Verification device and method for simulating concrete slump form by discrete elements

A verification device and verification method technology, applied in measurement devices, material inspection products, instruments, etc., can solve problems such as lack of devices and methods, and achieve the effect of reasonable quantitative evaluation indicators and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

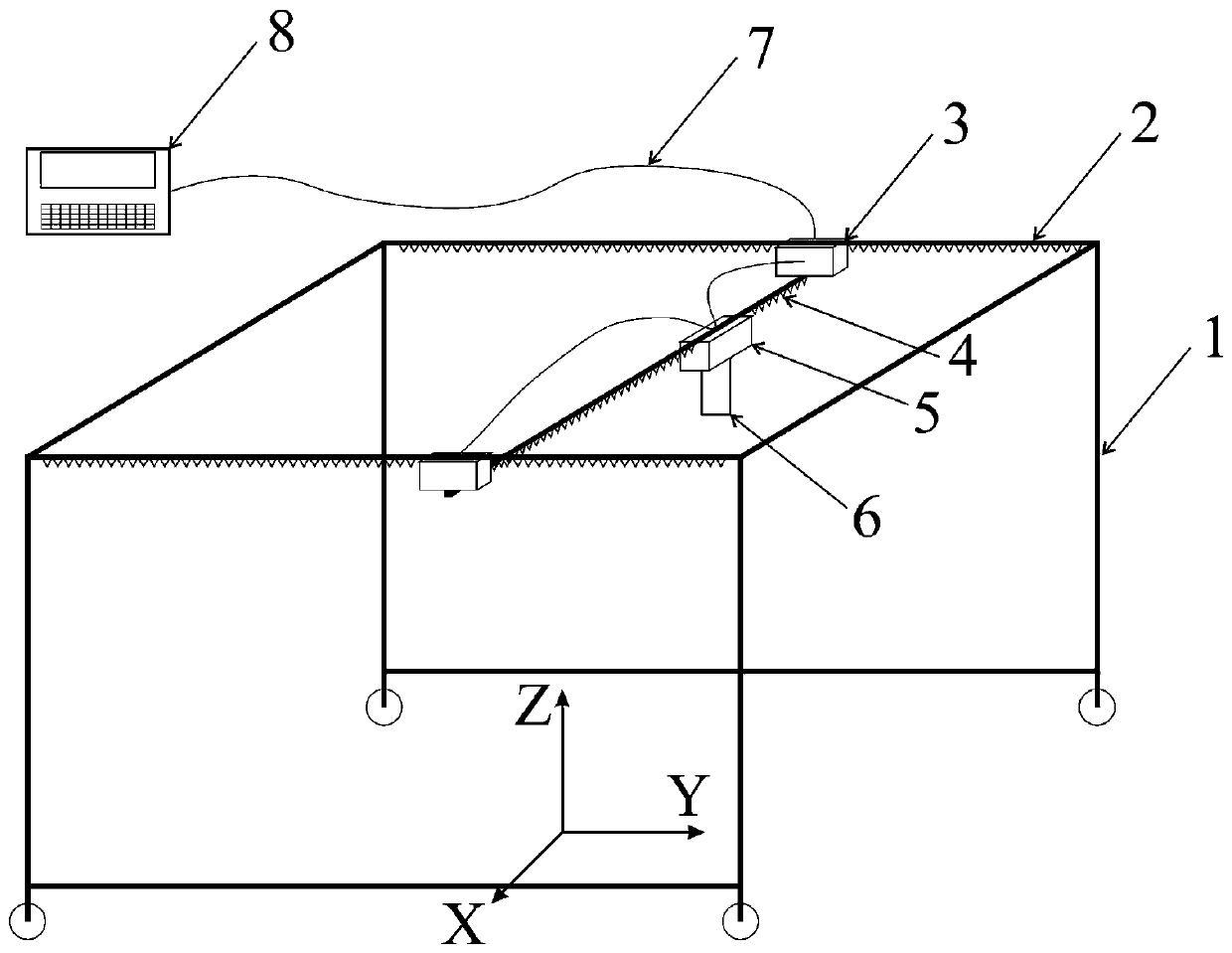

[0044] like figure 1 As shown, a verification device for discrete element simulation of concrete slump form provided in this embodiment is used to measure the surface elevation of concrete after slump, including:

[0045] The support frame 1 is provided with rollers at the bottom;

[0046] A pair of Y-guided rails 2 arranged in parallel, the Y-guided rails 2 are horizontally fixed on the support frame 1, and the Y-guided rails 2 are provided with a driving brake assembly-3;

[0047] The X guide rail 4, the two ends are respectively connected with the drive brake assembly one 3 on the Y guide rail 2 on both sides, and the drive brake assembly two 5 is arranged on the X guide rail 4;

[0048] The rangefinder 6 is arranged below the driving brake assembly 25, and measures the elevation of the measuring point on the surface of the object by a point light source emitted vertically;

[0049] The control terminal 8 includes a control module, a data acquisition and calculation module ...

Embodiment 2

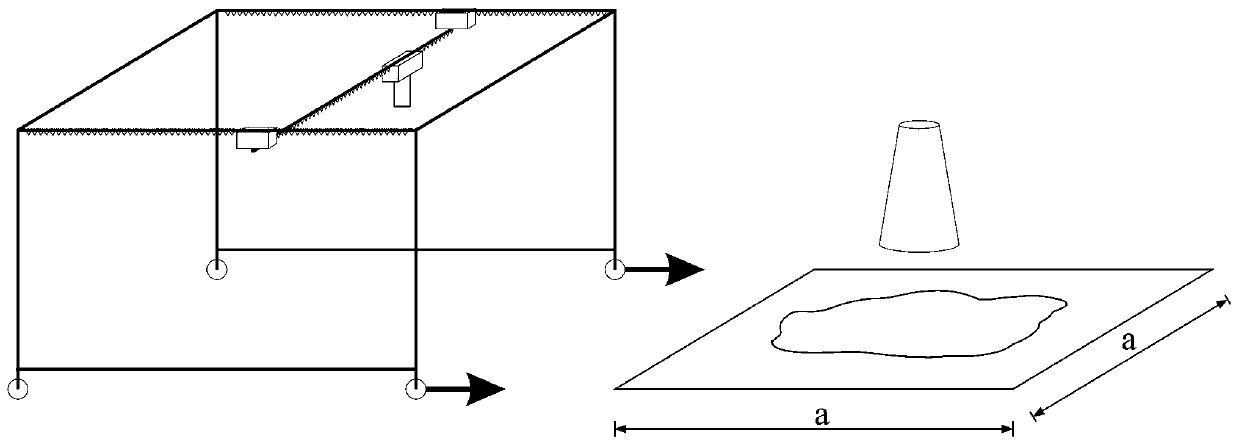

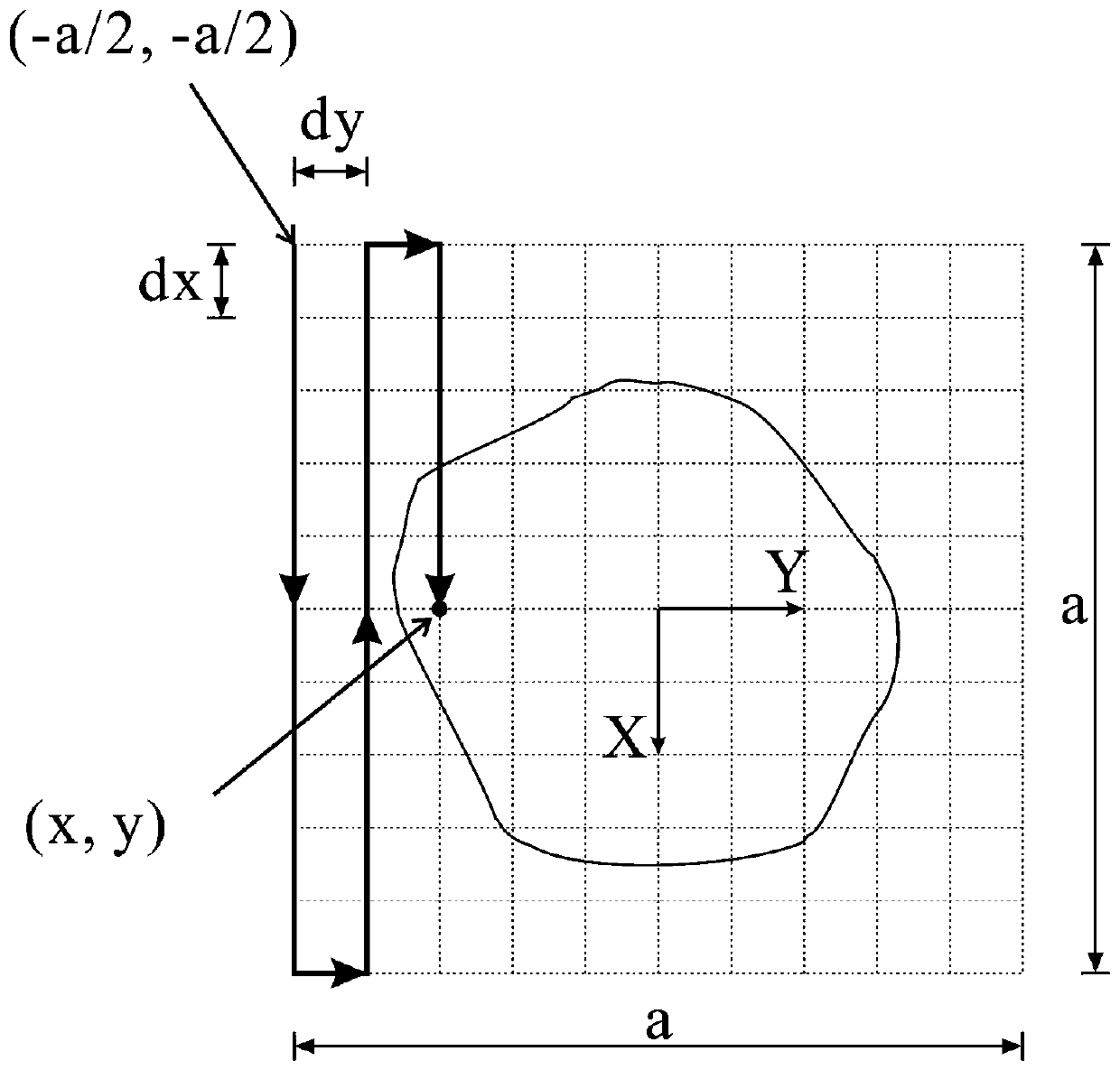

[0054] This embodiment provides a verification method for discrete element simulation of concrete slump form, combined below Figure 1 to Figure 7 This verification method is further introduced. The verification method includes the following steps:

[0055] Step 1: Install the verification device in Embodiment 1 for standby. Such as figure 1 As shown, the verification device includes a support frame 1, a pair of Y guide rails 2 arranged in parallel on the support frame 1, a drive brake assembly 3 arranged on the Y guide rail 2, two ends and a drive The first brake assembly 3 is fixedly connected to the X guide rail 4 , the driving brake assembly 2 5 arranged on the X guide rail 4 , the distance meter 6 and the control terminal 8 arranged under the drive brake assembly 2 5 . Rollers are arranged below the support frame 1 to realize the movement of the support frame 1 . The control terminal 8 includes a control module, a data acquisition and calculation module, and a data pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com