Patents

Literature

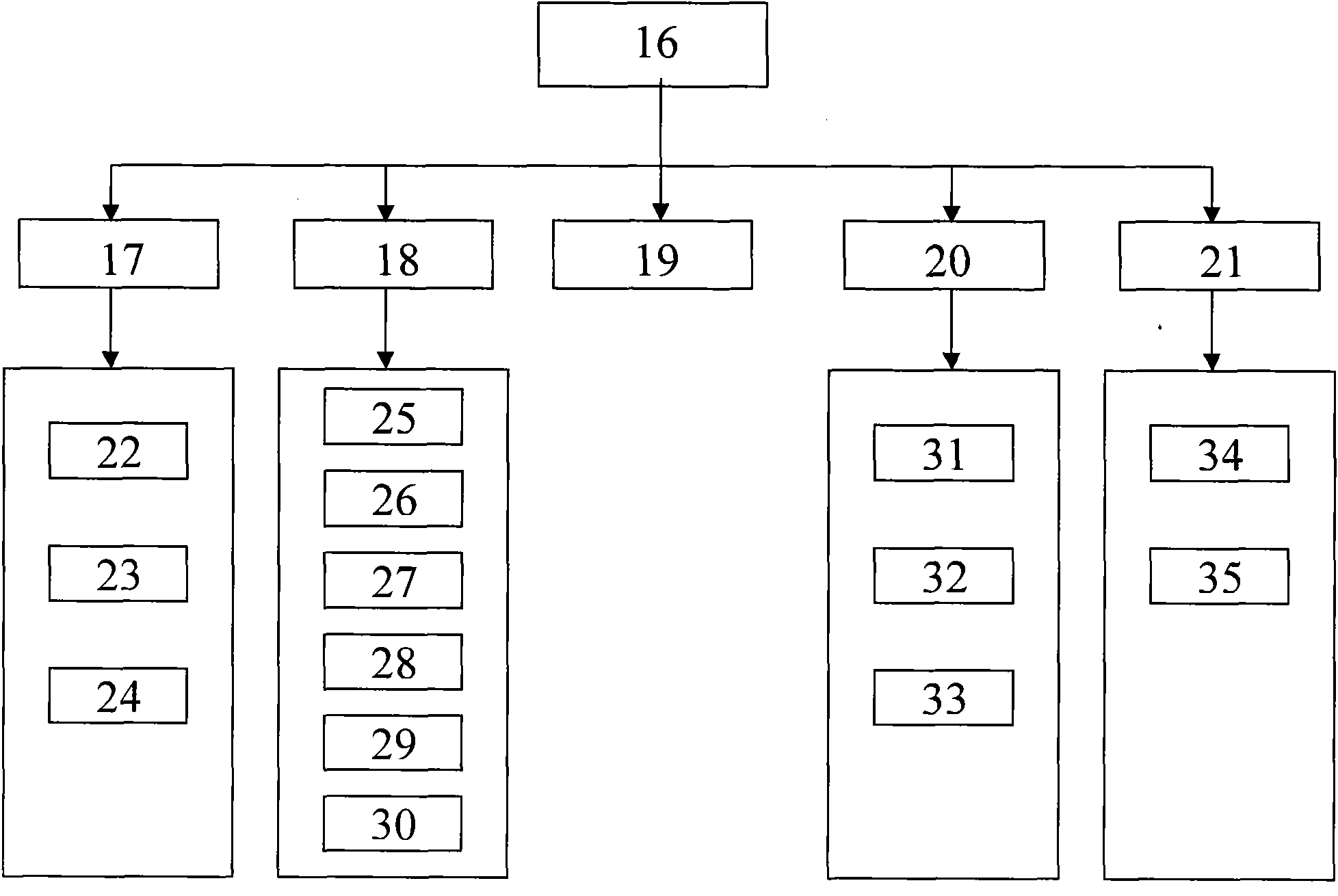

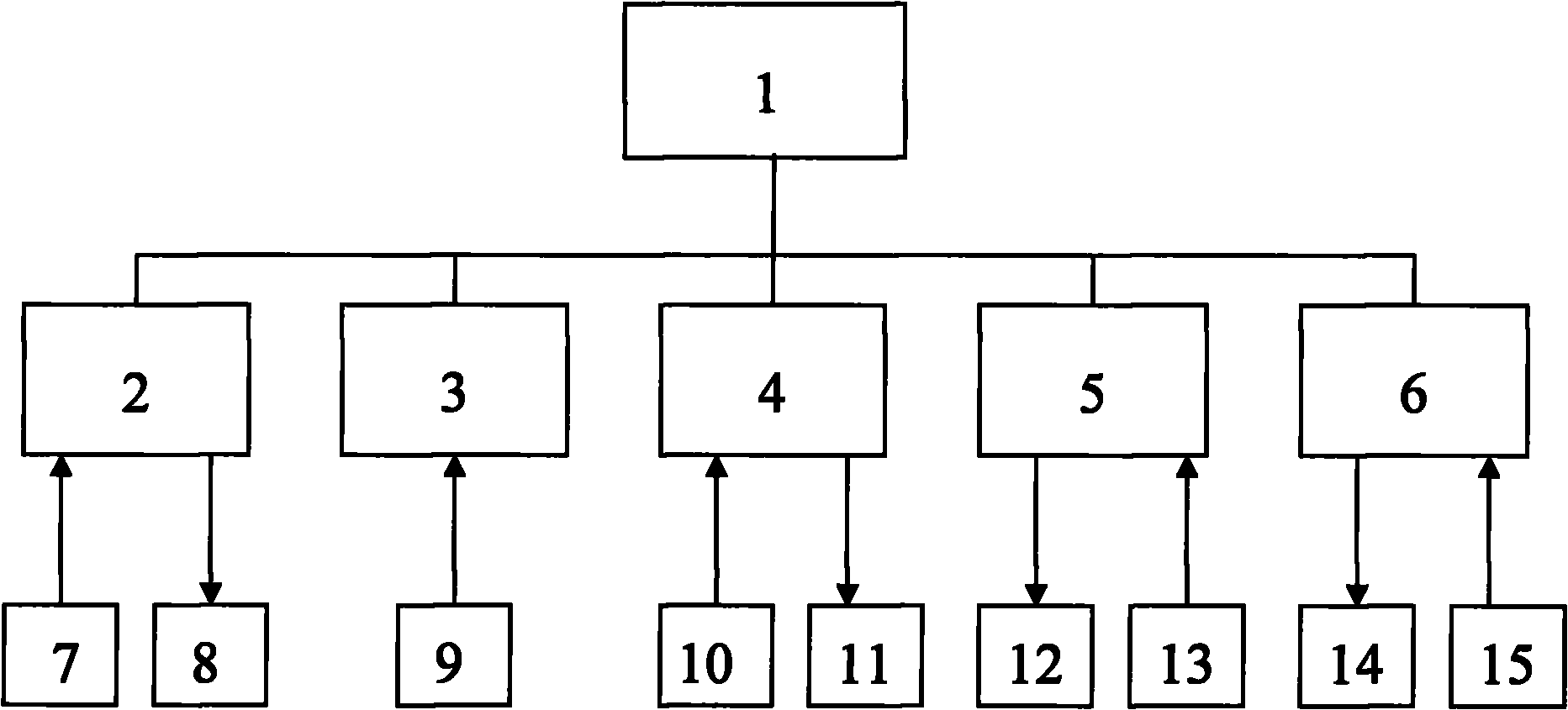

56 results about "Experimental control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An experimental control is used in scientific experiments to minimize the effect of variables which are not the interest of the study.

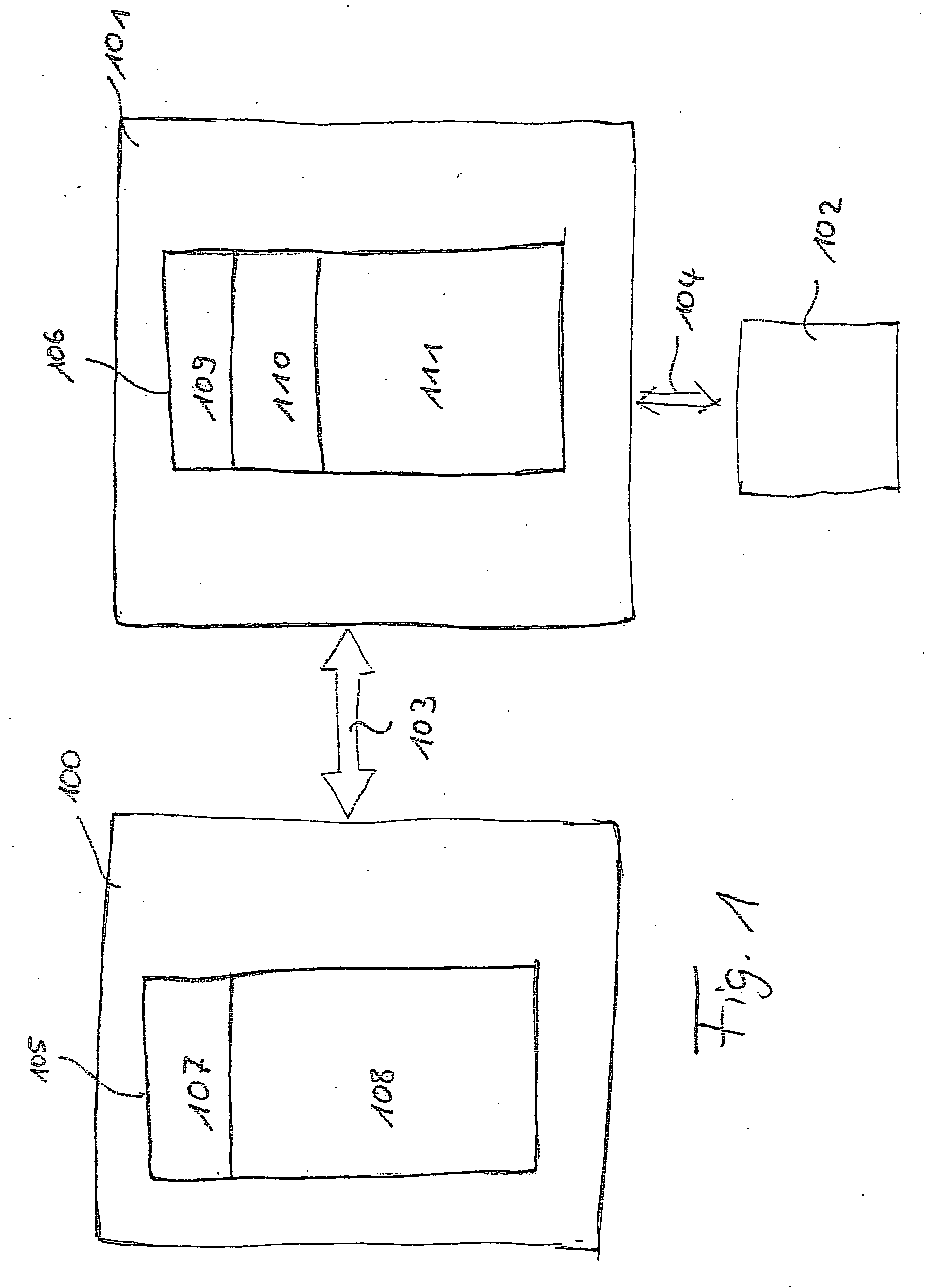

Software verification method for control units and verification system

InactiveUS20050022166A1Development risk can be minimizedLow costProgramme controlComputer controlComputer architectureExperimental control

A method and system for the verification of software functions for a control unit, using a simulation model to simulate the software functions and the control unit, the software code for the software functions being generated automatically from the identical simulation model, firstly for a first experimental control unit and secondly for a second standard control unit, identical input variables for the software functions being used on both control units and the output variables of both control units resulting therefrom being detected synchronized in time, i.e., simultaneously, the software functions being verified through comparison of the output variables of both control units.

Owner:ROBERT BOSCH GMBH

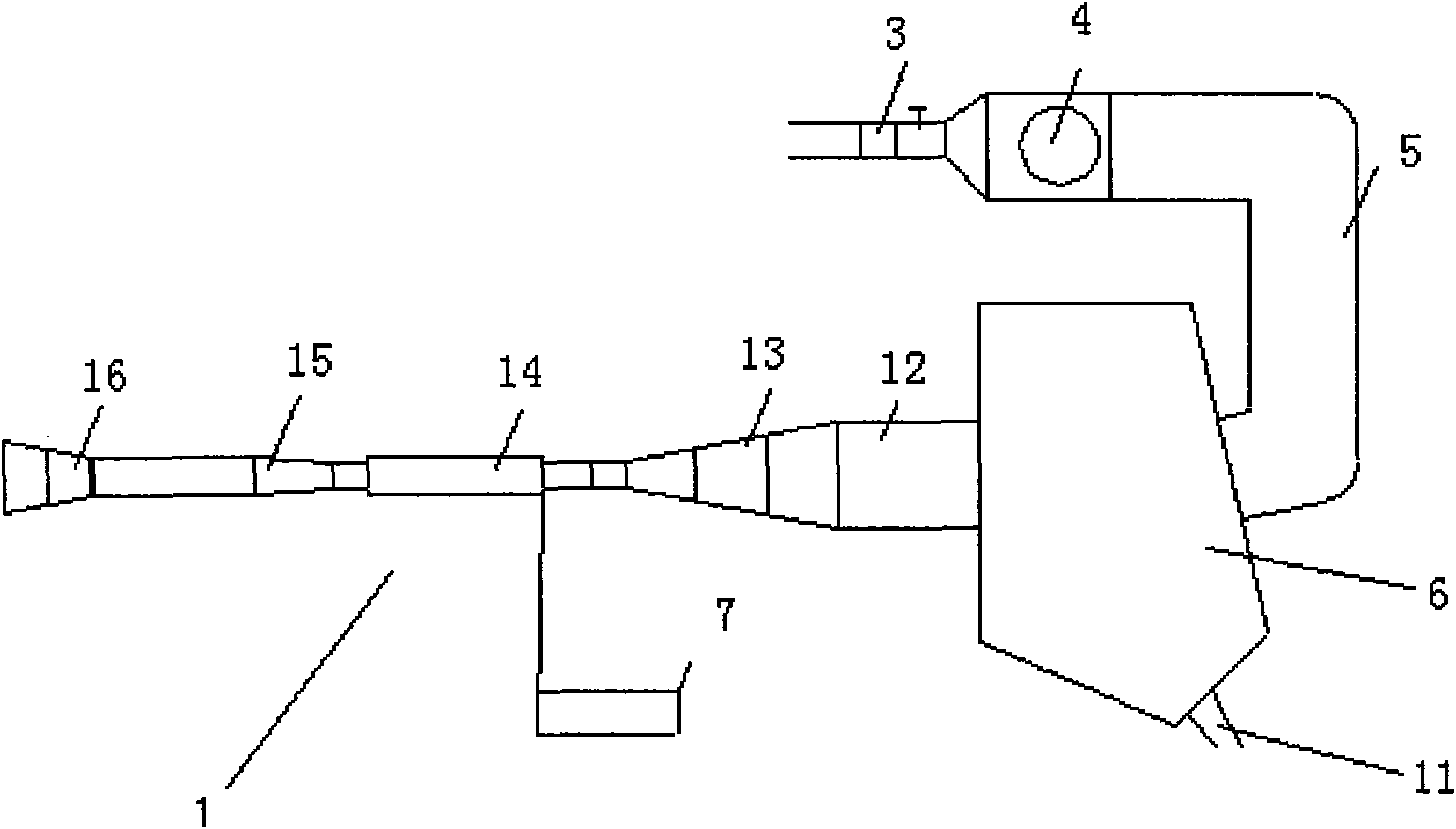

Aero-acoustic experimental apparatus

ActiveCN101571448AReduce turbulence intensityUniform flow velocity profileSubsonic/sonic/ultrasonic wave measurementAerodynamic testingSound sourcesControl system

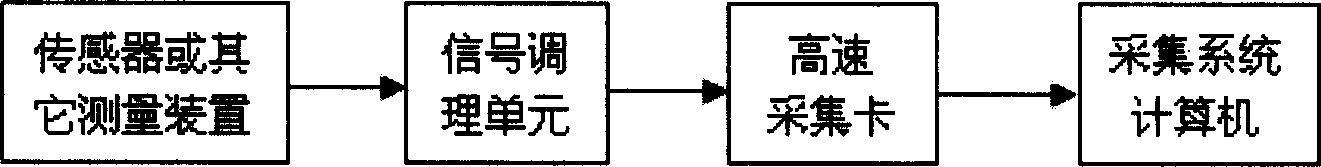

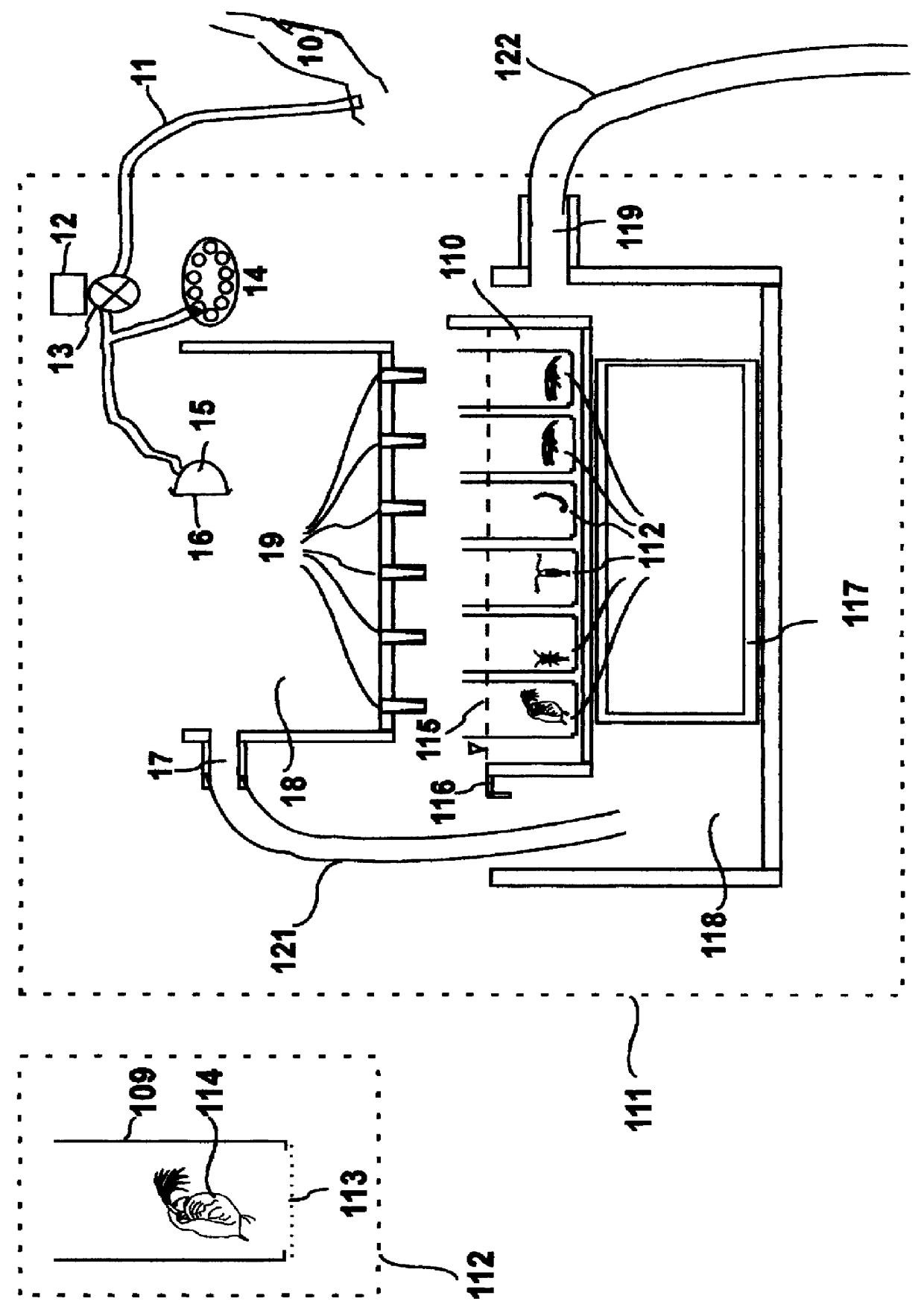

The invention disclose an aero-acoustic experimental apparatus, which consists of a high-pressure static air flow acoustic pneumatic device and a low-pressure static air flow acoustic pneumatic device, wherein when the highest flow Mach number reaches between 0.65 and 0.8 M and the working pressure is between 0.005 and 0.75 MPa, the measurement for a sound field and a flow field of air flow in a pipeline is achieved through simulation, and the frequencies and the amplitude values of the flow rate and the sound pressure on the surface of a sound lining material are measured and analyzed; under the condition that the air flow reaches the sound velocity and the working pressure, the measurements for the sound field and the flow field under the action of a loud strong sound source in the pipeline is achieved through simulation, and the acoustic experimental performance of the sound lining material is measured and analyzed; the signal acquisition and the mobile measurement of various detectors are achieved by an experimental control system; and the aero-acoustic experimental apparatus achieves a jet test of air under a static air flow condition and analyzes the flow field distribution and the sound field distribution conditions at various flow rates according to the stated steady flow.

