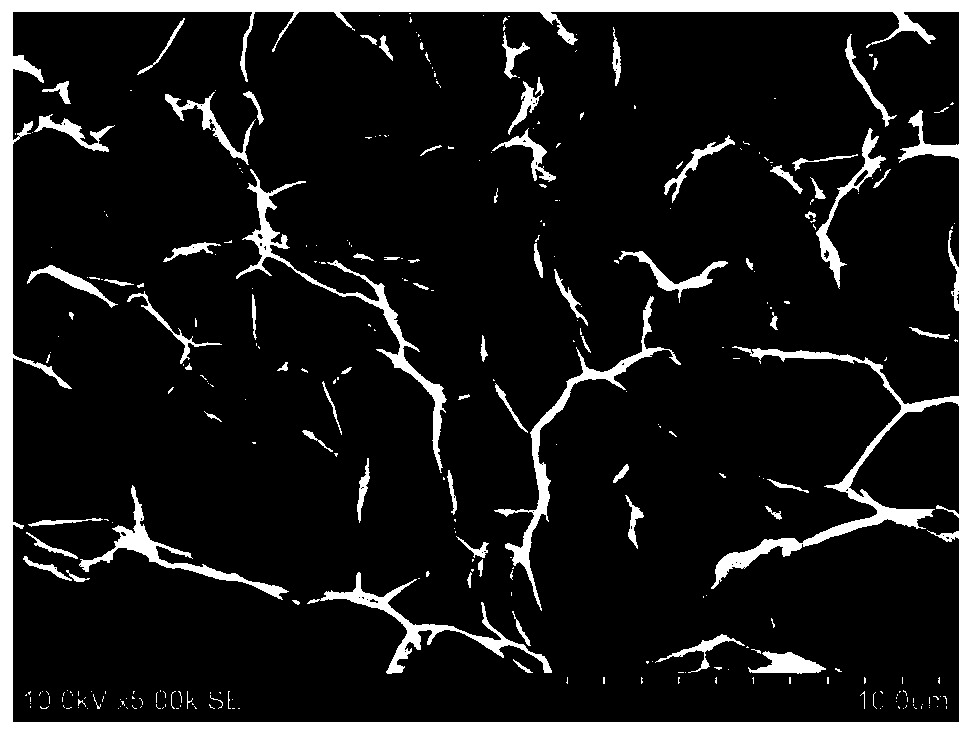

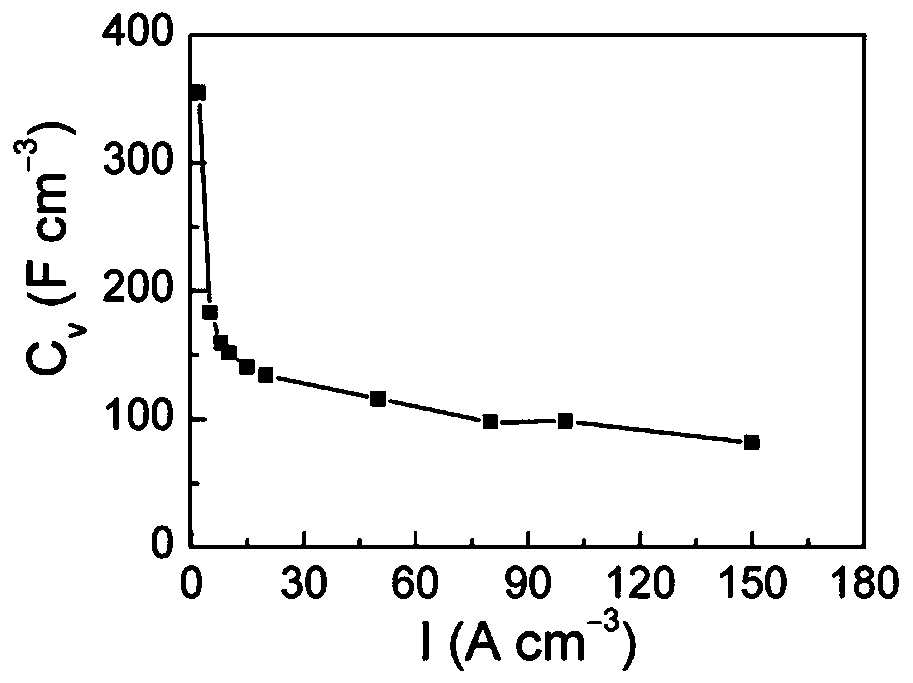

[0027] (1) Preparation of graphene precursor: using 325 mesh graphite powder as raw material, graphene oxide was prepared according to the Hummers method. Add 10.0mL hydrogen peroxide (30.0%) to 100.0mL 2.0mg / ml graphene oxide aqueous solution, stir vigorously, and react at 100.0°C for 4.0h to obtain graphene oxide nanosieve; (2) graphene / polyethylenedioxythiophene Preparation of (PEDOT) composite fiber assembly: uniformly mix graphene oxide nanosieve, PEDOT:PSS and sodium ascorbate, wherein the concentration of graphene oxide is 3.0mg / mL, the mass ratio of graphene oxide to PEDOT:PSS, sodium ascorbate All are 1:1. Add 150.0uL of 1.0M sulfuric acid to 2.0mL of the above mixture, shake vigorously until the solution gels, use a vacuum pump to remove air bubbles, inject the gelled mixture into the capillary, and conduct a hydrothermal reaction at 90.0°C for 3.0h. Cool to room temperature, take out the graphene / PEDOT:PSS gel fiber, soak with concentrated sulfuric acid to remove m...

Embodiment 2

[0030](1) Graphene precursor preparation: with 12000 order graphite powders as raw material, according to the Hummers method, the graphene oxide of high oxidation, small size (1.0-2.0 μm) is obtained; (2) Graphene / polyethylenedioxythiophene ( Preparation of PEDOT) composite fiber assembly: the above-mentioned small-sized high graphene oxide and PEDOT:PSS were uniformly mixed, wherein the concentration of graphene oxide was 9.0 mg / mL, and the mass ratio of graphene oxide to