Forming process of car seat connecting plate

An automobile seat and molding process technology, applied in the field of stamping process, can solve the problems of high production difficulty, high production cost and low yield, and achieve the effects of high production difficulty, high production cost and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

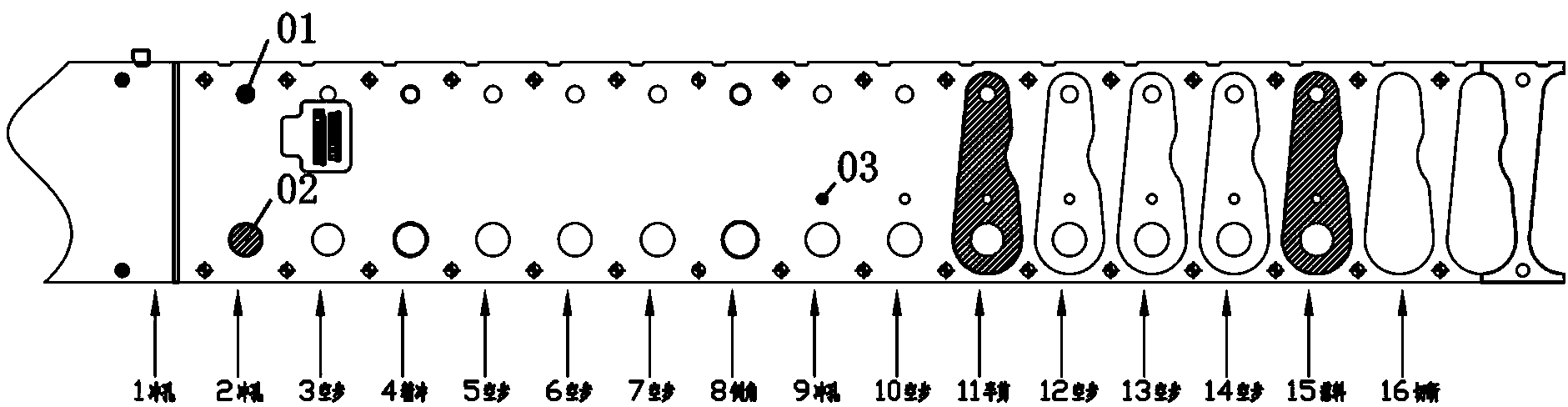

[0033] Embodiment 1: Adopting the steel plate that model is S500MC among the high-yield hot continuous rolling steel plates for cold forming as material plate material, the material plate thickness that adopts is 5mm, adopts one-time punching forming process, such as figure 1 Shown:

[0034] a. Take the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 5% of the thickness of the material plate, then the height of the bright band in the hole obtained by punching is 80% of the height of the punching surface; The height of the burr part is 20% of the height of the blanking surface; the life of the punch is 3041 times.

[0035] b. Taking the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 7% of the thickness of the material plate, the height of the bright band in the hole obtained by punching is 75% of the height of the punching surface; The height of the burr part is 12% of the ...

Embodiment 2

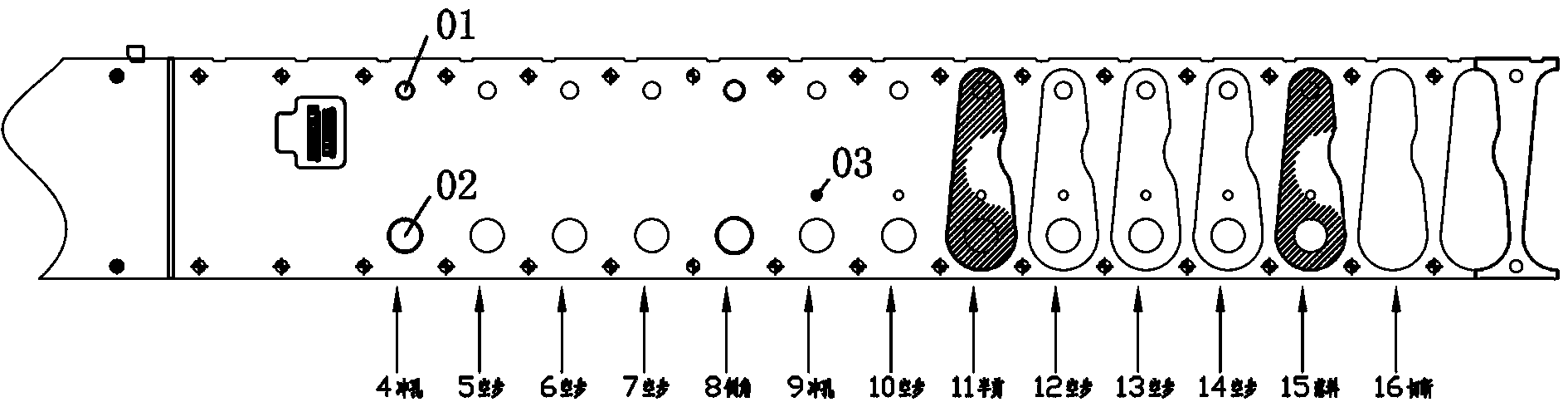

[0039] Embodiment 2: Adopt the steel plate that model is S315MC in the high-yield hot continuous rolling steel plate for cold forming as material plate material, the material plate thickness that adopts is 5mm, adopts one-time punching forming process, such as figure 2 Shown:

[0040] a. Taking the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 5% of the thickness of the material plate, the height of the bright band in the hole obtained by punching is 78.4% of the height of the punching surface; The height of the burr part is 18.5% of the height of the blanking surface; the life of the punch is 2872 times.