Owner:NANJING CHANGRONG ACOUSTIC INC

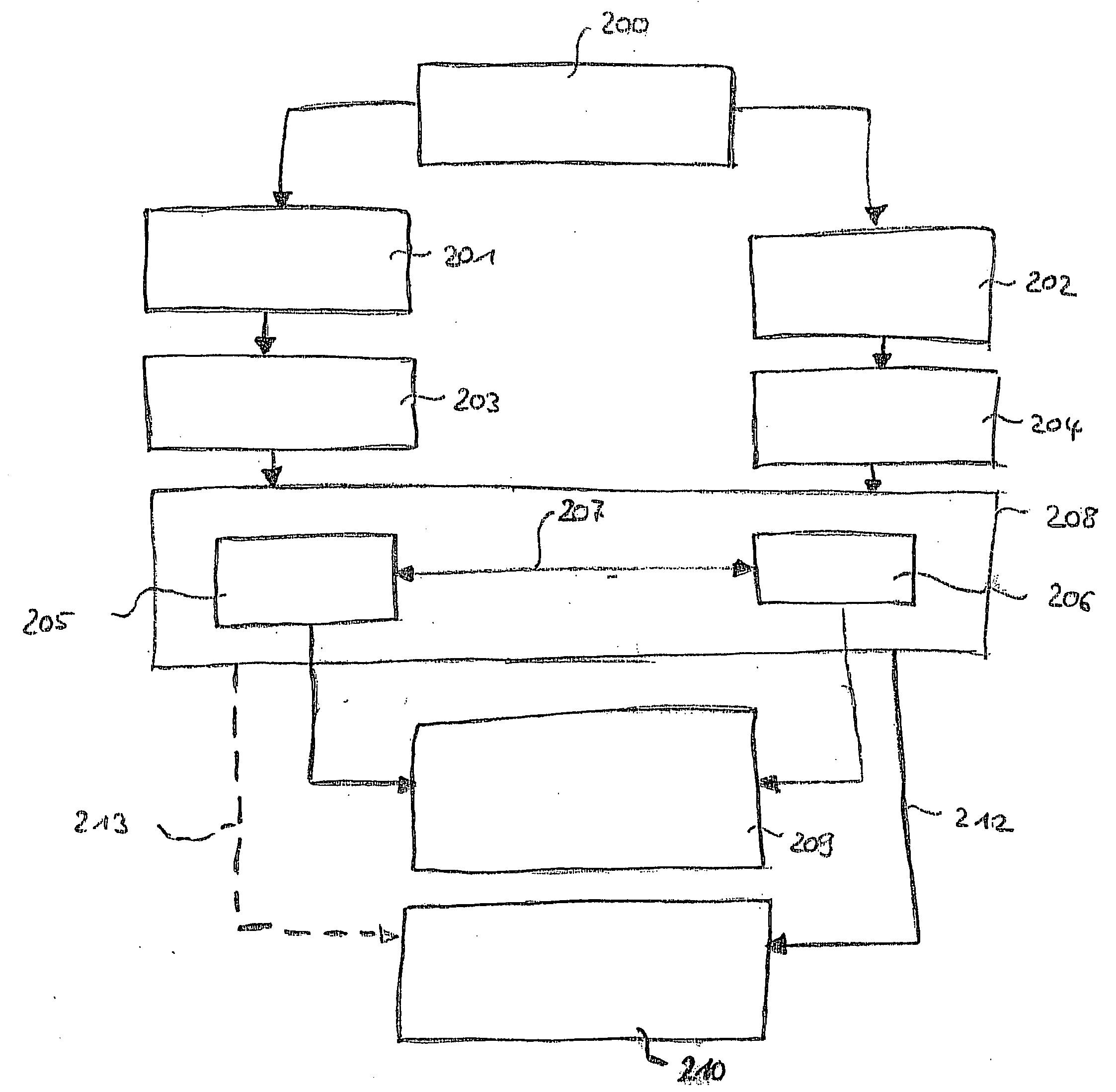

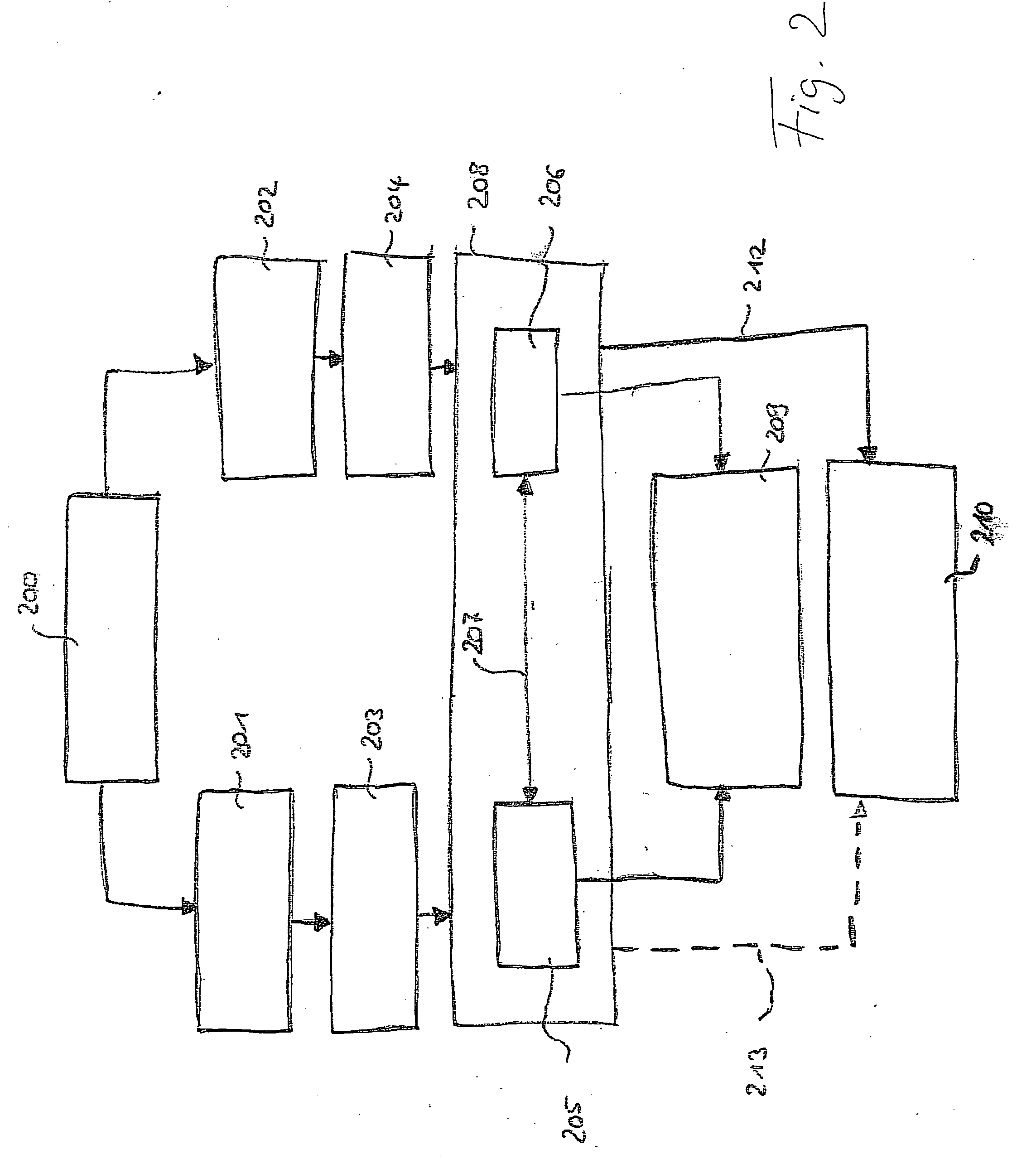

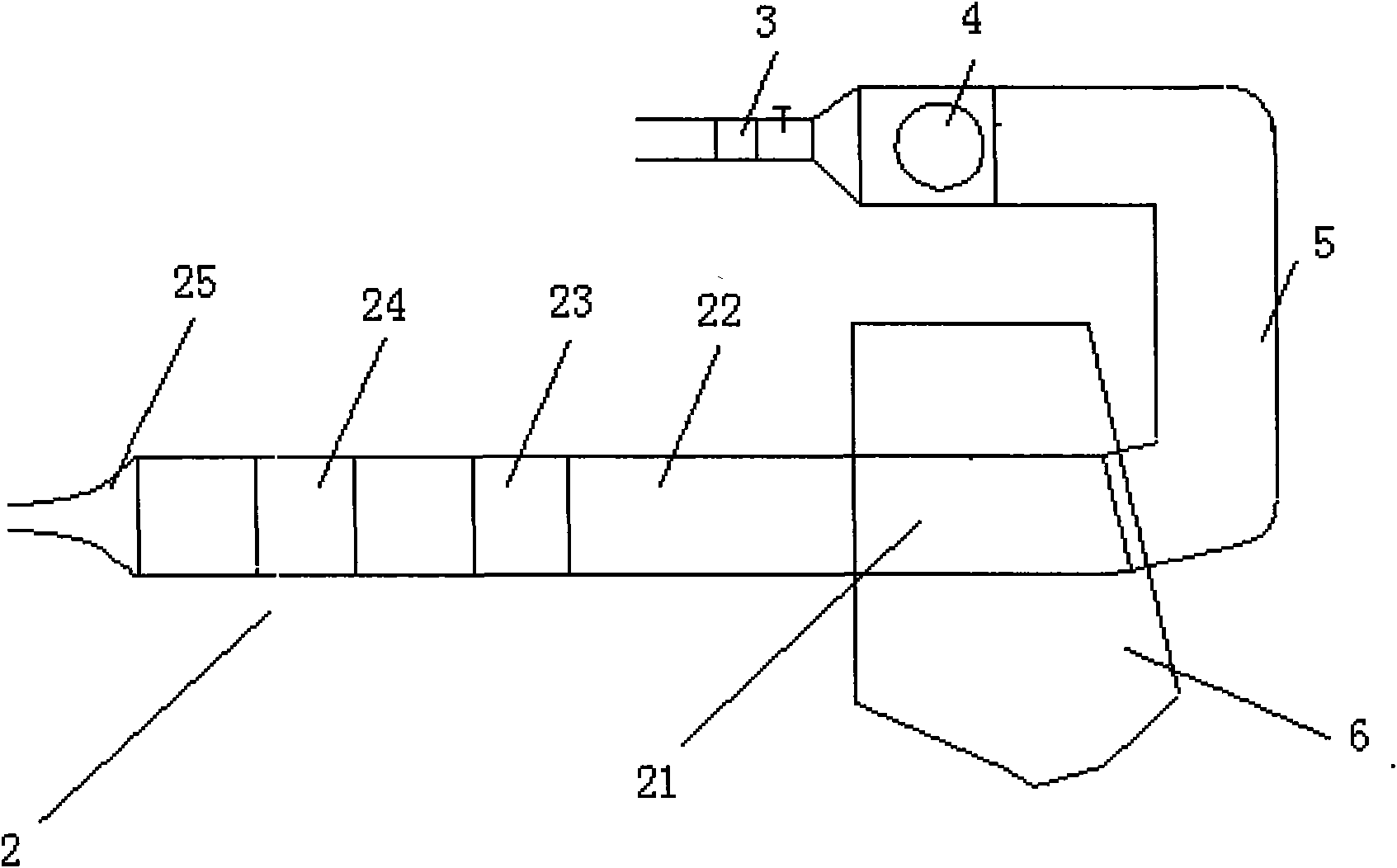

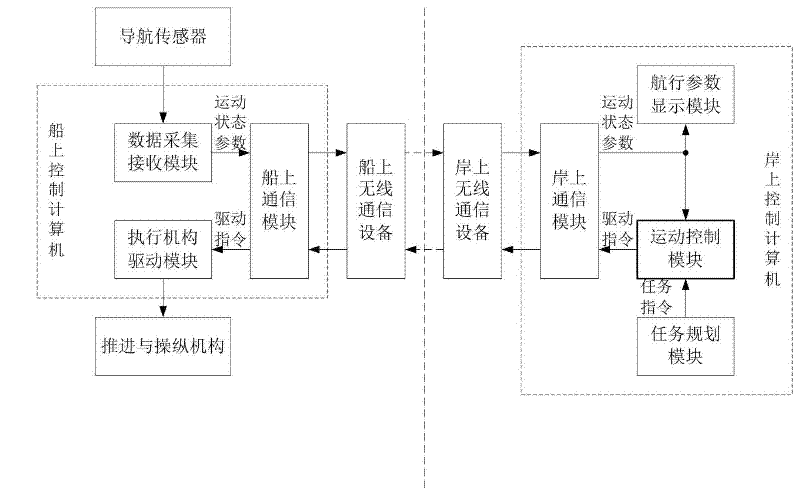

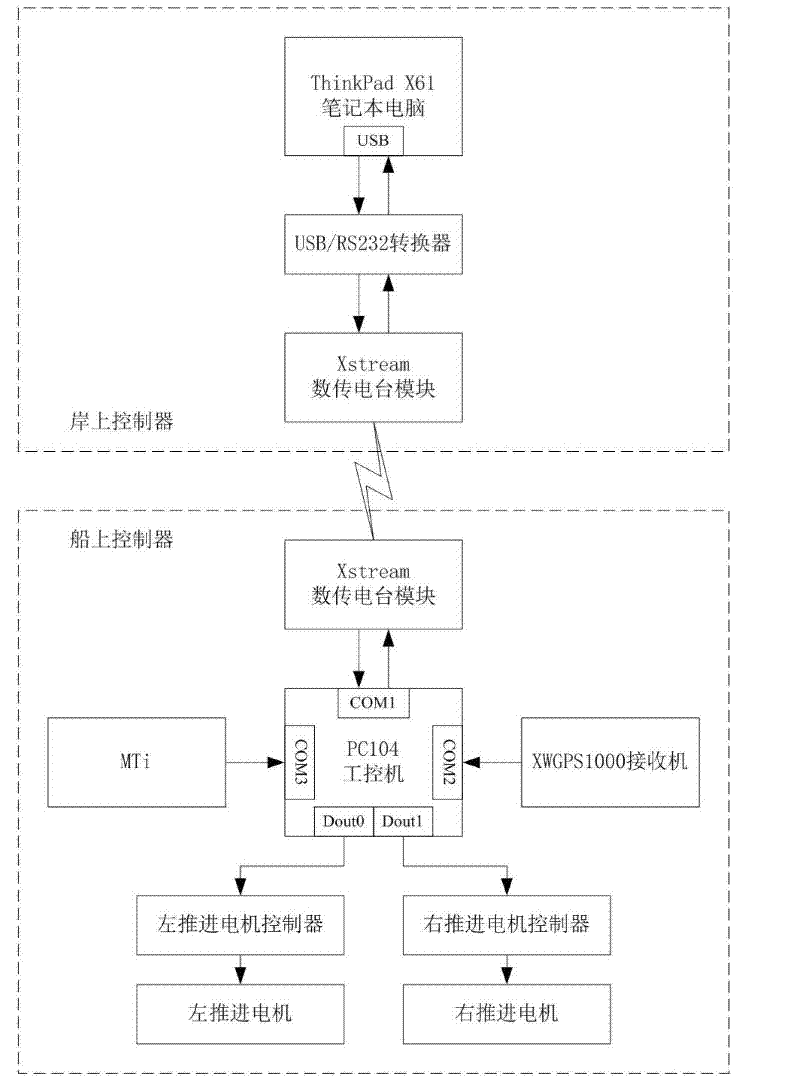

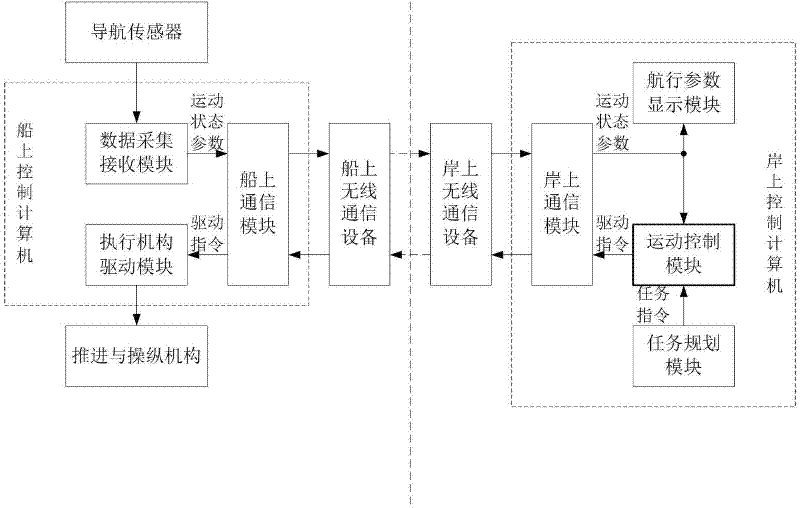

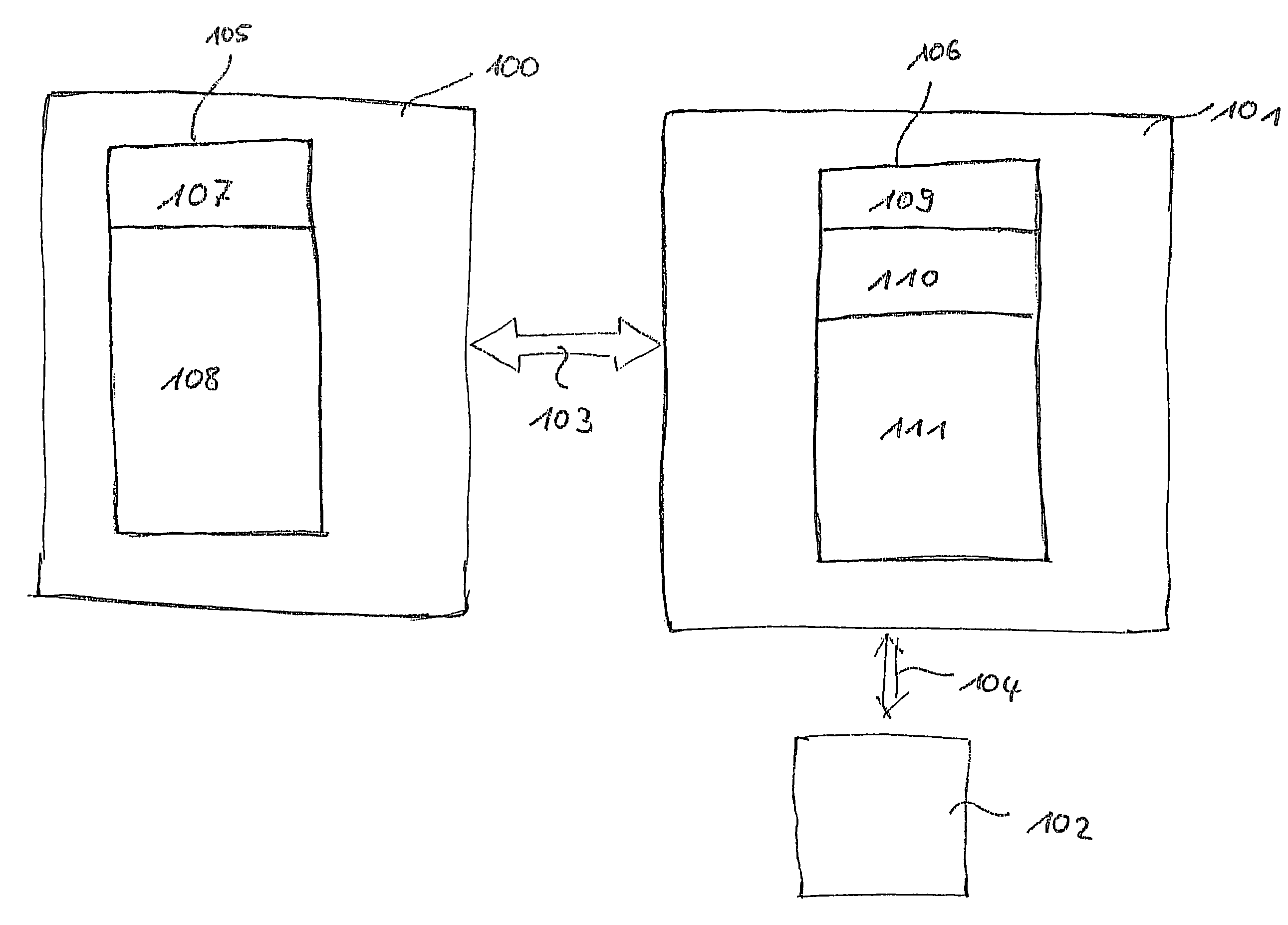

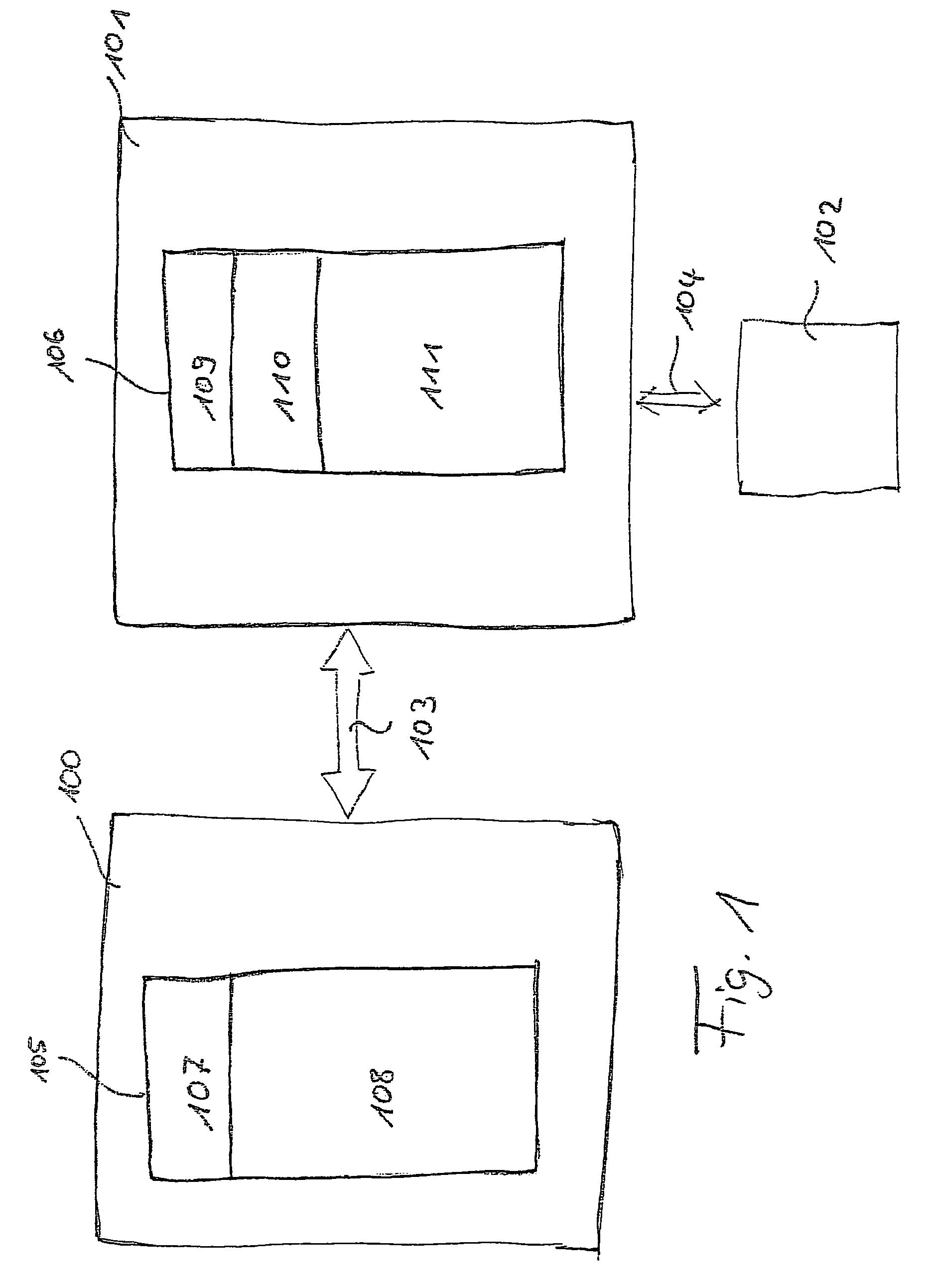

Experimental control structure of unmanned surface vessel

InactiveCN102692924ARealize motion control functionFacilitate the development of motion control experimentsPosition/course control in two dimensionsBody measureComputer module

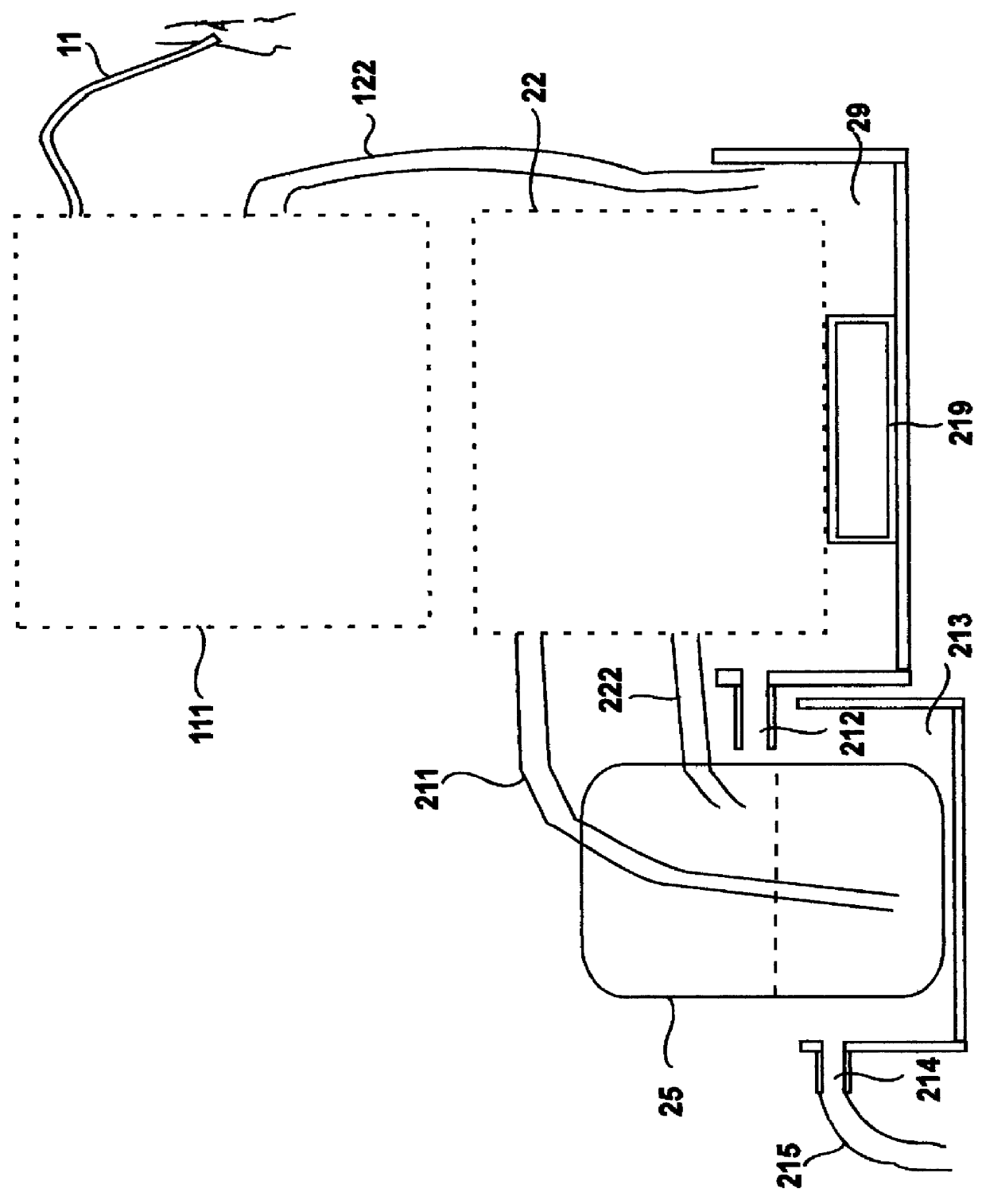

The invention provides an experimental control structure of an unmanned surface vessel, which comprises a shore module, a ship module, a navigation sensor and a ship body propelling and steering mechanism. A data collecting and receiving module collects movement parameter information of a ship body measured by the navigation sensor according to a set control cycle; a ship communication module transfers the movement parameter information of the ship body to a shore communication module; a navigational parameter display module displays the movement parameter information of the ship body; a movement control module carries out movement control resolving according to the movement parameter information of the ship body to obtain a drive instruction of movement of the ship body; and the shore communication module transfers the drive instruction to the ship communication module, and the ship communication module transfers an execution mechanism drive module and controls the ship body propelling and steering mechanism to drive the ship body to move according to the control requirement. According to the experimental control structure, modifying and validating of a movement control algorithm can be finished just by modifying shore control software in an experimental process without modifying ship control software, and a research of a movement control experiment of the unmanned surface vessel is conveniently carried out.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