PEDOT:PSS was 2:1. Add 100.0uL of 2.0M sulfuric acid to 2.0mL of the above mixture, shake vigorously until the solution gels, use a vacuum pump to remove air bubbles, inject the gelled mixture into a capillary, and conduct a hydrothermal reaction at 100.0°C for 6.0h. Cool to room temperature, take out the graphene oxide / PEDOT:PSS gel fiber; soak with concentrated sulfuric acid to remove most of the PSS, then wash with deionized water to obtain the graphene oxide / PEDOT gel fiber; soak the obtained composite fi...

Embodiment 3

[0033] (1) Preparation of graphene precursor: using 325 mesh graphite powder as raw material, graphene oxide was prepared according to the Hummers method, and a small size (1.0-2.0 μm) graphene oxide was obtained by ultrasonication for 15.0 minutes using a cell pulverizer; (2) Graphite Preparation of ene / polyethylenedioxythiophene (PEDOT) composite fiber assembly: uniformly mix the above-mentioned small-sized graphene and PEDOT:PSS, wherein the concentration of graphene oxide is 8.0mg / mL, and the concentration of graphene oxide and PEDOT:PSS The mass ratio is 1:2. Add 350.0uL of 0.5M sulfuric acid to 2.0mL of the above mixture, shake vigorously until the solution gels, use a vacuum pump to remove air bubbles, inject the gelled mixture into the capillary, and conduct a hydrothermal reaction at 70.0°C for 5.0h. Cool to room temperature, take out graphene oxide / PEDOT:PSS gel fiber; Soak with concentrated sulfuric acid to remove most of PSS, wash with deionized water again, obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com