[0041] b. Taking the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 7% of the thickness of the material plate, the height of the bright band in the hole obtained by punching is 74.3% of the height of the punching surface; The height of the burr part is 11.5% of the h...

Embodiment 3

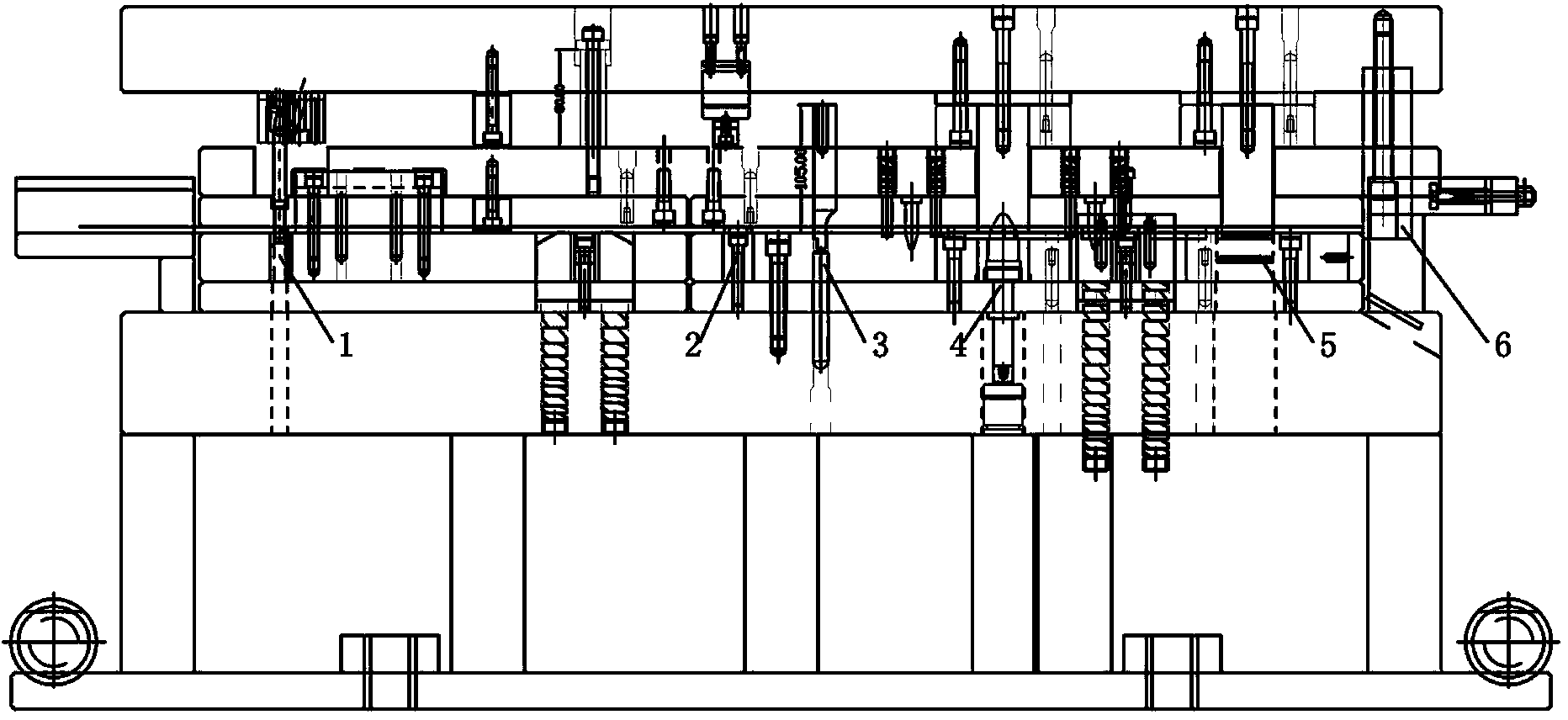

[0045] Embodiment 3: Adopt the steel plate that model is S700MC in the high-yield hot continuous rolling steel plate for cold forming as material plate material, the material plate thickness that adopts is 5mm, adopts one-time punching forming process, such as image 3 Shown:

[0046] a. Taking the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 5% of the thickness of the material plate, the height of the bright band in the hole obtained by punching is 80.6% of the height of the punching surface; The height of the burr part is 19.3% of the height of the blanking surface; the life of the punch is 3126 times.

[0047] b. Taking the unilateral gap between the inner wall surface of the die and the outer wall surface of the punch as 7% of the thickness of the material plate, the height of the bright band in the hole obtained by punching is 75.8% of the height of the punching surface; The height of the burr part is 12.3% of the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com