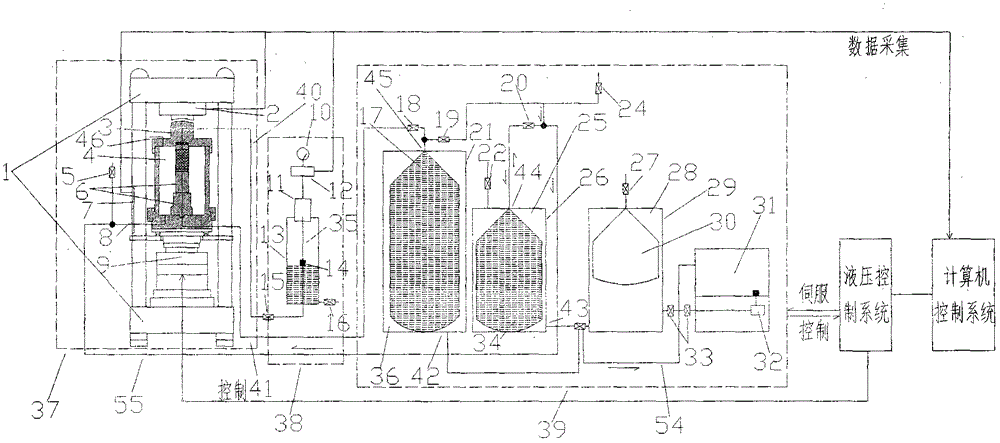

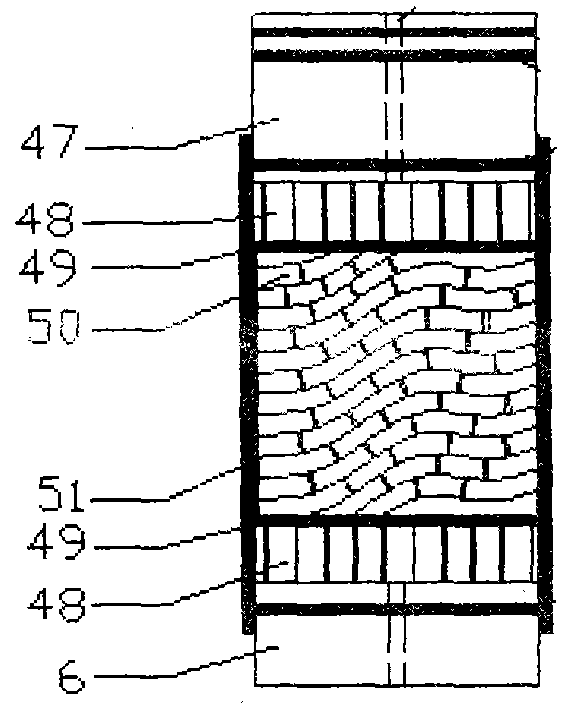

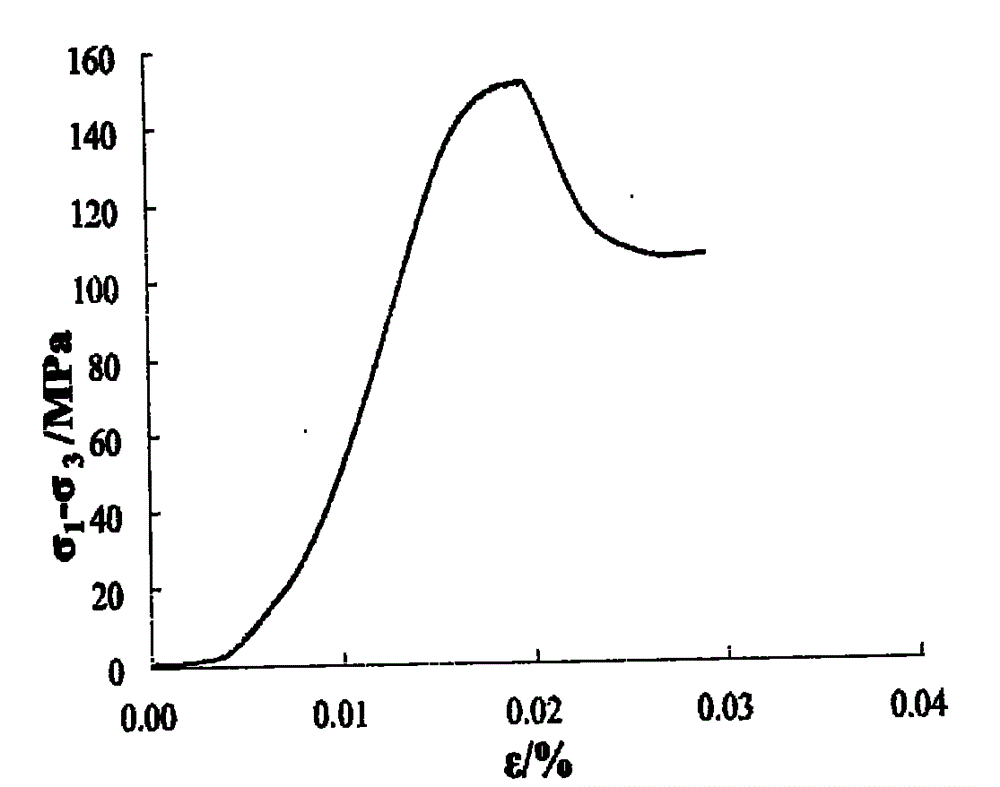

Test system for rock breaking mode at high ground stress and osmotic pressure

ActiveCN104483202AMaterial strength using tensile/compressive forcesData acquisitionExperimental control

The invention discloses a test system for a rock breaking mode at high ground stress and osmotic pressure. The test system comprises a test device for the rock breaking mode at the high ground stress and osmotic pressure and utilizes a test technique, wherein the test device is an organic combination of main equipment including an experimental sample mounting system, a high ground stress applying system, an high osmotic pressure applying system, an experimental control system, a measurement and data collection system and the like. According to the test system, the rock breaking mode and a rock breaking evolvement rule at the high ground stress and osmotic pressure can be tested.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Movement track tracking method of proppant in seam under experimental condition of high particle concentration

ActiveCN110566190AAccurate identificationEasy to identifyImage analysisConstructionsHigh concentrationImage processing software

The invention discloses a movement track tracking method of a proppant in a seam under an experimental condition of high particle concentration. The movement track tracking method comprises the following steps of S1, making a dye proppant and taking the dye proppant as a tracer particle; S2, evenly mixing a certain proportion of the dye proppant with a conventional proppant, and then configuring sand carrying liquid to carry out a physical simulation experiment of proppant transportation; S3, obtaining a moving state of tracer particles during the experiment by using a high-speed camera, and using an image processing software to capture video images at fixed time intervals; S4, coloring the tracer particles of the proppant twice, and using a computer program to identify the tracer particles in the captured images; and S5, using the computer program to calculate the velocity and track the track of identified tracer particles. According to the movement track tracking method, a migrationtrack of the proppant particles under a high concentration condition can be accurately identified and tracked, all proppant migration mechanisms in the process of hydraulic fracturing are convenient to be studied, and the movement track tracking method has great significance for guiding hydraulic fracturing construction.

Owner:SOUTHWEST PETROLEUM UNIV

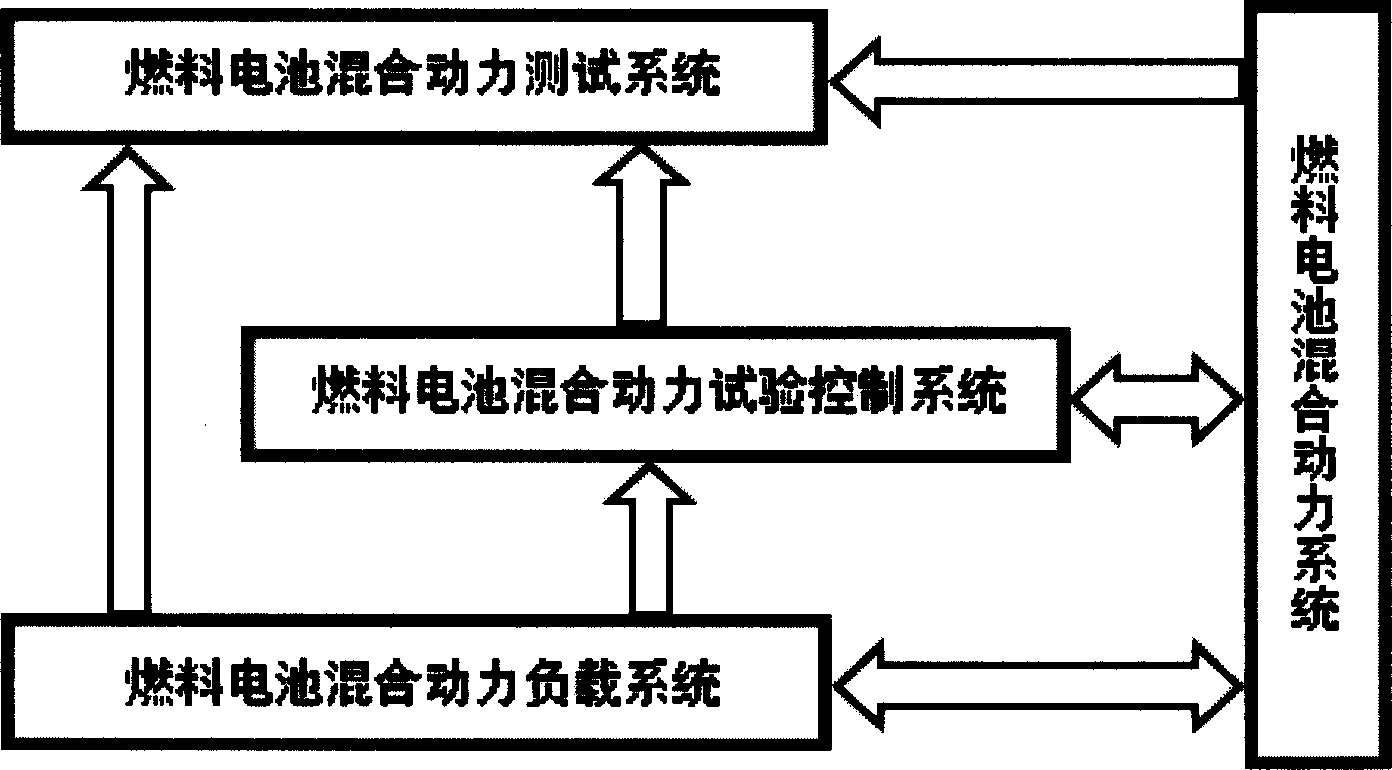

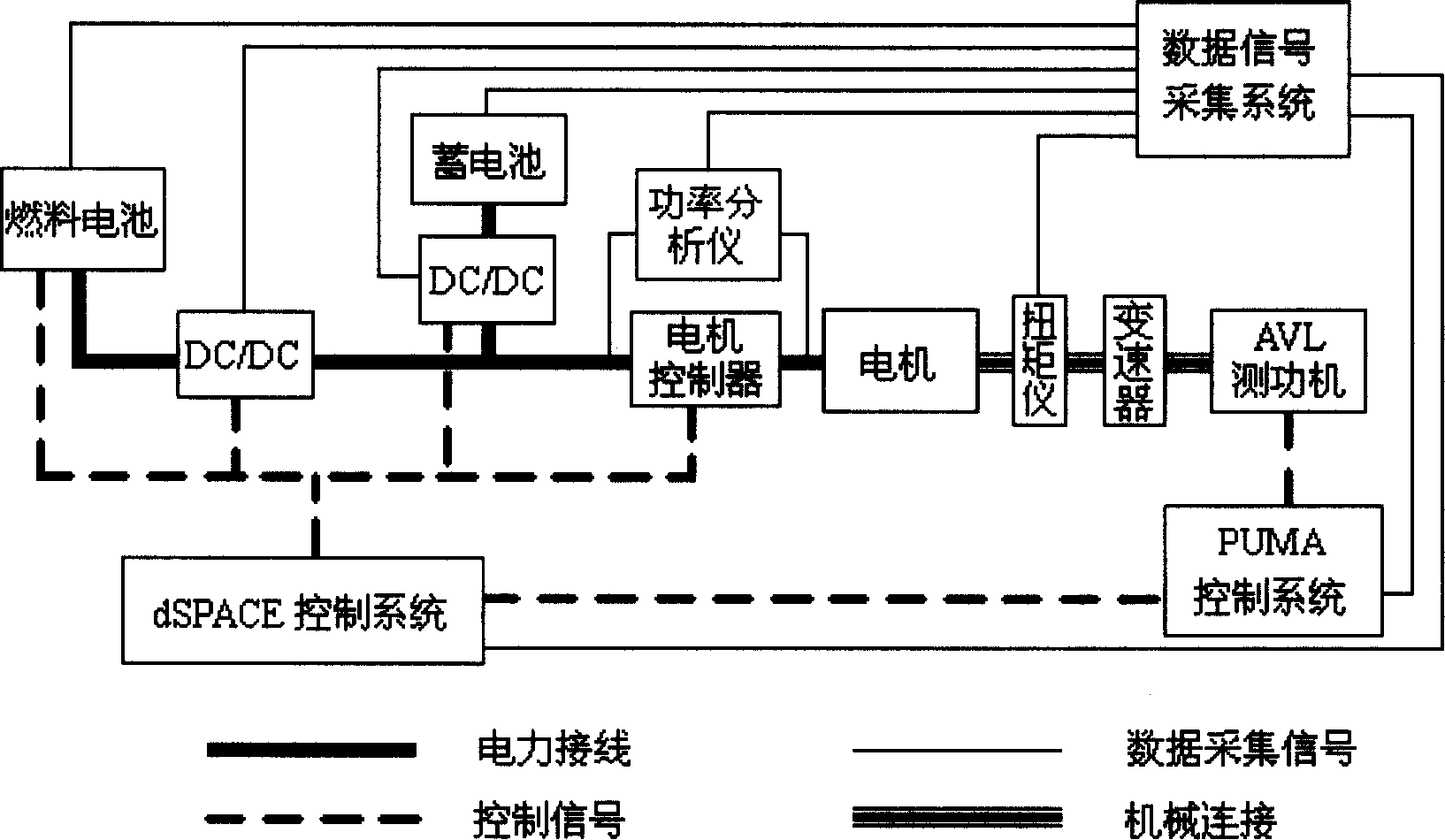

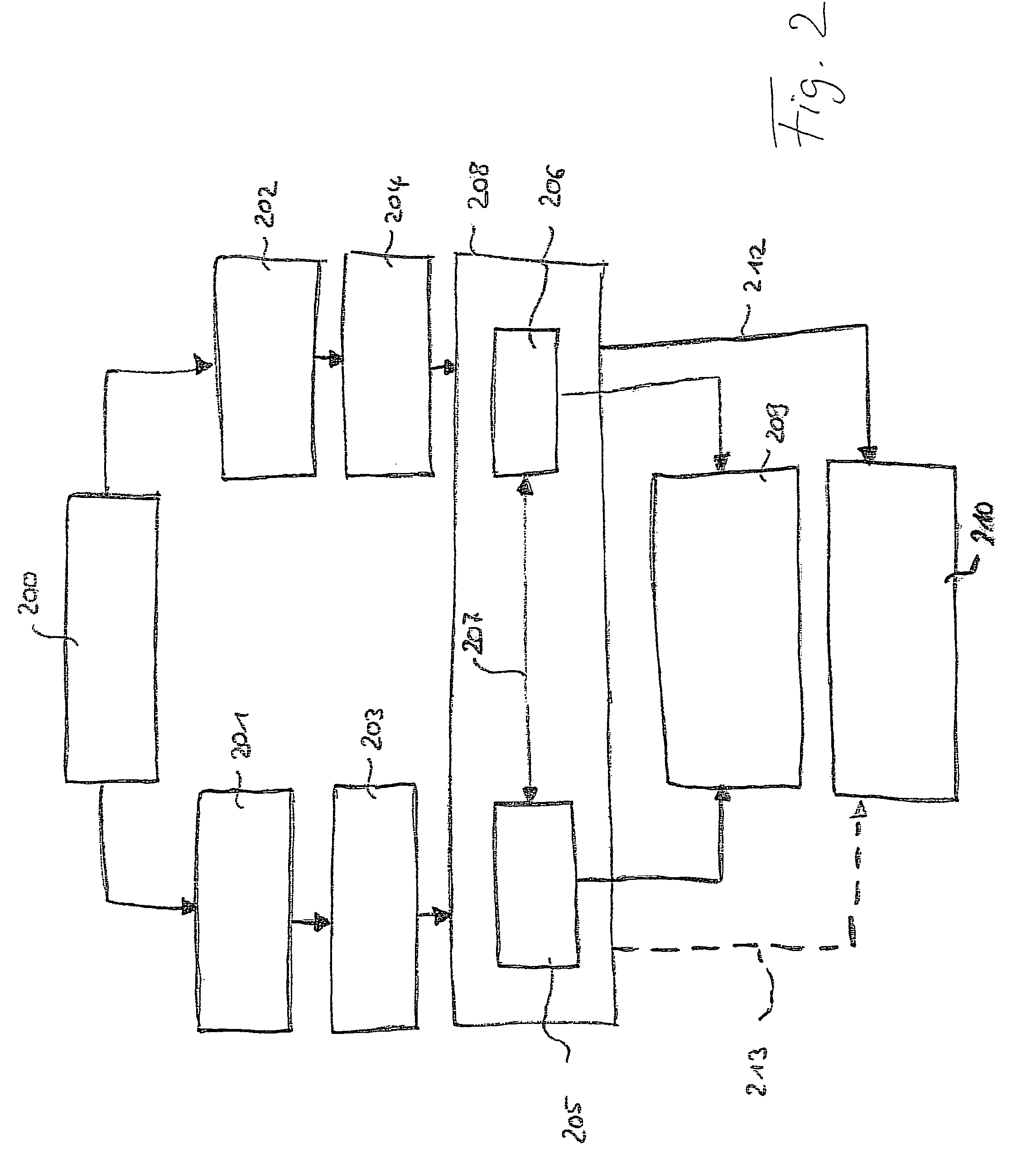

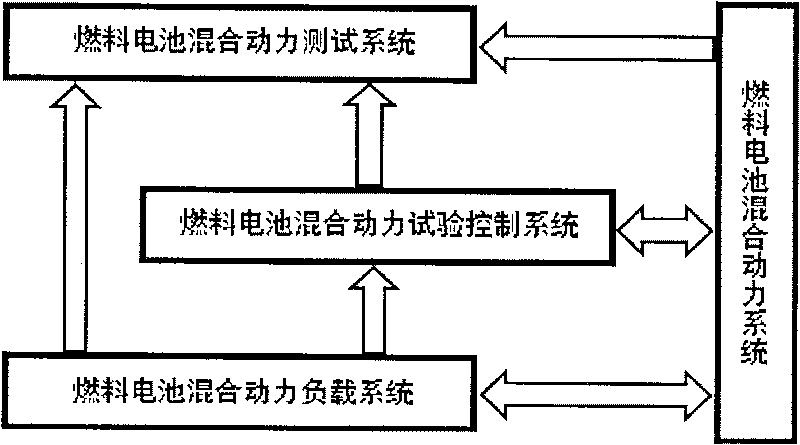

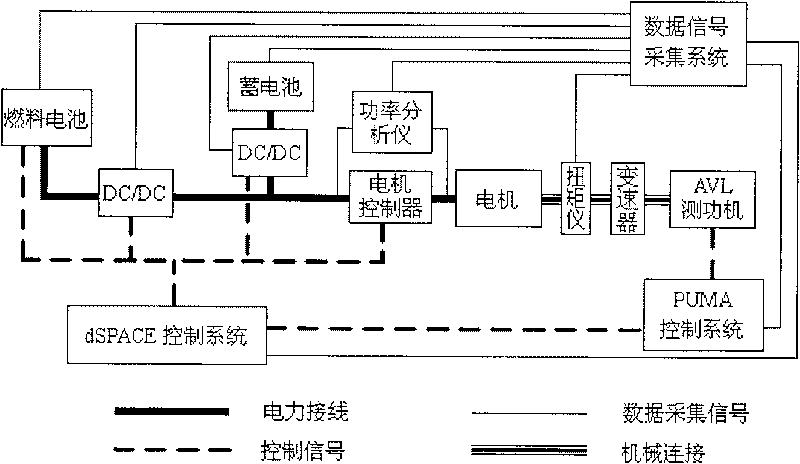

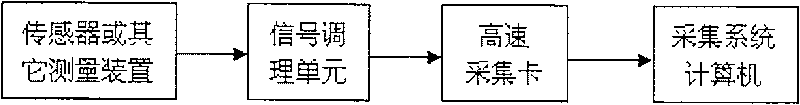

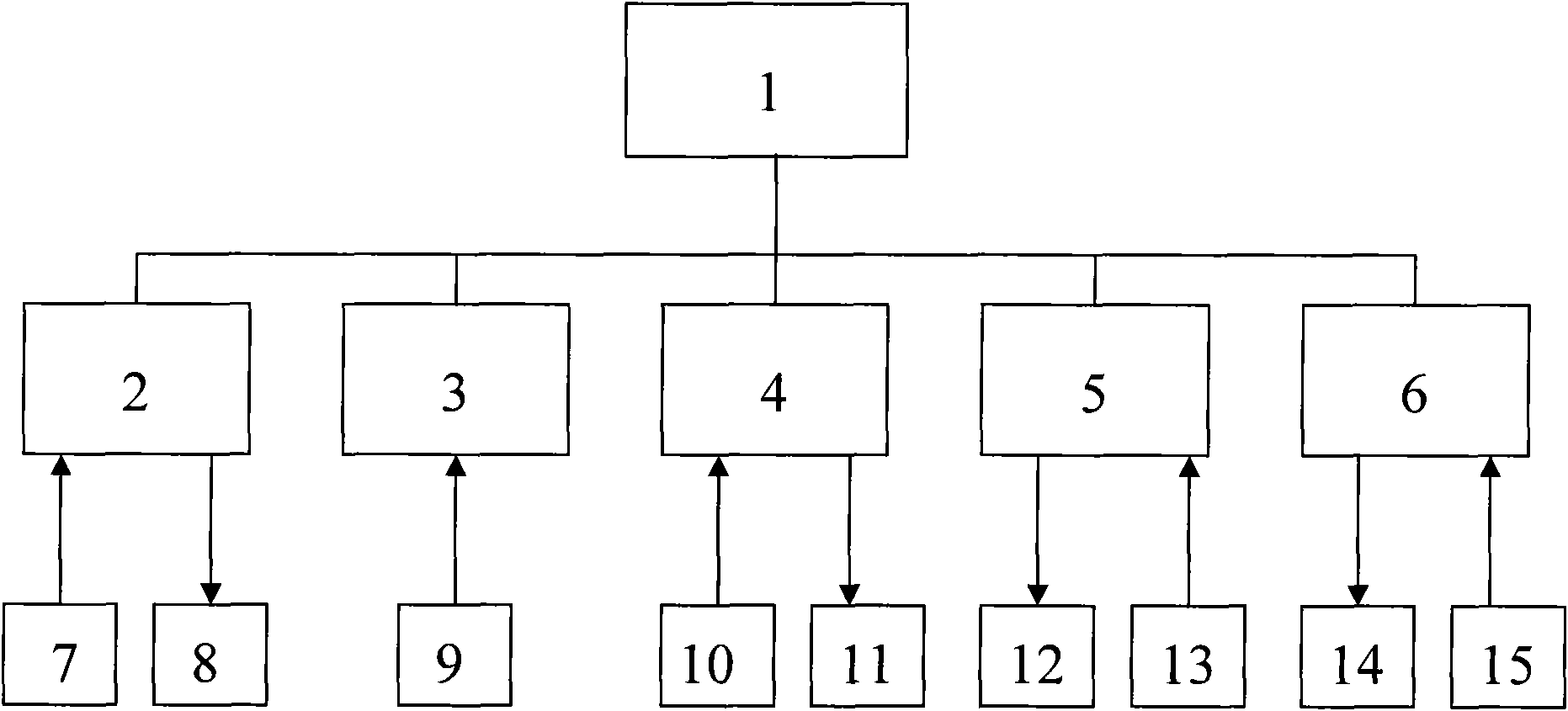

Test and research system for fuel cell hybrid power system

InactiveCN1601792ASystem dynamicEfficientElectric devicesFuel cellsInternal combustion engineExperimental control

Experimental investigation system of fuel cell hybrid power system includes loading system, experimental control system, hybrid power system and test system. The loading system simulates road condition, dynamics characteristics of car body, and drivers. Combining with operation conditions of each part in the system, the experimental control system converts each condition to control command for each part, controls and adjusts running condition. The hybrid power system is subject to the disclosed experimental investigation system investigates. The test system collects, monitors and records operation conditions of other three systems. The invention carries out experimental investigation functions of testing and checking fuel cell hybrid power system, that traditional testing system for internal combustion engine does not perform. Thus, the invention possesses high innovation.

Owner:清华大学苏州汽车研究院(吴江) +1

Flow-through system and method for toxicity testing

InactiveUS6093566ABioreactor/fermenter combinationsBiological substance pretreatmentsTest organismToxic material

A method and apparatus for evaluating the effects of toxic substances in the environment on aquatic organisms is disclosed. The apparatus allows for exposure of test organisms, placed in test chambers made of partially submerged sieves, to water that is pumped from an urban creek at preset time intervals. The invention also allows for maintenance of cool temperatures in the exposure chambers, both for the treatment (i.e., creek water) and the experimental control.

Owner:KATZNELSON REVITAL

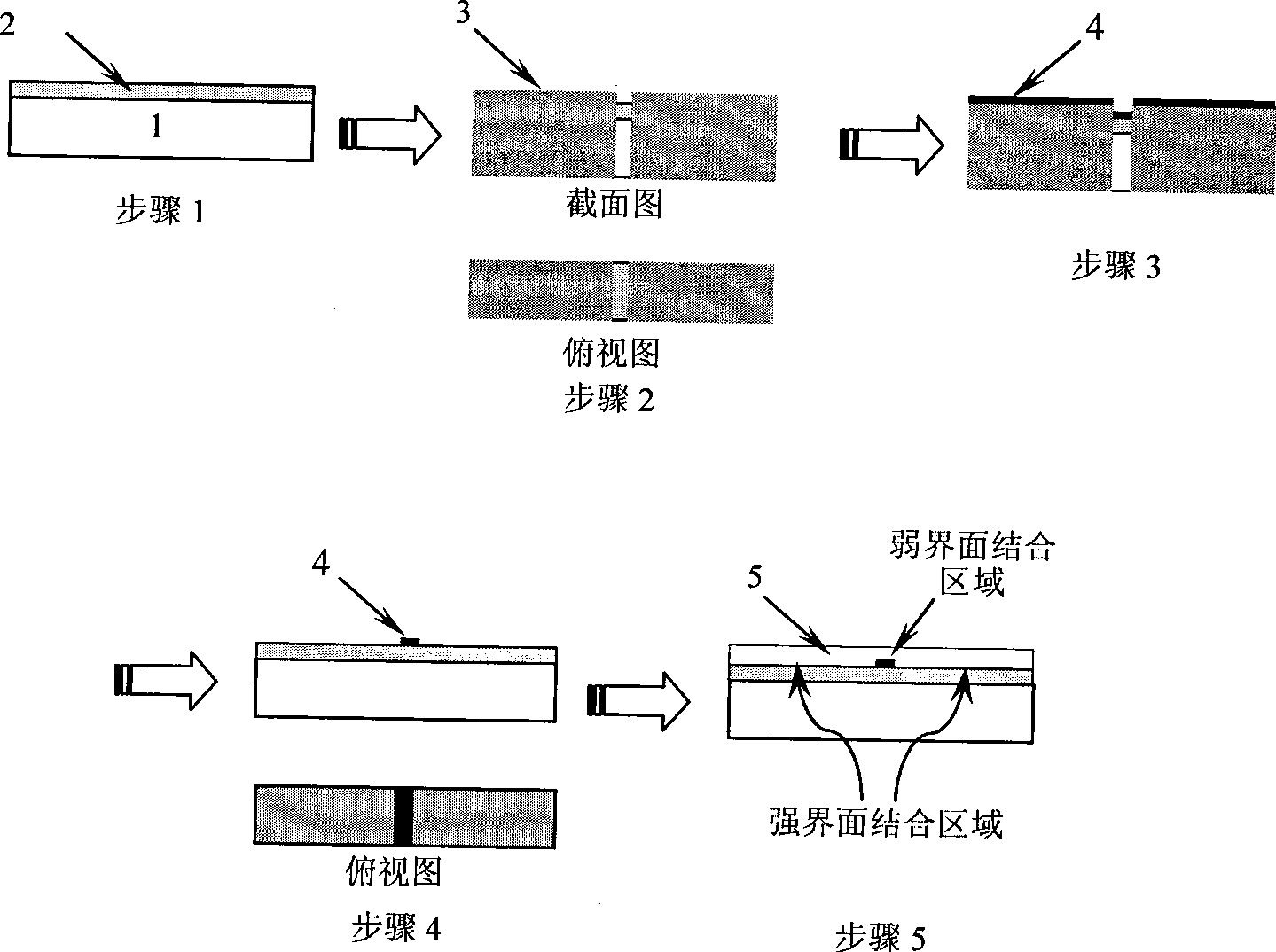

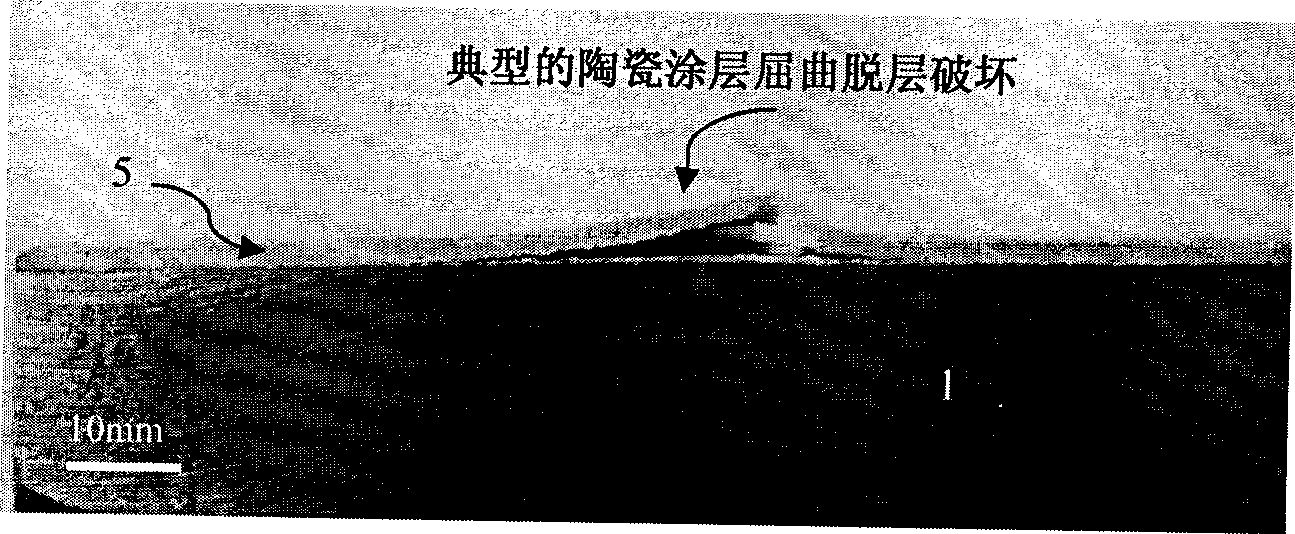

Experiment control method for researching flexion damage of thermal curtain coating interface containing inner embedded interface defect under high temperature environment

InactiveCN101435755AMaterial strength using tensile/compressive forcesUsing mechanical meansCoating systemCeramic coating

The invention discloses an experimental control method for experiments studying the interface buckling failure of thermal barrier coatings containing buried interface defects in high-temperature environment. Experimental equipment needed by the experimental method is as follows: a universal testing machine, an oxyacetylene high-temperature heating device, a thermocouple temperature measurement device, a CCD observation device for coating failure process and a computer. The method mainly comprises the following steps: a certain compressive load is applied in advance to a thermal barrier coating specimen containing interface defects; the method has corresponding requirements on the magnitude and application modes of the load; and residual compressive stress in a thermal barrier ceramic coating is approximately replaced with the compressive load. Therefore, the method is simple to operate and capable of shortening experimental time, thereby providing an important experimental method for analyzing the interface bonding performance of a ceramic layer and a bonding layer and providing a good basis and reference experience for studying the interface buckling problems of film / coating systems in future. The interface-crack critical length a[cr] of the thermal barrier ceramic coating with interface buckling failure is experimentally found to be 3 to 4 millimeters in general.

Owner:XIANGTAN UNIV

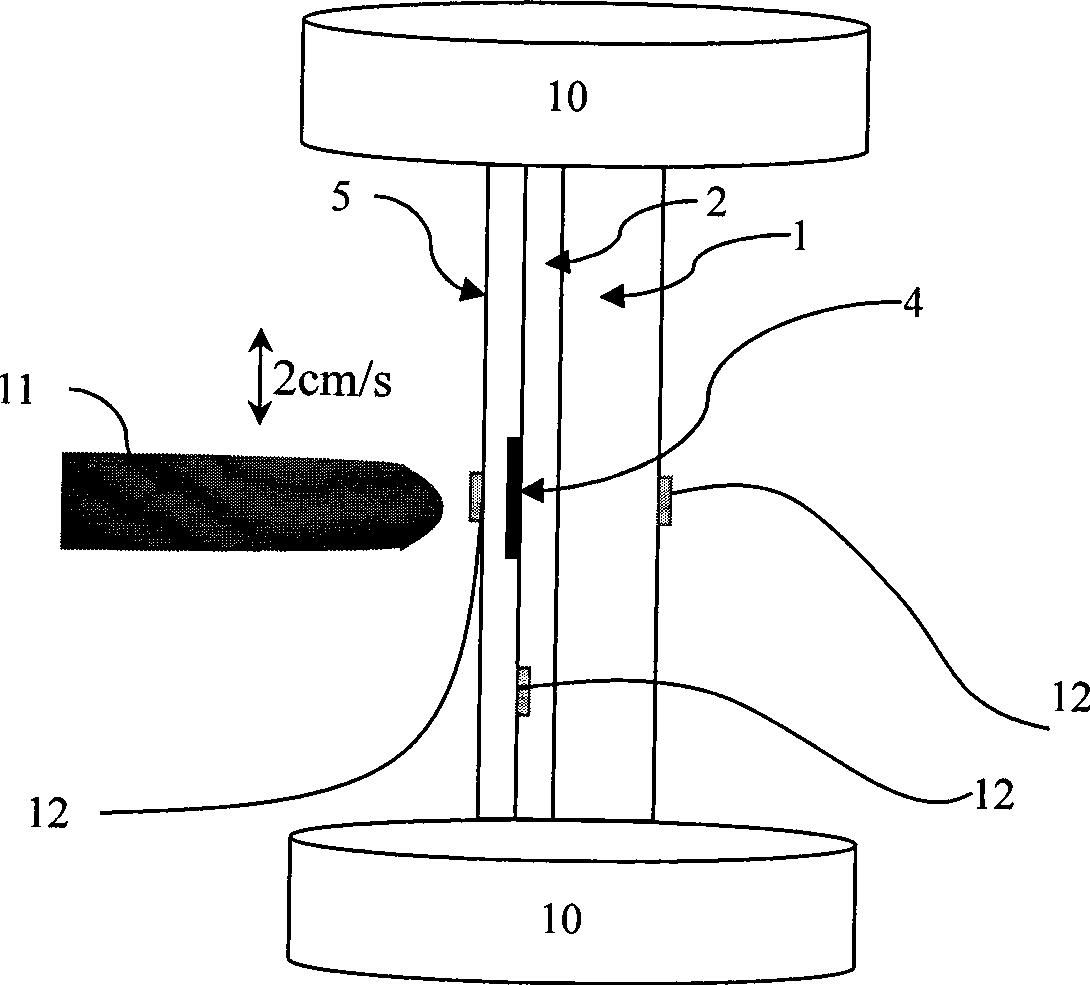

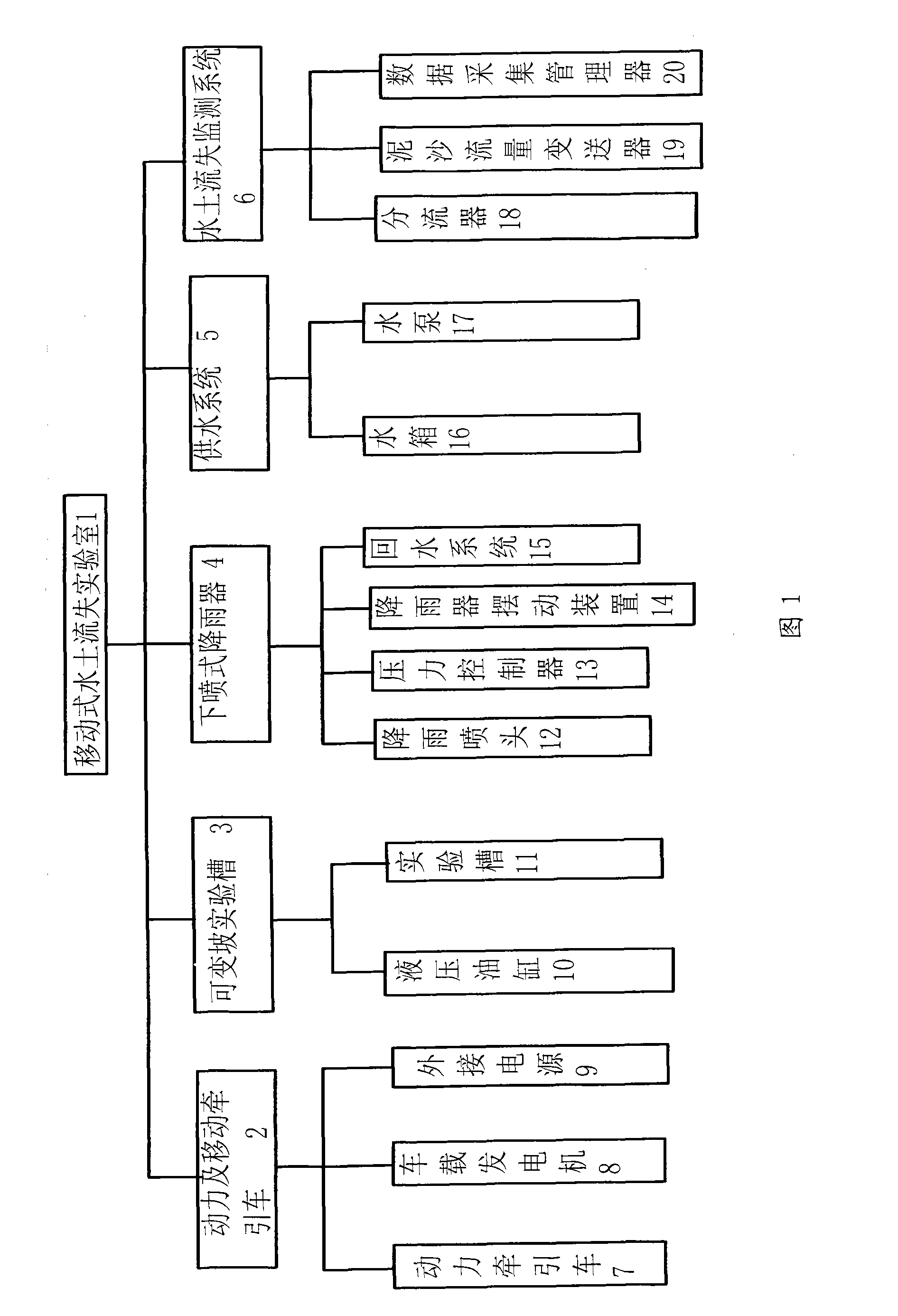

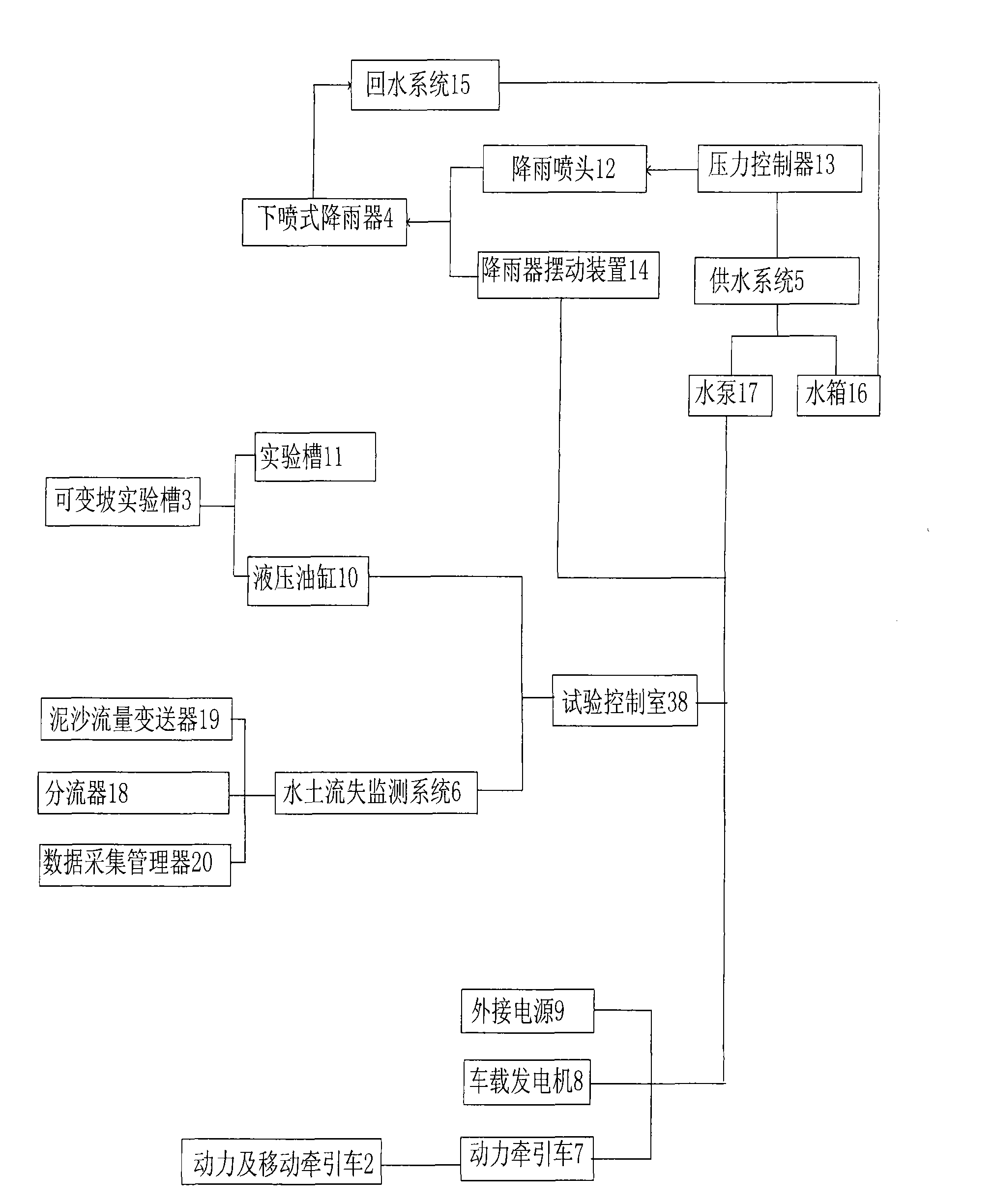

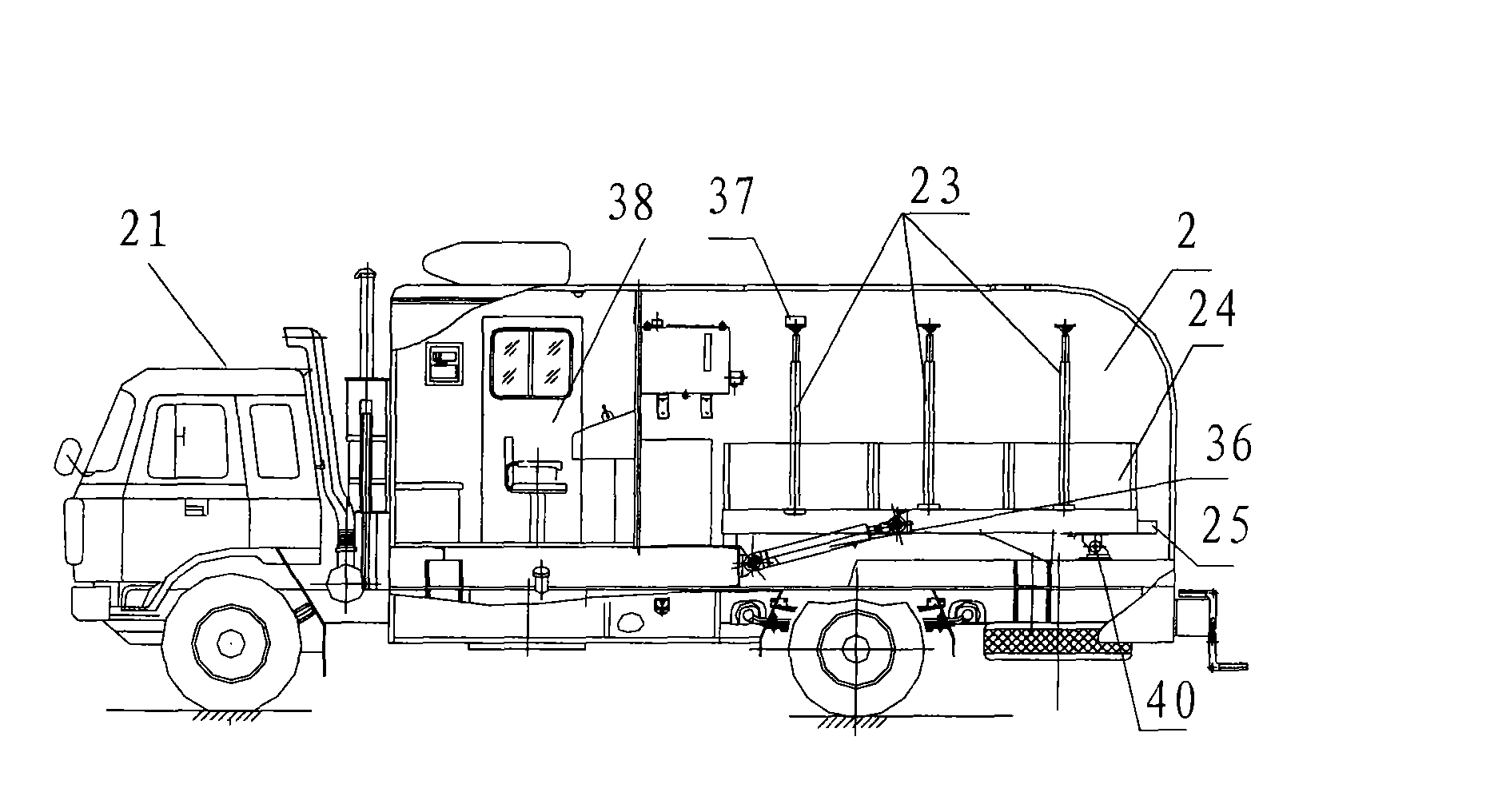

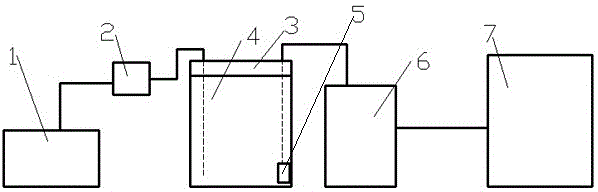

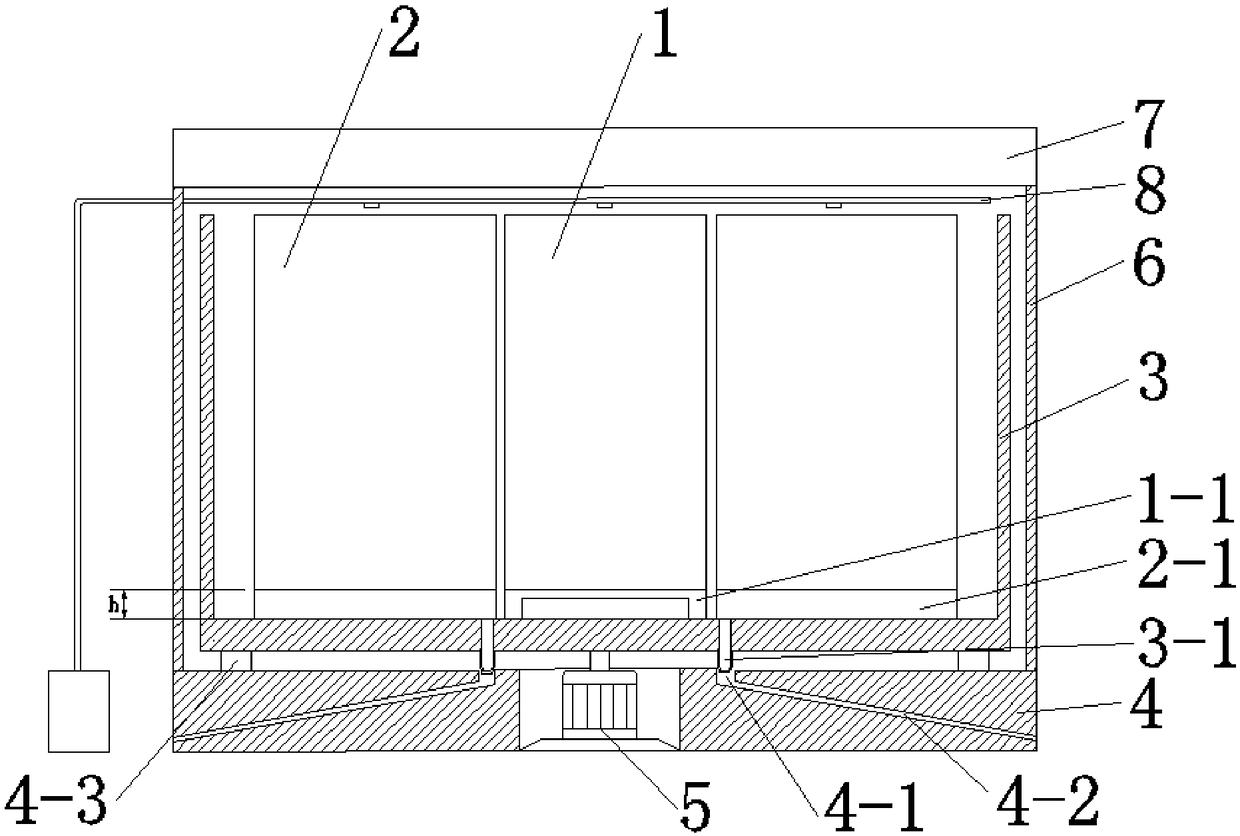

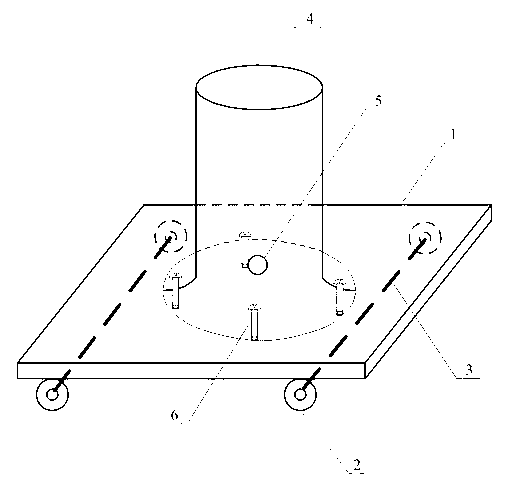

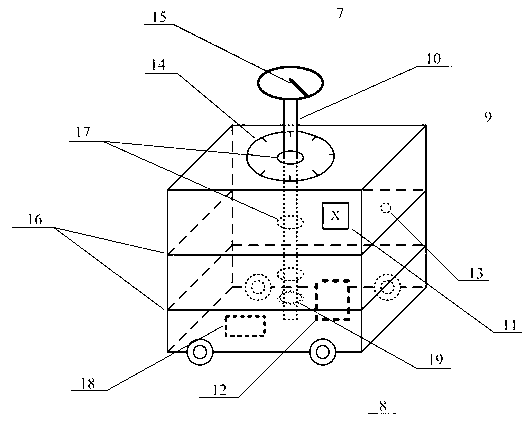

Movable water loss and soil erosion laboratory

ActiveCN101514911ALarge range of continuous changeReal-time measurementVolume/mass flow measurementEarth material testingBody compartmentEngineering

The invention relates to a movable water loss and soil erosion laboratory which comprises a power and movable towing vehicle (2), a variable slope experimental groove (3), a down-spraying type sprinkler (4), a water supply system (5) and a water loss and soil erosion observation system (6); wherein, the power and movable towing vehicle (2) comprises a power towing vehicle (7), a mobile generator (8) and an external power source (9), and the power towing vehicle (7) comprises a driving cab (47), a carriage (22) and an experimental control room (38) positioned between the driving cab (47) and the carriage (22); the mobile generator (8) and the external power source (9) are positioned on the power towing vehicle (7). The invention overcomes the defects of poor mobility, complicated control as well as time-wasting and labor-wasting experiments of various field water loss and soil erosion experimental methods and experimental facilities. The movable water loss and soil erosion laboratory can be conveniently moved in various field experimental sites, and an observing and controlling system can be used for adjusting and controlling the rainfall intensity and the variable slope experimental groove, thus the use and the operation are convenient, and the observing and controlling accuracy can be high.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

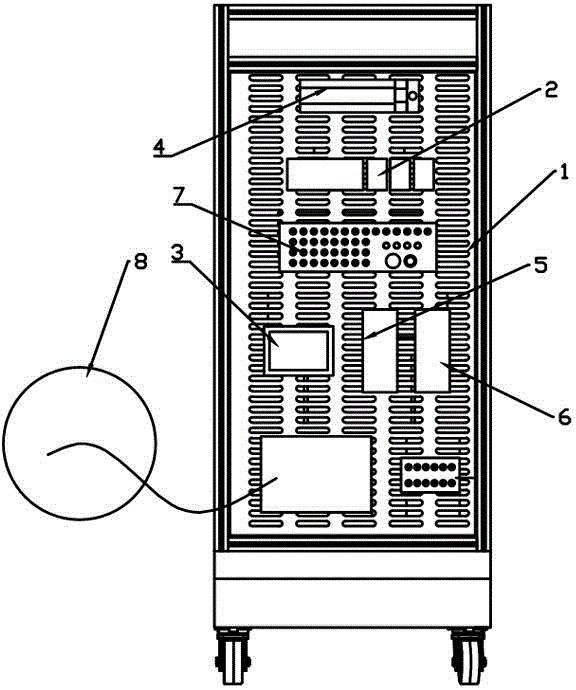

Automatic comprehensive practical training system

InactiveCN104134376AImprove reliabilityIncrease flexibilityCosmonautic condition simulationsSimulatorsHuman–machine interfaceModularity

The invention discloses an automatic comprehensive practical training system, which comprises a mesh plate base frame, a modular replaceable PLC unit, a man-machine interface, a power supply module, a servo drive module, a variable frequency drive module, a wiring terminal box and an experimental control object, wherein the mesh plate base frame is a frame body integratedly formed by a metal base and a steel spray-paint mesh plate; the modular replaceable PLC unit is a programmable controller; and the wiring terminal box is arranged on the mesh plate base frame, and on the basis of the wiring terminal box, all or selective parts of the modular replaceable PLC unit, the experimental control object corresponding to the teaching content, the man-machine interface, the power supply module, the servo drive module and the variable frequency drive module are arranged on the mesh plate base frame and are electrically connected to form a simulation practical training system. When the comprehensive practical training system of the invention is applied, the trainee can design a system scheme according to the teaching content and select devices for assembly and debugging and other practical training, and the teaching quality and comprehension of the trainee beyond book knowledge can be significantly enhanced.

Owner:SUZHOU INST OF INDAL TECH

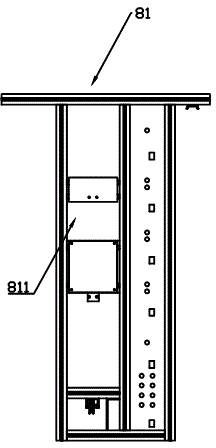

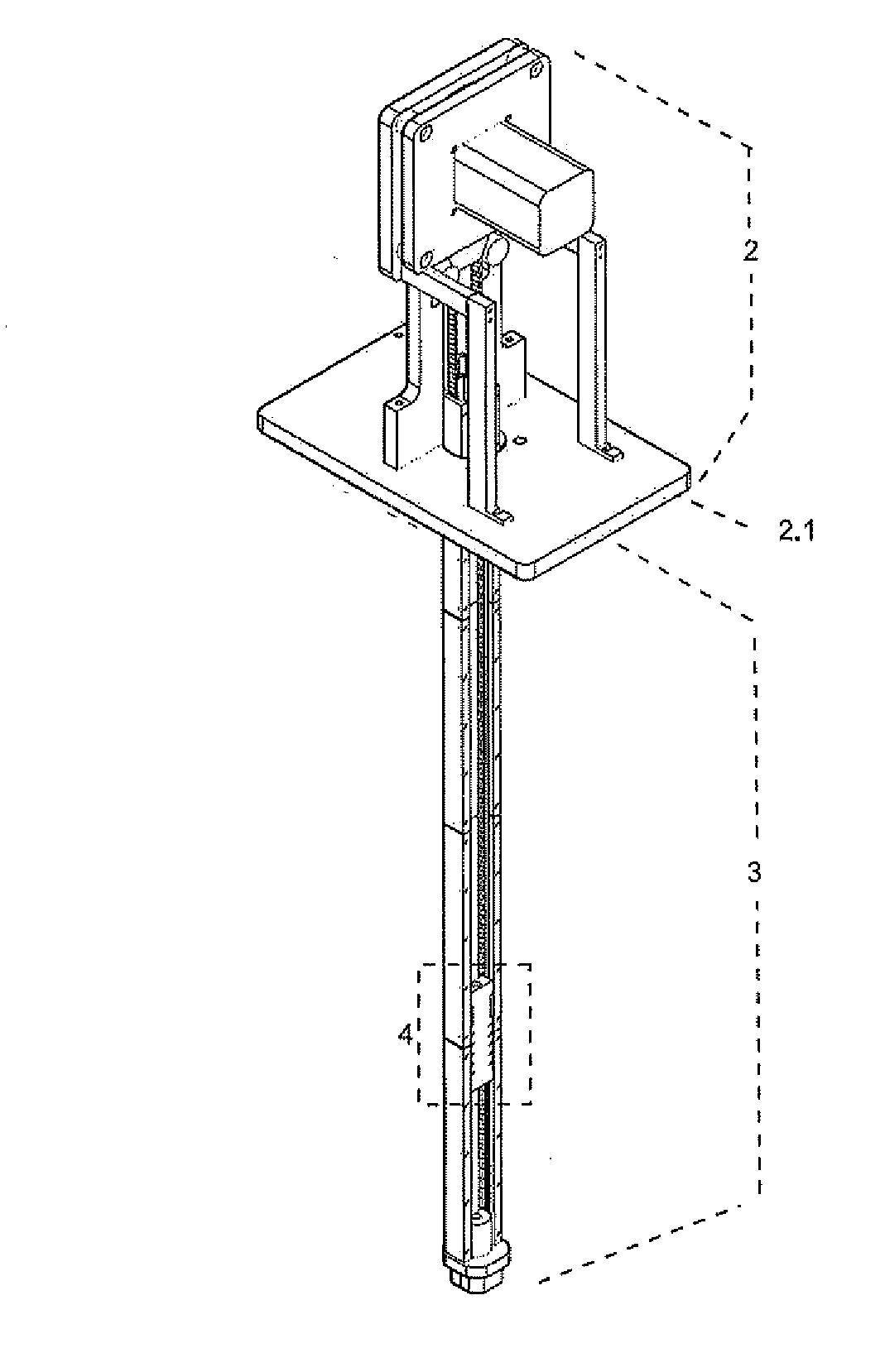

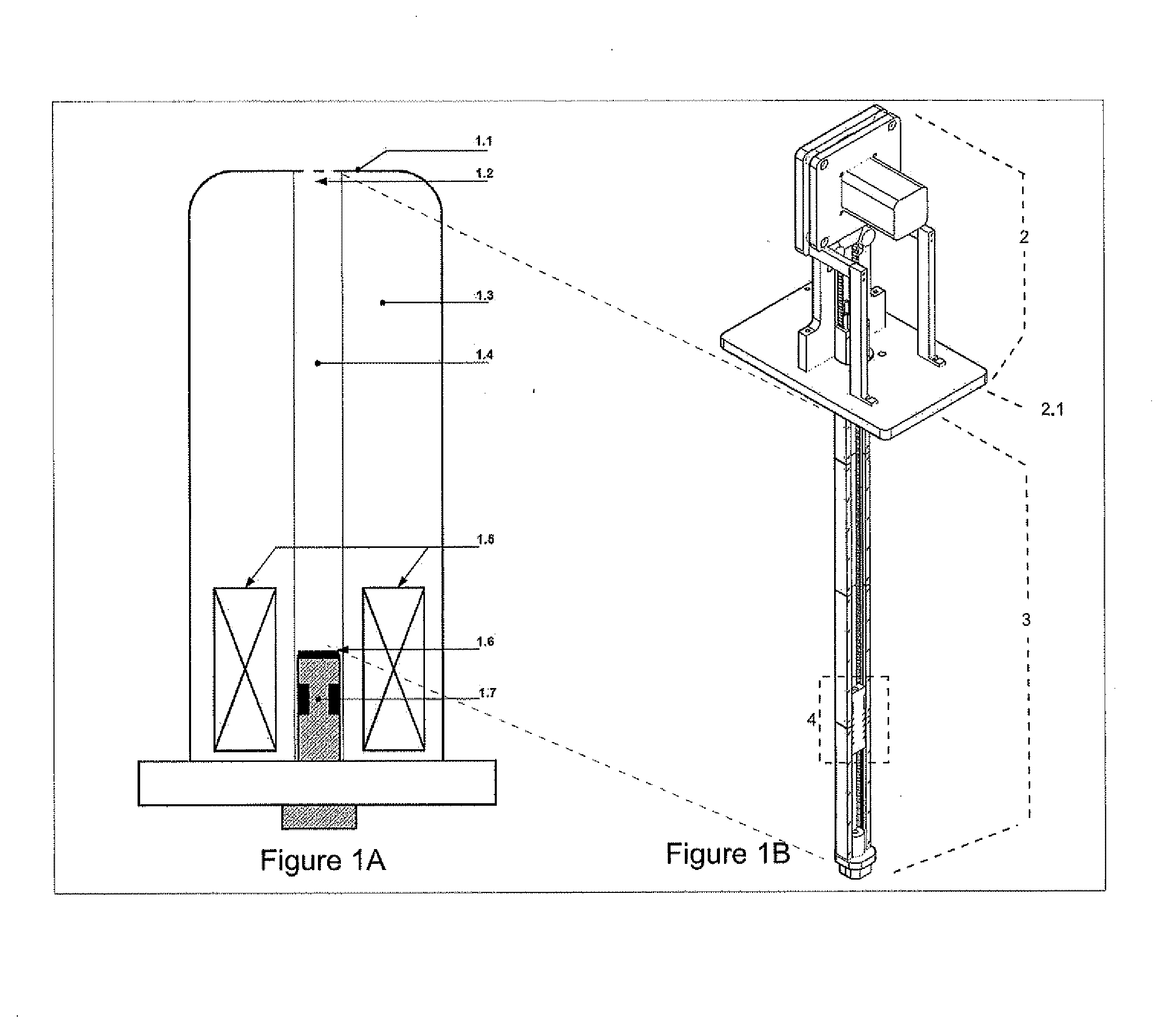

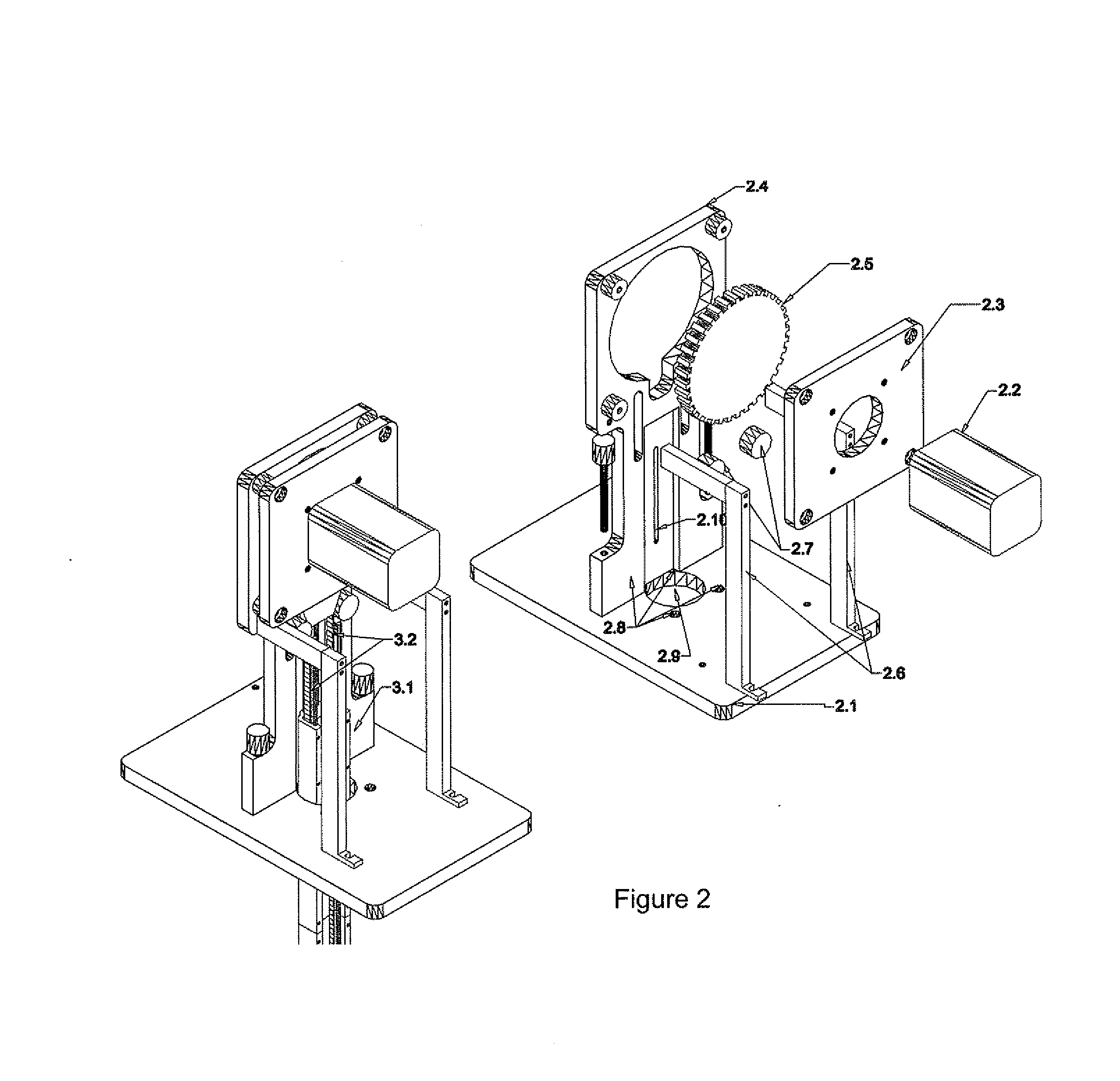

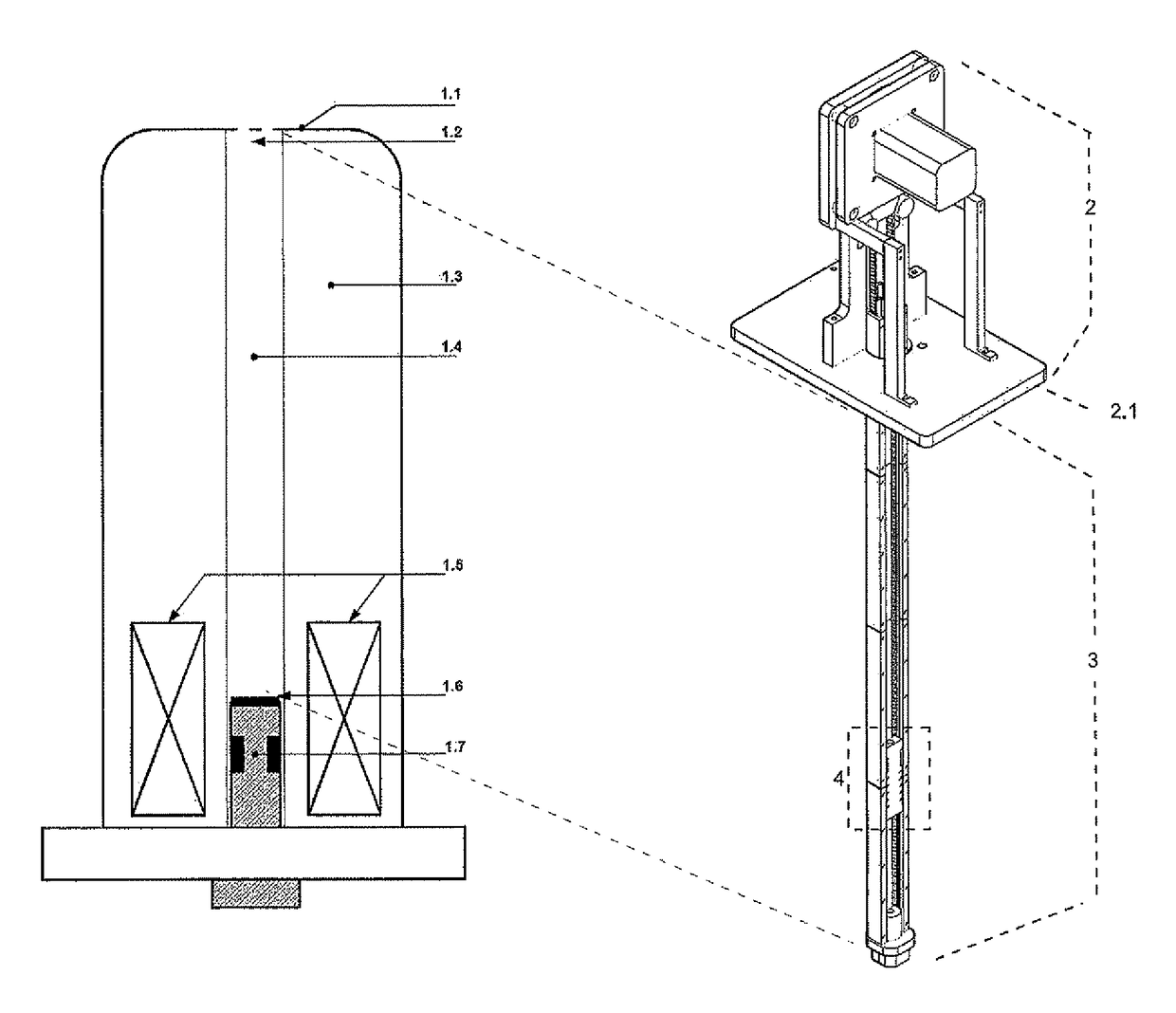

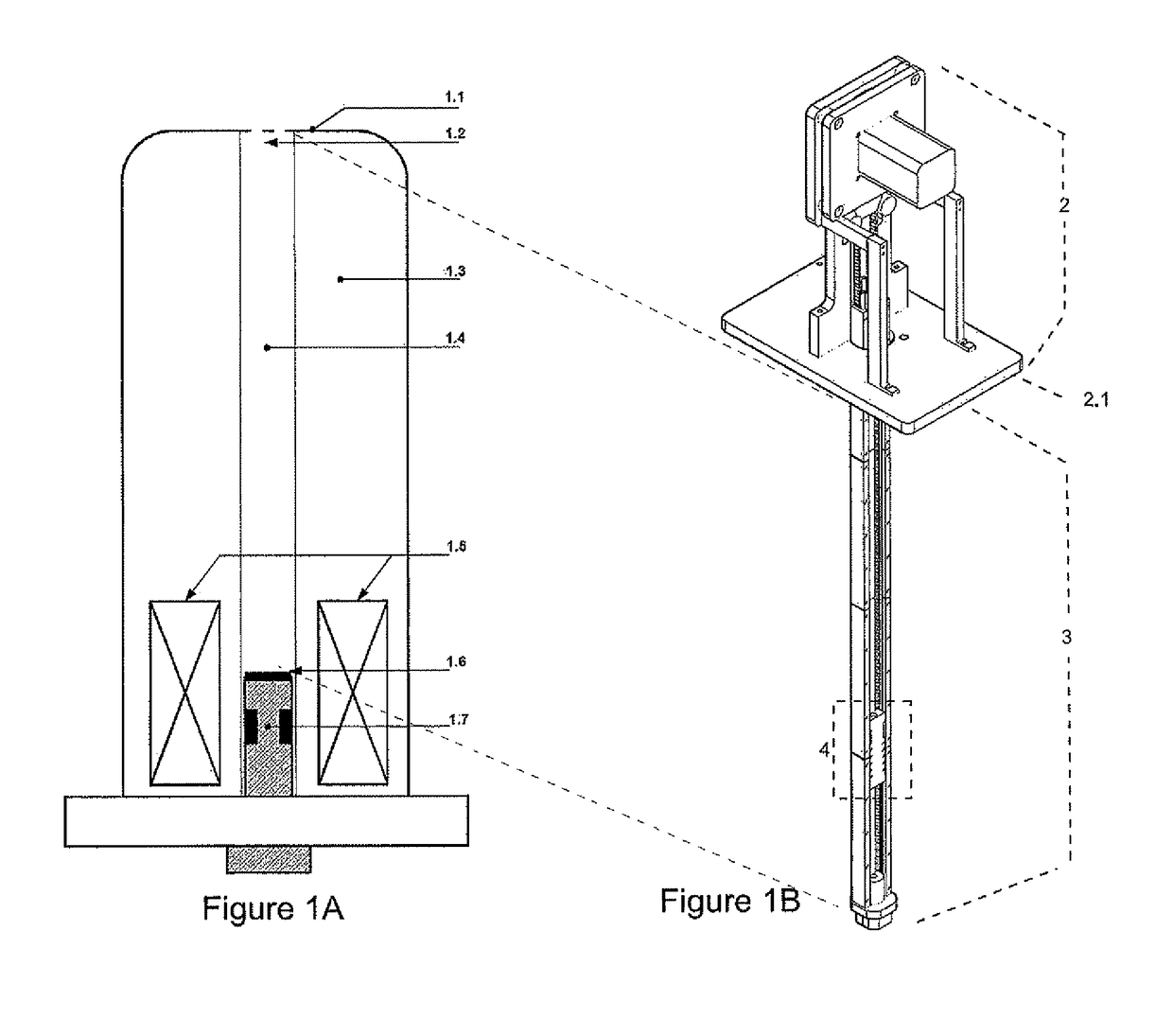

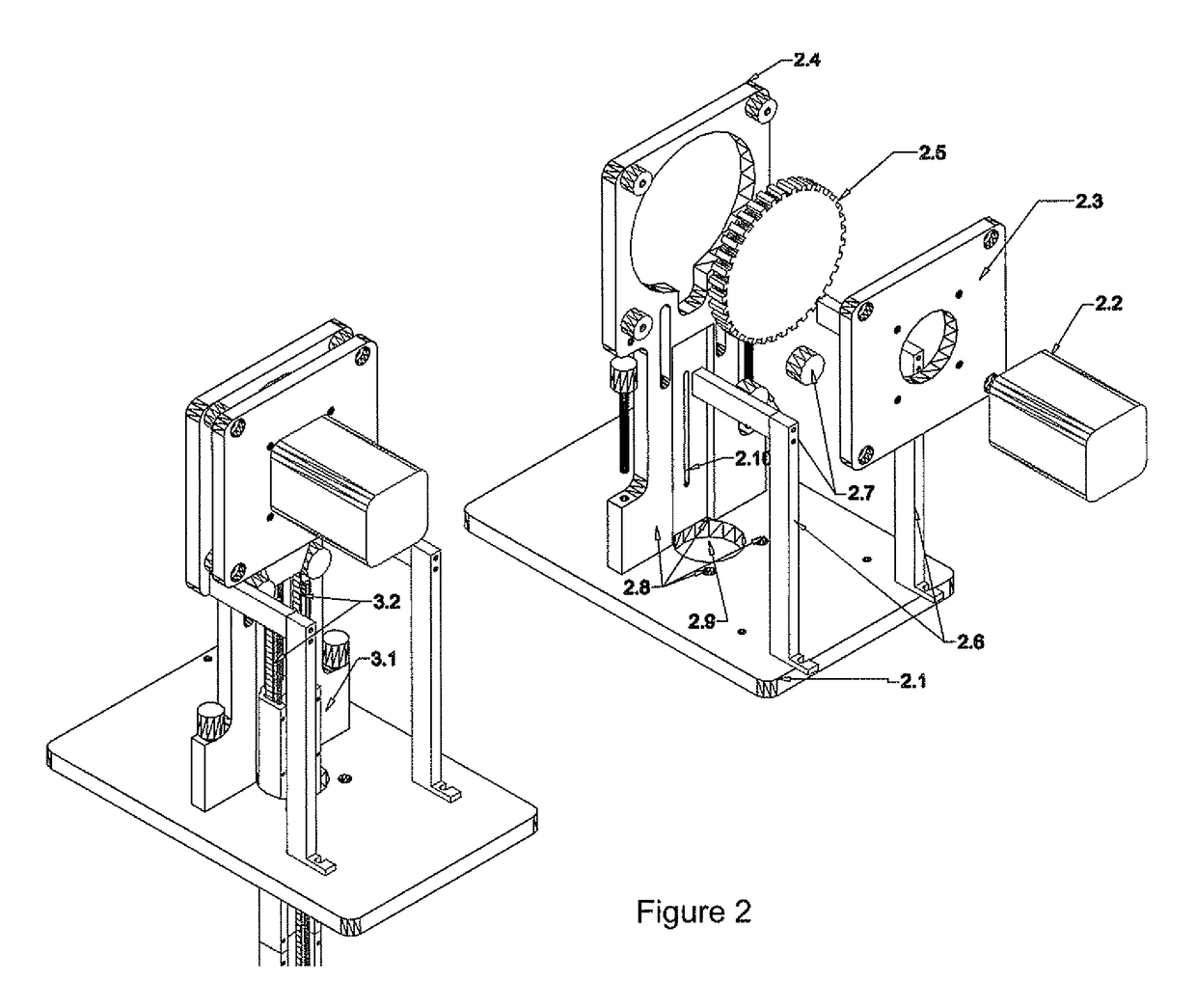

High speed sample transportation apparatus in a superconducting magnet and transporting method thereof

ActiveUS20130342209A1Minimizes sample denaturationHigh sensitivity and resolutionElectric/magnetic detectionMeasurements using magnetic resonanceNMR - Nuclear magnetic resonanceSuperconducting Coils

A precision high-speed shuttle device for transporting samples between different positions of a superconducting magnet with different magnetic field strength is provided. The sample equilibrated at the center of the magnet, where the magnetic field is the highest and homogeneous, is shuttled to a higher position above, where the fringe field is lower, for a defined period of time and shuttled back to the center for detection. By shuttling the sample to different positions in the magnet in different experiments one can obtain a field-dependent profile of particular physical parameters. The position and timing of the sample are precisely under the experimental controlled. In this way various magnetic field-dependent nuclear magnetic resonance (NMR) experiments can be conducted in a single high-field NMR spectrometer.

Owner:ACAD SINIC

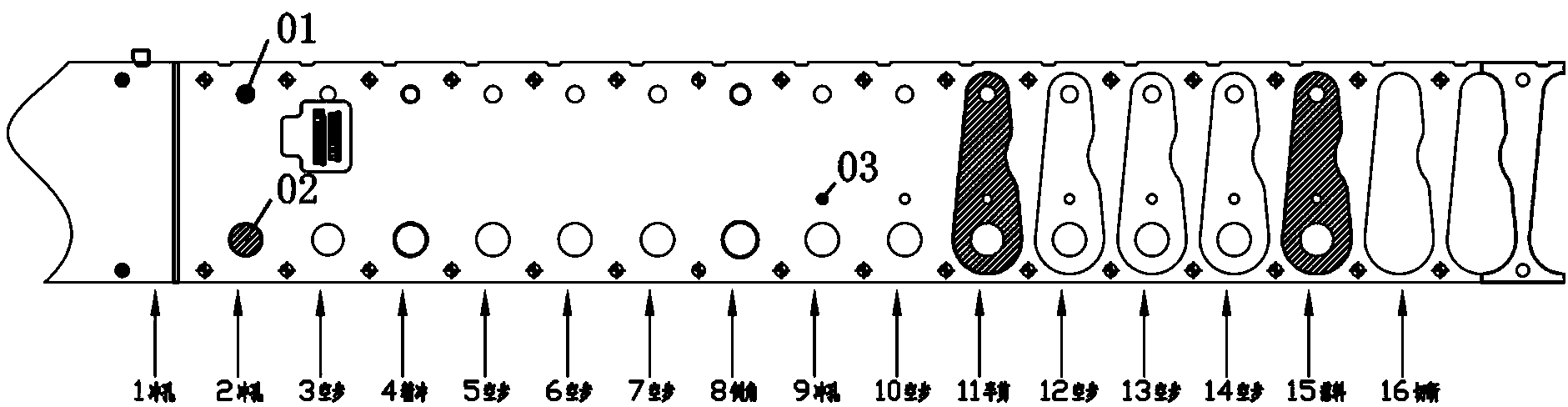

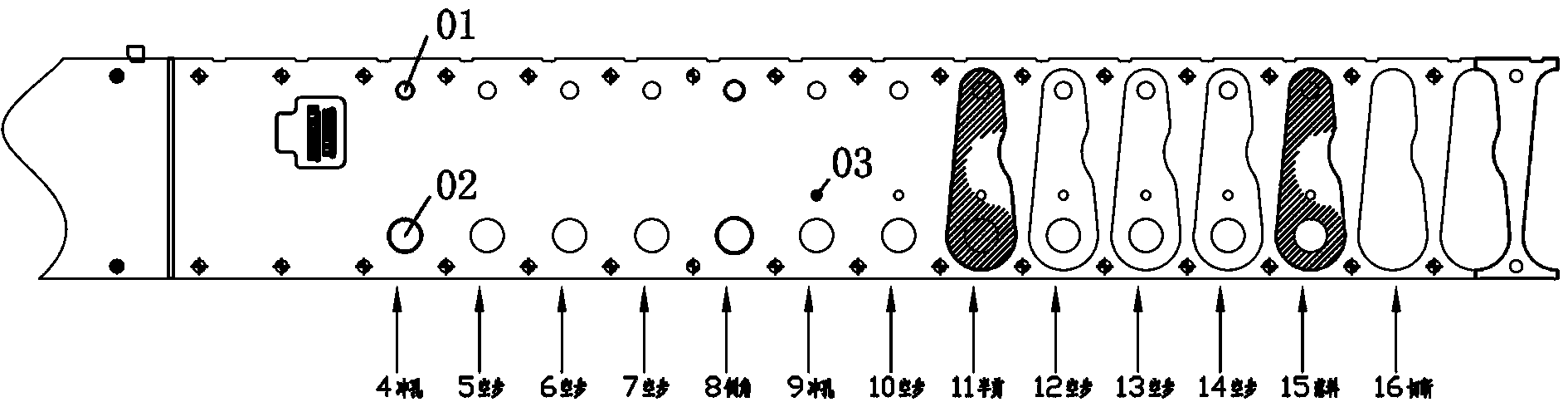

Forming process of car seat connecting plate

The invention discloses a forming process of a car seat connecting plate. The process is characterized by including the following process steps of firstly, punching locating holes, wherein a long-bar-shaped sheet of which the thickness ranges from 3mm to 10mm is placed on a continuous die, and the locating holes are formed in the two sides of the sheet respectively; secondly, punching assembly holes in the two sides, wherein the gap of single edges between the inner wall surfaces of two female dies and the outer wall surfaces of corresponding punches is set into the range from 0.25mm to 0.5mm, and the first assembly holes and the second assembly holes are punched; thirdly, punching middle assembly holes, wherein the gap of single edges between the inner wall surfaces of the two female dies and the outer wall surfaces of the corresponding punches is set into the range from 0.25mm to 0.5mm, and the third assembly holes are punched; fourthly, conducting semi-shearing, the outer contour of the car seat connecting plate is punched on the sheet, and the outer contour line of the car seat connecting plate is made to sink downwards by 1mm to 2mm; fifthly, conducting blanking, wherein a material is completely cut off along the outer contour line formed in the fourth step, and then a finished product is formed. When the gap of the single edges between the inner wall surfaces of the two female dies and the outer wall surfaces of the corresponding punches is set to be 5% to 10% of the thickness of the sheet through experimental control, the one-time punching process can be achieved, and the defects that the traditional technology secondary punching process is high in the requirement for accuracy of equipment, the production difficulty is large, production cost is high, the yield is low, materials are wasted, and the punches are not uniform in stress, severe in abrasion and short in service life are overcome.

Owner:RAINBOW METAL TECH

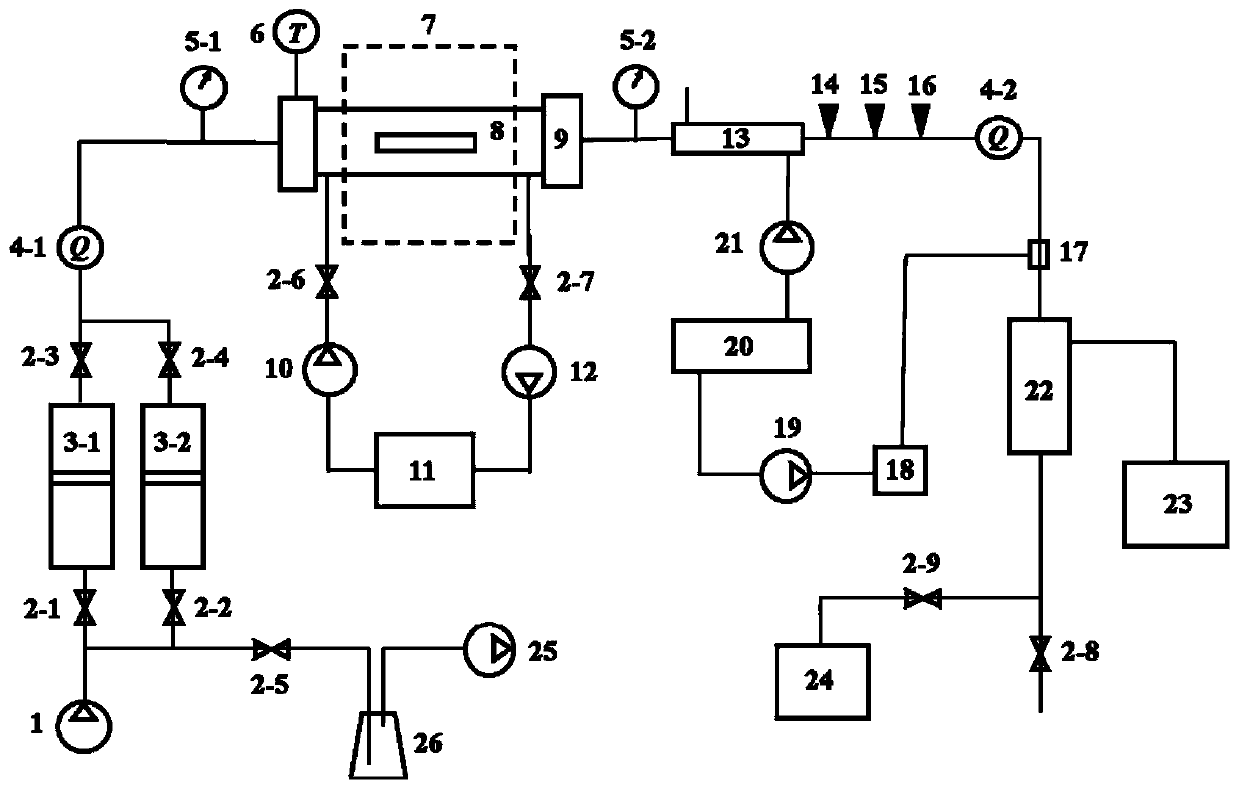

Real-time monitoring device for dynamic expansion of carbonate rock acidified wormhole and working method of real-time monitoring device

PendingCN110284880AMeet the requirements of fast imagingResolves rapid porosity changesBorehole/well accessoriesNMR - Nuclear magnetic resonanceControl system

The invention provides a real-time monitoring device for dynamic expansion of a carbonate rock acidified wormhole. The real-time monitoring device comprises an acid liquid injection system, an acid rock reaction system, a nuclear magnetic resonance testing system, an acid liquid recovery treatment system and a data collecting and experimental control system; the acid rock reaction system is used for simulating the formation temperature and pressure; the nuclear magnetic resonance testing system is used for core pore imaging; and the acid liquid recovery treatment system is used for recovering acid liquid and treating waste gas. Dynamic expansion of the carbonate rock acidified wormhole is monitored in real time through the device, the static imaging precision reaches 0.1-100 [mu]m, the shortest dynamic imaging time is 13 s, the requirements of pore accurate description before acidification and wormhole quick imaging during acidification can be met simultaneously, and the problem that as for a reaction fluid displacement experiment, pore change is quick, and consequently imaging is difficult is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Software verification method for control units and verification system

InactiveUS7275184B2Development risk can be minimizedLow costProgramme controlComputer controlComputer architectureSynchronous detection

A method and system for the verification of software functions for a control unit, using a simulation model to simulate the software functions and the control unit, the software code for the software functions being generated automatically from the identical simulation model, firstly for a first experimental control unit and secondly for a second standard control unit, identical input variables for the software functions being used on both control units and the output variables of both control units resulting therefrom being detected synchronized in time, i.e., simultaneously, the software functions being verified through comparison of the output variables of both control units.

Owner:ROBERT BOSCH GMBH

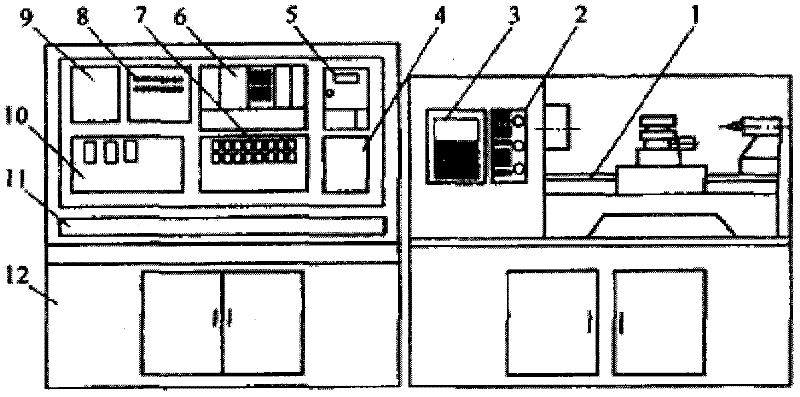

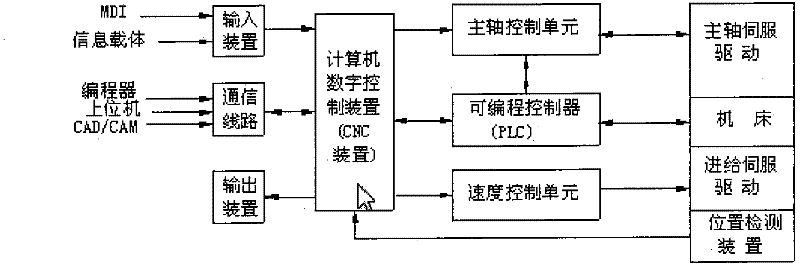

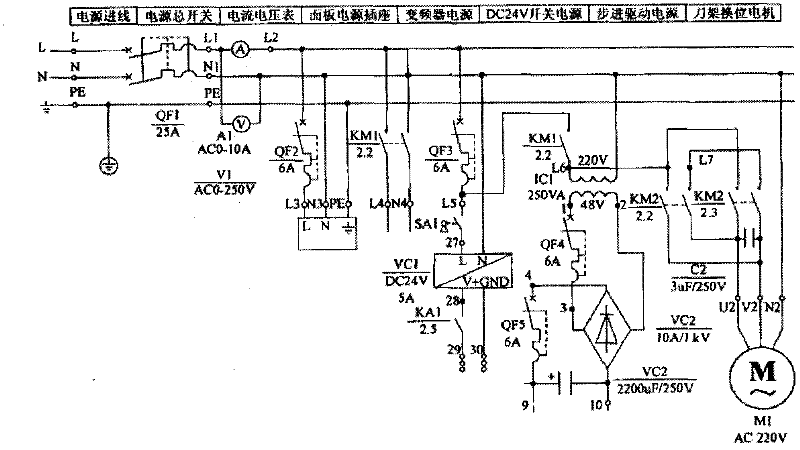

Machine tool device

InactiveCN102456289ARealize automatic barrier settingAutomatic barrier settingEducational modelsNumerical controlFrequency conversion

The invention belongs to the technical field of numerical control machine tools and particularly relates to a machine tool device for teaching. The invention aims to provide a comprehensive machine tool device with full functions so as to improve a condition of no high-level and full-functional experiment equipment in the school when operation, programming, installation, debugging and maintenance of the numerical control machine tool are trained, and fasten the teaching speed of engineering technical personnel on the aspects of programming, operation and maintenance of the numerical control machine tool. The machine tool device is provided with an open-type experimental control demonstration platform and a machine tool part, wherein the machine tool part comprises a numerically controlled lathe, a lathe control panel and a system operation panel; the open-type experimental control demonstration platform comprises a servo analogue unit, a main shaft frequency conversion unit, a numerical control unit, an input / output unit, a display control unit, a power supply input unit, a step drive unit, a power supply output unit and a cushion box.

Owner:杨燕

High speed sample transportation apparatus in a superconducting magnet and transporting method thereof

ActiveUS9696391B2High sensitivity and resolutionMinimize denaturationElectric/magnetic detectionMeasurements using NMRNMR - Nuclear magnetic resonanceSuperconducting Coils

A precision high-speed shuttle device for transporting samples between different positions of a superconducting magnet with different magnetic field strength is provided. The sample equilibrated at the center of the magnet, where the magnetic field is the highest and homogeneous, is shuttled to a higher position above, where the fringe field is lower, for a defined period of time and shuttled back to the center for detection. By shuttling the sample to different positions in the magnet in different experiments one can obtain a field-dependent profile of particular physical parameters. The position and timing of the sample are precisely under the experimental controlled. In this way various magnetic field-dependent nuclear magnetic resonance (NMR) experiments can be conducted in a single high-field NMR spectrometer.

Owner:ACAD SINIC

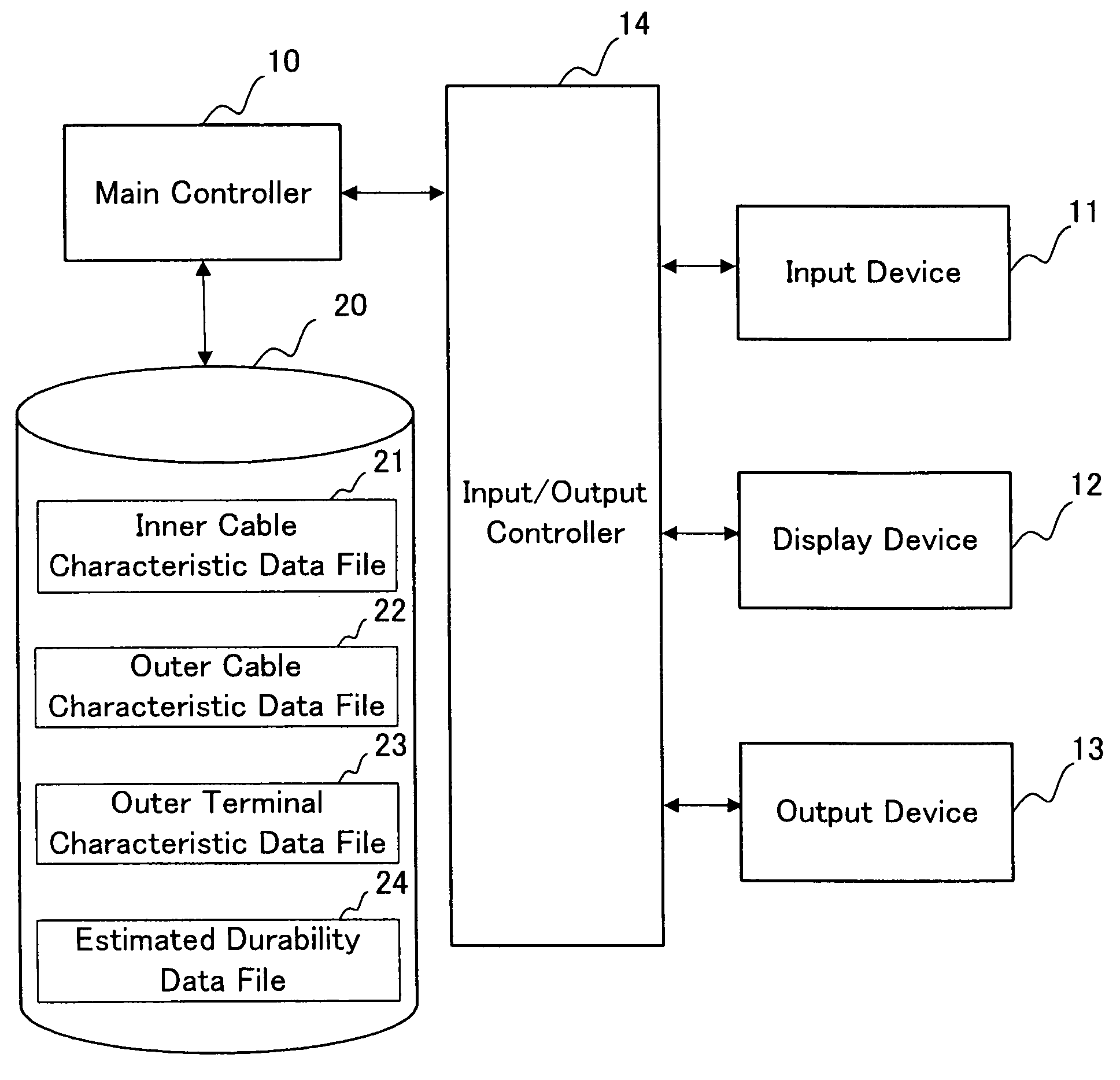

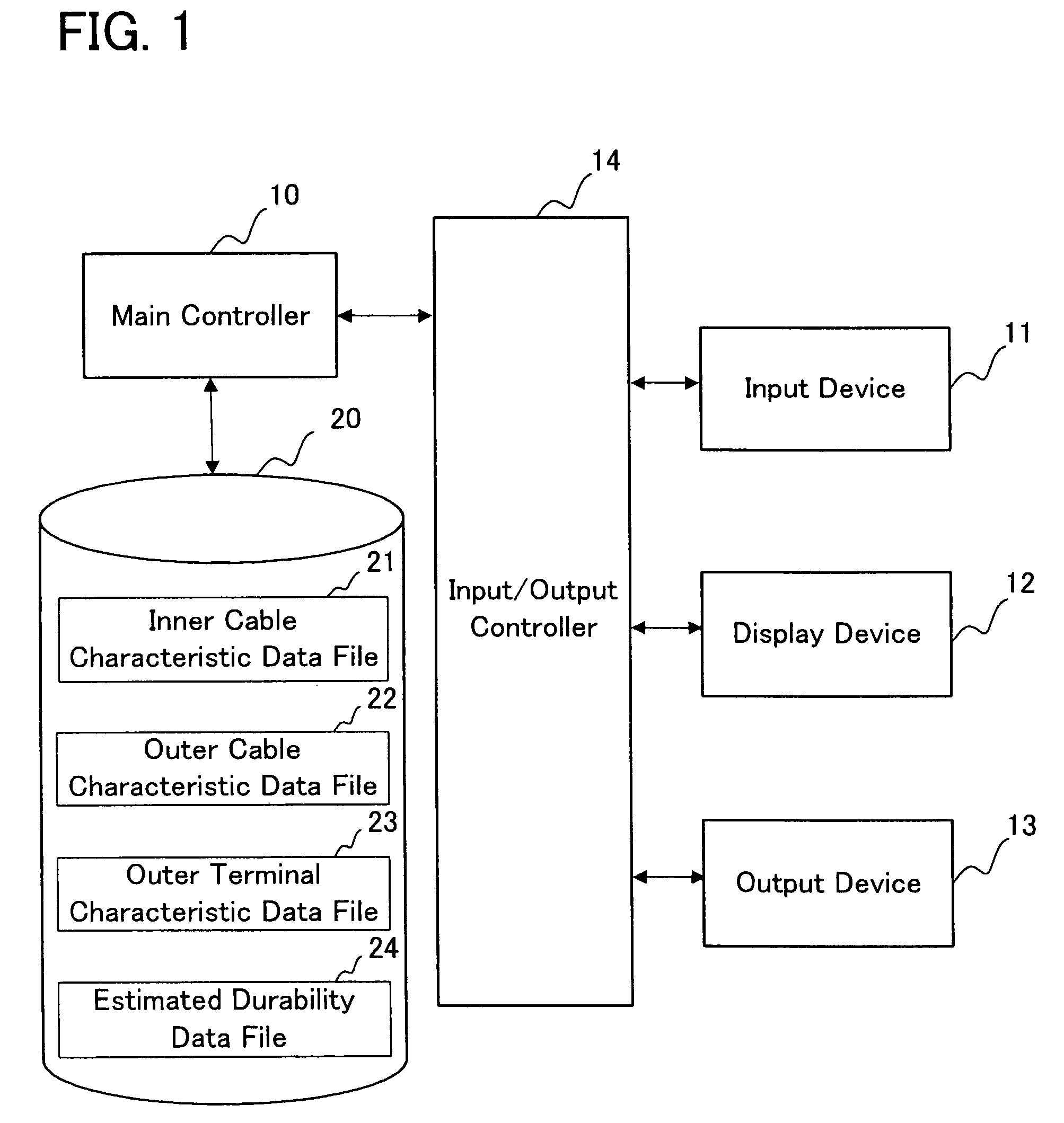

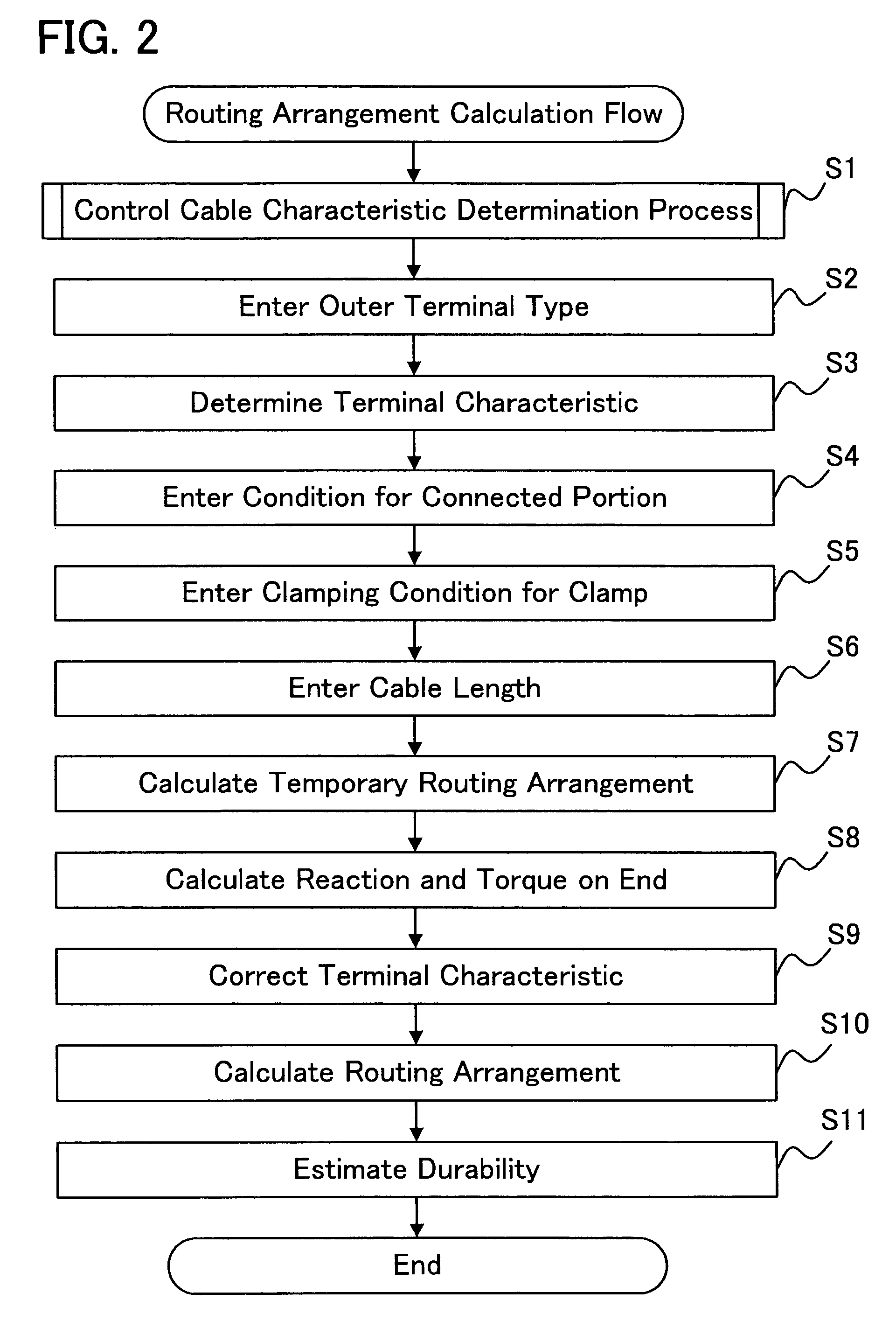

Methods and apparatus for calculating routing arrangements for control cables

InactiveUS7013236B2Easy to separatePrecise arrangementGeometric CADElectrical testingExperimental controlConnection control

The present invention provides a method for predicting a routing arrangement for control cable without preparing experimental control cables. In the method according to the present invention, characteristics of a control cable to be laid are obtained (S1, S2, and S3). The characteristics of the control cable can be obtained by subjecting a test piece of control cable to a known test (tensile test). Next, a length of the control cable and a condition for connecting the control cable are provided as conditions for a computation (S4 and S5). Then, the given length of the cable, the given condition for connecting the cable, and the obtained characteristic of the control cable are used for a computation model, which was formed by dividing the control cable into a plurality of elements, in order to perform a finite element method, and, thus, a routing arrangement is calculated (S7).

Owner:CHUO SPRING

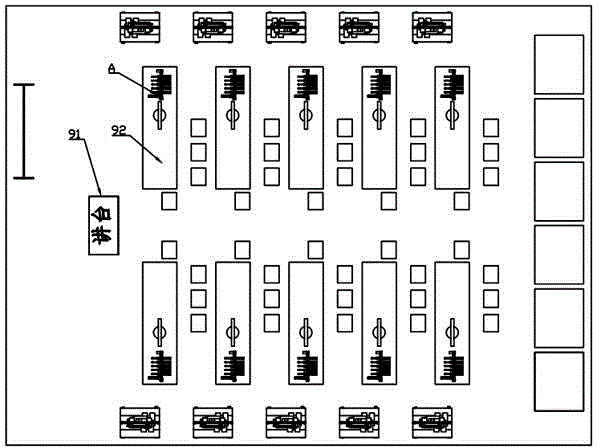

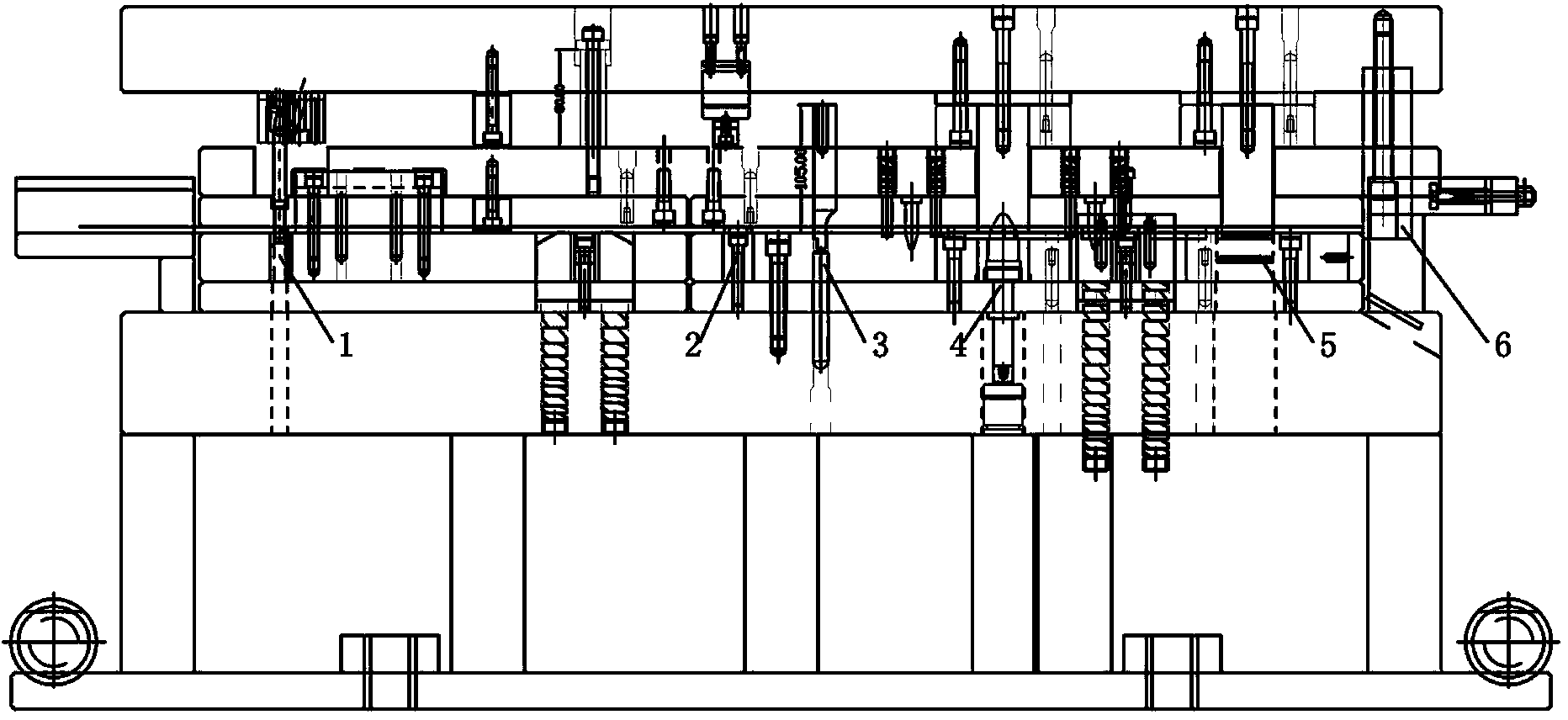

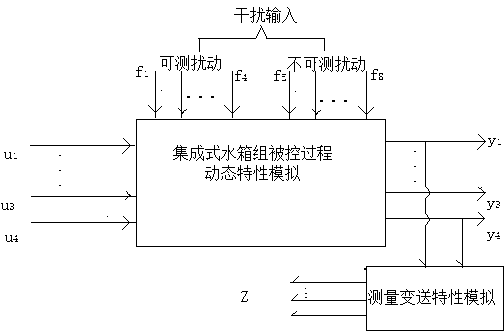

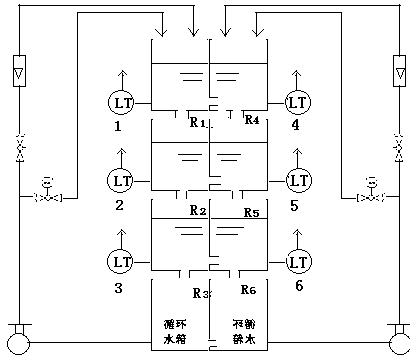

Integrated experimental device for controlling dynamic process of flow industry

ActiveCN103236202AFlexible exchangeFlexible adjustment performanceTeaching apparatusResistance capacitanceControl system

The invention discloses an integrated experimental device for controlling a dynamic process of a flow industry, and relates to an experimental control device. The device consists of more than two resistance-capacitance water tanks, and a pipeline-free and valve-free integration mode is used for forming the experimental device for simulating dynamic characteristics of an object. A plurality of control system modes are configured for test. A controlled object of the experimental device is formed by integrating basic units which are resistance-capacitance links without pipelines or valves. The fluidic resistance of a throttling hole is regulated in a threaded seat cover way, and is changed from 0 to infinite to simulate a plurality of linear or nonlinear dynamic characteristics. The water tanks are provided with measurement transmitters respectively, a field indication rotor flow meter, a throttling hole plate, a control valve and a circulation water pump are arranged in four paths of water inlet pipelines respectively, and a pressure meter is arranged at an outlet of the water pump. The device can be used for a process control simulation experiment in flow processes of large chemical production devices, equipment and machines, fluid production devices, equipment and machines and the like, and is applied to the automatic teaching and scientific researches of colleges, scientific research institutions, training institutions, factories and the like as well as teaching.

Owner:JIANGSU BOZHI SOFTWARE TECH CO LTD

Simulated soil solution test apparatus and method for evaluating toxicity of pollutants to earthworms

InactiveCN105136797AGood test reproducibilityHigh sensitivityMaterial analysis by optical meansIntestinal structureEcological risk

The invention relates to a simulated soil solution test apparatus and method for evaluating toxicity of pollutants to earthworms. The apparatus includes light transmitting and watertight incubators, each incubator is internally provided with a monitoring device, and the incubators are connected to an oxygen supply device. The method consists of: preparing a simulated solution containing the main components of a soil solution; adding environmental pollutants of different concentrations into the simulated solution, and conducting numbering respectively, and also taking a simulated solution without adding of environmental pollutants as the experimental control; adding the environmental pollutants added simulated solutions with different numbers into different incubators, putting intestine cleared earthworms into the incubators, and exposing the earthworms in the solutions completely; and introducing oxygen into the cubators through an oxygen supply device, and observing and recording the behavior reaction and fatality rate of the earthworms in different environmental pollutants' simulated solutions within a certain period of time through cameras. The test apparatus provided by the invention has the advantages of simplicity, good test reproducibility and high monitoring sensitivity, etc., thus having broad application prospects in the field of contaminated soil ecological risk assessment.

Owner:FUJIAN AGRI & FORESTRY UNIV

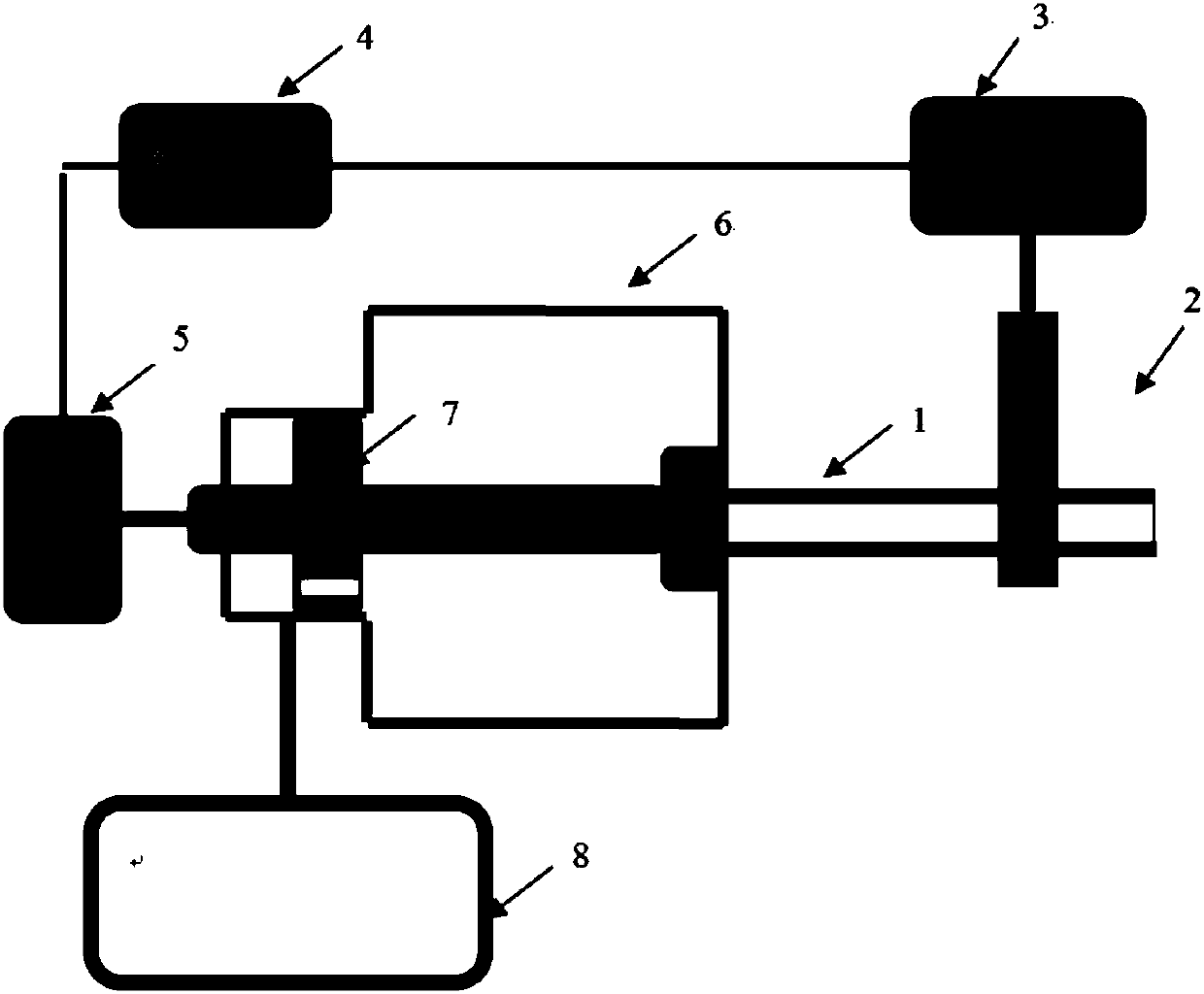

Single-tube air cannon capable of achieving continuous launching

ActiveCN109870069AGuaranteed repeatabilityRapid successionCompressed gas gunsShock testingServo actuatorElectricity

The invention discloses a single-tube air cannon capable of achieving continuous launching. The single-tube air cannon comprises a launching tube, a pellet feeding device 2, an electric servo actuator3 for pellet feeding, an experimental control system 4, an electric servo actuator 5 for launching / air supplement, a launching air chamber 6, a combination valve body 7 and an air supplement chamber8, wherein the launching tube 1 is connected with the pellet feeding device 2, and a plurality of pellets can be prearranged in the pellet feeding device 2; one pellet is pushed by the electric servoactuator 3 for pellet feeding to enter the launching tube; the launching tube 1 is connected with the launching air chamber 6, and the launching air chamber is of a rotator type stepped cylindrical structure, and, and is composed a large chamber at the right end and a small chamber at the left end; and the launching air chamber 6 is connected with the small chamber of the air supplement chamber 8through an air path. According to the technical scheme, the test requirements of aircraft structures, high speed trains, wind turbine blades and other high speed running machines for continuous impactby foreign objects can be met, and meanwhile the launching interval or frequency can be set through control over the regulation of parameters.

Owner:CHINA AIRPLANT STRENGTH RES INST

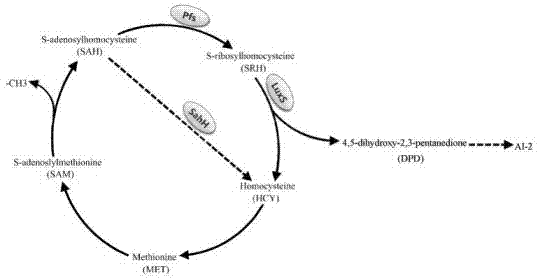

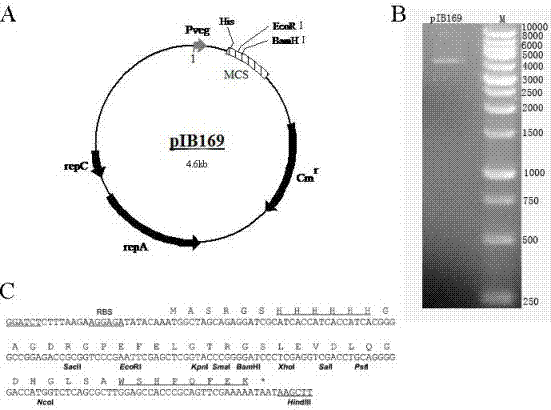

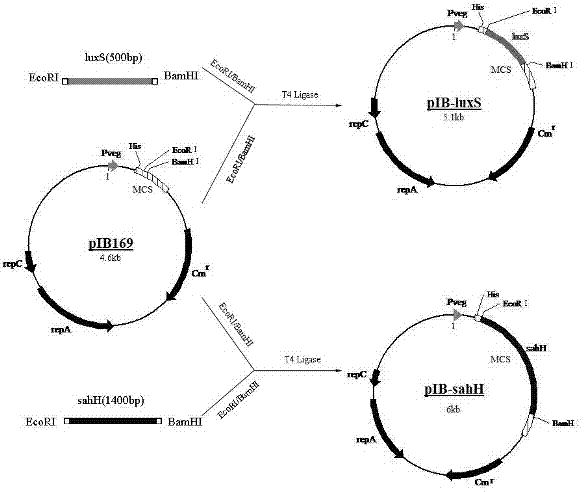

Streptococcus mutans AMC metabolic recovery strain based on LuxS defect

InactiveCN103865861AOvercoming research barriersEffective Molecular Biology ToolsBacteriaMicroorganism based processesHeterologousMicrobiology

The invention discloses a streptococcus mutans AMC metabolic recovery strain based on LuxS defect, wherein AMC metabolic recovery strain is StreptococcusmutansKO-SUA159:: delta luxS, pIB-sahH and has a preservation number of CCTCCM2013699. The LuxS-mediated metabolism is separated from density induction by heterologous expression of SahH in a Streptococcus mutans stain with LuxS defect, the obstacles to research on the LuxS mechanism, caused by dual-defect effect of the deletion of LuxS, is effectively overcome, and an effective molecular biology tool and experimental control are provided for the discuss about the regulation mechanism of Streptococcus mutans LuxS.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Modeling and detecting method for rapid detection on nitrate in vegetables

InactiveCN107024445AEasy to handleNo action requiredMaterial analysis by optical meansDesign optimisation/simulationModel sampleIntelligent algorithms

The invention relates to a modeling and detecting method for on-scene safe and rapid detection on nitrate in vegetables based on an infrared total-reflection spectrum of a screened range. The method comprises the steps: dividing the vegetables into two parts, measuring experimental control data of one part by a chemical method, and extracting characteristic absorption spectrograms with the wave number of 6.5 to 8 microns from the other part as modeling samples; preparing a series of nitrate standard solutions, and acquiring spectral information as modeling samples; subjecting two curves to preprocessing, so as to remove interference; modeling a spectral curve of the nitrate in the vegetables, a spectral curve of the standard solutions and chemical reference values so as to establish correlativity; acquiring characteristic absorption spectrograms of the vegetables to be detected, and subjecting spectra to preprocessing so as to remove interference; subjecting the spectral curve of the nitrate and models to intelligent identification classifying, selecting optimal-matched modeling samples and modeling sample numbers, acquiring samples with optimal similar characteristics through an intelligent algorithm, predicting nitrate content, and carrying out comparison, so as to obtain edible information on the vegetables. The method is safe, does not use chemical reagents, is applicable to on-scene rapid acquisition and is high in detection efficiency.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

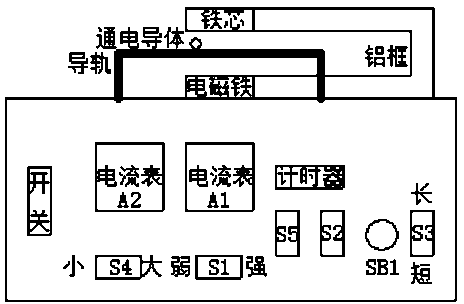

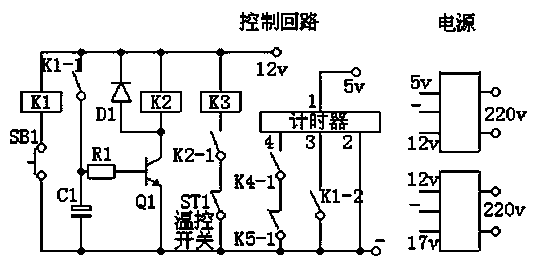

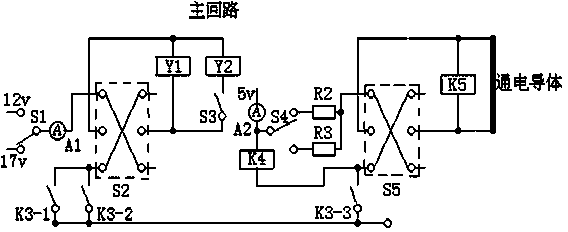

Ampere force experimental control device

InactiveCN103903498AChange directionEasy to exploreEducational modelsElectrical conductorAutomatic control

The invention relates to an ampere force experimental control device which is composed of an operation panel, an aluminum frame, an iron core, two electromagnets, a guide rail and an electrified conductor. Compared with a traditional ampere force experimental control device, the ampere force experimental control device can effectively change the direction and intensity of a magnetic field, change the magnitude and direction of a current flowing through the electrified conductor and the effective length of the access magnetic field, and automatic control, counting and the like further can be conducted on an experiment, students can conveniently research the direction and magnitude of ampere force according to the device, and the experiment effect is improved.

Owner:石小明

Test and research system for fuel cell hybrid power system

InactiveCN1601792BHighly innovativeSufficient measurement accuracyElectric devicesFuel cellsFuel cellsControl system

Experimental investigation system of fuel cell hybrid power system includes loading system, experimental control system, hybrid power system and test system. The loading system simulates road condition, dynamics characteristics of car body, and drivers. Combining with operation conditions of each part in the system, the experimental control system converts each condition to control command for each part, controls and adjusts running condition. The hybrid power system is subject to the disclosed experimental investigation system investigates. The test system collects, monitors and records operation conditions of other three systems. The invention carries out experimental investigation functions of testing and checking fuel cell hybrid power system, that traditional testing system for internal combustion engine does not perform. Thus, the invention possesses high innovation.

Owner:清华大学苏州汽车研究院(吴江) +1

Experimental control method for evaluating service life of transformer oil

InactiveCN102384929AStable controlEasy to controlMaterial heat developmentTemperature controlAutomatic control

The invention relates to an experimental control method for evaluating service life of transformer oil, which mainly resolves the problems that in the prior art, only sample temperature and oxygen flow can be controlled, practical application environment of the transformer oil can not be simulated really, and fault protection can not be achieved. A temperature sensor is adopted to sample experimental temperature of the transformer oil, a gas quality flow sensor is adopted to sample oxygen flow supplied into the transformer oil, a voltage transducer is adopted to sample working voltage of a transformer, and a high voltage transducer is adopted to sample experimental high voltage. Sampled temperature, oxygen flow, working voltage of the transformer and experimental voltage information are inputted into a computer. The computer is communicated with a temperature control digital instrument, a gas quantity flow meter, an alternating current voltage stabilizer and an experimental high voltage instrument, thereby achieving the aims of automatic control and fault protection of temperature oxygen flow, working voltage of the transformer and experimental high voltage. The experimental control method for evaluating service life of transformer oil can be applied to evaluation experiments of service life of the transformer oil.

Owner:CHINA PETROLEUM & CHEM CORP

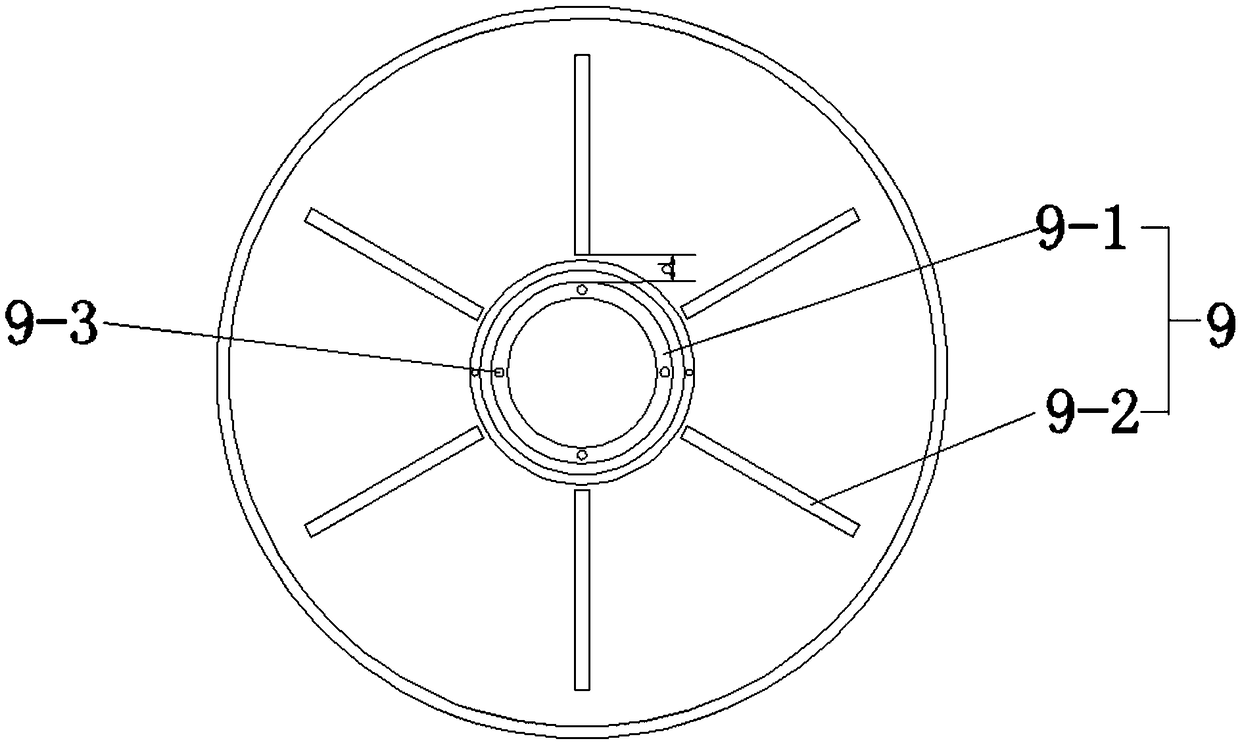

Split-type rotatable multi-ring mycorrhiza split-compartment cultivating and processing device

ActiveCN109251843AEasy to take out separatelyRealize functionBioreactor/fermenter combinationsBiological substance pretreatmentsGrowth plantArbuscular mycorrhizal fungi

The invention provides a split-type rotatable multi-ring mycorrhiza split-compartment cultivating and processing device and belongs to the field of arbuscular mycorrhizal fungi. The device solves a problem that existing split-compartment cultivating devices are difficult to sample on time. The split-compartment cultivating and processing device comprises a plant growth chamber, hypha development chambers, an experimental control tube and a base. A motor is arranged in a base body of the base, the experimental control tube rotates under the drive of the motor, the plant growth chamber is arranged in the experimental control tube, a plurality of hypha development chambers are arranged along the plant growth chamber in the circumferential direction, the hypha development chambers are pluggedin the top surface of the bottom of the experimental control tube, a flow passage is reserved between bottom walls of the plant growth chamber and the hypha development chambers and the bottom of theexperimental control tube, and a buffer zone is formed between a chamber side wall, close to the plant growth chamber, of each hypha development chamber and an outer surface of the plant growth chamber. By using of the split-type hypha development chambers plugged into the bottom of the experimental control tube, the split-type rotatable multi-ring mycorrhiza split-compartment cultivating and processing device is convenient for users to take out one of the hypha development chambers separately at different time periods.

Owner:HARBIN INST OF TECH

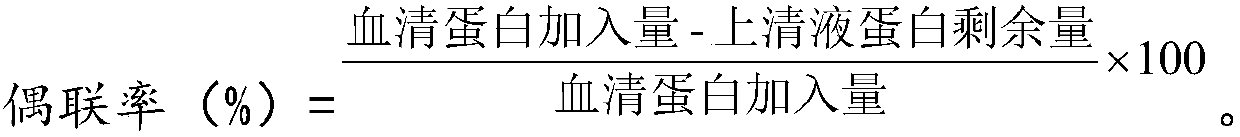

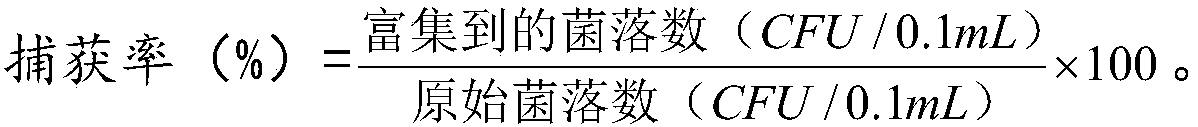

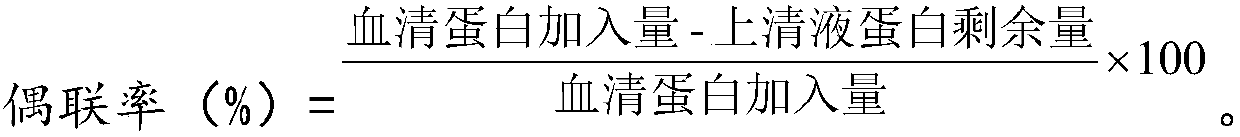

Preparation method and application of NHS immunomagnetic beads for capturing vibrio parahaemolyticus

InactiveCN107561267AReduce production processShorten the timeMaterial analysisVibrio parahemolyticusVibrio parahaemolyticus

The invention relates to a preparation method of NHS immunomagnetic beads modified with an NHS group, in particular to a preparation method and an application of NHS immunomagnetic beads for capturingvibrio parahaemolyticus. According to the method, a magnetic fluid is used as a carrier and coupled with a vibrio parahaemolyticus antibody, and the vibrio parahaemolyticus immunomagnetic beads capable of enriching a target strain is prepared. With adoption of the preparation method of the NHS immunomagnetic beads, the time is shortened from 26 h in a traditional preparation process to 2-3 h, andthe preparation efficiency is improved; experimental control shows that compared with the traditionally prepared vibrio parahaemolyticus immunomagnetic beads, accuracy rate of enriched target flora is increased by 6.7 %; sensitivity of the vibrio parahaemolyticus immunomagnetic beads is improved, and by means of the characteristics that the vibrio parahaemolyticus immunomagnetic beads are quick,convenient and cheap and a large detection instrument is needless, the immunomagnetic beads can be applied to separation and enrichment of the vibrio parahaemolyticus in food, feed, medical environment and natural environment, and the vibrio parahaemolyticus can be detected efficiently and rapidly.

Owner:广东省湛江市质量计量监督检测所

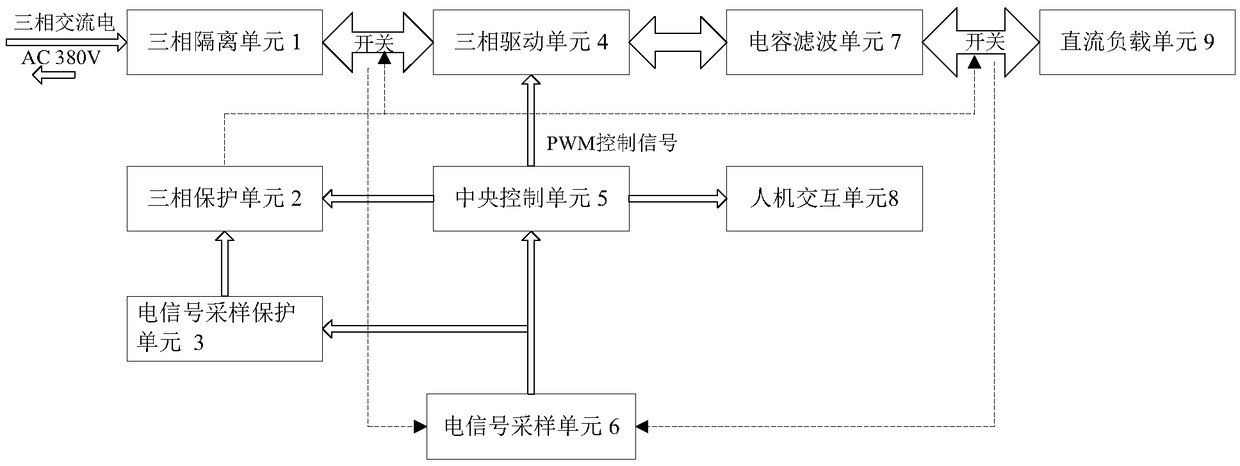

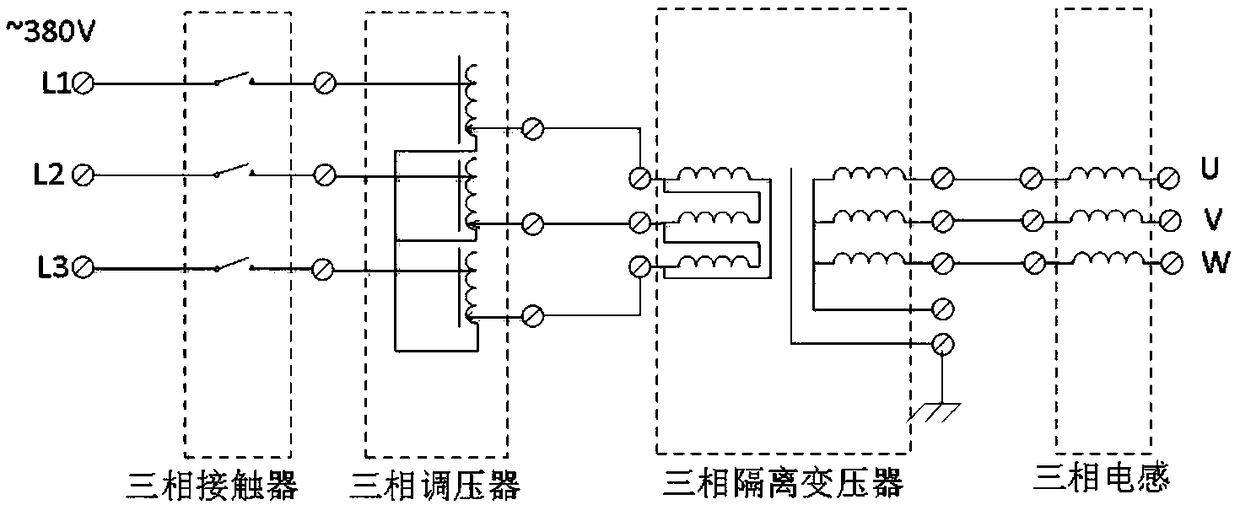

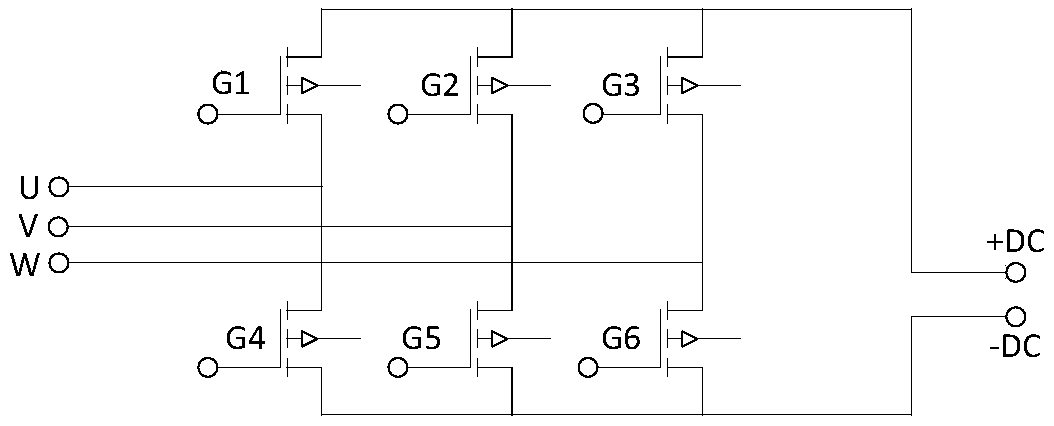

A three-phase variable flow experimental control device and an experimental control method thereof

PendingCN109194163AImprove electricity safetyEnsure personal safetyBatteries circuit arrangementsAc-dc conversionCapacitanceAlternating current

The invention discloses a three-phase change flow experiment control device and an experiment control method thereof, the experiment control device comprises a three-phase isolation unit, three-phaseprotection unit, Electrical Signal Sampling Protection Unit, three-phase drive unit, Central control unit, electrical signal sampling unit, capacitance filter unit, a man-machine interaction unit anda DC load unit, one end of the three-phase isolation unit is connected to the three-phase power grid side, the other end of the three-phase isolation unit is connected with the three-phase drive unitthrough an AC relay switch and a bus bar, the three-phase driving unit is connected with a capacitive filter unit. The capacitive filter unit is connected with the DC load unit through a DC relay switch and a bus bar, and the inputs of the electric signal sampling unit are respectively connected with the bus bar between the three-phase isolation unit and the three-phase driving unit and the bus bar between the capacitive filter unit and the DC load unit, and the inputs of the electric signal sampling unit are connected with the bus bar between the three-phase isolation unit and the three-phasedriving unit. The invention can simultaneously collect three-phase alternating current voltage and direct current voltage, and realizes mutual conversion between three-phase alternating current and direct current.

Owner:广西南宁市晨启科技有限责任公司

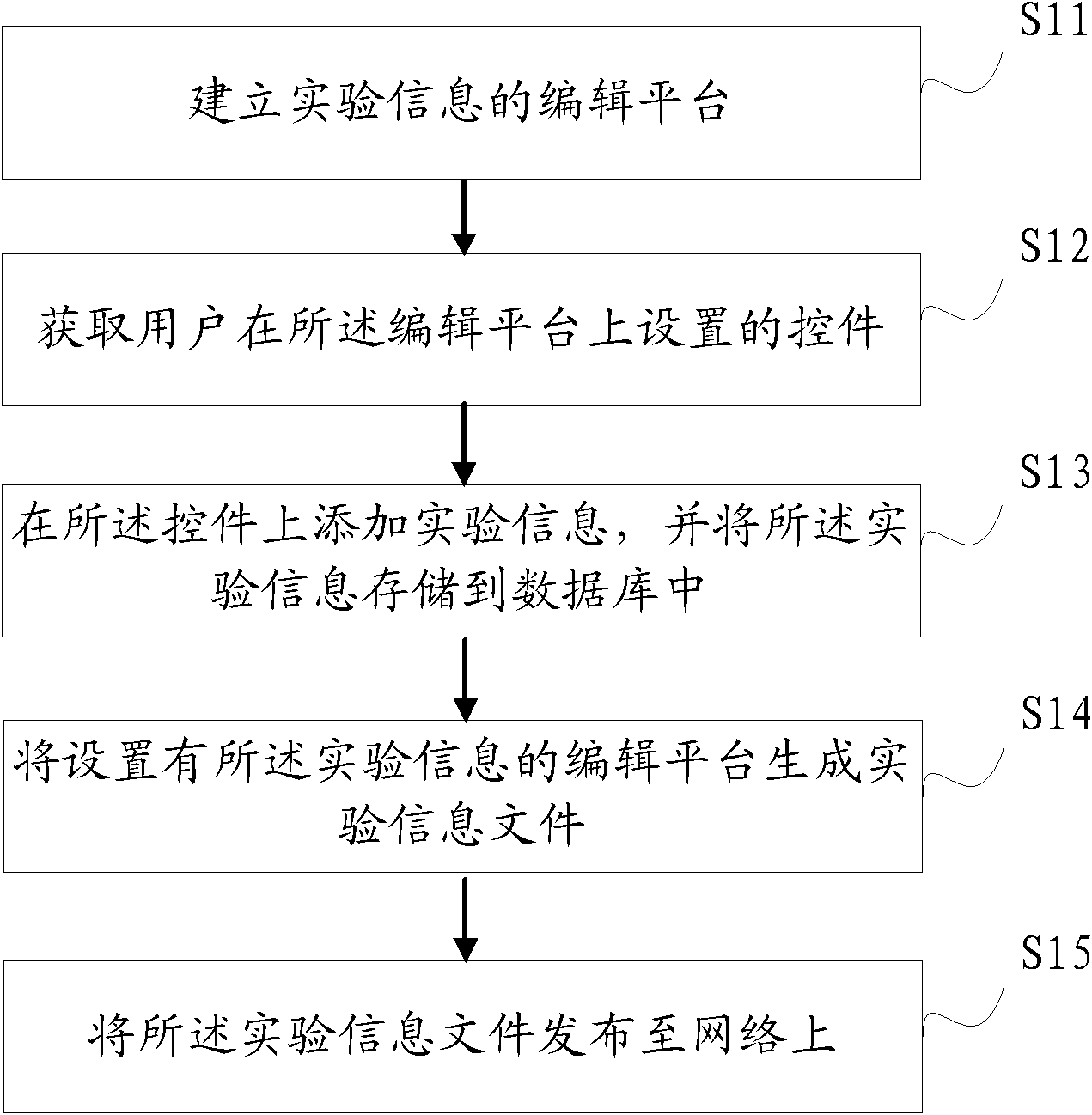

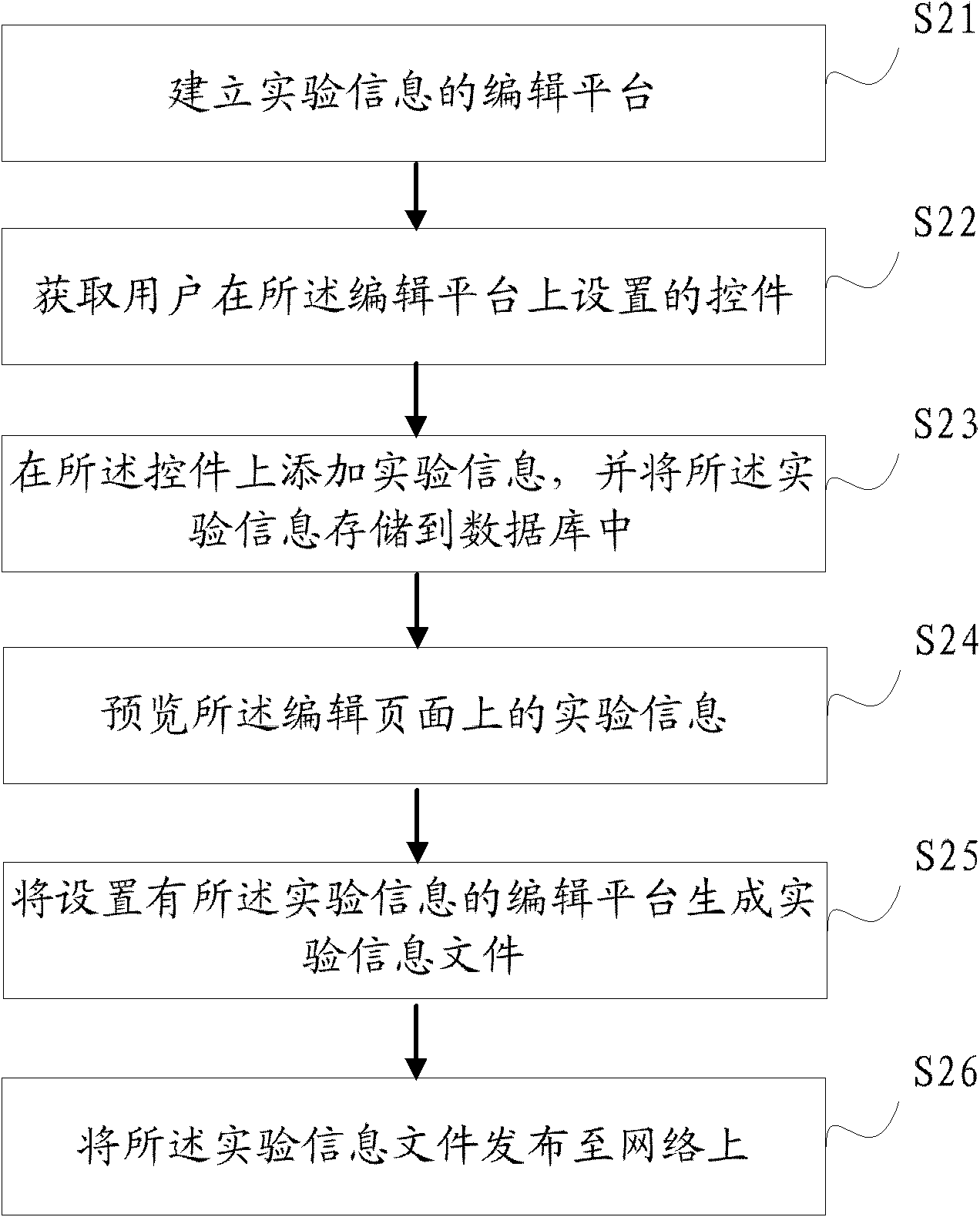

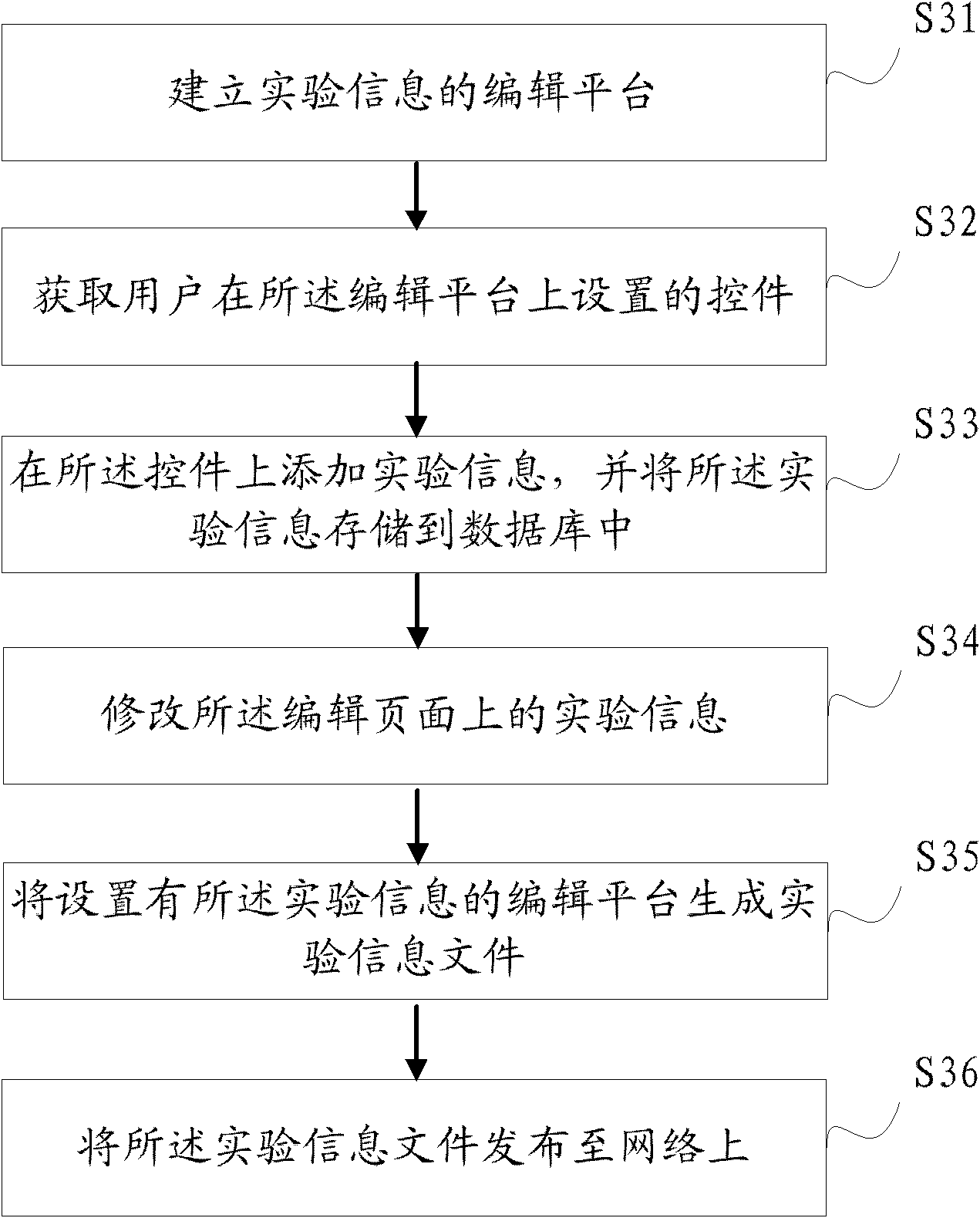

A method and device for generating experimental information

InactiveCN102289498AEasy to viewImprove experimental efficiencySpecial data processing applicationsControl setSoftware engineering

The invention discloses a method for generating experimental information, comprising: establishing an editing page of experimental information; obtaining controls set by users on the editing page; adding experimental information to the control, and storing the experimental information in In the database; generating an experiment information file on the editing page provided with the experiment information; publishing the experiment information file on the network. In the solution provided by the present invention, by setting the experimental information on the editing page in the form of controls, and then generating the experimental information file on the editing page with the experimental information, students can directly edit the experimental information on the computer during the experiment. View the experiment information file on the network, so it is very convenient for students to view the experiment information during the experiment process; moreover, because it is very easy for students to view the experiment information during the experiment process, the efficiency of the experiment can be improved.

Owner:吉林中软吉大信息技术有限公司

Multifunctional and intelligent X-ray lab and device thereof

ActiveCN103175853AImplement diagnosticsAchieve sharingMaterial analysis using wave/particle radiationExperimental laboratorySoftware engineering

The invention discloses a multifunctional and intelligent X-ray lab and a device thereof. The lab consists of a basic experimental platform positioned in a lead room, an intelligent detection platform and an experimental control platform positioned outside the lead room, wherein (1) the basic experimental platform is respectively provided with a ray machine bearing device, a sample bearing device, a gas high-pressure testing device and a liquid high-pressure testing device; (2) the intelligent detection platform is provided with a sample moving device; and (3) the experimental control platform is respectively provided with a remote control device, a monitoring device and a database center. The lab can develop basic experimental research related to X rays, the intelligent detection of equipment can be performed, and the lab has the obvious advantages of safe experimental and detection environment and high equipment detection efficiency.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com